Home>Technology>Smart Home Devices>What Is A Maintenance Box On A Printer

Smart Home Devices

What Is A Maintenance Box On A Printer

Modified: August 16, 2024

Learn about the purpose of a maintenance box on a printer and how it contributes to the functionality of smart home devices. Understand its role in ensuring optimal performance and longevity.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

**

Introduction

**

Printers have become an indispensable part of our daily lives, whether at home, in the office, or at educational institutions. These devices enable us to produce physical copies of documents, images, and other materials with remarkable ease and efficiency. However, the proper maintenance of a printer is crucial to ensure its longevity and optimal performance. One essential component of printer maintenance is the maintenance box, a vital but often overlooked part of the printing process.

The maintenance box plays a pivotal role in ensuring the smooth functioning of a printer, and understanding its purpose and functionality is essential for anyone who relies on printers for their daily tasks. In this article, we will delve into the intricacies of the maintenance box, exploring its purpose, operation, replacement, and associated costs. By shedding light on this often underappreciated component, we aim to equip readers with the knowledge necessary to maintain their printers effectively and prolong their lifespan. Let's embark on this journey to unravel the significance of the maintenance box in the realm of printing technology.

Key Takeaways:

- The maintenance box in a printer collects excess ink to prevent damage and maintain print quality, contributing to the printer’s reliability and environmental sustainability.

- Replacing the maintenance box when necessary is crucial for preventing ink-related issues and ensuring consistent print quality, supporting the longevity and performance of the printer.

Read more: How To Replace Box Gutters

Purpose of a Maintenance Box

The maintenance box, also known as a waste ink tank, serves a crucial function in inkjet printers. Its primary purpose is to collect and contain the excess ink that is generated during the printing and maintenance processes. As inkjet printers operate, a small amount of ink is used for tasks such as cleaning the print heads and maintaining optimal print quality. However, the residual ink that is not utilized in the actual printing process needs to be managed effectively to prevent it from accumulating within the printer and causing potential damage.

By channeling the excess ink into the maintenance box, the printer can maintain its internal components and ensure consistent print quality. This process helps in preventing ink from spilling or leaking inside the printer, which could lead to malfunctions and deteriorate the overall performance of the device. Moreover, the presence of a maintenance box minimizes the risk of ink-related issues, such as smudged prints or clogged nozzles, thereby contributing to the printer’s reliability and longevity.

Furthermore, the maintenance box aids in environmental sustainability by containing the residual ink in a dedicated receptacle. This containment prevents the ink from seeping into the surroundings, thereby reducing the potential environmental impact. Additionally, the segregation of waste ink facilitates proper disposal or recycling, aligning with eco-friendly practices and regulatory standards.

Understanding the purpose of a maintenance box underscores its significance in preserving the functionality of inkjet printers and minimizing the environmental footprint associated with ink disposal. As we delve deeper into the mechanics of the maintenance box, its role in maintaining printer performance and ink management will become increasingly evident.

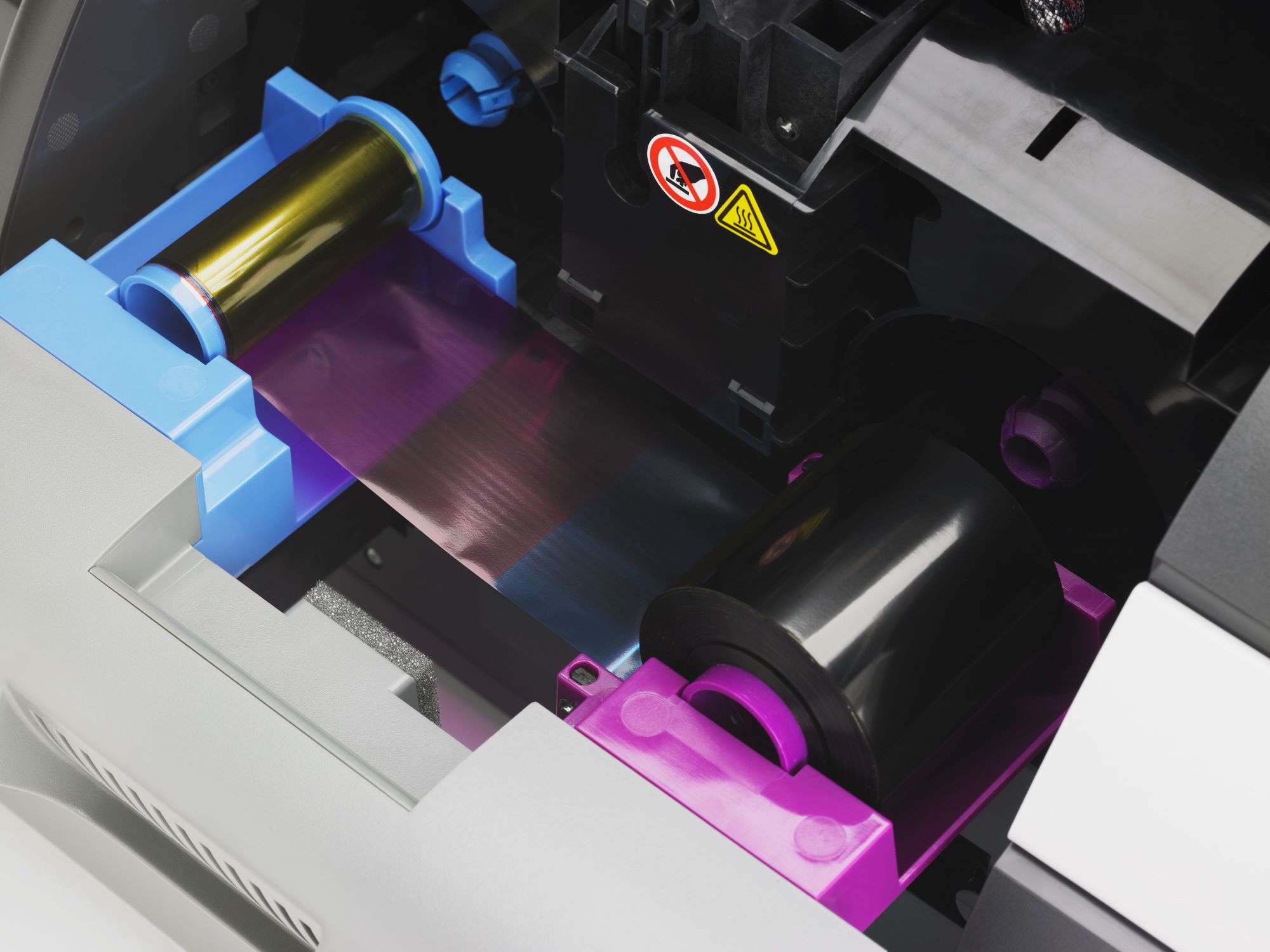

How a Maintenance Box Works

The functionality of a maintenance box is intricately linked to the operational dynamics of an inkjet printer. As the printer executes printing tasks, it engages in periodic maintenance routines to uphold print quality and prevent potential issues such as clogged nozzles or inconsistent output. During these maintenance cycles, the printer expels small amounts of ink to cleanse the print heads and ensure optimal performance.

The maintenance box serves as a reservoir for the excess ink generated during these cleaning and maintenance operations. When the printer expels ink for maintenance purposes, the surplus liquid is channeled into the maintenance box, where it is contained and stored. This process prevents the residual ink from accumulating within the internal components of the printer, safeguarding against potential damage or operational disruptions.

Moreover, the maintenance box features absorbent materials or mechanisms designed to manage the collected ink effectively. These materials facilitate the absorption and retention of the excess ink, preventing spillage and maintaining a clean and controlled internal environment within the printer. By efficiently managing the surplus ink, the maintenance box contributes to the overall operational integrity of the printer, ensuring consistent performance and print quality.

Additionally, the maintenance box is equipped with sensors or indicators that alert users when it approaches its capacity. This proactive notification system allows users to replace the maintenance box in a timely manner, preventing potential ink overflow or related complications. By adhering to the recommended maintenance box replacement schedule, printer users can sustain the optimal functionality of their devices and minimize the risk of ink-related issues.

Understanding the inner workings of a maintenance box provides valuable insights into its role as a critical component in inkjet printers. Its ability to manage surplus ink, maintain a clean internal environment, and facilitate timely replacements underscores its significance in sustaining the performance and longevity of printers.

When to Replace a Maintenance Box

Knowing when to replace a maintenance box is essential for maintaining the optimal performance of an inkjet printer. As the maintenance box accumulates excess ink over time, it reaches a point where it nears its capacity and requires replacement. The frequency of maintenance box replacement is influenced by various factors, including the printer model, usage patterns, and the volume of printing tasks undertaken.

Printer manufacturers typically provide guidelines regarding the estimated lifespan of a maintenance box based on standard printing conditions. These recommendations offer insights into the expected duration before a replacement becomes necessary. Additionally, modern inkjet printers are equipped with sensors or monitoring systems that track the ink accumulation in the maintenance box, providing users with timely alerts or indicators when the box approaches its capacity.

It is important to heed these notifications and replace the maintenance box promptly to prevent potential ink overflow or related complications. Ignoring the need for maintenance box replacement can lead to ink leakage within the printer, compromising its internal components and potentially causing operational issues. By adhering to the recommended replacement intervals, printer users can safeguard the printer’s functionality and minimize the risk of ink-related malfunctions.

Furthermore, the decision to replace a maintenance box may also be influenced by visual inspections or print quality assessments. If users notice abnormal print quality, such as ink smudges, streaks, or inconsistent output, it may indicate that the maintenance box is reaching its capacity. In such cases, replacing the maintenance box can address these issues and restore optimal print quality.

Ultimately, proactive maintenance box replacement, guided by manufacturer recommendations, sensor alerts, and print quality evaluations, is crucial for sustaining the performance and longevity of inkjet printers. By staying attuned to the indicators and factors signaling the need for replacement, users can ensure that their printers operate smoothly and consistently, delivering high-quality prints without encountering ink-related complications.

A maintenance box on a printer is a container that collects waste ink during the cleaning and maintenance process. It needs to be replaced when full to ensure the printer continues to function properly.

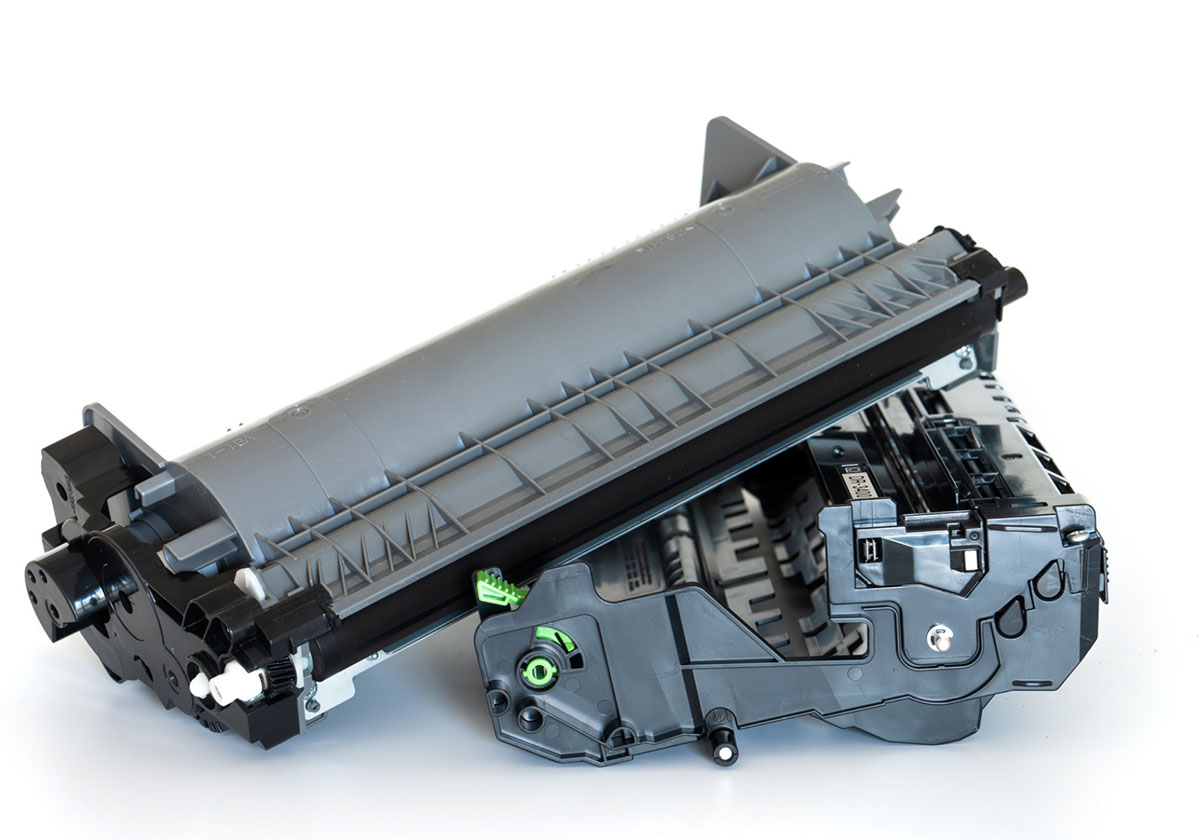

How to Replace a Maintenance Box

Replacing a maintenance box in an inkjet printer is a straightforward process that can be accomplished with minimal effort. Printer manufacturers typically provide clear instructions and guidelines for replacing the maintenance box, ensuring a user-friendly experience. Here are the general steps involved in replacing a maintenance box:

- Check Printer Status: Before initiating the replacement process, it is advisable to verify the printer’s status and ensure that it is not actively engaged in a printing task. This precautionary step prevents any potential disruptions during the replacement procedure.

- Access Maintenance Box: Locate the maintenance box compartment within the printer. Depending on the printer model, the maintenance box may be easily accessible from the front, rear, or top of the device. Follow the manufacturer’s instructions to open the compartment housing the maintenance box.

- Remove Old Maintenance Box: Carefully extract the old maintenance box from its designated slot or compartment. Exercise caution to prevent any ink spillage or contact with residual ink. Dispose of the old maintenance box in accordance with local regulations and environmental guidelines.

- Install New Maintenance Box: Unpack the new maintenance box from its packaging, ensuring that it is compatible with the specific printer model. Insert the new maintenance box into the designated slot or compartment, following any alignment or installation instructions provided by the manufacturer.

- Reset Maintenance Box Counter (if applicable): In some inkjet printers, it may be necessary to reset the maintenance box counter to notify the printer that a new maintenance box has been installed. This step ensures that the printer accurately tracks the usage of the new maintenance box.

- Close Compartment and Confirm Replacement: Once the new maintenance box is securely installed, close the compartment or cover as per the manufacturer’s instructions. Confirm that the replacement process has been completed, and the printer recognizes the presence of the new maintenance box.

- Perform Test Print: To validate the successful replacement of the maintenance box, initiate a test print to ensure that the printer functions as expected and delivers high-quality output without any ink-related issues.

By following these steps and adhering to the manufacturer’s guidelines, users can effectively replace the maintenance box in their inkjet printers, ensuring that the device continues to operate optimally and maintain consistent print quality.

Read more: How To Use A Box Blade On A Gravel Driveway

Cost of a Maintenance Box

The cost of a maintenance box varies depending on the printer model, brand, and the specific requirements of the printing device. Maintenance box prices are influenced by factors such as the technology employed in the printer, the capacity of the maintenance box, and the manufacturer’s pricing strategies. It is important for printer users to consider the cost of maintenance boxes when assessing the overall operational expenses associated with their printing equipment.

When evaluating the cost of a maintenance box, it is essential to recognize that this component contributes to the sustained functionality and print quality of the printer. While the initial investment in a maintenance box may incur a certain expense, its role in preventing ink-related complications and preserving the internal components of the printer is invaluable. By replacing the maintenance box in a timely manner, users can mitigate the risk of potential printer malfunctions and ensure consistent performance.

Furthermore, the pricing of maintenance boxes is often reflective of the printer manufacturer’s commitment to providing reliable and efficient printing solutions. As part of the overall cost of printer maintenance and consumables, the expense of a maintenance box aligns with the long-term benefits it offers in terms of printer reliability and print quality.

It is advisable for printer users to explore the pricing and availability of maintenance boxes through authorized retailers, online stores, or directly from the printer manufacturer. Additionally, considering the estimated lifespan and replacement intervals of the maintenance box can aid in assessing its cost-effectiveness and integrating it into the overall maintenance budget for the printer.

While the cost of a maintenance box constitutes a recurring aspect of printer maintenance, its role in sustaining the printer’s performance and minimizing potential issues underscores its value as an essential consumable. By factoring in the cost of maintenance boxes as part of the printer’s operational expenses, users can proactively manage their printing equipment and ensure consistent and reliable output.

Conclusion

The maintenance box, often overlooked in the realm of printer maintenance, emerges as a critical component that plays a pivotal role in preserving the functionality and print quality of inkjet printers. Its purpose in containing excess ink, maintaining a clean internal environment, and contributing to eco-friendly ink management underscores its significance in the printing process.

Understanding the inner workings of a maintenance box, including its functionality, replacement indicators, and cost considerations, empowers printer users to proactively manage their printing equipment and sustain optimal performance. By adhering to manufacturer recommendations and promptly replacing the maintenance box when necessary, users can mitigate the risk of ink-related complications and ensure consistent print quality.

Furthermore, the cost of a maintenance box, while constituting a recurring expense, aligns with the long-term benefits it offers in terms of printer reliability and operational integrity. By factoring in the cost of maintenance boxes as part of the overall printer maintenance budget, users can effectively manage their printing equipment and prioritize sustained performance.

In essence, the maintenance box serves as a testament to the intricate engineering and thoughtful design that underpins modern inkjet printers. Its role in ink management, environmental sustainability, and printer maintenance highlights its value as an essential consumable that contributes to the seamless operation of printing devices.

As we navigate the landscape of printer maintenance and consumables, the maintenance box stands as a silent guardian, ensuring that inkjet printers continue to deliver crisp, high-quality prints without encountering ink-related complications. By recognizing and appreciating the significance of the maintenance box, printer users can embark on a journey of proactive maintenance, sustaining the longevity and performance of their printing equipment with confidence and efficiency.

Frequently Asked Questions about What Is A Maintenance Box On A Printer

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is A Maintenance Box On A Printer”