Home>Technology>Smart Home Devices>What Is A Fuser In A Printer

Smart Home Devices

What Is A Fuser In A Printer

Published: January 18, 2024

Learn about the role of a fuser in a printer and its importance in maintaining the quality of your smart home devices. Explore fuser functionality and troubleshooting tips.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Printers play a crucial role in our daily lives, whether it's for producing important documents, school assignments, or creative projects. However, have you ever wondered about the intricate components that make a printer function effectively? One such essential component is the fuser. In this article, we will delve into the world of fusers, exploring their function, types, components, operation, common issues, and maintenance. By the end, you'll have a comprehensive understanding of the importance of the fuser in a printer and how to ensure its optimal performance.

Key Takeaways:

- The fuser in a printer uses heat and pressure to permanently bond toner to paper, ensuring smudge-free prints. Regular maintenance and timely replacement are crucial for optimal performance and print quality.

- Understanding the function, types, and components of fusers is essential for maintaining high-quality prints. Proactive maintenance and adherence to manufacturer guidelines can mitigate common fuser issues and prolong printing equipment lifespan.

Read more: What Is The Fuser On A Printer

Function of a Fuser

The fuser in a printer serves a crucial role in the printing process. Its primary function is to permanently bond the toner to the paper, ensuring that the printed text or images do not smudge or smear. This is achieved through a combination of heat and pressure, which allows the toner to fuse with the fibers of the paper, resulting in a durable and long-lasting print.

When the paper passes through the fuser assembly, it is exposed to heat that softens the toner particles. Simultaneously, pressure is applied to ensure that the toner is firmly bonded to the paper. Once the paper exits the fuser, the toner is fully fused, creating a professional-quality print that is ready for handling without any risk of smudging.

Without a properly functioning fuser, prints would be susceptible to smudging and smearing, ultimately compromising the quality of the output. Therefore, the fuser is an indispensable component that directly impacts the overall print quality and durability.

Types of Fusers

Printers employ different types of fusers, each designed to accommodate specific printing technologies and requirements. The two primary types of fusers are:

- Heat Roller Fusers: This type of fuser utilizes a heated roller to fuse the toner onto the paper. The roller is heated to a precise temperature, allowing the toner to melt and bond with the paper as it passes through the fuser assembly. Heat roller fusers are commonly found in laser printers and are known for their efficiency and consistent performance.

- Pressure Roller Fusers: In contrast to heat roller fusers, pressure roller fusers rely on pressure to fuse the toner onto the paper. The toner is heated as it passes through the fuser, and pressure is applied to ensure proper adhesion to the paper. This type of fuser is often used in high-speed laser printers and copiers, delivering rapid and reliable fusing of toner onto various types of media.

Each type of fuser offers distinct advantages and is selected based on the specific requirements of the printing equipment and the desired print quality. Understanding the differences between these fuser types is essential for maintaining and optimizing printer performance.

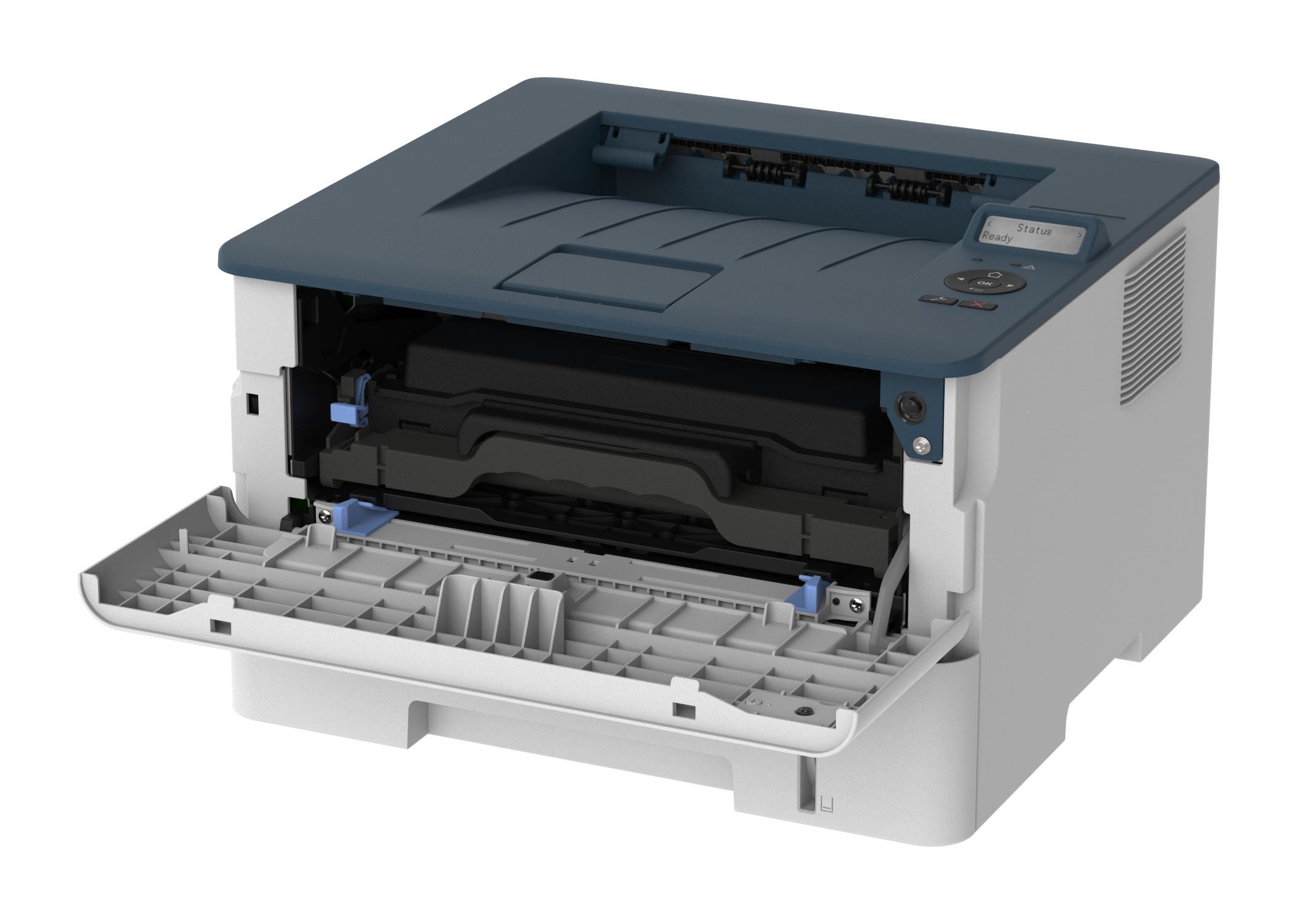

Components of a Fuser

A fuser assembly consists of several key components that work in tandem to ensure the effective fusion of toner onto the paper. These components include:

- Fusing Rollers: The fusing rollers, including the heat and pressure rollers, are pivotal elements of the fuser assembly. The heat roller, often coated with a non-stick material, heats up to the required temperature to melt the toner, while the pressure roller applies the necessary force to bond the toner to the paper.

- Thermostat: The thermostat is responsible for regulating the temperature of the fusing rollers, ensuring that the heat is maintained at the optimal level for effective toner fusion. Precise temperature control is essential for achieving consistent and high-quality prints.

- Heat Lamp or Heating Element: In some fuser designs, a heat lamp or heating element is employed to heat the fusing rollers, initiating the toner melting process. This component is integral to the fuser’s heat generation mechanism.

- Pressure Mechanism: The pressure mechanism, often comprising springs or pneumatic elements, is essential for applying the appropriate pressure to the fusing rollers. This pressure is crucial for ensuring the proper adhesion of the toner to the paper, resulting in durable prints.

- Cleaning Web or Blade: To maintain the integrity of the fusing rollers and prevent toner buildup, a cleaning web or blade is employed to remove excess toner and debris from the rollers. This component plays a significant role in prolonging the fuser’s lifespan and maintaining print quality.

These components work in harmony within the fuser assembly, facilitating the precise fusion of toner onto the paper and contributing to the overall reliability and performance of the printing process.

A fuser in a printer is a component that uses heat and pressure to permanently bond the toner to the paper. It is important for creating high-quality prints and should be handled carefully to avoid damage.

How a Fuser Works

The fuser’s operation is a carefully orchestrated process that culminates in the permanent bonding of toner to the paper. Understanding the step-by-step functioning of a fuser provides valuable insight into its pivotal role in the printing process.

When a printed page enters the fuser assembly, it has already been imprinted with toner by the printer’s imaging components. As the paper enters the fuser, it passes between the heated fusing roller and the pressure roller. The heat generated by the fusing roller causes the toner particles to melt, allowing them to adhere to the paper fibers. Simultaneously, the pressure roller applies the necessary force to ensure that the toner is firmly bonded to the paper, creating a durable and smudge-resistant print.

Throughout this process, the thermostat continuously monitors and regulates the temperature of the fusing rollers, ensuring that the heat is maintained at the precise level required for effective toner fusion. This meticulous temperature control is essential for consistently achieving high-quality prints with optimal adhesion and durability.

Additionally, the cleaning web or blade plays a crucial role in maintaining the integrity of the fusing rollers. By removing excess toner and debris, it prevents buildup that could compromise print quality and fuser performance. This component contributes to the longevity of the fuser assembly and ensures the continued production of professional-grade prints.

Ultimately, the seamless coordination of heating, pressure application, temperature regulation, and cleaning within the fuser assembly results in the successful fusion of toner onto the paper, producing crisp, durable prints that meet the highest standards of quality.

Common Issues with Fusers

While fusers play a critical role in the printing process, they are susceptible to various issues that can impact print quality and overall performance. Understanding these common issues is essential for diagnosing and addressing fuser-related problems effectively. Some prevalent issues include:

- Uneven Heating: Uneven heating within the fuser assembly can result in inconsistent toner fusion, leading to print defects such as streaks or areas of poor adhesion. This issue may stem from thermostat malfunctions, heat roller damage, or other internal factors.

- Toner Smearing: If the fuser’s temperature is not adequately regulated, toner smearing may occur, compromising the clarity and durability of prints. This issue often arises from thermostat inaccuracies or insufficient pressure application.

- Excessive Toner Buildup: Over time, the fusing rollers can accumulate excess toner and debris, impeding their ability to facilitate proper toner fusion. This buildup may result from a worn cleaning web or blade, necessitating timely maintenance to prevent print quality degradation.

- Fuser Error Messages: Modern printers are equipped with diagnostic systems that can detect fuser-related issues and display error messages. These messages may indicate fuser malfunctions, overheating, or other operational irregularities that require attention.

- Reduced Print Quality: A deteriorating fuser can lead to diminished print quality, manifesting as faded prints, inconsistent toner adhesion, or visible defects. This decline in print quality may signal the need for fuser maintenance or replacement.

Addressing these common fuser issues promptly is crucial for preserving print quality, optimizing printer performance, and extending the fuser’s lifespan. Regular maintenance and timely intervention can mitigate these issues, ensuring that the fuser continues to deliver professional-grade prints with reliability and consistency.

Maintenance and Replacement of Fusers

Proactive maintenance and, when necessary, timely replacement of fusers are essential for sustaining optimal print quality and prolonging the lifespan of printing equipment. Here are key considerations for maintaining and replacing fusers:

- Regular Cleaning: Periodic cleaning of the fuser assembly, including the fusing rollers and the cleaning web or blade, is vital for preventing toner buildup and ensuring consistent print quality. This maintenance task helps mitigate issues such as toner smearing and uneven toner fusion.

- Monitoring Print Quality: Regularly evaluating print output for signs of toner adhesion issues, streaking, or other abnormalities can provide early indications of potential fuser problems. Addressing these issues promptly can prevent further deterioration of print quality.

- Following Manufacturer Guidelines: Adhering to the manufacturer’s recommended maintenance schedule and procedures for fuser care is crucial. This includes replacing consumable components such as the cleaning web or blade according to the specified intervals to uphold optimal fuser performance.

- Professional Servicing: In cases of persistent fuser issues or error messages, seeking professional servicing from authorized technicians can identify underlying problems and ensure comprehensive fuser maintenance. Professional technicians can diagnose fuser issues accurately and perform intricate repairs as needed.

- Replacement Considerations: When fuser issues persist despite thorough maintenance, or when the fuser reaches the end of its service life, replacement may be necessary. Selecting a genuine, compatible fuser unit from the printer’s manufacturer is essential to maintain print quality and ensure seamless integration with the printing equipment.

- Installation and Calibration: Proper installation and calibration of a new fuser unit are critical for optimal performance. Following the manufacturer’s guidelines for fuser replacement, including calibration procedures, safeguards against operational issues and ensures consistent print quality.

By prioritizing regular maintenance, promptly addressing fuser issues, and adhering to manufacturer recommendations for replacement, businesses and individuals can sustain high-quality print output, minimize operational disruptions, and maximize the longevity of their printing equipment.

Conclusion

The fuser in a printer is a remarkable and indispensable component that plays a pivotal role in ensuring the quality and durability of printed materials. By employing heat and pressure, the fuser facilitates the permanent bonding of toner to paper, resulting in professional-grade prints that resist smudging and maintain clarity. Understanding the function, types, components, operation, common issues, and maintenance of fusers is essential for optimizing print quality and prolonging the lifespan of printing equipment.

From heat roller fusers to pressure roller fusers, each type offers distinct advantages and is tailored to specific printing technologies and requirements. The careful orchestration of fuser components, including fusing rollers, thermostats, heat lamps, pressure mechanisms, and cleaning webs, ensures the precise fusion of toner onto paper, contributing to reliable and consistent print output.

Despite the critical role of fusers, they are susceptible to common issues such as uneven heating, toner smearing, and excessive toner buildup. Proactive maintenance, regular cleaning, and adherence to manufacturer guidelines for fuser care are essential for mitigating these issues and preserving print quality. In cases of persistent fuser problems, professional servicing and timely replacement may be necessary to uphold optimal performance and print quality.

By recognizing the significance of fusers and implementing proactive maintenance practices, businesses and individuals can ensure that their printing equipment consistently delivers high-quality prints, minimizes operational disruptions, and operates at peak efficiency. The fuser’s impact on print quality and overall printing experience underscores its status as a cornerstone of modern printing technology, deserving of careful attention and maintenance.

Frequently Asked Questions about What Is A Fuser In A Printer

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is A Fuser In A Printer”