Home>Technology>Smart Home Devices>What Printer To Use For Heat Transfer Paper

Smart Home Devices

What Printer To Use For Heat Transfer Paper

Modified: February 18, 2024

Discover the best printers for heat transfer paper and elevate your smart home devices with high-quality, vibrant designs. Choose the perfect printer for your DIY projects today!

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of heat transfer paper printing, where creativity and technology converge to bring your designs to life on fabric. Whether you're a passionate crafter, a small business owner, or a DIY enthusiast, understanding the nuances of heat transfer paper and the ideal printers for this medium is crucial for achieving vibrant and long-lasting results.

In the realm of heat transfer paper, the choice of printer plays a pivotal role in determining the quality, durability, and color accuracy of your transferred designs. From inkjet to laser and dye-sublimation printers, each type offers unique advantages and considerations, making the selection process an essential aspect of your printing journey.

In this comprehensive guide, we'll delve into the intricacies of heat transfer paper and explore the various types of printers best suited for this application. By the end, you'll gain valuable insights to help you make an informed decision when choosing the perfect printer for your heat transfer paper projects. So, let's embark on this enlightening exploration of the fascinating intersection between printing technology and fabric artistry.

Key Takeaways:

- Choose the right printer for heat transfer paper projects based on fabric compatibility, color accuracy, and durability to achieve vibrant and long-lasting designs on fabric.

- Inkjet printers offer versatility and vibrant color reproduction, while laser printers excel in precision and durability. Dye-sublimation printers cater to professional-grade applications on polyester fabrics, ensuring unparalleled color accuracy and durability.

Understanding Heat Transfer Paper

Heat transfer paper is a specialized medium that allows you to print custom designs, graphics, and text onto fabric using a standard desktop printer. This versatile material is designed to seamlessly transfer your printed images onto textiles through the application of heat and pressure, resulting in vibrant and durable designs on clothing, accessories, and other fabric-based items.

Typically, heat transfer paper consists of three essential layers: the top printable layer, a middle adhesive layer, and a bottom backing layer. The printable layer is specially coated to capture and retain the ink from your printer, ensuring crisp and vivid image reproduction. The adhesive layer enables the transfer of the printed design onto fabric when subjected to heat and pressure, while the backing layer provides stability and support during the transfer process.

When selecting heat transfer paper, it’s essential to consider the fabric type and color, as well as the intended application of the transferred design. Different heat transfer papers are optimized for use on light or dark fabrics, offering distinct characteristics to suit specific printing needs. Additionally, some varieties are engineered for use with specific types of printers, ensuring compatibility and optimal results.

Understanding the intricacies of heat transfer paper is crucial for achieving professional-quality results. From selecting the right paper for your project to ensuring proper image preparation and transfer techniques, mastering the art of heat transfer paper printing opens up a world of creative possibilities for customizing apparel, accessories, and more.

Types of Printers for Heat Transfer Paper

When it comes to heat transfer paper printing, selecting the right printer is a critical decision that directly impacts the quality and longevity of your transferred designs. Different types of printers offer distinct advantages and considerations, catering to various printing needs and preferences. Let’s explore the primary printer options suitable for heat transfer paper applications:

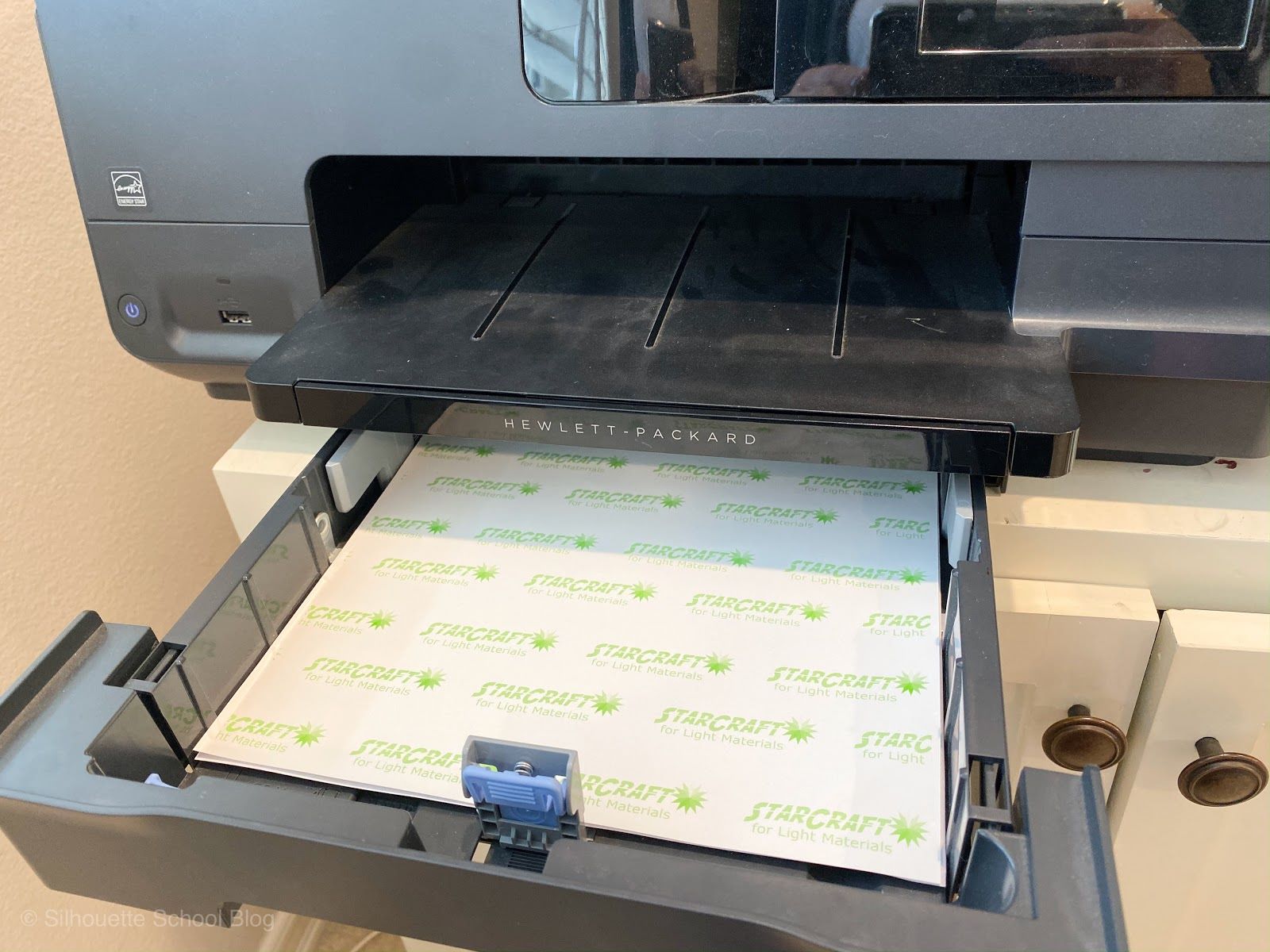

- Inkjet Printers: Inkjet printers are widely favored for heat transfer paper projects due to their versatility and ability to produce vibrant, high-resolution prints. These printers utilize liquid ink, which is absorbed by the heat transfer paper’s coated surface, resulting in vivid and detailed designs. Inkjet printers are suitable for both light and dark heat transfer papers, offering flexibility and exceptional color reproduction for a wide range of fabric materials.

- Laser Printers: Laser printers are known for their speed and precision, making them a popular choice for heat transfer paper printing, especially for light-colored fabrics. These printers utilize toner, which is fused onto the heat transfer paper using heat and pressure. While laser printers excel in producing crisp and durable designs, they are generally not recommended for dark heat transfer papers, as the toner may not effectively adhere to dark fabric surfaces.

- Dye-Sublimation Printers: Dye-sublimation printers are designed for professional-grade heat transfer applications, particularly on polyester-based fabrics. Unlike traditional inkjet and laser printers, dye-sublimation printers use heat to transfer dye onto the fabric, resulting in exceptionally vibrant and permanent designs. While dye-sublimation printing offers unparalleled color accuracy and durability, it is primarily suited for polyester textiles, limiting its versatility for other fabric types.

Each type of printer offers unique capabilities and considerations, influencing the choice of heat transfer paper and the desired outcome of your fabric printing projects. Understanding the characteristics and compatibility of these printers is essential for making informed decisions when embarking on heat transfer paper applications.

Inkjet Printers

Inkjet printers are a popular choice for heat transfer paper applications, offering exceptional versatility, color accuracy, and compatibility with a wide range of fabric materials. These printers utilize liquid ink, which is precisely deposited onto the heat transfer paper’s coated surface, resulting in vibrant and high-resolution prints that are ideal for customizing apparel, accessories, and more.

One of the key advantages of inkjet printers for heat transfer paper projects is their ability to produce detailed and intricate designs with remarkable color fidelity. Whether you’re transferring photographs, illustrations, or text-based designs, inkjet printers excel in capturing the nuances of your images, ensuring that the transferred designs retain their visual impact and clarity on fabric.

Furthermore, inkjet printers are suitable for both light and dark heat transfer papers, offering flexibility and adaptability for various fabric colors and types. Light heat transfer papers are designed for use on white or light-colored fabrics, while dark heat transfer papers are engineered to produce vibrant designs on dark-colored textiles. With the right inkjet printer, you can achieve stunning results on a diverse array of fabric surfaces, empowering you to unleash your creativity without limitations.

When selecting an inkjet printer for heat transfer paper applications, it’s essential to consider factors such as print resolution, ink compatibility, and overall performance. Opting for a printer with dedicated pigment-based or sublimation inks can further enhance the longevity and color vibrancy of your transferred designs, ensuring that they withstand repeated washing and maintain their visual appeal over time.

Whether you’re a hobbyist, a small business owner, or a dedicated crafter, investing in a quality inkjet printer for heat transfer paper projects can elevate your fabric customization endeavors, allowing you to bring your unique designs to life with uncompromising quality and precision.

When choosing a printer for heat transfer paper, look for one that uses pigment-based inks rather than dye-based inks. Pigment-based inks are more durable and resistant to fading when exposed to heat and washing.

Laser Printers

Laser printers are renowned for their speed, precision, and durability, making them a compelling choice for certain heat transfer paper applications. These printers utilize toner, a powdered ink that is fused onto the heat transfer paper’s surface using heat and pressure, resulting in crisp and long-lasting designs on fabric.

One of the primary advantages of laser printers for heat transfer paper projects is their ability to produce highly detailed and precise designs with exceptional clarity. The toner-based printing process ensures that fine lines, intricate patterns, and text elements are reproduced with sharpness and accuracy, making laser printers an ideal choice for designs that demand meticulous attention to detail.

While laser printers excel in producing vibrant designs on light-colored fabrics, they may not be the optimal choice for dark heat transfer papers. The nature of toner may pose challenges when transferring designs onto dark fabric surfaces, potentially impacting the color intensity and overall visual impact of the transferred designs. As such, it’s important to consider the intended fabric color and type when determining the suitability of laser printers for your heat transfer paper projects.

Additionally, laser printers are known for their durability, producing designs that exhibit excellent wash-fastness and resistance to fading over time. This ensures that your transferred designs maintain their vibrancy and integrity through repeated laundering, making laser-printed heat transfers a reliable choice for creating long-lasting custom apparel, accessories, and textile-based creations.

When selecting a laser printer for heat transfer paper applications, it’s advisable to choose a model that offers dedicated support for heat transfer printing, ensuring optimal performance and compatibility with the specific requirements of this printing process. By leveraging the precision and durability of laser printers, you can achieve professional-quality heat transfers that embody the meticulous craftsmanship and enduring appeal of your custom designs.

Dye-Sublimation Printers

Dye-sublimation printers represent a specialized category of printers designed to deliver professional-grade heat transfer printing, particularly on polyester-based fabrics. Unlike traditional inkjet and laser printers, which deposit ink or toner onto the surface of the heat transfer paper, dye-sublimation printers utilize a unique process that involves heat-induced dye sublimation, resulting in exceptionally vibrant and permanent designs on fabric.

One of the distinctive advantages of dye-sublimation printing is its unparalleled color accuracy and saturation. The dye sublimation process allows the ink to permeate the fabric fibers, resulting in designs with vivid and lifelike colors that resist fading and washing. This makes dye-sublimation printers an ideal choice for applications that demand superior color reproduction, such as custom sportswear, promotional apparel, and personalized textile products.

Furthermore, dye-sublimation printers are renowned for their ability to produce seamless and continuous tone designs, making them particularly well-suited for photographic and high-resolution image transfers. The absence of visible dot patterns and the smooth blending of colors achieved through dye sublimation contribute to the professional and polished appearance of the transferred designs, enhancing their visual impact and appeal.

It’s important to note that dye-sublimation printing is primarily compatible with polyester fabrics, as the process relies on the polyester fibers’ ability to bond with the sublimation dyes under high heat. While this limitation may restrict the versatility of dye-sublimation printers in terms of fabric compatibility, it ensures that the resulting transfers exhibit exceptional durability, colorfastness, and resistance to abrasion and washing.

When considering a dye-sublimation printer for heat transfer paper applications, it’s essential to assess your specific printing needs and the fabric materials you intend to customize. By harnessing the advanced capabilities of dye-sublimation printing, you can elevate your fabric customization endeavors, producing designs that embody the pinnacle of color accuracy, durability, and visual impact.

Choosing the Right Printer for Your Heat Transfer Paper

When embarking on heat transfer paper projects, selecting the ideal printer is a pivotal decision that directly influences the quality, vibrancy, and longevity of your transferred designs. To make an informed choice, it’s essential to consider various factors that align with your specific printing needs, fabric preferences, and design requirements. Here are key considerations to guide you in choosing the right printer for your heat transfer paper endeavors:

- Fabric Compatibility: Assess the types of fabrics you intend to customize with heat transfers. Determine whether your chosen printer is compatible with the fabric materials, colors, and textures you plan to work with. Consider the specific requirements for light and dark heat transfer papers, as well as any limitations related to fabric composition and surface characteristics.

- Color Accuracy and Vibrancy: Evaluate the printer’s capability to reproduce vibrant and true-to-life colors, especially for designs that demand high color fidelity and visual impact. Consider the printer’s color management features, ink technology, and overall color reproduction capabilities to ensure that your transferred designs reflect the intended hues and tones with precision.

- Detail and Precision: If your designs encompass intricate patterns, fine lines, or detailed imagery, prioritize printers that excel in producing sharp and precise prints. Look for printers with high-resolution capabilities, advanced print heads, and precision printing technologies to ensure that your transferred designs maintain their clarity and intricacy on fabric.

- Durability and Wash Resistance: Assess the durability of the printed transfers, particularly their resistance to fading, cracking, and washing. Choose printers and inks that are engineered to withstand laundering and maintain the integrity of the transferred designs over time, ensuring that your custom apparel and textile creations retain their visual appeal through regular use and care.

- Specialized Printing Needs: If your projects demand specific printing requirements, such as photographic-quality transfers, continuous tone designs, or compatibility with polyester fabrics, consider specialized printers such as dye-sublimation models that cater to these advanced printing needs.

By carefully evaluating these considerations and aligning them with your unique printing goals, you can make an informed decision when selecting the right printer for your heat transfer paper projects. Whether you prioritize color accuracy, detail precision, or fabric versatility, choosing a printer that complements your specific requirements empowers you to unleash your creativity and achieve exceptional results in the realm of heat transfer paper printing.

Conclusion

As we conclude this enlightening exploration of heat transfer paper printing and the diverse array of printers suited for this creative endeavor, it’s evident that the choice of printer plays a pivotal role in shaping the quality, vibrancy, and durability of transferred designs on fabric. Whether you’re a seasoned crafter, a small business owner, or an enthusiastic DIY enthusiast, understanding the nuances of heat transfer paper and selecting the right printer empowers you to bring your custom designs to life with uncompromising precision and visual impact.

From the versatile inkjet printers that excel in producing vibrant and detailed designs on a wide range of fabric materials to the precision and durability of laser printers for meticulous and long-lasting transfers, each printer type offers unique advantages and considerations. Furthermore, the specialized capabilities of dye-sublimation printers cater to professional-grade heat transfer applications, particularly on polyester fabrics, ensuring unparalleled color accuracy and durability.

By considering factors such as fabric compatibility, color accuracy, detail precision, durability, and specialized printing needs, you can make informed decisions when choosing the right printer for your heat transfer paper projects. Whether you prioritize vibrant color reproduction, meticulous design clarity, or advanced printing capabilities, aligning your specific requirements with the features of your chosen printer sets the stage for achieving exceptional results in your fabric customization endeavors.

As you embark on your heat transfer paper printing journey, may this comprehensive guide serve as a valuable resource, empowering you to make informed decisions and unleash your creativity with confidence. Whether you’re personalizing apparel, accessories, or textile-based creations, the seamless integration of technology and artistry through heat transfer paper printing opens up a world of possibilities, allowing you to express your unique vision and style through vibrant and enduring designs on fabric.

With the right printer at your disposal, you’re poised to embark on a captivating journey of fabric customization, where every transferred design becomes a testament to your creativity, passion, and attention to detail. Here’s to embracing the art of heat transfer paper printing and infusing your world with the beauty and allure of custom-designed textiles.

Frequently Asked Questions about What Printer To Use For Heat Transfer Paper

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Printer To Use For Heat Transfer Paper”