Home>Articles>How Many Different Types Of Circuit Breakers Are There

Articles

How Many Different Types Of Circuit Breakers Are There

Modified: December 7, 2023

Discover the different types of circuit breakers in this informative article. Learn about the various technologies and applications for circuit breakers.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

A circuit breaker is an essential component of an electrical system that helps protect against short circuits, overloads, and other electrical faults. It acts as a safety device, automatically interrupting the flow of electric current when it detects abnormal conditions. Circuit breakers come in various types, each designed for specific applications and environments.

In this article, we will explore the different types of circuit breakers commonly used in residential, commercial, and industrial settings. Understanding their functionalities, advantages, and limitations can help individuals and professionals make informed decisions when selecting the appropriate circuit breaker for a particular electrical installation.

Whether you are an electrical engineer, a homeowner, or a curious reader, read on to discover the diverse world of circuit breakers and the role they play in safeguarding electrical systems.

Key Takeaways:

- Understanding the diverse world of circuit breakers is crucial for selecting the most suitable option for specific applications, ensuring the safety and reliability of electrical installations.

- The proper selection and use of circuit breakers contribute to the protection of electrical systems, prevention of accidents, and the overall safety of individuals and property.

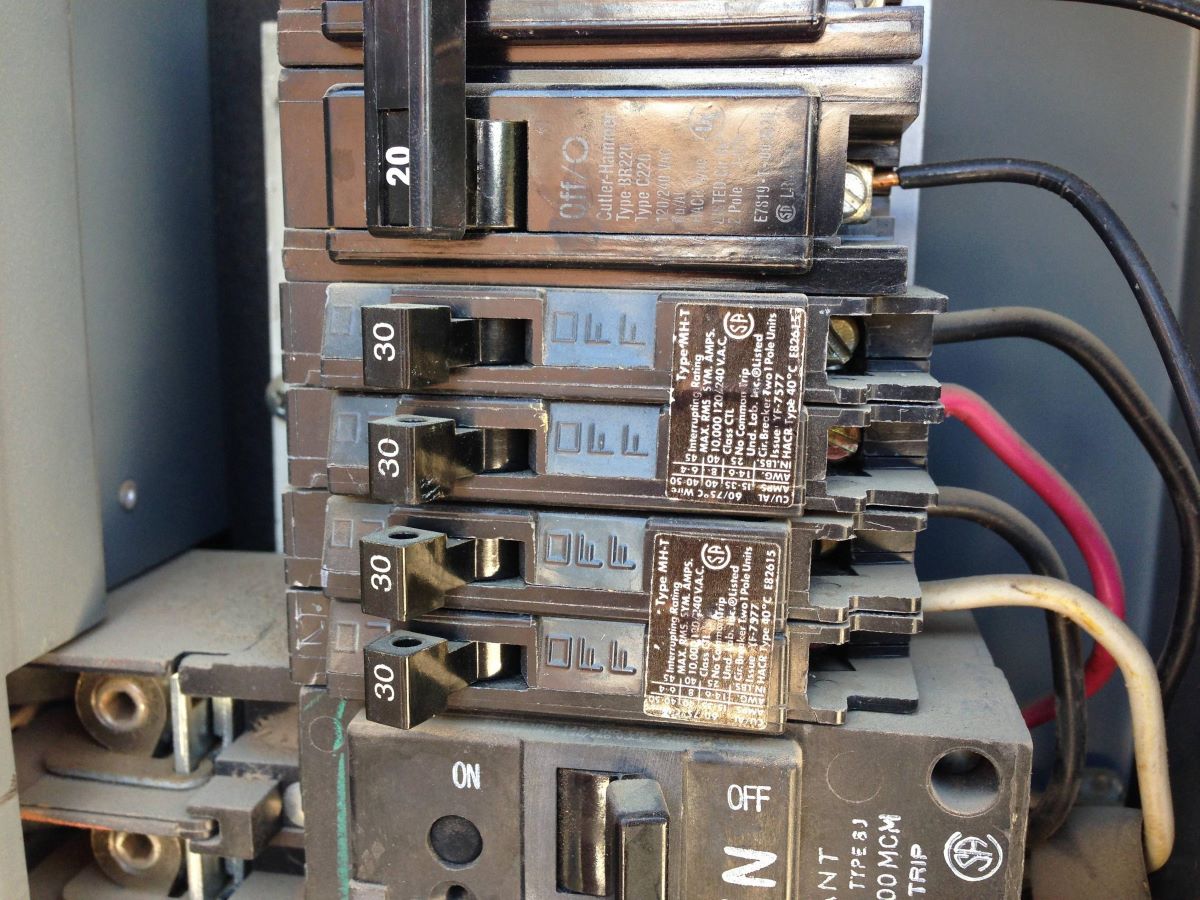

Common Types of Circuit Breakers

There are several common types of circuit breakers, each designed with unique features and characteristics to suit specific electrical applications. Let’s explore these types in more detail:

- Thermal Circuit Breakers: Thermal circuit breakers are widely used in residential and commercial applications. They operate on the principle of thermal expansion and utilize a bimetallic strip that bends when exposed to excessive heat, thereby tripping the circuit.

- Magnetic Circuit Breakers: Magnetic circuit breakers are commonly employed in industrial and commercial settings where high currents are involved. They rely on an electromagnet that responds to the magnetic field produced by excessive current, causing the circuit breaker to trip and interrupt the flow of electricity.

- Hybrid Circuit Breakers: Hybrid circuit breakers combine the functionalities of both thermal and magnetic circuit breakers. They provide effective protection against both high currents and overloads, making them suitable for a wide range of applications.

- Solid-State Circuit Breakers: Solid-state circuit breakers, also known as electronic circuit breakers, use solid-state components instead of traditional mechanical parts. They offer faster response times, greater precision, and enhanced control features compared to their conventional counterparts.

- Oil Circuit Breakers: Oil circuit breakers are commonly used in high voltage applications and utilize oil as an arc extinguishing medium. When a fault occurs, the oil is vaporized, creating an insulating gas that extinguishes the arc and interrupts the circuit.

- Air Circuit Breakers: Air circuit breakers are primarily used in low-voltage applications. They rely on compressed air to quench the arc and interrupt the circuit when a fault occurs.

- Vacuum Circuit Breakers: Vacuum circuit breakers are designed with a vacuum as the arc-quenching medium. They offer excellent insulation and interruption capabilities, making them suitable for medium to high voltage applications.

- SF6 Circuit Breakers: SF6 circuit breakers use sulfur hexafluoride gas as the arc-quenching medium. They are highly efficient and offer excellent insulation properties, making them suitable for high voltage applications.

- Miniature Circuit Breakers: Miniature circuit breakers (MCBs) are commonly used in residential and commercial installations. They provide protection against overcurrents and short circuits and are installed in circuit breaker panels.

- Molded Case Circuit Breakers: Molded case circuit breakers are widely used in commercial and industrial applications. They are housed in a molded case and can be easily installed and maintained.

- Ground Fault Circuit Interrupters (GFCIs): GFCIs are specialized circuit breakers designed to protect against electric shocks and ground faults. They quickly detect any imbalance in current flow and disconnect the circuit to prevent electrical accidents.

- Arc Fault Circuit Interrupters (AFCIs): AFCIs are designed to detect and mitigate the risk of electrical arcs, which can potentially cause fires. They monitor the circuit for any abnormal arcing conditions and quickly interrupt the circuit to prevent fire hazards.

- Residual Current Circuit Breakers (RCCBs): RCCBs, also known as ground fault circuit interrupters (GFCIs), provide protection against earth leakage currents. They are commonly used in areas where water and electricity may come into contact, such as bathrooms, kitchens, and outdoor sockets.

Each type of circuit breaker has its own advantages and limitations, and the choice depends on factors such as the application, voltage level, current capacity, and specific safety requirements. Understanding the various types can help individuals and professionals make informed decisions when selecting the most suitable circuit breaker for their specific needs.

Thermal Circuit Breakers

Thermal circuit breakers are a type of circuit protection device commonly used in residential and commercial applications. They operate based on the principle of thermal expansion, which allows them to protect against overloads and excessive heat.

Thermal circuit breakers are generally composed of a bimetallic strip and a contact mechanism. The bimetallic strip consists of two metal layers with different coefficients of thermal expansion bonded together. When the current passing through the circuit breaker exceeds the rated value or when there is a significant increase in temperature due to a fault, the bimetallic strip heats up and bends, causing the contacts to open and interrupt the flow of current.

One of the key advantages of thermal circuit breakers is their simplicity and reliability. They work on a mechanical basis and do not require any external power source or complex electronics to operate. This makes them cost-effective and suitable for a wide range of applications. Additionally, thermal circuit breakers have a relatively slow response time, which allows them to withstand short-duration overloads and prevent false tripping.

However, there are some limitations to consider when using thermal circuit breakers. Their response time may not be fast enough to protect sensitive components or equipment that require instantaneous protection against short circuits. Additionally, thermal circuit breakers may not be suitable for applications where precise current control or selective tripping is required.

Thermal circuit breakers are commonly found in electrical panels, distribution boards, and appliances such as refrigerators, ovens, and air conditioners. They provide a reliable level of protection against excessive currents and overloads, helping prevent damage to electrical systems and ensuring the safety of individuals and property.

When selecting a thermal circuit breaker, it is important to consider factors such as the rated current, ambient temperature, and the specific requirements of the electrical system or equipment. It is also crucial to follow the manufacturer’s guidelines and ensure proper installation and maintenance to ensure the breaker operates effectively.

Magnetic Circuit Breakers

Magnetic circuit breakers, also known as magnetic trip circuit breakers, are widely used in industrial and commercial applications where higher currents are involved. These circuit breakers operate based on the principle of electromagnetism and provide effective protection against short circuits and excessive currents.

The main components of a magnetic circuit breaker include an electromagnet, a toggle mechanism, and a set of contacts. When current flows through the circuit breaker, the electromagnet produces a magnetic field proportional to the current. If there is a fault or an overload condition, the magnetic field strength exceeds a threshold value, causing the toggle mechanism to trip and open the contacts, thus interrupting the circuit.

One of the primary advantages of magnetic circuit breakers is their fast response time. They can trip within milliseconds, providing quick and reliable protection against short circuits that can cause severe damage to electrical systems and equipment. Magnetic circuit breakers are also capable of handling higher current levels, making them suitable for industrial applications.

Another benefit of magnetic circuit breakers is their ability to provide selective coordination. Selective coordination ensures that only the circuit breaker closest to the fault trips, while upstream breakers remain unaffected. This feature helps minimize downtime and allows for better fault isolation and troubleshooting.

However, there are some considerations to keep in mind when using magnetic circuit breakers. They are not as suitable for applications that require precise current control or protection against low-level faults. Additionally, magnetic circuit breakers may have a higher cost compared to other types, particularly at high current ratings.

Magnetic circuit breakers are commonly used in industries such as manufacturing, power generation, and heavy machinery. They provide reliable and instantaneous protection against short circuits and excessive currents, helping to prevent equipment damage and ensure the safety of personnel.

When selecting a magnetic circuit breaker, it is important to consider factors such as the rated current, voltage level, and specific application requirements. Proper coordination and sizing of the circuit breakers are crucial to ensure effective protection and optimize the overall electrical system’s performance.

Hybrid Circuit Breakers

Hybrid circuit breakers, also known as combination or dual-function circuit breakers, are a type of circuit protection device that combines the functionalities of both thermal and magnetic circuit breakers. These breakers are designed to provide effective protection against both high currents and overloads, making them versatile and suitable for a wide range of applications.

The hybrid circuit breakers incorporate both thermal and magnetic trip mechanisms into a single unit. The thermal component provides protection against overloads by detecting excessive heat, similar to a thermal circuit breaker. The magnetic component, on the other hand, responds to short circuits and excessive currents, similar to a magnetic circuit breaker. This combination enables hybrid circuit breakers to respond swiftly and accurately to various fault conditions.

One of the key advantages of hybrid circuit breakers is their ability to provide a higher degree of protection and reliability compared to individual thermal or magnetic circuit breakers alone. They can quickly respond to both overloads and short circuits, ensuring optimal safety for electrical systems and equipment.

Another benefit of hybrid circuit breakers is their compact size and space-saving design. By combining multiple functionalities into a single unit, these breakers help save valuable space in electrical panels and distribution boards.

However, there are some limitations to consider when using hybrid circuit breakers. They may have a higher cost compared to individual circuit breakers due to their advanced design and combined functionality. Additionally, the selection and sizing of hybrid circuit breakers require careful consideration to ensure compatibility with the electrical system’s requirements.

Hybrid circuit breakers are commonly used in various applications, including residential, commercial, and industrial settings. They provide reliable and comprehensive protection against both overloads and short circuits, helping to prevent damage to electrical systems and ensuring the safety of individuals and property.

When selecting a hybrid circuit breaker, it is important to consider factors such as the rated current, voltage level, and specific application requirements. Consulting with a qualified electrician or engineer can help ensure the proper selection and installation of hybrid circuit breakers for optimal performance and safety.

Solid-State Circuit Breakers

Solid-state circuit breakers, also known as electronic circuit breakers, are a modern type of circuit protection device that utilize solid-state components instead of traditional mechanical parts. These circuit breakers offer advanced features and enhanced control capabilities compared to their conventional counterparts.

Unlike traditional circuit breakers that rely on mechanical mechanisms, solid-state circuit breakers use electronic components to monitor and control the flow of electric current. They are typically designed with microprocessors, sensors, and power electronics that allow for precise monitoring, protection, and control of electrical circuits.

One of the key advantages of solid-state circuit breakers is their fast response time and accuracy. They can detect and react to current abnormalities within microseconds, providing quick and reliable protection against short circuits and overcurrents. Additionally, solid-state circuit breakers can offer precise current control, allowing for more efficient and optimized use of electrical systems.

Another benefit of solid-state circuit breakers is their ability to provide advanced protection and diagnostic functionalities. They can monitor electrical parameters such as voltage, current, and power quality, and transmit this data for analysis or remote monitoring. Solid-state circuit breakers often come equipped with communication capabilities, allowing for integration with smart grid systems and advanced control automation.

However, there are some considerations to keep in mind when using solid-state circuit breakers. They may have higher upfront costs compared to traditional circuit breakers due to their advanced technology and additional functionalities. Reliability can also be a concern with solid-state devices, as they may be more susceptible to power surges or electronic component failures. Adequate protection measures, such as surge protection devices, should be implemented to ensure the longevity and reliability of solid-state circuit breakers.

Solid-state circuit breakers are commonly used in various applications, including renewable energy systems, electric vehicles, data centers, and industrial automation. They provide advanced protection, control, and monitoring capabilities, allowing for more efficient and reliable operation of electrical systems.

When selecting a solid-state circuit breaker, it is important to consider factors such as the rated current and voltage, protection features, communication capabilities, and specific application requirements. Consulting with a qualified electrician or engineer can help ensure the proper selection and installation of solid-state circuit breakers for optimal performance and protection.

Oil Circuit Breakers

Oil circuit breakers are a type of circuit protection device commonly used in high voltage applications, such as power transmission and distribution systems. These circuit breakers utilize oil as an arc extinguishing medium to interrupt the flow of electric current when a fault occurs.

The main components of an oil circuit breaker include a tank filled with insulating oil, a set of contacts, and an arc chamber. When a fault or overload condition is detected, the contacts open, creating a gap for the current to arc between. The insulating oil surrounding the arc chamber plays a crucial role in extinguishing the arc by absorbing the energy and facilitating rapid cooling.

One of the key advantages of oil circuit breakers is their ability to handle high voltage and current levels. The insulating properties of the oil allow for effective interruption of the arc, ensuring the safe and reliable operation of electrical systems in high voltage environments.

Oil circuit breakers also offer excellent insulation properties, enhancing the overall reliability and safety of electrical installations. The insulating oil helps prevent flashovers and ensures proper insulation between the live parts of the circuit breaker.

However, there are some limitations to consider when using oil circuit breakers. Maintenance requirements are higher compared to other types of circuit breakers, as the oil needs periodic testing and replacement to maintain its dielectric strength and extinguishing properties. There is also a risk of oil leakage, which can lead to environmental pollution and pose a safety hazard if not properly managed.

Due to their high voltage capabilities and robust design, oil circuit breakers are commonly used in power substations, industrial plants, and large electrical systems. They provide reliable protection against high short-circuit currents and help ensure the continuity of electrical supply.

When selecting an oil circuit breaker, it is important to consider factors such as the rated voltage, current capacity, insulation requirements, and maintenance procedures. Working with experienced professionals and following industry standards and guidelines will help ensure the safe and efficient operation of oil circuit breakers.

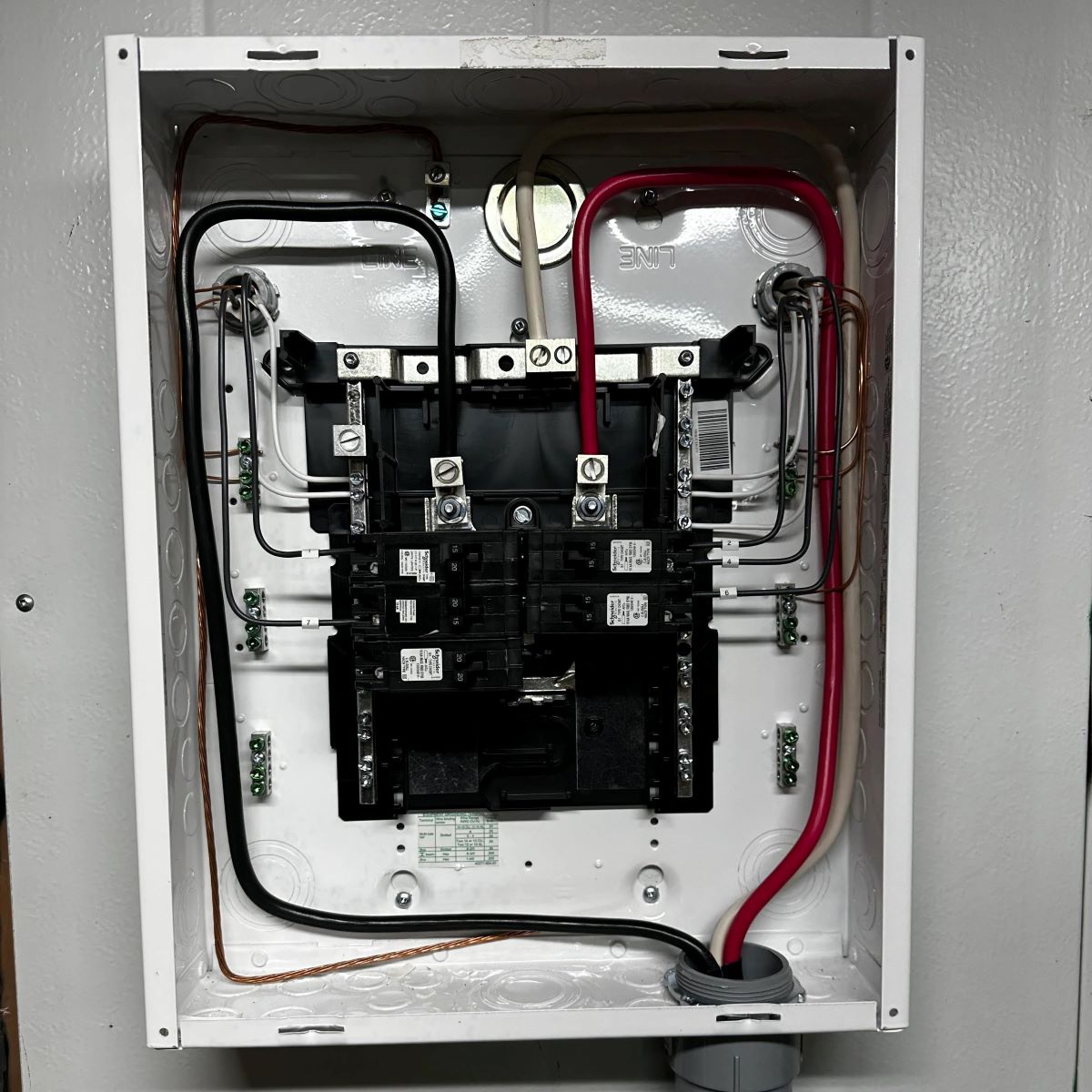

Air Circuit Breakers

Air circuit breakers, also known as ACBs, are widely used in low voltage applications for both commercial and industrial purposes. These circuit breakers rely on compressed air to quench the arc and interrupt the flow of electric current when a fault occurs.

The main components of an air circuit breaker include a set of contacts and an arc chute. When a fault is detected, the contacts open, creating a gap for the current to arc between. The arc chute is designed to rapidly redirect the arc into a series of arc runners or plates, allowing it to be extinguished by high-speed air flow.

One of the key advantages of air circuit breakers is their high breaking capacity. They are capable of interrupting high short-circuit currents, providing reliable protection for electrical systems against faults and overloads.

Air circuit breakers also offer a high level of selectivity, which means that only the breaker closest to the fault will trip, while other breakers upstream remain unaffected. This selective coordination helps minimize downtime, isolate faults, and streamline maintenance and troubleshooting activities.

Additionally, air circuit breakers are known for their long mechanical life and durability. They can withstand frequent operations, making them suitable for applications that require frequent switching, such as motor control centers and distribution boards.

However, there are some considerations to keep in mind when using air circuit breakers. They require a larger physical space due to the need for compressed air systems, which may limit their usage in compact or space-constrained environments. Proper maintenance and periodic inspections of the air compression system are essential to ensure the efficient operation of air circuit breakers.

Air circuit breakers find applications in various industries, including manufacturing plants, commercial buildings, and large-scale infrastructure projects. They provide reliable and efficient protection against electrical faults and contribute to the overall safety and stability of electrical systems.

When selecting an air circuit breaker, it is important to consider factors such as the rated current, breaking capacity, voltage level, and specific application requirements. Adhering to industry standards and guidelines, as well as working with knowledgeable professionals, will help ensure the proper selection, installation, and maintenance of air circuit breakers.

There are three main types of circuit breakers: thermal, magnetic, and thermal-magnetic. Each type has its own unique characteristics and is designed for specific applications.

Vacuum Circuit Breakers

Vacuum circuit breakers are high-performance circuit protection devices commonly used in medium to high voltage applications. These circuit breakers utilize a vacuum as the arc-quenching medium, providing efficient and reliable interruption of the electric current when a fault occurs.

The main components of a vacuum circuit breaker include a vacuum interrupter, a set of contacts, and a sealing mechanism. When a fault is detected, the contacts open, creating a gap for the current to arc between. The vacuum interrupter is designed with special metal contacts that create a vacuum environment, which prevents the arc from reigniting and allows for quick and reliable extinguishing of the arc.

One of the key advantages of vacuum circuit breakers is their high breaking capacity, making them suitable for medium to high voltage applications. They are capable of interrupting both high fault currents and capacitive or inductive loads, providing reliable and efficient protection for electrical systems.

Vacuum circuit breakers also offer excellent insulation properties. The vacuum environment within the interrupter provides optimal dielectric strength and insulation, reducing the risk of flashovers and ensuring safe operation in high voltage environments.

Furthermore, vacuum circuit breakers have a compact design and are generally maintenance-free. They do not require regular refilling of insulating materials like oil or gas circuit breakers, resulting in lower maintenance costs and minimal downtime for servicing.

However, there are some limitations to consider when using vacuum circuit breakers. They may have higher initial costs compared to other types of circuit breakers due to the intricate design and specialized manufacturing processes involved. Additionally, vacuum circuit breakers may have limitations in interrupting very high short-circuit currents.

Vacuum circuit breakers find applications in various industries, including power generation, transmission and distribution systems, and industrial plants. They provide reliable and efficient protection against electrical faults, contributing to the overall safety and reliability of electrical networks.

When selecting a vacuum circuit breaker, it is important to consider factors such as the rated voltage, breaking capacity, specific application requirements, and adherence to relevant standards and guidelines. Working with experienced professionals and manufacturers will ensure the proper selection, installation, and maintenance of vacuum circuit breakers for optimal performance and protection.

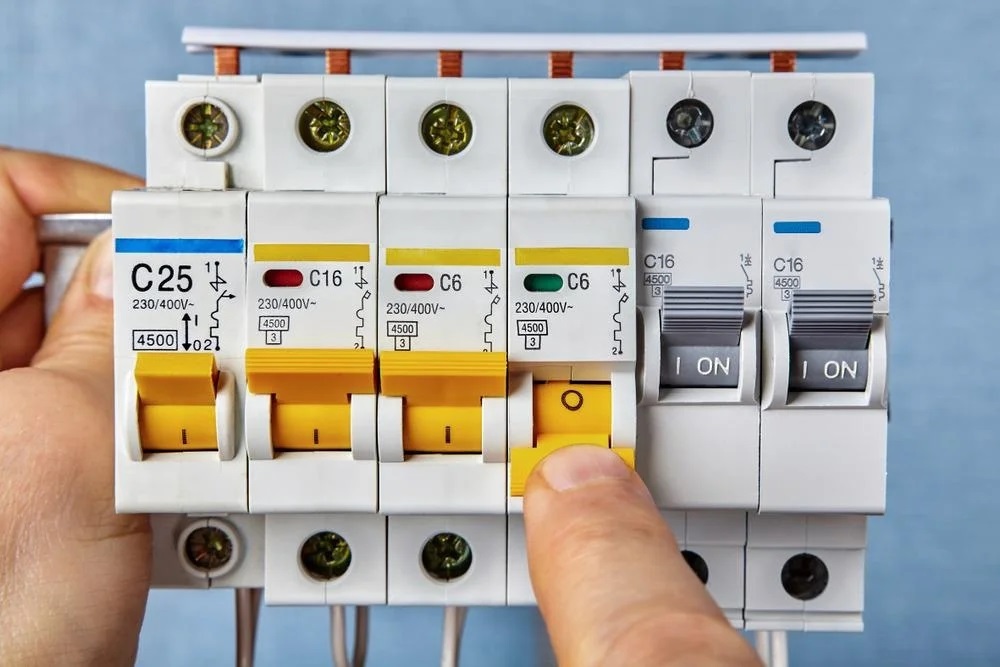

SF6 Circuit Breakers

SF6 circuit breakers are a type of circuit protection device commonly used in high voltage applications, such as power transmission and distribution systems. These circuit breakers utilize sulfur hexafluoride gas (SF6) as the arc-quenching medium, enabling efficient interruption of the electric current during fault conditions.

The main components of an SF6 circuit breaker include a gas-filled chamber, a set of contacts, and an arc quenching system. When a fault is detected, the contacts open, creating a gap for the current to arc between. The SF6 gas, with its excellent arc extinguishing properties, quickly absorbs the energy and extinguishes the arc, allowing for the interruption of the current flow.

One of the key advantages of SF6 circuit breakers is their high dielectric strength. SF6 gas has excellent insulating properties, allowing for compact and efficient designs of circuit breakers. The high dielectric strength of SF6 contributes to the reduction in size and weight of the circuit breaker, making it suitable for applications where space is limited.

SF6 circuit breakers also offer a high breaking capacity, enabling them to interrupt high short-circuit currents and provide reliable protection for electrical systems. They are known for their quick response time and efficient arc quenching abilities, minimizing the duration of faults and ensuring the safety and stability of electrical networks.

However, there are some considerations to bear in mind when using SF6 circuit breakers. SF6 gas is a potent greenhouse gas with a significant global warming potential, and its release into the atmosphere has environmental implications. Proper handling and disposal of SF6 gas are essential to mitigate these environmental impacts. Also, because of the gas’s high dielectric strength, SF6 circuit breakers require specialized equipment and expertise for installation, maintenance, and repairs, adding to the complexity and costs.

SF6 circuit breakers are commonly used in power substations, industrial plants, and high-voltage applications where reliable performance and compact design are crucial. They provide efficient interruption of fault currents, preventing damage to equipment and ensuring the reliability of electrical systems.

When selecting an SF6 circuit breaker, it is important to consider factors such as the rated voltage, breaking capacity, gas handling requirements, and adherence to regulations regarding SF6 gas handling. Consulting with knowledgeable professionals and following industry standards and guidelines will help ensure the safe and efficient use of SF6 circuit breakers.

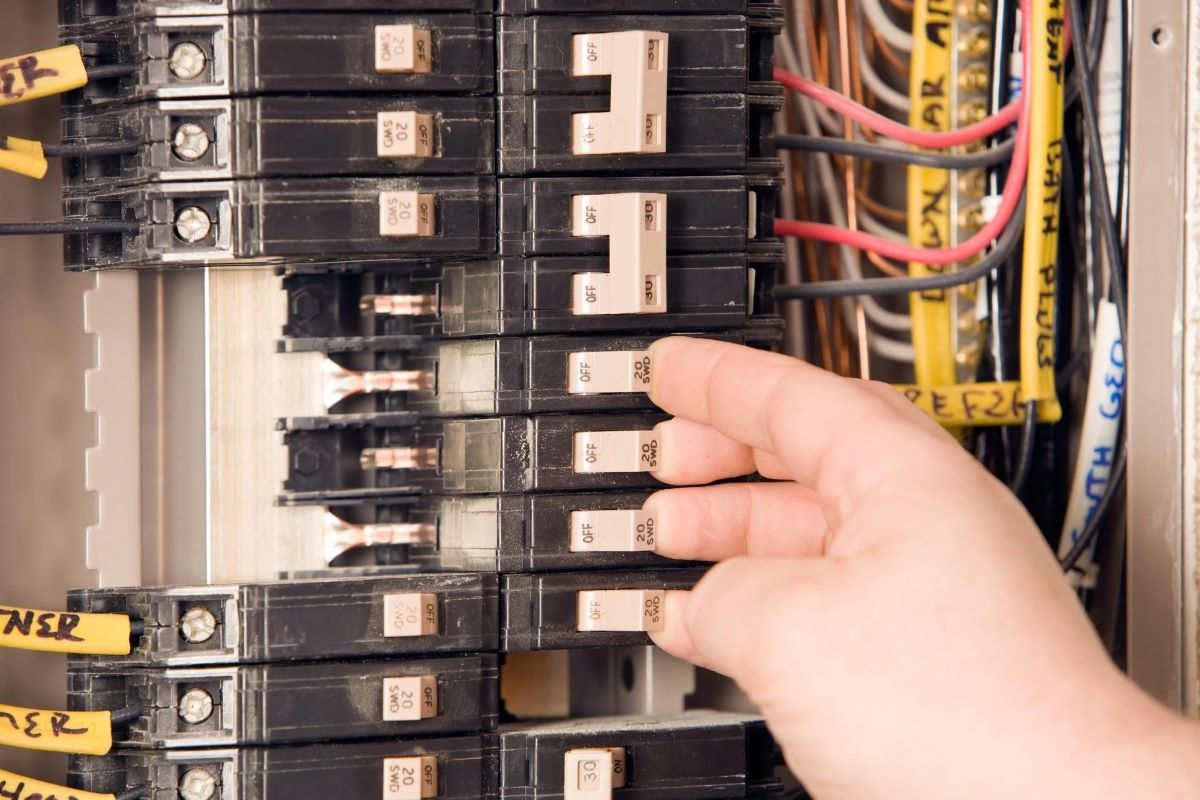

Miniature Circuit Breakers

Miniature Circuit Breakers (MCBs) are commonly used in residential, commercial, and industrial electrical installations. As the name suggests, these circuit breakers are compact in size and provide reliable protection against overcurrents and short circuits.

The main components of an MCB include a bimetallic strip, a trip mechanism, and a set of contacts. When the current flowing through the MCB exceeds the rated value or there is a short circuit, the bimetallic strip heats up and bends, causing the trip mechanism to trip the breaker, opening the contacts and interrupting the current flow.

One of the key advantages of MCBs is their simplicity and cost-effectiveness. They are easy to install and provide convenient and reliable protection for electrical systems. MCBs are available in various current ratings and trip characteristics, allowing for customization based on specific application requirements.

MCBs also offer a fast response time, providing quick protection against overcurrents and short circuits. Their ability to quickly detect and interrupt faults helps prevent damage to electrical equipment and ensures the safety of individuals and property.

Another benefit of MCBs is their ability to be reset manually after tripping. Once the fault condition is rectified, the MCB can be easily reset by moving the operating lever back to its original position, restoring the circuit’s functionality.

However, it is important to note that MCBs do not provide protection against residual currents or ground faults. For applications where additional protection is necessary, devices such as Ground Fault Circuit Interrupters (GFCIs) or Residual Current Circuit Breakers (RCCBs) should be used in conjunction with MCBs.

MCBs find widespread use in residential homes, offices, commercial buildings, and low voltage industrial applications. They are commonly found in consumer units, distribution boards, and electrical panels.

When selecting an MCB, it is important to consider factors such as the rated current, breaking capacity, and specific application requirements. Adhering to relevant electrical standards and regulations will ensure the proper selection, installation, and use of MCBs in electrical systems.

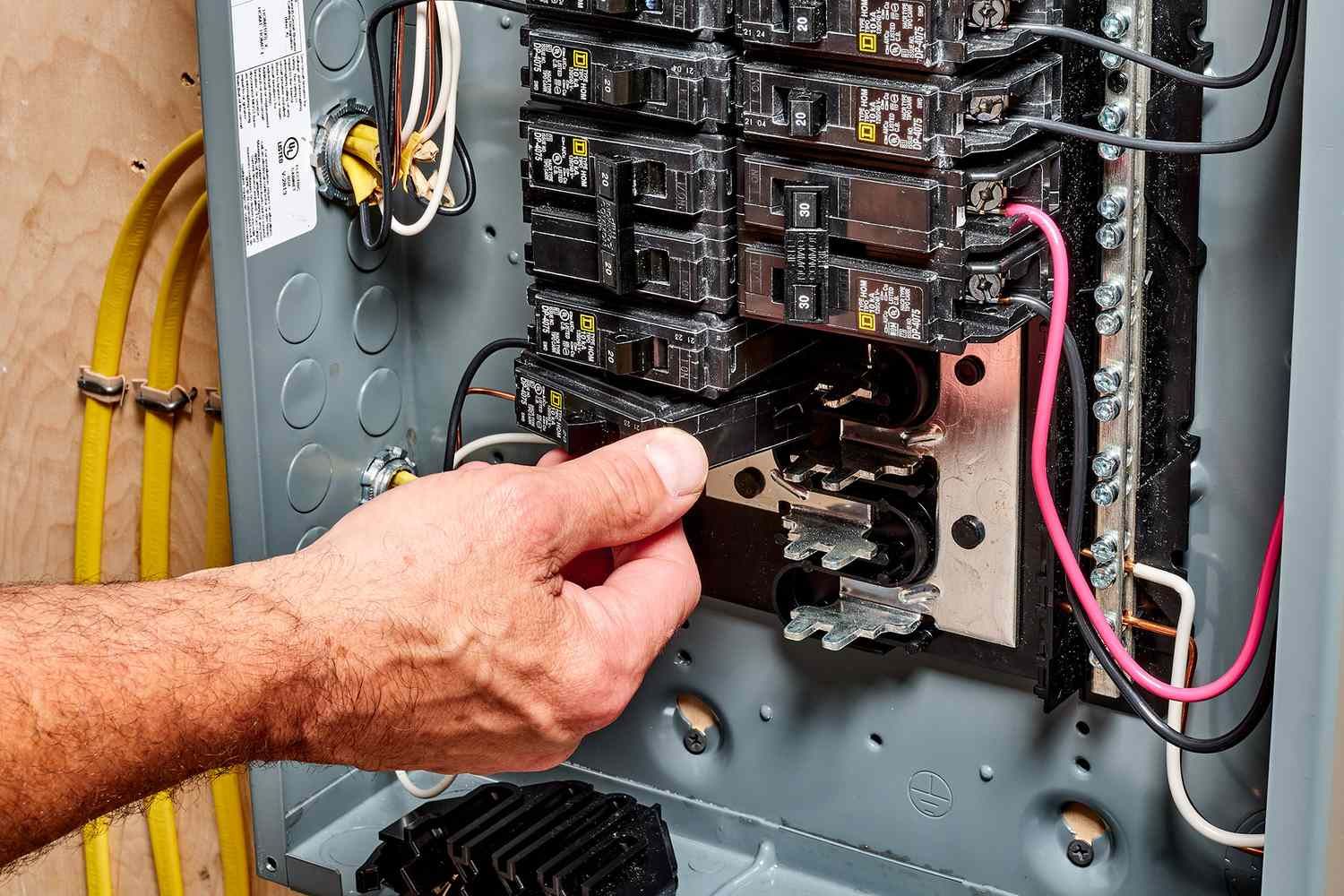

Molded Case Circuit Breakers

Molded Case Circuit Breakers (MCCBs) are widely used in commercial and industrial applications where higher current capacities are required. These circuit breakers are designed with a molded case enclosure, providing durability, protection, and ease of installation.

The main components of an MCCB include a trip unit, a set of contacts, and a molded plastic or insulating material case. The trip unit is responsible for sensing overcurrents and short circuits and tripping the breaker when necessary. The contacts open, interrupting the fault current, and protecting the electrical system.

One of the key advantages of MCCBs is their high breaking capacity. They are capable of handling higher current levels compared to miniature circuit breakers (MCBs) and provide reliable protection against overcurrents and short circuits in commercial and industrial environments.

MCCBs also offer a wide range of current ratings and trip characteristics, allowing for customization and flexibility based on specific application requirements. This adaptability makes them suitable for a variety of electrical systems with different load capacities.

Another benefit of MCCBs is their robust construction. The molded case enclosure provides protection against environmental factors such as dust, debris, and moisture, enhancing the reliability and durability of the circuit breaker. The enclosure also helps prevent accidental contact with live parts, ensuring the safety of individuals and reducing the risk of electrical hazards.

MCCBs are typically equipped with features such as thermal and magnetic trip mechanisms, adjustable trip settings, and trip indication. These features allow for enhanced protection and monitoring of the electrical system, facilitating maintenance and troubleshooting activities.

However, it is important to note that MCCBs are not designed for frequent switching operations and may have a slower response time compared to MCBs. For applications requiring frequent operations or precise control, specialized circuit breakers such as air circuit breakers or solid-state circuit breakers may be more suitable.

MCCBs are commonly used in commercial buildings, industrial plants, and large-scale infrastructure projects where higher current levels and reliable performance are required. They are typically found in distribution boards, switchgear panels, and motor control centers.

When selecting an MCCB, it is important to consider factors such as the rated current, breaking capacity, trip characteristics, and compatibility with the electrical system. Consulting with qualified professionals and following industry standards will ensure the proper selection, installation, and maintenance of MCCBs.

Ground Fault Circuit Interrupters (GFCIs)

Ground Fault Circuit Interrupters (GFCIs) are specialized circuit breakers designed to protect against electric shocks and ground faults. They play a crucial role in enhancing electrical safety, particularly in areas where water and electricity may come into contact, such as bathrooms, kitchens, and outdoor sockets.

The primary function of a GFCI is to monitor the imbalance of current between the hot and neutral conductors. When a ground fault occurs, such as a leakage of current to the ground, the GFCI quickly detects the imbalance and interrupts the circuit, preventing electric shocks and potential hazards.

GFCIs are typically installed in electrical outlets or circuit breaker panels and provide protection to multiple outlets downstream from their location. In the event of a ground fault, the GFCI trips in a fraction of a second, protecting individuals from hazardous electrical currents.

One of the key features of GFCIs is their high level of sensitivity. GFCIs are designed to detect very small current imbalances, typically in the range of 4 to 6 milliamperes. This level of sensitivity helps ensure that even minor ground faults are detected and quickly addressed before they escalate into more dangerous situations.

Another advantage of GFCIs is their ability to be manually tested and reset. GFCI outlets or circuit breakers are equipped with a test and reset button, allowing users to periodically check if the device is functioning properly. This testing procedure helps ensure the continued effectiveness of the GFCI in protecting against ground faults.

GFCIs are essential in meeting electrical safety codes and regulations in many countries. They are particularly important in areas where electrical equipment or appliances are in close proximity to water sources, significantly reducing the risk of electric shock and potential electrical fires.

When selecting a GFCI, it is crucial to ensure that it is suited for the specific application and meets the necessary safety certifications and standards. Regular testing and maintenance of GFCIs are essential to ensure optimal performance and protection against electrical hazards.

Overall, GFCIs play a critical role in electrical safety by providing effective protection against ground faults and electrical shocks. By detecting and interrupting dangerous fault conditions, GFCIs significantly reduce the risk of electrical injuries and enhance the safety of electrical systems and individuals.

Read more: How Many Breakers In 100 Amp Panel

Arc Fault Circuit Interrupters (AFCIs)

Arc Fault Circuit Interrupters (AFCIs) are specialized circuit breakers designed to detect and mitigate the risk of electrical arcs, which can potentially cause electrical fires. AFCIs play a crucial role in improving electrical safety, particularly in residential and commercial buildings where outdated or faulty wiring may lead to arc faults.

The primary function of an AFCI is to monitor the electrical currents in a circuit and identify characteristic patterns associated with arcing faults. Arcing faults occur when there is a breakdown in the insulation or an abnormal connection in the electrical system, resulting in an arc of electricity. These arcs can generate heat and sparks, which may ignite nearby combustible materials.

AFCIs are designed to quickly detect the unique signatures of arcing faults and interrupt the circuit to prevent fires. They have advanced circuitry that can differentiate between normal electrical loads and potentially dangerous arcing conditions. When an arc fault is detected, the AFCI interrupts the circuit, thereby reducing the risk of fire hazards.

One of the key advantages of AFCIs is their ability to provide advanced fire protection by addressing arcing faults specifically. By responding to these potentially hazardous conditions, AFCIs significantly reduce the likelihood of electrical fires and help minimize property damage and personal injury.

AFCIs are typically installed in electrical panel boxes, replacing standard circuit breakers for specific circuits or as a combination AFCI breaker that protects an entire branch circuit. They are commonly required in bedrooms, living rooms, and other areas where occupants may sleep or spend significant amounts of time.

When selecting an AFCI, it is essential to ensure compliance with local code requirements and safety standards. Regular testing and maintenance of AFCIs are also necessary to ensure their proper functioning and continued protection against arc faults.

Overall, AFCIs are critical components in electrical safety, providing targeted protection against arc faults that may lead to electrical fires. By detecting and interrupting these hazardous conditions, AFCIs minimize the risk of fire-related incidents, enhancing the safety and security of residential and commercial electrical systems.

Residual Current Circuit Breakers (RCCBs)

Residual Current Circuit Breakers (RCCBs), also known as Residual Current Devices (RCDs), are specialized circuit breakers designed to protect against electrical leakage and the risk of electric shock. They play a crucial role in enhancing electrical safety, particularly in areas where water and electrical equipment come into contact, such as bathrooms, kitchens, and outdoor installations.

The primary function of an RCCB is to monitor the flow of electrical currents between the live and neutral conductors. It detects any imbalance or leakage of current, known as a residual current, and quickly interrupts the circuit, preventing electric shocks and potential hazards.

Unlike conventional circuit breakers that primarily protect against overcurrents and short circuits, RCCBs are specifically designed to detect small current leaks that may occur due to faulty insulation or direct contact with conductive materials. These leaks are often indicative of dangerous ground faults or accidental human contact with live parts.

RCCBs are typically installed in electrical distribution boards, switchgear panels, or socket outlets. They provide residual current protection not only to the specific circuit they are connected to but also to all downstream circuits connected to the same RCCB, ensuring comprehensive protection throughout the electrical installation.

One of the key advantages of RCCBs is their high level of sensitivity. They are designed to detect very small residual currents, typically in the range of 10 to 30 milliamperes. This level of sensitivity helps ensure the quick detection and interruption of potentially hazardous leakage currents.

RCCBs are available in different types, including AC, A, and B, each offering varying levels of sensitivity and leakage protection. AC type RCCBs are commonly used in residential and general-purpose applications, while A and B types are often utilized in more specialized or sensitive environments, such as medical facilities and industrial settings.

Regular testing and maintenance of RCCBs are crucial to ensure their proper functioning and continued protection against residual currents. It is important to follow the manufacturer’s guidelines and periodic testing recommendations to ensure optimal performance and reliability.

Overall, RCCBs are essential components in electrical safety, providing effective protection against ground faults and minimizing the risk of electric shock. By detecting and interrupting leakage currents, RCCBs significantly enhance the safety of individuals, electrical systems, and property.

Conclusion

Circuit breakers are indispensable components in electrical systems, providing protection against overcurrents, short circuits, and electrical faults. Understanding the different types of circuit breakers available is crucial for selecting the most appropriate option for specific applications and ensuring the safety and reliability of electrical installations.

In this article, we explored a wide range of circuit breakers, including thermal circuit breakers, magnetic circuit breakers, hybrid circuit breakers, solid-state circuit breakers, oil circuit breakers, air circuit breakers, vacuum circuit breakers, SF6 circuit breakers, miniature circuit breakers, molded case circuit breakers, ground fault circuit interrupters (GFCIs), arc fault circuit interrupters (AFCIs), and residual current circuit breakers (RCCBs).

Each type of circuit breaker has its own unique features, advantages, and limitations. Thermal circuit breakers are commonly used in residential and commercial settings, while magnetic circuit breakers provide protection against higher currents in industrial applications. Hybrid circuit breakers combine the functionalities of thermal and magnetic breakers, offering comprehensive protection.

Solid-state circuit breakers utilize advanced electronics for precise current control, while oil circuit breakers and air circuit breakers use oil or compressed air as arc-quenching mediums. Vacuum circuit breakers and SF6 circuit breakers offer high breaking capacities for medium to high voltage applications.

Miniature circuit breakers are commonly found in residential and commercial installations, while molded case circuit breakers are used in industrial settings. GFCIs and AFCIs provide additional protection against ground faults and arc faults, respectively. RCCBs are specifically designed to detect and interrupt residual currents that may lead to electrical shocks and injuries.

Overall, the selection of the appropriate circuit breaker depends on factors such as the application, voltage level, current capacity, and specific safety requirements. Consulting with qualified professionals and following industry standards and guidelines will help ensure the proper selection, installation, and maintenance of circuit breakers.

By understanding the various types of circuit breakers and their functionalities, individuals and professionals can make informed decisions that prioritize safety, efficiency, and reliability in electrical systems. The proper selection and use of circuit breakers contribute to the protection of electrical systems, prevention of accidents, and the overall safety of individuals and property.

Frequently Asked Questions about How Many Different Types Of Circuit Breakers Are There

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Many Different Types Of Circuit Breakers Are There”