Home>Articles>An In-Depth Guide On The Different Types Of Circuit Breakers

Articles

An In-Depth Guide On The Different Types Of Circuit Breakers

Modified: March 7, 2024

Looking for articles on general classifications of circuit breakers? Discover which options do not fall under this category and expand your knowledge.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to our guide on different types of circuit breakers! Circuit breakers are crucial components in electrical systems, designed to protect circuits and appliances from damage caused by overloads, short circuits, and other electrical faults. They are essential for maintaining the safety and functionality of electrical installations. In this article, we will explore the different types of circuit breakers, their classifications, and their unique features. Understanding these distinctions will help you choose the right circuit breaker for your specific needs. Circuit breakers can be classified based on various factors, such as their operating mechanism, tripping characteristics, and application. One common approach to categorizing circuit breakers is based on their operational principles: thermal, magnetic, hybrid, and solid-state.

Key Takeaways:

- Choose the right circuit breaker based on your needs: thermal for residential use, magnetic for industrial applications, hybrid for critical systems, and solid-state for advanced control and monitoring.

- Understanding circuit breaker classifications is crucial for optimal protection and reliability of electrical systems. Consult professionals and adhere to safety standards when selecting and installing circuit breakers.

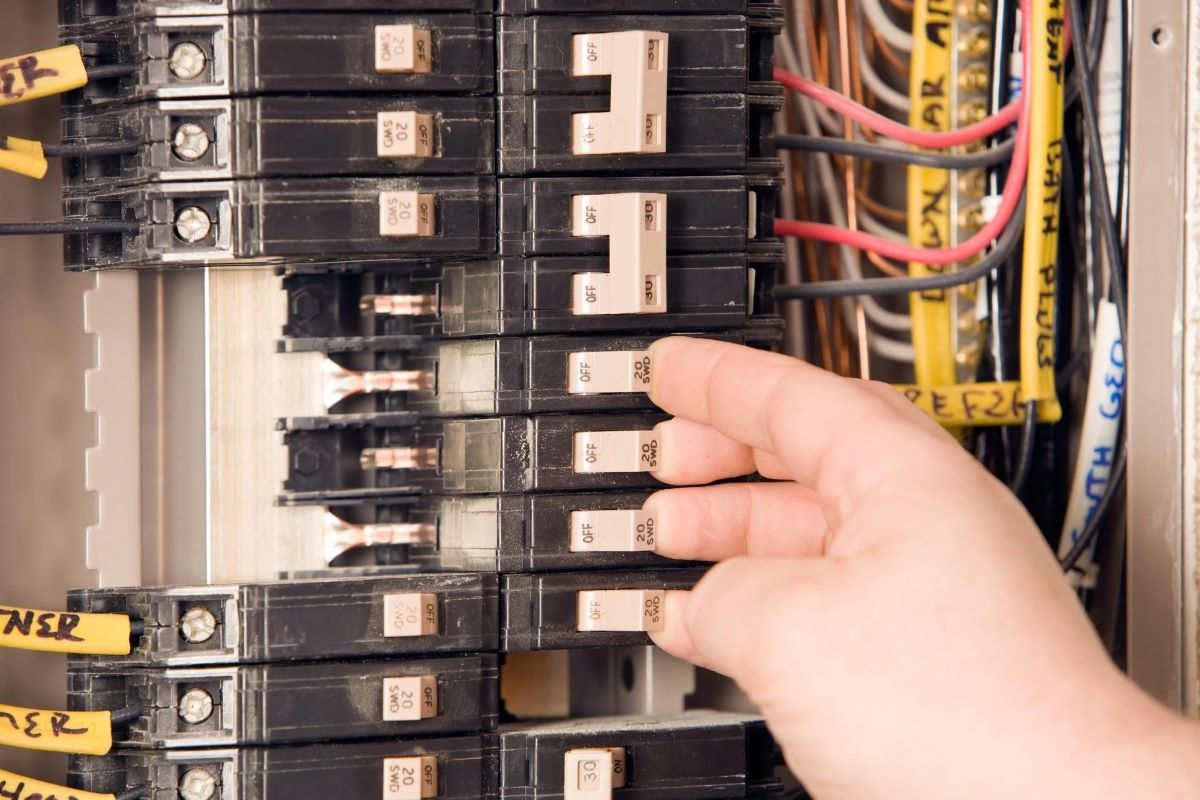

Thermal Circuit Breakers

Thermal circuit breakers, also known as thermal-magnetic circuit breakers, are one of the most common types used in residential and commercial applications. These circuit breakers operate on the principle of heat and electromagnetism.

The primary mechanism of a thermal circuit breaker is a bi-metal strip. This strip consists of two different metals with different coefficients of thermal expansion bonded together. Under normal operating conditions, the bi-metal strip remains straight, allowing current to flow through the circuit. However, if the current exceeds the circuit breaker’s rated capacity, the strip heats up and bends due to the difference in thermal expansion rates of the two metals.

When the bi-metal strip bends, it triggers the tripping mechanism, opening the circuit and disconnecting the power supply. This bending action is reversible. Once the strip cools down, it returns to its original shape, allowing the circuit breaker to reset and restore power.

Thermal circuit breakers are characterized by their ability to handle both short-duration and sustained overloads. The bi-metal strip takes time to heat up, which allows the circuit breaker to tolerate brief overloads or current surges without tripping. However, prolonged overloads can cause the strip to bend further, leading to a full trip of the circuit breaker.

These circuit breakers are commonly used for protecting lighting circuits, small appliances, and residential outlets. They are not as precise as other types of circuit breakers, but their simplicity and affordability make them popular choices for basic electrical protection.

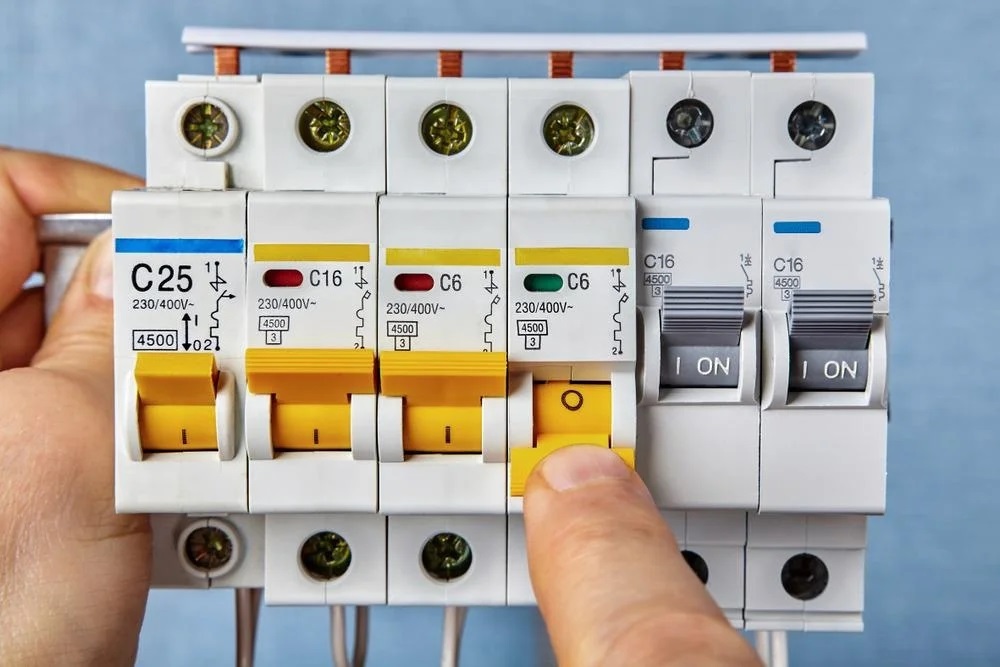

Magnetic Circuit Breakers

Magnetic circuit breakers, also known as magnetic trip circuit breakers, are designed to protect against short circuits and high instantaneous currents. These circuit breakers operate based on the principle of electromagnetism.

The key component of a magnetic circuit breaker is an electromagnet. When an excessive current passes through the circuit, the electromagnetic coil within the breaker creates a magnetic field. This magnetic field generates a force that mechanically opens the circuit breaker contacts, interrupting the current flow and disconnecting the circuit.

Magnetic circuit breakers are highly sensitive to sudden current surges and can quickly respond to short circuits. Their primary function is to protect electrical circuits and equipment from the potentially damaging effects of these high-current events.

Compared to thermal circuit breakers, magnetic circuit breakers have a faster response time. They can almost instantly trip when subjected to a short circuit or a large current surge. This rapid response helps prevent further damage and improves the overall safety of the electrical system.

However, one limitation of magnetic circuit breakers is their lower tolerance for continuous overloads. They are not as effective in handling sustained high currents compared to thermal circuit breakers. If the current exceeds the breaker’s rated capacity for an extended period, it can cause overheating and failure of the breaker itself.

Due to their high sensitivity and quick response, magnetic circuit breakers are commonly used in industrial applications, such as motor control centers, transformers, and heavy machinery. They provide reliable protection against short circuits while allowing for efficient operation of electrical systems.

When identifying a general classification of circuit breakers, it’s important to remember that they are typically categorized as thermal-magnetic, magnetic, or thermal. Any other classification would not fall under the general categories of circuit breakers.

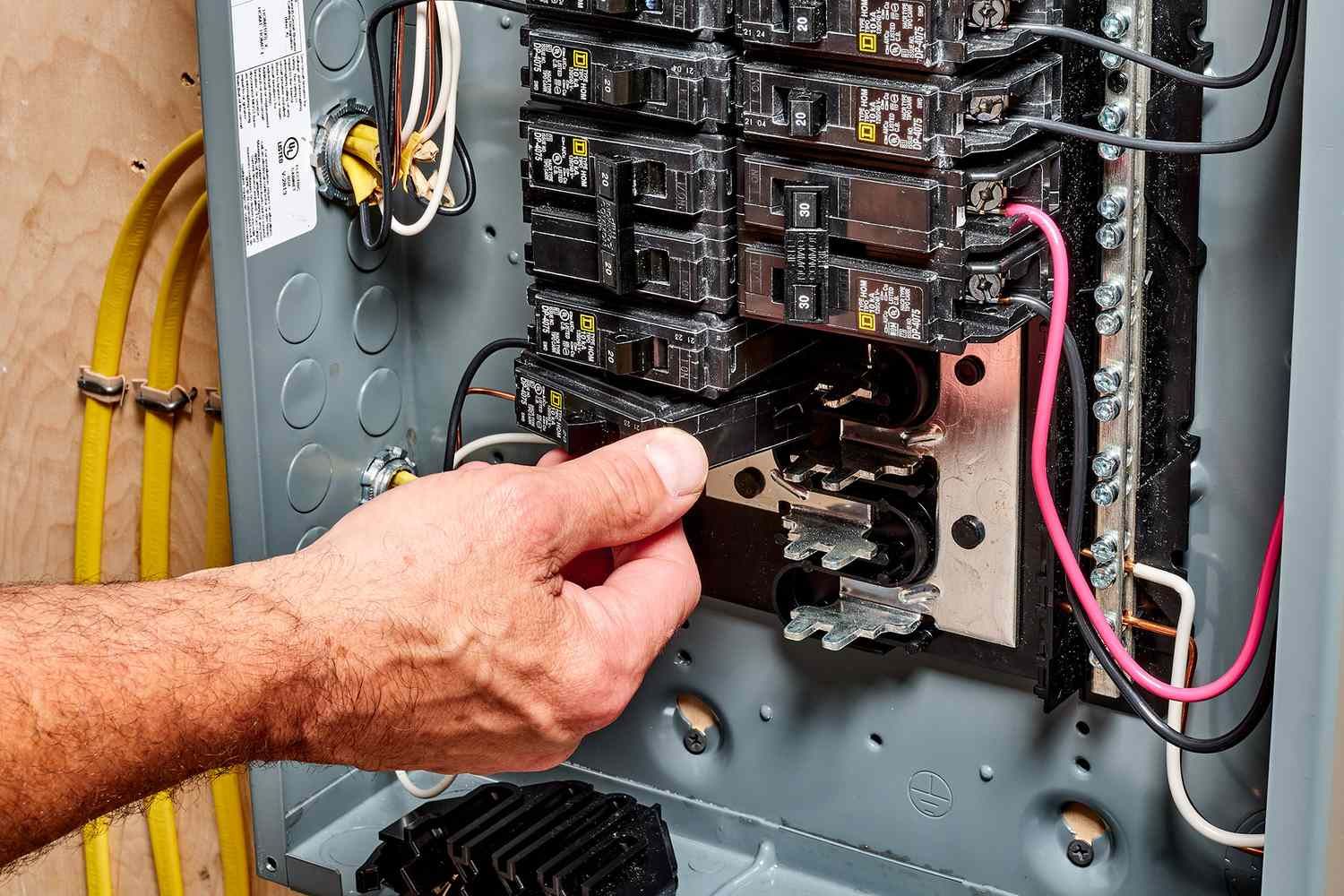

Hybrid Circuit Breakers

Hybrid circuit breakers, also known as electronic trip circuit breakers, combine the features of both thermal and magnetic circuit breakers. They offer the advantages of precise tripping and enhanced protection against various electrical faults.

These circuit breakers utilize a combination of thermal and magnetic technologies to provide optimal performance. The thermal element is responsible for protecting against sustained overload conditions, while the magnetic element provides quick response to short circuits.

Hybrid circuit breakers incorporate a microprocessor-based trip unit that constantly monitors the current flowing through the circuit. This trip unit analyzes the current characteristics and uses algorithms to determine the appropriate response in case of an electrical fault.

When the current exceeds the breaker’s rated capacity for a sustained period, the thermal element reacts by generating heat and opening the contacts. In the event of a short circuit, the magnetic element rapidly trips the breaker by creating a strong magnetic field. The combination of these two mechanisms ensures efficient and accurate protection against a wide range of electrical faults.

One of the primary benefits of hybrid circuit breakers is their adjustable tripping settings. The trip unit can be programmed to suit specific application requirements, allowing for greater flexibility and customization. This feature is particularly useful in scenarios where different types of loads or equipment are present in the same electrical system.

Hybrid circuit breakers are commonly found in commercial and industrial settings where precise and reliable protection is essential. They are often used in critical applications such as data centers, hospitals, and manufacturing facilities where any downtime can result in significant financial losses or potential harm to human life.

Solid-State Circuit Breakers

Solid-state circuit breakers, also known as digital circuit breakers, represent the latest advancement in circuit breaker technology. Unlike traditional circuit breakers that rely on mechanical components, these circuit breakers utilize semiconductor devices to control and protect electrical circuits.

The main component of a solid-state circuit breaker is a solid-state switch, such as a power transistor or a thyristor. These switches can handle high power levels and provide fast response times, making them ideal for protecting electrical systems against faults.

One of the key advantages of solid-state circuit breakers is their ability to control current flow with high precision. The solid-state switches can be rapidly turned on and off using electronic control signals, allowing for instant interruption of current in case of a fault or overload.

Furthermore, solid-state circuit breakers can be programmed to have different trip characteristics, enabling customized protection settings for specific application needs. This flexibility allows for finer control over the protection of sensitive equipment, reducing the risk of damage or downtime.

Another noteworthy feature of solid-state circuit breakers is their ability to provide advanced monitoring and diagnostics. These circuit breakers are equipped with integrated sensors and built-in communication capabilities, which allow them to continuously monitor the electrical parameters and transmit data to a central monitoring system.

By collecting and analyzing this data, solid-state circuit breakers can provide valuable insights into the electrical system’s health and performance. This proactive monitoring helps identify potential issues before they escalate, enabling timely maintenance and preventing costly downtime.

Although solid-state circuit breakers offer numerous benefits, they are still relatively new and may have higher costs compared to traditional circuit breakers. However, their advanced features and improved reliability make them a promising technology for future electrical system protection.

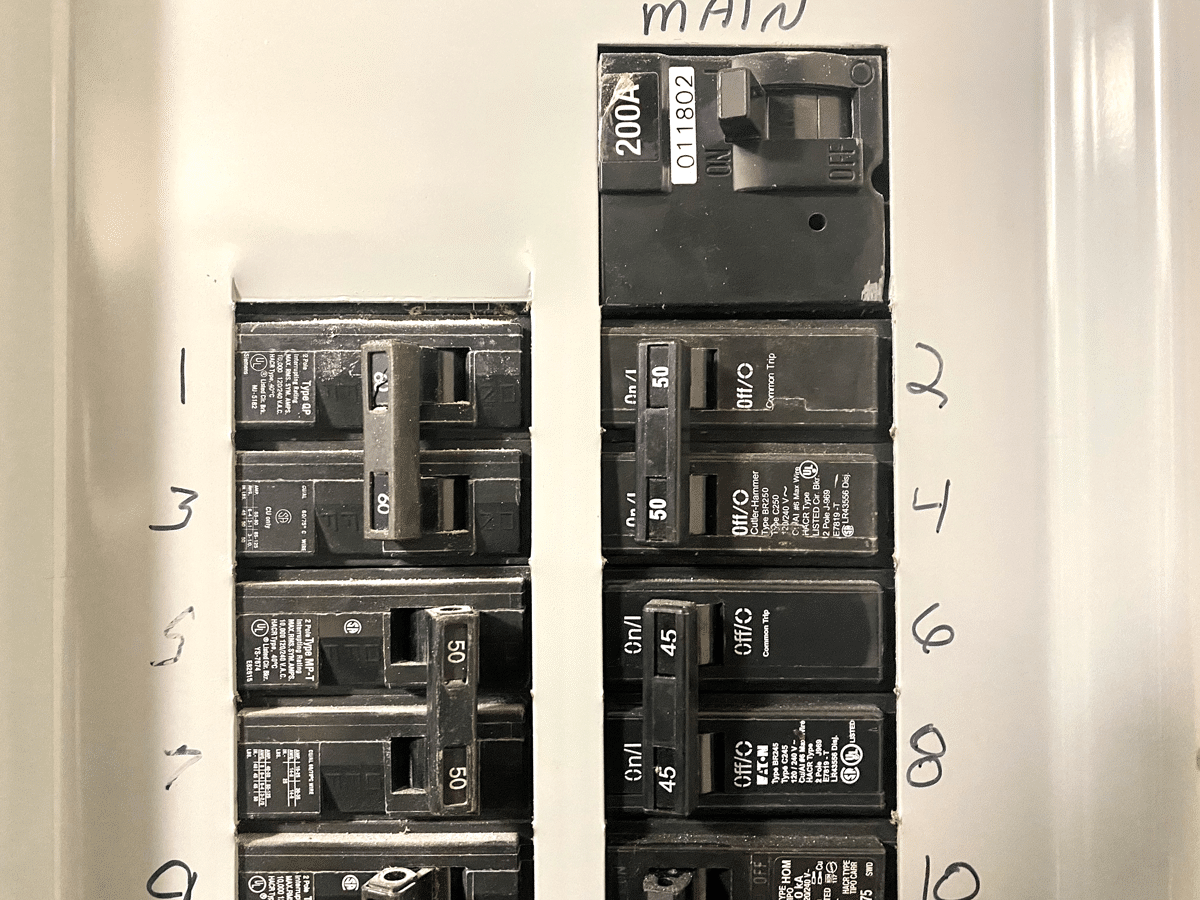

Conclusion

Choosing the right circuit breaker is vital for ensuring the safety and efficient operation of electrical systems. Understanding the different types of circuit breakers and their classifications is essential in making informed decisions.

Thermal circuit breakers are commonly used for residential and small-scale applications. They provide reliable protection against overloads and short circuits, offering a cost-effective solution.

Magnetic circuit breakers are highly sensitive to short circuits and have a rapid response time. They are ideal for industrial applications where quick tripping is crucial to prevent further damage.

Hybrid circuit breakers combine the benefits of thermal and magnetic mechanisms, providing precise tripping and adjustable settings. They are suitable for critical systems that require tailored protection.

Solid-state circuit breakers represent the future of circuit protection, utilizing semiconductor technology for enhanced control and advanced monitoring. While still emerging, they offer greater precision and diagnostic capabilities for more sophisticated electrical systems.

Ultimately, the choice of circuit breaker depends on factors such as the application, load requirements, and budget. It is essential to consult with professionals and adhere to relevant safety standards and regulations when selecting and installing circuit breakers.

By understanding the different types of circuit breakers and their unique features, you can ensure the optimal protection and reliability of your electrical installations. Invest in quality circuit breakers that align with your specific requirements and enjoy the peace of mind knowing that your electrical system is well-protected.

Frequently Asked Questions about An In-Depth Guide On The Different Types Of Circuit Breakers

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “An In-Depth Guide On The Different Types Of Circuit Breakers”