Articles

How Circuit Breakers Work

Modified: January 19, 2024

Learn about circuit breakers in this informative article. Understand how they work and why they are crucial for electrical safety.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

A circuit breaker is an essential component of any electrical system, designed to protect against electrical overloads and faults. It acts as a safety device that automatically interrupts the flow of electricity when it detects abnormalities in current flow. By doing so, circuit breakers prevent damage to electrical equipment, minimize the risk of electrical fires, and ensure the safety of individuals.

Understanding how circuit breakers work is crucial for anyone involved in electrical installations or maintenance. In this article, we will delve into the basics of circuit breakers, explore their components, and discuss their operation. We will also examine the different types of circuit breakers, their ratings, and the common tripping mechanisms employed.

Furthermore, we will analyze the advantages and disadvantages of circuit breakers, as well as provide guidelines for their maintenance and safety precautions. By the end of this article, you will have a comprehensive understanding of circuit breakers and their role in electrical systems.

Whether you are an electrician, a homeowner, or simply someone interested in understanding the inner workings of electrical systems, this article will serve as a valuable resource.

Key Takeaways:

- Circuit breakers are essential for protecting electrical systems from overloads and faults, ensuring safety and preventing damage to equipment. Understanding their components, operation, and maintenance is crucial for creating a safe electrical environment.

- Regular maintenance and adherence to safety precautions are vital for optimizing the performance and longevity of circuit breakers, minimizing the risk of accidents, and ensuring a safe working environment for maintenance personnel.

Read more: How Do Tandem Breakers Work

Basics of Circuit Breakers

Before diving into the intricacies of circuit breakers, let’s first establish a basic understanding of what they are and why they are essential. At its core, a circuit breaker is a switching device that interrupts the flow of electrical current in a circuit. It acts as a protective mechanism, ensuring the safe operation of electrical systems by preventing overloads and short circuits.

The primary function of a circuit breaker is to detect and respond to abnormal voltage and current conditions. When the current flowing through a circuit exceeds the rated capacity of the conductor or equipment, or when a short circuit occurs, the circuit breaker automatically trips or opens the circuit to halt the flow of electricity. This action protects the electrical system from damage and potential hazards.

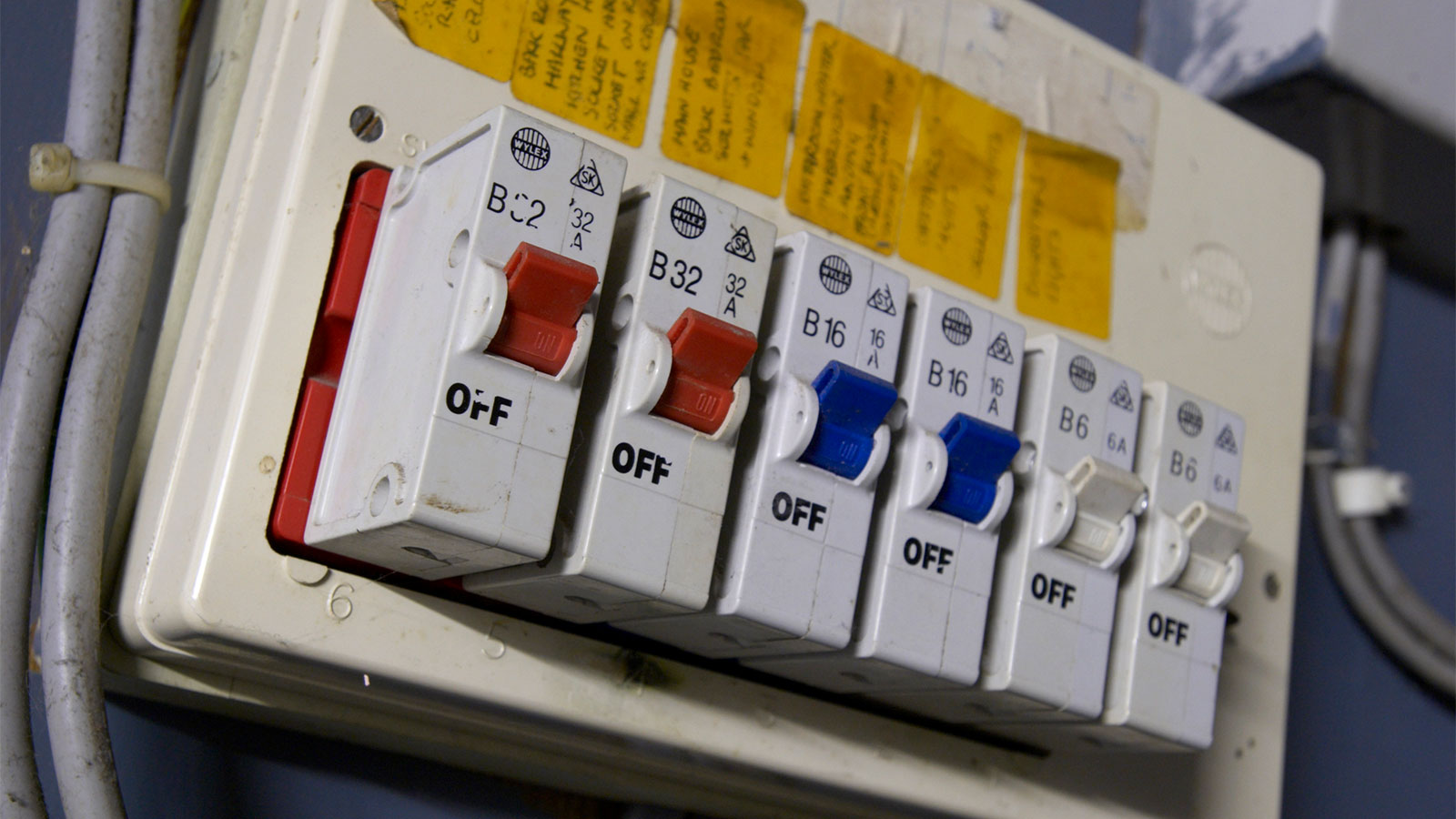

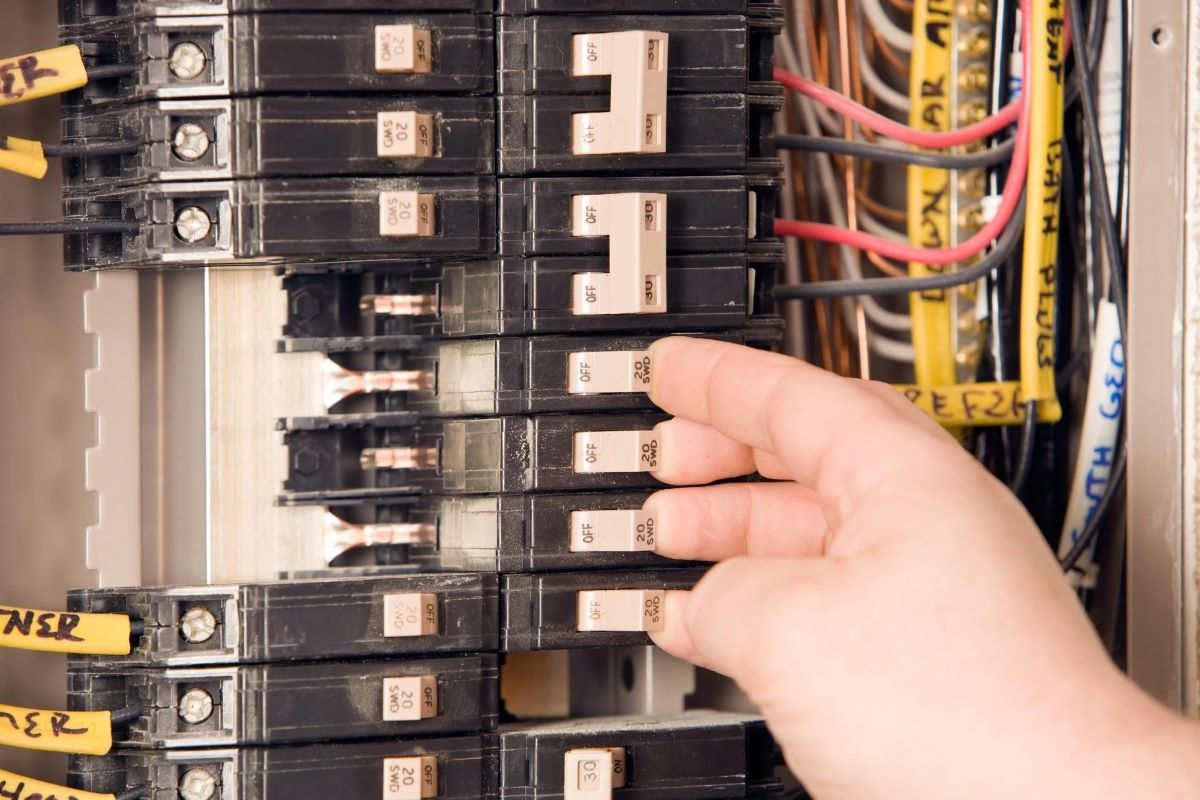

Circuit breakers are often installed in electrical distribution panels, where they are responsible for controlling the flow of electricity to various circuits throughout a building or facility. They are typically designed to handle different amperage ratings, depending on the specific application and the amount of current that needs to be supported.

One of the key benefits of circuit breakers is their ability to be reset after tripping. Unlike fuses, which require replacement after they have blown, circuit breakers can be easily reset by simply flipping the switch back into the “on” position once the fault or overload has been resolved. This makes circuit breakers a cost-effective alternative, as they eliminate the need for constantly replacing fuses.

Overall, circuit breakers are an integral part of electrical systems, providing protection against overloads and short circuits. Their ability to automatically interrupt the flow of electricity when necessary ensures the safety of both the electrical equipment and the individuals involved.

Components of a Circuit Breaker

A circuit breaker consists of several components working together to provide reliable protection against electrical faults. Understanding these components is essential for grasping the inner workings of a circuit breaker. Let’s take a closer look at the key components:

- Frame: The frame of a circuit breaker is the outer housing that encloses and supports all the internal components. It provides mechanical strength and ensures proper insulation.

- Contacts: The contacts are conductive plates that establish and break the electrical connection in a circuit. When the circuit breaker is closed, the contacts are in contact with each other, allowing current to flow. When the circuit breaker trips, the contacts are forcibly separated, interrupting the current flow.

- Operating Mechanism: The operating mechanism is responsible for manually or automatically tripping and closing the circuit breaker. It can be operated by a handle, lever, or motorized mechanism, depending on the type and size of the circuit breaker.

- Trip Unit: The trip unit is the brain of the circuit breaker. It consists of various sensors, relays, and electronic circuits that monitor the current flowing through the circuit and initiate the tripping mechanism when abnormal conditions are detected.

- Arc Quenching System: Arc quenching refers to the process of extinguishing the electrical arc that forms when the circuit breaker opens. The arc quenching system rapidly evacuates the ionized gas created by the arc, preventing it from sustaining and causing damage. Different types of circuit breakers employ various arc quenching methods, such as oil, air, vacuum, or sulfur hexafluoride (SF6).

- Operating Handle: The operating handle allows manual operation of the circuit breaker. It is used to manually trip or close the circuit breaker, providing control to the user.

- Indicator: The indicator provides visual indication of the status of the circuit breaker, such as whether it is in the “on” or “off” position.

All these components work in harmony to ensure the reliable and safe operation of the circuit breaker. Together, they detect abnormal electrical conditions, interrupt the current flow, and provide visual indications of the circuit breaker’s status.

Operation of a Circuit Breaker

The operation of a circuit breaker is a carefully controlled process that involves detecting abnormal electrical conditions and interrupting the flow of current to protect the electrical system. Let’s explore the step-by-step operation of a typical circuit breaker:

- Normal Operation: In normal operation, when the current flowing through a circuit is within the rated capacity of the circuit breaker, the contacts remain closed, allowing the current to flow uninterrupted. The circuit remains energized, and electrical devices connected to the circuit receive power.

- Fault Detection: When a fault occurs, such as an overload or a short circuit, the current flowing through the circuit exceeds the circuit breaker’s rated capacity. The trip unit, which monitors the current continuously, detects the abnormal condition and initiates the trip mechanism.

- Tripping Mechanism Activation: Once the fault is detected, the trip unit sends a signal to the tripping mechanism, activating it. The activation mechanism depends on the type of circuit breaker. For example, in a thermal-magnetic circuit breaker, the trip unit uses a bimetallic strip to release the latch, whereas in an electronic trip unit, it utilizes solid-state components.

- Contact Separation: Upon activation of the tripping mechanism, the contacts of the circuit breaker are forcibly separated. This action creates an air gap between the contacts, effectively interrupting the flow of current. The opening of the contacts generates an arc, which is quenched by the arc quenching system within the circuit breaker.

- Arc Extinction: The arc quenching system rapidly extinguishes the arc and prevents it from sustaining. Different circuit breaker technologies employ various methods to achieve this, such as cooling the arc with oil, redirecting it into a chamber filled with gas, or utilizing solid-state materials to interrupt the arc.

- Isolation: Once the arc is extinguished, and the current is interrupted, the circuit breaker isolates the faulty section of the circuit from the rest of the electrical system. This prevents the fault from spreading and causing further damage.

- Resetting: After the fault has been addressed and resolved, the circuit breaker can be reset. Manual circuit breakers can be reset by manually closing the contacts and re-energizing the circuit, while electronically controlled circuit breakers may require a reset command from the control system.

The operation of a circuit breaker is a swift and critical process that ensures the protection and integrity of the electrical system. By promptly detecting and interrupting faults, circuit breakers prevent equipment damage, minimize downtime, and ensure the safety of individuals working with or around electrical systems.

Types of Circuit Breakers

There are various types of circuit breakers available, each designed for specific applications and operating conditions. Let’s explore some of the most commonly used types:

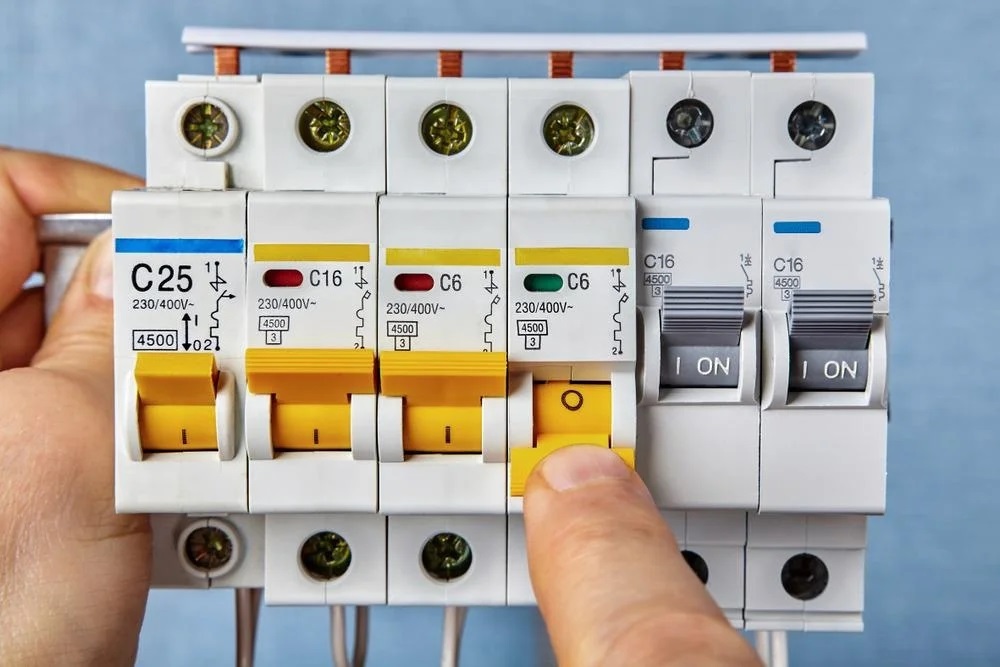

- Miniature Circuit Breakers (MCBs): MCBs are commonly found in residential and commercial electrical installations. They are compact in size and provide protection against overcurrents, short circuits, and ground faults. MCBs can be easily reset after tripping and are available in different current ratings.

- Molded Case Circuit Breakers (MCCBs): MCCBs are larger and more robust than MCBs. They are commonly used in industrial applications and provide protection against higher currents. MCCBs have adjustable trip settings, allowing for greater flexibility in customization.

- Ground Fault Circuit Interrupters (GFCIs): GFCIs are specifically designed to protect against ground faults, which occur when current flows from an energized conductor to the ground. GFCIs are commonly used in areas with a higher risk of electrical shock, such as bathrooms, kitchens, and outdoor environments.

- Residual Current Circuit Breakers (RCCBs): RCCBs, also known as residual current devices (RCDs), are similar to GFCIs and protect against ground faults. However, RCCBs can also detect imbalances in currents between the live and neutral conductors, providing protection against leakage currents and electrical fires.

- Arc Fault Circuit Interrupters (AFCIs): AFCIs are designed to detect and prevent electrical fires caused by arcing faults, which can occur due to damaged wiring or loose connections. AFCIs monitor the circuit for abnormal arcing and trip the circuit breaker to interrupt the flow of current if such arcs are detected.

- Vacuum Circuit Breakers: Vacuum circuit breakers utilize a vacuum to extinguish the electrical arc created when the circuit is interrupted. They are commonly used in medium-voltage applications and offer greater reliability and longer life compared to other types.

- SF6 Circuit Breakers: SF6 circuit breakers use sulfur hexafluoride gas to quench the arc when the contacts open. They are often used in high-voltage applications and provide excellent arc quenching properties.

These are just a few examples of the types of circuit breakers available. Each type has its own advantages and is suitable for specific applications, depending on factors such as voltage level, current capacity, and environmental conditions.

When selecting a circuit breaker, it is important to consider the specific requirements of the electrical system and consult with professionals to ensure the right type is chosen to provide optimal protection.

Read more: What Breakers Work With Murray Panel

Different Ratings of Circuit Breakers

Circuit breakers are available in various ratings to accommodate different electrical systems and applications. These ratings help ensure that the circuit breaker is capable of safely handling the expected current and voltage levels. Let’s explore some of the different ratings of circuit breakers:

- Current Rating: The current rating of a circuit breaker refers to the maximum continuous current that it can carry without tripping. This rating is typically expressed in amperes (A) and is based on the capacity of the conductors and equipment in the circuit. Common current ratings include 15A, 20A, 30A, and higher.

- Voltage Rating: The voltage rating of a circuit breaker specifies the maximum voltage that it can safely handle. This rating is vital to ensure that the circuit breaker can withstand the voltage levels present in the electrical system. Voltage ratings can range from low voltages, such as 120V, to high voltages, such as 600V or more.

- Short-Circuit Breaking Capacity (SCBC): The SCBC rating of a circuit breaker represents its ability to interrupt short-circuit currents without getting damaged. It indicates the maximum level of fault current that the circuit breaker can handle safely. Higher SCBC ratings are essential for electrical systems with larger fault currents.

- Interrupting Rating: The interrupting rating, also known as the breaking capacity, is similar to the SCBC rating. It represents the maximum current that a circuit breaker can interrupt without causing an arc flash or damaging its internal components. The interrupting rating is crucial for protecting the equipment and ensuring personnel safety.

- Time-Current Characteristic: The time-current characteristic of a circuit breaker specifies the trip curve, which depicts the response time of the circuit breaker for different levels of overcurrent. It indicates how quickly the circuit breaker will trip under varying current conditions, helping to match the protection to the characteristics of the connected equipment.

These ratings are essential considerations when selecting the appropriate circuit breaker for a specific application. It is crucial to ensure that the ratings of the circuit breaker align with the requirements of the electrical system to ensure reliable and safe operation.

It is important to note that circuit breakers are labeled with their specific ratings, providing valuable information for electricians, engineers, and users. By understanding and matching the ratings, one can ensure that the circuit breaker will perform effectively within its intended operating environment.

Common Circuit Breaker Tripping Mechanisms

Circuit breakers are designed with different tripping mechanisms to detect abnormal electrical conditions and interrupt the flow of current. These tripping mechanisms are crucial for protecting electrical systems and preventing damage. Let’s explore some of the common circuit breaker tripping mechanisms:

- Thermal Tripping Mechanism: This type of tripping mechanism utilizes a bimetallic strip that responds to the heat generated by the current flowing through the circuit. The bimetallic strip consists of two different metals with different coefficients of thermal expansion, causing it to bend when exposed to high temperatures. When the current exceeds the rated capacity, the bimetallic strip bends and releases the latch, tripping the circuit breaker.

- Magnetic Tripping Mechanism: The magnetic tripping mechanism relies on the electromagnetic effect of the current to operate. When a short circuit or a high-current overload occurs, the magnetic field generated around the conductor exceeds a certain threshold, causing an electromagnet within the circuit breaker to trip. This mechanism provides faster tripping times for high-current faults than thermal mechanisms.

- Electronic Tripping Mechanism: This modern tripping mechanism employs solid-state components, such as microprocessors and sensors, to monitor and analyze the current flowing through the circuit. It can provide advanced protection features and is programmable to cater to specific requirements. Electronic tripping mechanisms offer high precision and additional functionalities, such as adjustable tripping curves and communication capabilities.

- Ground Fault Sensing: Some circuit breakers are equipped with ground fault sensing mechanisms, often found in GFCIs and RCCBs. These mechanisms monitor the difference between the current flowing through the live and neutral conductors and trip the circuit breaker if an imbalance is detected. Ground fault sensing is crucial for protecting against electrical shock hazards.

- Arc Fault Detection: Arc fault detection mechanisms are incorporated into AFCIs to identify and respond to potentially dangerous arcing faults. These mechanisms use advanced algorithms and sensors to analyze the waveforms and characteristics of the current, allowing them to distinguish between normal and unwanted arcing conditions. If abnormal arcing is detected, the AFCI trips to prevent electrical fires.

These different tripping mechanisms work in conjunction with each other to ensure accurate and reliable operation of circuit breakers. Depending on the type and application of the circuit breaker, one or more of these mechanisms may be incorporated to provide the necessary protection.

Understanding the tripping mechanisms is crucial for selecting the appropriate circuit breaker for a specific application and ensuring the safety and reliability of the electrical system.

When a circuit becomes overloaded, a circuit breaker automatically cuts off the flow of electricity to prevent damage or fire. It can be reset once the issue is resolved.

Advantages and Disadvantages of Circuit Breakers

Circuit breakers offer numerous advantages over other protective devices, but they also have some limitations. Understanding the advantages and disadvantages of circuit breakers is crucial for evaluating their suitability for different applications. Let’s explore these pros and cons:

Advantages:

- Overcurrent Protection: Circuit breakers provide reliable protection against overcurrents, such as short circuits and overloads. They automatically trip when abnormal current conditions are detected, preventing damage to electrical equipment and reducing the risk of electrical fires.

- Resettable: Unlike fuses, which need to be replaced after they have blown, circuit breakers are resettable. After tripping, they can be easily reset by flipping the switch or button to restore power, saving time and money on replacement components.

- Multiple Tripping Mechanisms: Circuit breakers are available with different tripping mechanisms, allowing for customized protection based on specific requirements. Thermal, magnetic, and electronic tripping mechanisms offer versatility in detecting and responding to various electrical faults.

- Higher Interrupting Capacity: Circuit breakers typically have a higher interrupting capacity compared to fuses, allowing them to interrupt fault currents more effectively. This capability ensures that faults are promptly cleared, minimizing damage to the electrical system.

- Selective Coordination: Circuit breakers can be selectively coordinated, meaning they can be configured to selectively trip in the event of a fault, limiting the impact to a specific area or circuit. This selective coordination enhances the reliability and availability of power distribution systems.

Disadvantages:

- Higher Initial Cost: Circuit breakers typically have higher initial costs compared to fuses, especially for specialized or advanced models. This cost difference may be a consideration, especially in less critical or low-budget applications.

- Space Requirements: Circuit breakers occupy more space compared to fuses, particularly in higher current ratings. This factor should be taken into account when planning electrical panels or installations with limited space.

- Complex Design: Circuit breakers are sophisticated devices with complex designs, incorporating multiple components and mechanisms. This complexity can make troubleshooting and maintenance more challenging, requiring trained professionals for accurate diagnosis and repair.

- Limited Sensitivity: In some cases, circuit breakers may not be as sensitive as other protection devices, such as electronic fuses or relays, when it comes to detecting specific faults or abnormalities. Specialized applications requiring precise fault detection may require additional protective devices in conjunction with circuit breakers.

Overall, circuit breakers offer significant advantages in terms of overcurrent protection, resetability, and selectable tripping mechanisms. However, they may have higher costs, space requirements, and complex designs compared to alternative protective devices. Careful consideration of the specific application and its requirements is essential when deciding to utilize circuit breakers.

Circuit Breaker Maintenance and Safety Precautions

Maintaining circuit breakers is essential to ensure their proper functionality and to prevent any potential hazards. Regular maintenance and following safety precautions can help extend the lifespan of the circuit breakers and promote a safer electrical environment. Let’s explore some important maintenance practices and safety precautions:

Maintenance:

- Visual Inspection: Perform regular visual inspections of circuit breakers to check for any signs of damage, overheating, or loose connections. Look for issues such as corrosion, worn-out components, or pitting on contacts.

- Cleaning: Keep circuit breakers and their surroundings clean and free from dust, debris, or moisture. Use a soft brush or compressed air to remove any buildup that could impair their operation.

- Trip Test: Periodically test the tripping mechanism of the circuit breakers to ensure that they trip under normal conditions. Follow the manufacturer’s guidelines and use appropriate test equipment.

- Torque Checks: Verify that all connections, such as terminal screws and busbar connections, are properly tightened according to the manufacturer’s specifications. Loose connections can result in overheating or arcing, affecting the performance of the circuit breaker.

- Timing Tests: Perform timing tests to check the response time of the circuit breaker. This test helps ensure that the circuit breaker operates within the specified time frame, providing effective protection against faults.

- Function Checks: Test the functionality of auxiliary devices associated with the circuit breaker, such as shunt trips or undervoltage releases. These tests confirm that the additional safety features are working as intended.

Safety Precautions:

- De-Energize: Always de-energize and isolate the power supply before conducting any maintenance or inspection activities on the circuit breaker. This step helps prevent electrical shocks or injuries.

- Personal Protective Equipment (PPE): Wear appropriate PPE, such as gloves, safety glasses, and insulated tools, when working on or around live electrical equipment. This protective gear helps minimize the risk of electric shock or arc flash incidents.

- Follow Procedures: Adhere to the prescribed procedures and guidelines provided by the manufacturer or relevant regulatory authorities when working on circuit breakers. This ensures that maintenance activities are conducted correctly and safely.

- Training and Qualifications: Ensure that personnel involved in circuit breaker maintenance are properly trained and qualified to perform the tasks. They should have a clear understanding of the equipment, its potential hazards, and the necessary safety protocols.

- Proper Handling: Handle circuit breakers with care, avoiding excessive force or impact that could potentially damage the internal components. Follow the manufacturer’s instructions for installation, removal, and transportation.

- Documentation: Maintain a record of all maintenance activities, including inspections, tests, and repairs. This documentation helps track the maintenance history and provides valuable information for future diagnostics and troubleshooting.

By implementing regular maintenance practices and following proper safety precautions, circuit breakers can operate reliably and protect electrical systems effectively. These measures minimize the risk of accidents, ensure compliance with regulations, and promote a safe working environment for maintenance personnel.

Read more: How To Test Breakers

Conclusion

Circuit breakers play a vital role in protecting electrical systems from overloads, faults, and potential hazards. Understanding the basics, components, operation, types, ratings, and maintenance of circuit breakers is essential for anyone working with or around electrical installations. By grasping these concepts, individuals can make informed decisions, select the right circuit breaker for specific applications, and ensure the safety and reliability of electrical systems.

Throughout this article, we have explored the fundamentals of circuit breakers, including their role in interrupting the flow of current, the components that make up their structure, and the different mechanisms employed for tripping. We have discussed the advantages they offer, such as resetability, selective coordination, and higher interrupting capacities, as well as the disadvantages, including initial costs and complexity of design.

We have also examined the significance of circuit breaker maintenance, emphasizing visual inspections, cleaning procedures, testing, and checks to optimize their performance and extend their longevity. Additionally, safety precautions have been highlighted, emphasizing the importance of de-energizing, using appropriate personal protective equipment (PPE), following procedures, and obtaining proper training.

It is crucial to remember that circuit breakers are just one component in maintaining a safe and reliable electrical system. Regular maintenance, adherence to safety protocols, and compliance with regulations must be accompanied by a comprehensive electrical safety program that encompasses proper installation, regular inspections, and ongoing training.

By prioritizing the maintenance and safety of circuit breakers, individuals can protect equipment, prevent electrical fires, minimize downtime, and ensure the safety of individuals working with or around electrical systems.

In conclusion, circuit breakers are indispensable devices that provide critical protection in electrical systems. By understanding their functioning, components, types, maintenance requirements, and safety precautions, we empower ourselves to make informed decisions and create a safer electrical environment for all.

Frequently Asked Questions about How Circuit Breakers Work

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Circuit Breakers Work”