Home>Technology>Smart Home Devices>What Is A Printer Ribbon

Smart Home Devices

What Is A Printer Ribbon

Modified: February 18, 2024

Discover how printer ribbons enhance the functionality of smart home devices. Learn about the benefits and uses of printer ribbons for your smart home setup.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Introduction

Welcome to the world of printing technology, where innovation and functionality go hand in hand. In this digital age, the concept of printing may seem overshadowed by the prevalence of electronic communication, yet the need for physical documentation remains ever-present. Printers, the indispensable devices that bring digital content to life on paper, come in various forms, each with its unique set of components and mechanisms. One such essential component is the printer ribbon, a fundamental element in certain types of printers.

Printer ribbons play a crucial role in the printing process, yet their significance is often overlooked in comparison to other printer components. This article aims to shed light on the often-underappreciated printer ribbon, exploring its definition, types, functionality, advantages, disadvantages, and maintenance requirements. By the end of this journey, you will have a comprehensive understanding of printer ribbons and their role in the realm of printing technology. So, let's embark on this enlightening exploration of printer ribbons and unravel the mysteries behind these essential printing components.

Definition of Printer Ribbon

Key Takeaways:

- Printer ribbons are essential for impact printers, creating durable prints through precise ink transfer. They come in various types, each tailored to specific printing needs, and require proper maintenance for optimal performance.

- Understanding how printer ribbons work unveils their pivotal role in impact printing technology, offering durable and precise print outputs. While they have unique advantages, their maintenance and replacement are crucial for sustained efficiency.

Read more: What Kind Of Ribbon Is Used For Mums

Definition of Printer Ribbon

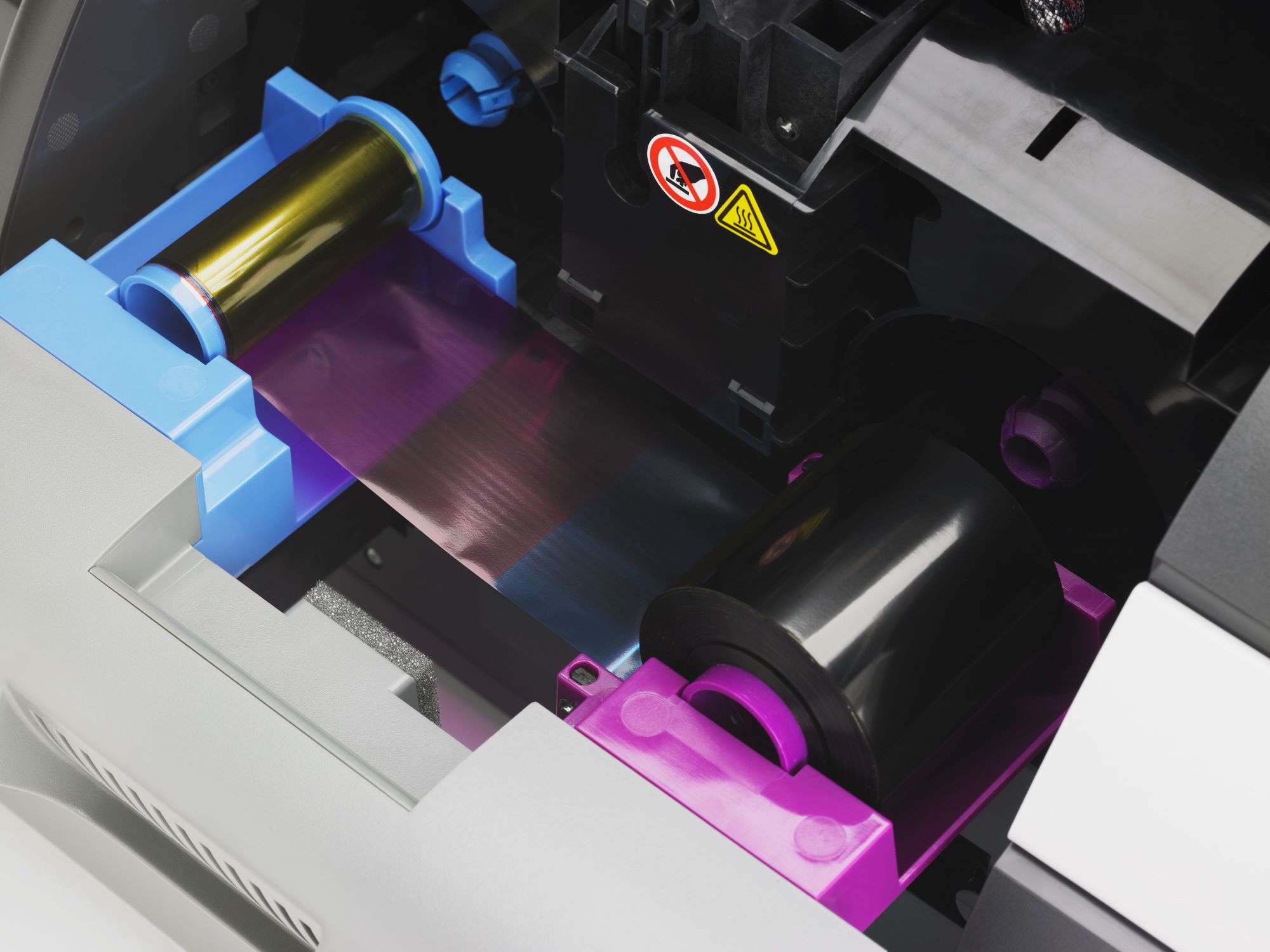

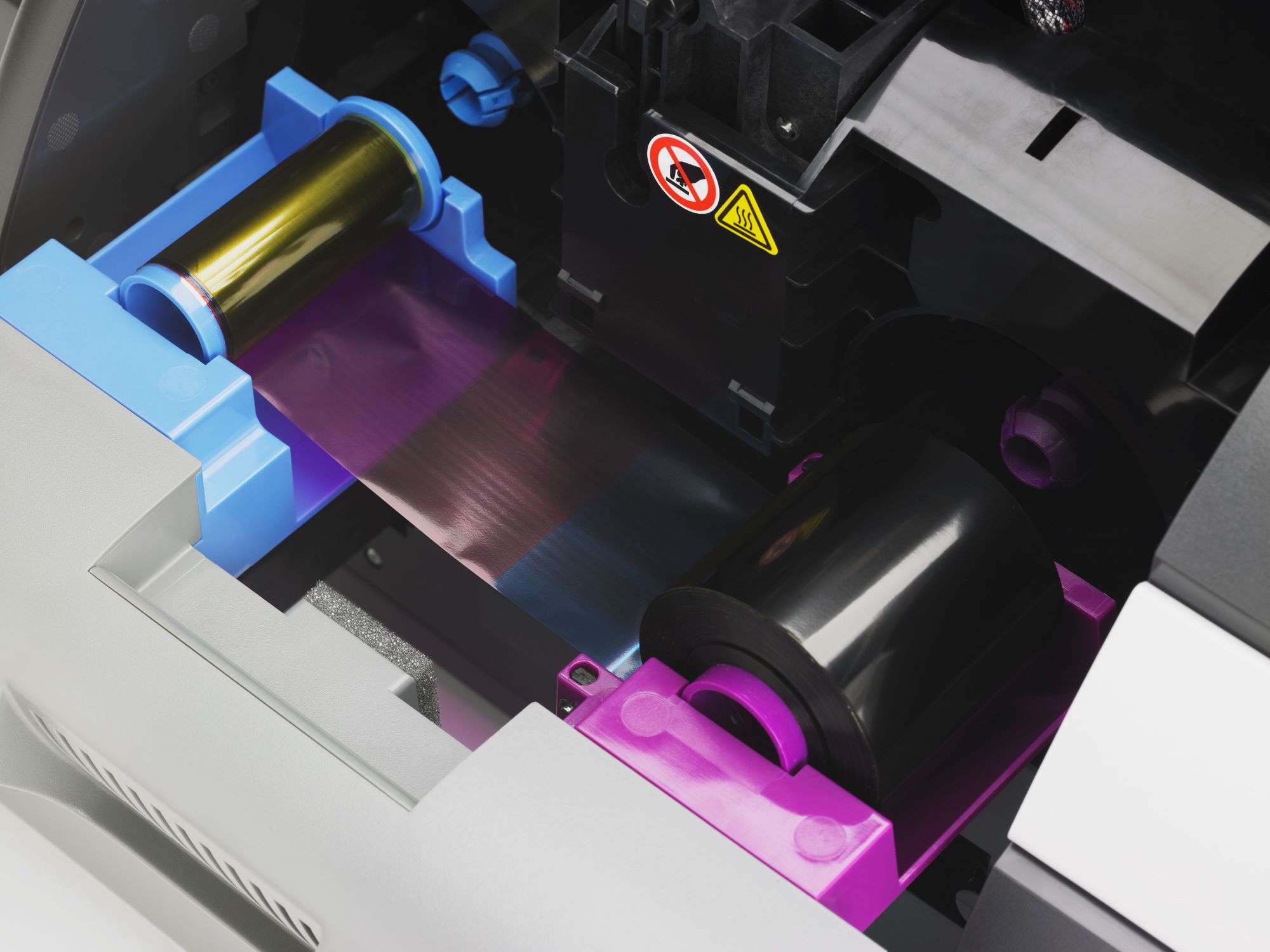

Before delving into the intricacies of printer ribbons, it’s essential to grasp the fundamental concept behind this integral printing component. A printer ribbon is a consumable element used in impact printers, such as dot matrix and line printers, to produce text and images on paper. Unlike modern inkjet or laser printers that utilize liquid or powdered toner, impact printers rely on a physical mechanism to transfer ink onto the printing surface, and the printer ribbon is central to this process.

Typically, a printer ribbon consists of a length of fabric or plastic strip coated with ink on one side. This ink-coated side faces the paper during the printing process, and as the printer head strikes the ribbon, it transfers the ink onto the paper, creating the desired text or image. The ink used in printer ribbons is designed to be long-lasting and resistant to fading, ensuring that the printed content remains legible over time.

It’s important to note that printer ribbons are not universal and vary in design and compatibility based on the specific printer model. Different printers require specific types of ribbons, and using an incompatible ribbon can result in poor print quality or damage to the printer. As such, understanding the compatibility requirements for printer ribbons is crucial when replacing or purchasing new ribbons for a printer.

In essence, the printer ribbon serves as the conduit through which ink is transferred onto the printing surface, playing a pivotal role in the functionality of impact printers. Its unique design and ink composition enable it to produce clear and durable prints, making it an indispensable component in certain printing environments.

Types of Printer Ribbons

Types of Printer Ribbons

Printer ribbons come in various types, each tailored to meet specific printing needs and compatible with different printer models. Understanding the different types of printer ribbons is essential for ensuring optimal print quality and compatibility. Here are the primary types of printer ribbons:

- Nylon Ribbons: Nylon ribbons are among the most commonly used printer ribbons, especially in dot matrix printers. They are durable and offer consistent ink transfer, making them suitable for high-volume printing tasks. The nylon material ensures longevity, and the ink saturation on the ribbon facilitates clear and precise prints.

- Polyester Ribbons: Polyester ribbons are known for their exceptional durability and resistance to smudging and fading. They are often preferred for applications requiring archival-quality prints, such as in environments where printed documents need to withstand extended periods without degradation.

- Cotton Ribbons: Cotton ribbons, though less common in modern printers, were once prevalent in early impact printers. While they may not offer the same longevity and ink saturation as nylon or polyester ribbons, they can still be found in certain specialized printing applications.

- Multicolor Ribbons: For applications that demand color printing, multicolor ribbons are available to facilitate the creation of vibrant and visually appealing prints. These ribbons contain multiple ink segments, each dedicated to a specific color, enabling the printer to produce a diverse range of hues and shades.

- Re-Inking Ribbons: Re-inking ribbons are designed for reusability, featuring an ink reservoir that can be refilled once the ink depletes. This sustainable approach reduces environmental impact and ongoing consumable costs, making it an eco-friendly option for certain printing requirements.

Each type of printer ribbon offers distinct advantages and is tailored to specific printing scenarios, ensuring that users can select the most suitable ribbon for their unique needs. Understanding the characteristics and capabilities of each type empowers users to make informed decisions when choosing printer ribbons for their printing devices.

How Printer Ribbons Work

How Printer Ribbons Work

Understanding the inner workings of printer ribbons unveils the intricate process through which these essential components facilitate the transfer of ink onto paper. The functionality of printer ribbons is closely intertwined with the mechanisms of impact printers, where precise and controlled ink deposition is achieved through a series of coordinated actions. Here’s a comprehensive look at how printer ribbons work:

1. Ink Transfer: When a print command is initiated, the printer head, equipped with pins or a striking mechanism, engages with the printer ribbon. As the head strikes the ribbon, it transfers ink onto the paper, creating the desired text or image. The ribbon’s ink-coated surface ensures efficient ink transfer, resulting in clear and legible prints.

2. Impact Printing: Printer ribbons are primarily used in impact printers, where the printer head physically strikes the ribbon to imprint characters or images onto the paper. The impact force, combined with the ink-coated ribbon, produces precise and consistent marks on the printing surface, making it suitable for applications requiring high-quality text and graphics.

3. Character Formation: As the printer head interacts with the ribbon, it forms characters or images by selectively striking the ribbon at specific points. This controlled impact creates the desired print pattern, resulting in accurate and well-defined outputs. The ink’s adhesion properties ensure that the printed content adheres to the paper surface effectively.

4. Compatibility Considerations: Printer ribbons are designed to be compatible with specific printer models, ensuring seamless integration and optimal performance. Understanding the compatibility requirements for printer ribbons is essential to avoid potential issues such as poor print quality or damage to the printer.

By comprehending the operational dynamics of printer ribbons, users gain insight into the precision and reliability of impact printing processes. The orchestrated interplay between the printer head, ribbon, and printing surface culminates in the production of clear, durable, and visually appealing prints, showcasing the indispensable role of printer ribbons in the realm of impact printing technology.

Advantages and Disadvantages of Printer Ribbons

When replacing a printer ribbon, make sure to align the ribbon properly with the printer’s spools to prevent any printing errors or damage to the ribbon.

Advantages and Disadvantages of Printer Ribbons

Printer ribbons, integral to impact printing technology, offer unique advantages and present certain limitations that are essential to consider when evaluating their suitability for specific printing requirements. By examining the pros and cons of printer ribbons, users can make informed decisions regarding their printing consumables. Here’s a detailed exploration of the advantages and disadvantages of printer ribbons:

Advantages:

- Durable Prints: Printer ribbons facilitate the creation of durable prints, resistant to fading and smudging, ensuring that the printed content remains legible over extended periods.

- Consistent Ink Transfer: The ink-coated ribbons enable consistent and precise ink transfer onto the printing surface, resulting in clear and well-defined text and images.

- Compatibility: Printer ribbons are designed to be compatible with specific printer models, ensuring seamless integration and optimal print quality.

- Archival Quality: Certain types of printer ribbons, such as polyester ribbons, offer archival-quality prints, making them suitable for applications requiring long-lasting documentation.

- Impact Printing Capabilities: Printer ribbons are essential for impact printers, which are capable of producing high-quality text and graphics through controlled impact mechanisms.

Disadvantages:

- Noisy Operation: Impact printers, which utilize printer ribbons, are often louder during operation compared to non-impact printers, potentially causing disruptions in quiet environments.

- Limited Color Options: Printer ribbons are primarily used for monochromatic printing, and while multicolor ribbons are available, the color range may be limited compared to modern inkjet or laser printers.

- Consumable Replacement: Printer ribbons are consumable items that require periodic replacement, adding to ongoing operational costs and maintenance requirements.

- Environmental Impact: The disposability of printer ribbons contributes to waste generation, necessitating proper disposal or recycling practices to mitigate environmental impact.

By weighing the advantages and disadvantages of printer ribbons, users can assess their compatibility with specific printing needs and operational preferences. While printer ribbons excel in producing durable and precise prints, their limitations in color options and consumable nature warrant careful consideration when incorporating them into printing workflows.

Maintenance and Replacement of Printer Ribbons

Read more: How To Store Ribbon

Maintenance and Replacement of Printer Ribbons

Proper maintenance and timely replacement of printer ribbons are essential practices to ensure consistent print quality and prolong the operational lifespan of impact printers. By adhering to recommended maintenance procedures and understanding the nuances of ribbon replacement, users can optimize the performance of their printing devices. Here’s a comprehensive guide to the maintenance and replacement of printer ribbons:

Maintenance Guidelines:

- Regular Cleaning: Periodically cleaning the printer’s interior, including the ribbon mechanism and print head, helps prevent ink buildup and ensures smooth ribbon movement during printing tasks.

- Storage Conditions: Store unused printer ribbons in a cool, dry environment to maintain ink integrity and prevent deterioration, preserving the quality of the ribbons for future use.

- Printer Inspection: Routinely inspect the printer for any signs of ribbon-related issues, such as uneven ink transfer or ribbon misalignment, and address these issues promptly to prevent print quality degradation.

- Optimal Tension: Ensure that the printer ribbon is correctly tensioned to facilitate consistent ink transfer and prevent ribbon slippage during printing operations.

Replacement Procedures:

- Identify Compatibility: When replacing printer ribbons, verify compatibility with the specific printer model to prevent operational issues and ensure seamless integration.

- Follow Manufacturer Guidelines: Adhere to the manufacturer’s recommended replacement procedures, including ribbon installation and alignment, to maintain optimal print quality and prevent damage to the printer.

- Dispose Responsibly: Dispose of used printer ribbons responsibly, following local regulations and considering recycling options to minimize environmental impact.

- Stock Adequacy: Maintain an adequate supply of replacement printer ribbons to avoid operational disruptions and ensure continuous printing capabilities.

By prioritizing maintenance best practices and following prescribed replacement protocols, users can uphold the efficiency and reliability of their impact printers, leveraging the full potential of printer ribbons for consistent and high-quality print outputs. Additionally, staying informed about proper storage and disposal practices contributes to sustainable and responsible utilization of printer consumables, aligning with environmental stewardship principles.

Conclusion

Conclusion

As we conclude our exploration of printer ribbons, we emerge with a comprehensive understanding of these essential components and their pivotal role in impact printing technology. Printer ribbons, though often overshadowed by modern inkjet and laser printing methods, remain indispensable for specific printing applications, offering unique advantages and presenting distinct considerations for maintenance and replacement.

Throughout this journey, we’ve delved into the definition of printer ribbons, unraveling their composition and functionality in facilitating ink transfer onto paper. We’ve explored the diverse types of printer ribbons, each tailored to meet specific printing needs and compatible with various printer models, offering users a range of options to suit their unique requirements.

Understanding how printer ribbons work has shed light on the intricate process through which these consumable components contribute to the creation of clear, durable, and visually appealing prints. The advantages and disadvantages of printer ribbons have been carefully examined, providing users with a balanced perspective on their capabilities and limitations in the realm of impact printing.

Furthermore, by delving into the maintenance and replacement of printer ribbons, we’ve underscored the importance of adhering to recommended practices to sustain optimal print quality and prolong the operational lifespan of impact printers. From regular cleaning and storage considerations to responsible disposal and adherence to manufacturer guidelines for ribbon replacement, users are equipped with the knowledge to maximize the performance and efficiency of their printing devices.

In essence, printer ribbons, with their enduring relevance and distinctive characteristics, continue to play a vital role in specific printing environments, offering durable, precise, and impactful print outputs. As technology advances, the legacy of printer ribbons persists, ensuring that impact printing remains a reliable and effective method for producing essential documentation.

By embracing the insights gleaned from this exploration, users can harness the capabilities of printer ribbons with confidence, making informed decisions regarding their printing consumables and optimizing the functionality of their impact printers. As the evolution of printing technology unfolds, the enduring significance of printer ribbons serves as a testament to their enduring value in the realm of document creation and information dissemination.

Frequently Asked Questions about What Is A Printer Ribbon

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is A Printer Ribbon”