Articles

How Long Does It Take After Driveway Sealing

Modified: January 18, 2024

Discover how long it takes for your driveway to dry after sealing in this informative article. Find expert advice and tips to ensure a successful sealing process.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

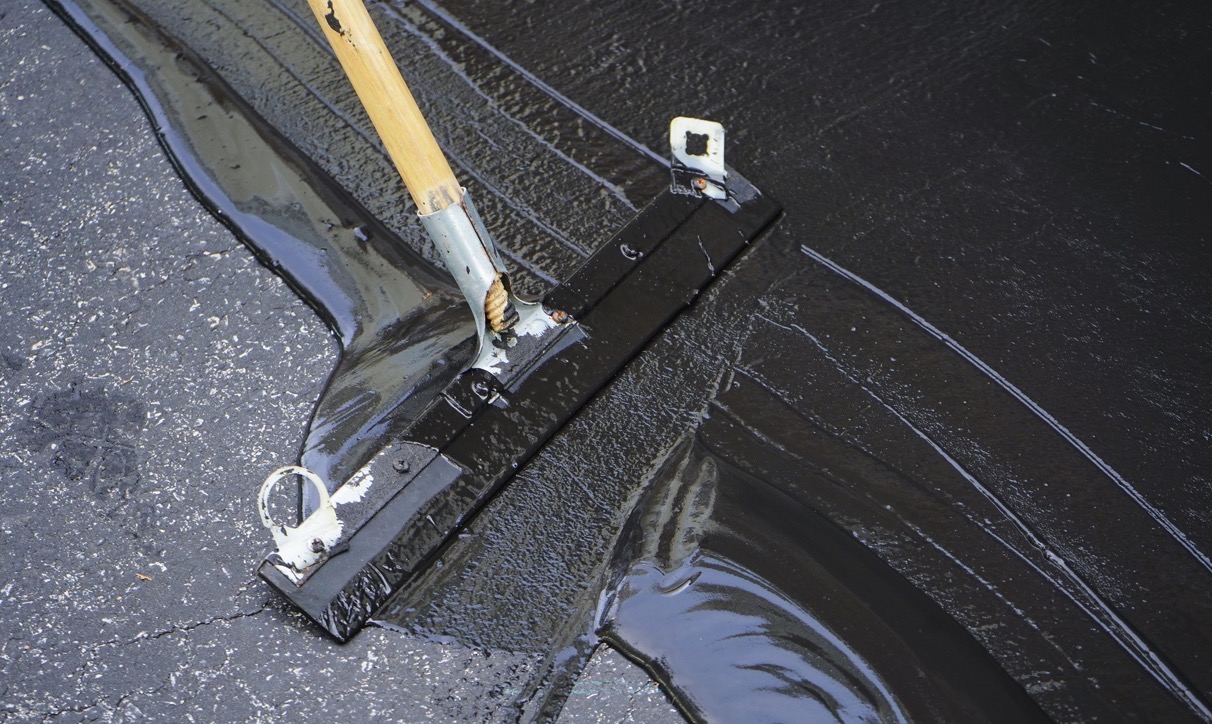

Driveway sealing is a vital maintenance step that helps protect your driveway from damage caused by weather elements and everyday wear and tear. After going through the process of sealing your driveway, it’s natural to wonder how long it will take for the sealant to dry and for you to be able to use your driveway again.

The drying time of driveway sealants can vary depending on several factors. Understanding these factors can give you a better idea of when you can expect your driveway to be ready for use.

Key Takeaways:

- Properly sealing your driveway is essential for protection. Consider factors like sealant type, weather, and curing time. Patience and maintenance are key for long-lasting results.

- Understand drying and curing times for driveway sealants. Protect the surface from foot and vehicle traffic until fully cured. Regular maintenance ensures lasting protection.

Read more: How Long Does It Take For A Driveway To Dry

Factors Affecting Drying Time

1. Type of Sealant Used: Different types of sealants have different drying times. Asphalt-based sealants, coal tar sealants, acrylic sealants, and silicone sealants all have their unique properties that affect the drying time.

2. Weather conditions: Weather plays a significant role in the drying process. If it’s a hot and sunny day with low humidity, the sealant will dry faster. In contrast, cool and humid weather can prolong the drying time.

3. Temperature and Humidity: Both temperature and humidity levels can significantly impact the drying time. Sealants typically dry slower in colder temperatures and high humidity.

4. Thickness of Sealer Applied: The thickness of the sealer layer can affect drying time. A thicker layer will take longer to dry compared to a thinner one.

5. Surface Porosity: The porosity of the driveway surface can impact drying time. If the surface is more porous, it may absorb the sealant more quickly, resulting in faster drying.

By considering these factors, you can get a general idea of how long it may take for the sealant to dry and when you can safely use your driveway again. However, it is important to note that exact drying times may vary based on specific product instructions and environmental conditions.

Type of Sealant Used

The type of sealant you choose for your driveway can have a significant impact on the drying time. Different sealants have different properties and compositions, which can affect how quickly they dry.

Here are some common types of sealants and their respective drying times:

- Asphalt-based Sealants: Asphalt-based sealants are popular for driveways due to their durability and ability to withstand harsh weather conditions. These sealants typically have a quicker drying time compared to other types. In optimal weather conditions, such as warm and sunny days, asphalt-based sealants may dry within 24 to 48 hours. However, factors like temperature, humidity, and thickness of the application can influence drying time.

- Coal Tar Sealants: Coal tar sealants are another common option for driveway sealing. These sealants provide excellent protection against UV rays and chemicals, making them a popular choice. Coal tar sealants generally have a longer drying time compared to asphalt-based sealants. It may take anywhere from 24 to 72 hours for coal tar sealants to dry completely.

- Acrylic Sealants: Acrylic sealants are known for their flexibility and ability to adhere well to different surfaces. They are water-based and have a relatively quick drying time. Depending on the weather conditions, acrylic sealants may dry within 12 to 24 hours or even sooner.

- Silicone Sealants: Silicone sealants are highly durable and resistant to extreme temperatures. They are often used for joint sealing and crack sealing. Silicone sealants can have varying drying times, with some products drying within a few hours and others taking up to 24 hours or more.

It’s important to read and follow the manufacturer’s instructions on the specific sealant you choose. They will provide guidance on the recommended drying time for the product, taking into account its unique formulation and characteristics.

Remember, these drying times are approximate and can be influenced by various factors such as weather conditions, surface porosity, and the thickness of the sealant applied. It’s always a good idea to allow ample time for the sealant to dry and cure before subjecting your driveway to heavy use or traffic.

Weather Conditions

Weather conditions play a crucial role in the drying time of driveway sealants. The temperature, humidity, and overall weather pattern can impact how quickly the sealant dries and cures.

Here’s how different weather conditions can affect the drying time:

- Temperature: The temperature can have a significant impact on drying time. In general, warmer temperatures promote faster drying. When the temperature is high, the solvents in the sealant evaporate more quickly, allowing it to dry faster. On the other hand, colder temperatures can slow down the drying process. If the temperature drops below the recommended range specified by the sealant manufacturer, it may take longer for the sealant to dry.

- Humidity: Humidity refers to the moisture content present in the air. High humidity levels can hinder the evaporation of solvents from the sealant, leading to a longer drying time. This is because the moisture in the air competes with the sealant’s solvents for evaporation. In humid conditions, it’s crucial to allow extra time for the sealant to dry properly.

- Sunlight: Sunlight can have both positive and negative effects on the drying time. On one hand, direct sunlight can accelerate the drying process by providing heat and promoting evaporation. This is especially true if the sunlight is accompanied by warm temperatures. However, excessive sunlight and heat can also cause the sealant to dry too quickly, potentially leading to cracking. It’s important to strike a balance and ensure that the sealant is drying evenly.

- Rain: Rain can have a detrimental effect on the drying process. If the sealant is still wet and rain comes in contact with it, it can wash away the solvents and disrupt the drying process. Therefore, it’s crucial to check the weather forecast and avoid sealing your driveway if rain is expected within the drying time window specified by the sealant manufacturer.

It’s essential to consider the prevailing weather conditions and plan your driveway sealing accordingly. Choose a time when the temperature is within the recommended range and the humidity levels are relatively low. Additionally, aim for a period when rain is not expected in the following days to ensure optimal drying conditions.

Remember to always follow the manufacturer’s instructions regarding weather conditions for the specific sealant you are using. These guidelines will help you achieve the best results and ensure the proper curing of the sealant.

Temperature and Humidity

The temperature and humidity levels are key factors in determining the drying time of driveway sealants. Both of these elements can significantly affect the evaporation and curing process of the sealant.

Here’s how temperature and humidity can impact the drying time:

- Temperature: Temperature plays a crucial role in the drying process. Warmer temperatures help accelerate the evaporation of the solvents in the sealant, leading to faster drying. In contrast, cooler temperatures can slow down the drying time. It’s essential to ensure that the temperature remains within the manufacturer’s recommended range for the specific sealant you are using. If the temperature falls outside of that range, the drying time may be significantly prolonged.

- Humidity: Humidity refers to the amount of moisture present in the air. High humidity levels can hinder the evaporation of solvents from the sealant, thereby extending the drying time. When the air is saturated with moisture, the solvents in the sealant have a harder time evaporating. This is why it’s generally ideal to seal your driveway on days when the humidity is relatively low. However, keep in mind that excessively low humidity can cause the sealant to dry too quickly, potentially leading to cracking. Striking a balance is key to ensuring proper drying without compromising the integrity of the sealant.

- Combining Temperature and Humidity: It’s important to consider the interplay between temperature and humidity. In high-temperature, high-humidity conditions, drying time can be significantly extended. The excess moisture in the air prevents the solvents from evaporating effectively, even if the temperature is relatively warm. On the other hand, low-temperature, low-humidity conditions can also prolong the drying time. If both temperature and humidity are low, the sealant will take longer to dry and cure properly.

When planning to seal your driveway, it’s vital to choose a time when the temperature is within the recommended range provided by the sealant manufacturer. It’s also beneficial to consider the humidity levels and aim for a day when the air is relatively dry. This will help promote optimal evaporation and drying of the sealant.

By paying attention to temperature and humidity, you can ensure that the sealant dries and cures properly, providing your driveway with the protection it needs.

Read more: How Long Does It Take To Pave A Driveway

Thickness of Sealer Applied

The thickness of the sealer layer applied to your driveway can affect the drying time. The amount of sealant used and the thickness of the application can vary depending on factors such as the condition of your driveway and personal preference. However, it’s important to consider that a thicker sealer layer will generally take longer to dry compared to a thinner layer.

Here’s how the thickness of the sealer applied can impact drying time:

- Evaporation: The drying process of driveway sealants involves the evaporation of solvents within the sealant. Thicker layers of sealant have more solvents to evaporate, which can extend the drying time. As the solvents evaporate, the sealant forms a protective barrier on the driveway. The thicker the layer, the longer it takes for the solvents to completely evaporate and for the sealant to dry.

- Curing Time: In addition to the drying time, thicker layers of sealant may also require longer curing times. Curing refers to the process by which the sealant fully hardens and reaches its maximum protective capabilities. While drying refers to the evaporation of solvents, curing involves the chemical reactions that occur within the sealant. Thicker layers of sealant take longer to cure compared to thinner layers, as the chemical reactions need more time to complete.

- Application Techniques: The way the sealant is applied can also impact its thickness. If the sealant is applied unevenly or in patches, some areas may have a thicker layer than others. In such cases, the areas with a thicker layer will take longer to dry compared to the thinner areas. It’s important to ensure a consistent and even application of the sealant to promote uniform drying.

When applying the sealant, it’s essential to follow the manufacturer’s instructions regarding the recommended thickness of the layer. Applying a thicker layer may provide added protection, but it will also increase the drying and curing time. Conversely, a thinner layer may dry faster but may provide less long-lasting protection.

Keep in mind that thicker layers of sealant may also be more prone to drying unevenly or developing cracks if not given adequate time to dry and cure. It’s important to allow ample time for the sealant to dry completely before subjecting your driveway to heavy foot or vehicle traffic.

By considering the thickness of the sealer applied and allowing sufficient drying and curing time, you can ensure that your driveway receives the necessary protection and extends its lifespan.

Surface Porosity

The porosity of the surface on which you’re applying the sealant can influence the drying time. Porosity refers to the degree or extent to which a material, such as concrete or asphalt, can absorb water or other substances.

Here’s how surface porosity can affect the drying time of driveway sealants:

- Absorption: A more porous surface will absorb the sealant more readily, allowing it to penetrate deeper into the material. This can result in faster drying times since the sealant is absorbed and dispersed throughout the surface. On the other hand, a less porous surface will have limited absorption capabilities, which can slow down the drying time as the sealant sits on the surface.

- Uniformity: Surface porosity also affects the uniformity of the drying process. If the surface has uneven porosity, certain areas may absorb the sealant more quickly while others may take longer to dry. This can lead to an uneven final result. It’s important to prepare the surface properly before applying the sealant, ensuring that it is clean and free from debris that may hinder absorption and drying.

- Sealing Efficiency: The porosity of the surface can also impact the overall effectiveness of the sealant. A more porous surface allows for better penetration and adhesion of the sealant, resulting in a more durable and long-lasting seal. Conversely, a less porous surface may require additional coats of sealant to achieve the desired level of protection. It’s important to follow the manufacturer’s instructions regarding the recommended number of coats for the specific sealant being used.

The drying time of sealants can be influenced by the surface porosity. However, it’s important to note that other factors, such as the type of sealant used and weather conditions, also play a significant role in drying time. It’s essential to consider all these factors in conjunction to get a better estimation of the drying time for your specific project.

Typical Drying Times for Different Sealants

While drying times can vary based on various factors, including weather conditions and surface porosity, here are some general guidelines for the typical drying times of different types of driveway sealants:

- Asphalt-based Sealants: Depending on the specific product and weather conditions, asphalt-based sealants typically dry within 24 to 48 hours.

- Coal Tar Sealants: Coal tar sealants generally have a longer drying time and may take anywhere from 24 to 72 hours to dry completely.

- Acrylic Sealants: Acrylic sealants have a relatively quick drying time and may dry within 12 to 24 hours or sooner, depending on the conditions.

- Silicone Sealants: The drying time for silicone sealants can vary, with some products drying within a few hours and others taking up to 24 hours or more.

It’s important to keep in mind that these are rough estimates, and exact drying times can vary based on specific product instructions, weather conditions, and surface porosity. It’s always advisable to read and follow the manufacturer’s instructions for the best results.

By considering the surface porosity and being aware of the typical drying times for different sealants, you can plan your driveway sealing project more effectively and ensure that you give the sealant sufficient time to dry and cure properly.

Asphalt-based Sealants

Asphalt-based sealants are a popular choice for sealing driveways due to their durability and ability to withstand harsh weather conditions. These sealants form a protective barrier on the surface of the asphalt, preventing damage from sunlight, water, and chemicals.

Here are some key points about asphalt-based sealants:

- Drying Time: The drying time of asphalt-based sealants can vary depending on several factors, such as weather conditions, temperature, humidity, and thickness of the application. In optimal weather conditions, such as warm and sunny days, asphalt-based sealants may dry within 24 to 48 hours. However, it’s important to note that drying times can be longer in cooler temperatures or high humidity.

- Application: Asphalt-based sealants are typically applied with a brush, roller, or sprayer. The surface needs to be clean and free from loose debris before application. It’s important to follow the manufacturer’s instructions regarding the recommended thickness of the sealant layer to ensure proper drying and curing.

- Benefits: Asphalt-based sealants offer several benefits for driveways. They provide an extra layer of protection against UV rays, preventing the asphalt from fading and deteriorating. They also create a water-resistant barrier, reducing the risk of cracks and potholes caused by freeze-thaw cycles. Additionally, asphalt-based sealants can enhance the overall appearance of the driveway, making it look freshly paved and well-maintained.

- Longevity: When applied correctly and maintained properly, asphalt-based sealants can last for several years. However, it’s important to periodically inspect the driveway and apply a new sealant layer as needed to ensure continued protection.

It’s crucial to read and follow the manufacturer’s instructions for the specific asphalt-based sealant you are using. They will provide guidance on the recommended drying time, application techniques, and any additional steps required for optimal results.

Remember that drying times can be influenced by various factors, such as weather conditions and the thickness of the sealant application. Plan your driveway sealing project accordingly, giving the sealant ample time to dry and cure before subjecting the surface to heavy foot or vehicle traffic.

By using asphalt-based sealants and properly maintaining your driveway, you can extend its lifespan, enhance its appearance, and protect it from the effects of weather and everyday use.

Coal Tar Sealants

Coal tar sealants are a common choice for driveway sealing due to their durability and ability to provide excellent protection against UV radiation, chemicals, and water damage. These sealants are composed of refined coal tar, additives, and fillers, creating a thick, glossy coating on the surface of the driveway.

Here are some important points to know about coal tar sealants:

- Drying Time: Coal tar sealants typically have a longer drying time compared to other types of sealants. The drying time can range from 24 to 72 hours, depending on various factors such as temperature, humidity, and the thickness of the applied layer. It’s crucial to allow sufficient time for the sealant to dry completely before using the driveway.

- Application: Coal tar sealants are usually applied using a brush, roller, or squeegee. It’s important to prepare the surface properly, ensuring it is clean and free from debris, to promote better adhesion and drying. The sealant should be applied uniformly and evenly to achieve the desired protection and appearance.

- Benefits: Coal tar sealants offer several advantages for driveway sealing. They provide excellent resistance to gas, oil, and other chemicals that can cause damage to the asphalt. The dark color of coal tar sealants also enhances the appearance of the driveway, giving it a fresh and revitalized look. Additionally, coal tar sealants have good weather resistance, protecting the driveway from environmental elements and extending its lifespan.

- Maintenance: To maintain the protective qualities of coal tar sealants, it’s important to periodically inspect the driveway for any signs of wear or damage. Small cracks or areas of deterioration should be repaired promptly to prevent further damage. Additionally, a new layer of coal tar sealant should be applied every few years to ensure ongoing protection.

It’s important to follow the manufacturer’s instructions when applying and maintaining coal tar sealants. They will provide specific guidelines on the recommended drying time, application techniques, and frequency of reapplication.

Keep in mind that drying times can be influenced by various factors, including weather conditions and the thickness of the sealant layer. It’s crucial to allow ample time for the coal tar sealant to dry and cure before subjecting the driveway to heavy traffic or harsh conditions.

By using coal tar sealants and properly maintaining your driveway, you can protect it from the damaging effects of chemicals, UV radiation, and water, ensuring its longevity and keeping it looking great for years to come.

Acrylic Sealants

Acrylic sealants are a popular choice for driveway sealing due to their versatility, ease of application, and quick drying time. These sealants are water-based and offer several benefits for protecting and enhancing the appearance of driveways.

Here are some important points to know about acrylic sealants:

- Drying Time: Acrylic sealants are known for their relatively quick drying time. Depending on the weather conditions and thickness of the applied layer, acrylic sealants can typically dry within 12 to 24 hours. In some cases, they may even dry sooner. However, it’s important to allow sufficient time for the sealant to cure completely before using the driveway.

- Application: Acrylic sealants are typically applied using a brush, roller, or sprayer. The surface should be clean and free from dirt and debris before application. One of the advantages of acrylic sealants is their ease of application, making them suitable for both DIY enthusiasts and professionals.

- Benefits: Acrylic sealants offer several benefits for driveway sealing. They provide excellent protection against UV rays, preventing the fading and deterioration of the asphalt. Acrylic sealants are also flexible, allowing them to expand and contract with temperature fluctuations without cracking. Additionally, they enhance the overall appearance of the driveway by providing a smooth, glossy finish that can make it look more aesthetically pleasing.

- Maintenance: Proper maintenance is important to ensure the longevity and effectiveness of acrylic sealants. Regular cleaning and periodic inspections for any signs of wear or damage are recommended. If small cracks or areas of deterioration are observed, repairing them promptly and applying a new layer of acrylic sealant will help prevent further damage and maintain the protective qualities of the driveway.

It’s essential to follow the manufacturer’s instructions when using acrylic sealants. They will provide specific recommendations regarding the drying time, application techniques, and additional steps required for optimal results.

Although acrylic sealants have a relatively quick drying time, it’s important to note that the drying time can be affected by factors such as temperature, humidity, and the thickness of the applied layer. It’s advisable to allow ample time for the sealant to dry and cure before subjecting the driveway to heavy traffic or other potential sources of damage.

By using acrylic sealants and implementing regular maintenance practices, you can protect your driveway from UV radiation, enhance its appearance, and ensure its longevity.

It typically takes 24-48 hours for driveway sealer to fully cure and dry. Avoid driving or walking on the sealed surface during this time to ensure the best results.

Silicone Sealants

Silicone sealants are renowned for their durability and ability to withstand extreme temperatures. They are commonly used for joint sealing and crack sealing in driveways and other construction projects. These sealants offer excellent adhesion and flexibility, making them ideal for areas that require movement and expansion.

Here are some key points to know about silicone sealants:

- Drying Time: The drying time of silicone sealants can vary depending on factors such as temperature, humidity, and the specific product being used. Some silicone sealants can dry in as little as a few hours, while others may take up to 24 hours or more. It’s crucial to follow the manufacturer’s instructions for the specific product to ensure proper drying and curing.

- Application: Silicone sealants are typically applied using a caulking gun or squeeze tube. It’s important to prepare the surface by cleaning it thoroughly and removing any loose debris or old sealant. Applying the silicone sealant in a smooth and consistent manner will improve its adhesion and drying capabilities.

- Benefits: Silicone sealants offer several advantages for driveway sealing. They are highly durable and resistant to UV radiation, extreme temperatures, chemicals, and water. Silicone sealants also maintain their flexibility over time, allowing for movement and expansion without cracking or peeling. Due to their excellent adhesion properties, they create a strong barrier that helps prevent water penetration and protect the underlying surface.

- Maintenance: While silicone sealants are known for their long-lasting properties, it’s important to regularly inspect the driveway for any signs of damage or wear. Promptly repairing small cracks or damaged areas will prevent further deterioration and maintain the effectiveness of the sealant. If the silicone sealant begins to deteriorate or lose adhesion over time, it may need to be removed and replaced with a fresh layer.

Accelerating Drying Time

In certain situations, you may want to accelerate the drying time of silicone sealants. Here are some methods that can help speed up the drying process:

- Protecting the Sealed Surface: To prevent dust, debris, or moisture from interfering with the drying process, consider covering the sealed surface with a protective material, such as plastic sheeting or tape. This will create a barrier and allow the sealant to dry undisturbed.

- Using Fans or Blowers: Increasing air circulation around the sealed area can help expedite the drying process. You can use fans or blowers to create a gentle breeze that aids in the evaporation of moisture within the sealant. However, be mindful of the direction and intensity of the airflow to ensure that it doesn’t cause any damage to the freshly applied sealant.

- Applying Heat: Applying gentle heat to the sealed area can accelerate the drying of silicone sealants. However, it’s important to use caution when using heat sources such as hairdryers or heat guns. Keep the heat source at a safe distance from the sealant to avoid overheating or damaging the surface.

It’s important to note that while these methods can help speed up the drying process, they should be used with caution and within the guidelines provided by the sealant manufacturer. It’s always recommended to allow the proper drying and curing time as specified by the manufacturer to ensure the best results and long-term performance of the silicone sealant.

By utilizing silicone sealants and implementing suitable methods to accelerate drying if necessary, you can protect your driveway from various elements and ensure its durability and longevity.

Protecting the Sealed Surface

After applying a sealant to your driveway, it’s important to take necessary precautions to protect the freshly sealed surface during the drying process. Proper protection will help ensure that the sealant adheres well and dries evenly, resulting in a more durable and long-lasting seal. Here are some methods you can use to protect the sealed surface:

- Cordon Off the Area: Create physical barriers to prevent foot traffic and vehicles from accessing the sealed surface. Use caution tapes, cones, or barricades to clearly mark off the area and notify others to avoid it. This will minimize the risk of accidental damage and disturbance to the drying sealant.

- Use Warning Signs: Install visible signs or posters to inform people that the driveway has been recently sealed and should not be walked on or driven over. Clear and informative signage will help communicate the need for caution and prevent any unintentional damage to the sealant.

- Avoid Parking: If possible, avoid parking vehicles on the freshly sealed surface until it has fully dried and cured. The weight of vehicles can create pressure on the sealant and potentially leave tire marks or indentations. Find alternative parking areas during the drying period to safeguard the integrity of the sealant.

- Keep Pets Away: Pets, particularly dogs with sharp claws, can inadvertently damage the fresh sealant by scratching or walking on it. Ensure that your pets are kept away from the sealed surface during the drying process to avoid any unwanted marks or imprints.

- Protect Against Debris: Prevent loose debris, such as leaves, dirt, or small rocks, from accumulating on the sealed surface. Regularly sweep or blow away any debris that may settle on the driveway during the drying period. This will help maintain a clean and smooth surface and prevent potential damage when the sealant is still vulnerable.

By taking these protective measures, you can safeguard the integrity of the freshly sealed surface and allow the sealant to dry and cure undisturbed. It’s important to be patient and follow the manufacturer’s recommendations regarding the recommended drying time before allowing foot traffic or vehicle use on the driveway.

Remember, the goal is to ensure that the sealant obtains proper adhesion and dries evenly, resulting in an effective and long-lasting protective layer for your driveway.

Using Fans or Blowers

Accelerating the drying time of sealants can be achieved by increasing air circulation around the freshly sealed surface. Fans or blowers can help facilitate the evaporation of moisture within the sealant, speeding up the drying process. Here’s how you can effectively use fans or blowers to expedite the drying time:

- Positioning: Place the fan or blower in a strategic location where it can provide even airflow across the sealed surface. Position it in a way that maximizes coverage and minimizes the risk of displacing the sealant. Consider angling the fan or blower to ensure that the air reaches all parts of the sealed area.

- Airflow Direction: Pay attention to the direction of the airflow from the fan or blower. Ensure that it blows across the sealant rather than directly onto it to prevent any disruption or deformation. Gentle and consistent airflow is preferred to prevent unintended damage to the freshly applied sealant.

- Avoid Too Much Force: While it may be tempting to use high-powered blowers or fans, it’s important to remember that excessive force can lead to problems. Strong airflow can disturb or displace the sealant, causing uneven drying or other undesirable effects. Opt for a moderate airflow that promotes evaporation without causing damage.

- Continuous Operation: Allow the fan or blower to operate continuously during the initial drying phase. Keeping a consistent airflow will aid in the evaporation of moisture from the sealant. Depending on the weather conditions and the specific sealant used, you may need to operate the fan or blower for several hours or even overnight.

- Supplement Natural Airflow: If weather conditions permit, you can also open windows or doors to create cross ventilation in the area. This can supplement the artificial airflow from the fan or blower, helping to expedite the drying process. However, ensure that the additional airflow does not introduce dust or debris that can affect the quality of the finished sealant.

By using fans or blowers effectively, you can promote faster evaporation of moisture within the sealant, reducing the overall drying time. However, it’s important to balance the airflow to prevent any damage to the freshly sealed surface. Remember to follow the manufacturer’s instructions regarding drying time and consider the impact of weather conditions and the specific sealant being used.

It’s essential to exercise caution and monitor the drying process carefully. Once the sealant has reached the recommended drying time, you can discontinue the use of fans or blowers and allow the sealant to cure fully. This will ensure that the sealant provides maximum protection and durability for your driveway.

Applying Heat

If you’re looking to accelerate the drying time of sealants, applying heat can be an effective method. However, it’s crucial to exercise caution to prevent any potential damage to the sealant or the underlying surface. Here’s how you can safely apply heat to expedite the drying process:

- Moderate Heat Source: Use a heat source such as a heat gun or hairdryer on a moderate setting. Avoid using high heat, as it can cause the sealant to bubble, blister, or crack. Keep the heat source at a safe distance from the sealant to prevent overheating.

- Maintain Constant Movement: Keep the heat source moving continuously over the sealed surface. Point the heat in a sweeping motion, ensuring that no single area is subjected to prolonged heat exposure. This will help avoid localized overheating and ensure even drying.

- Monitor Temperature: While applying heat, be mindful of the temperature of the sealant and the surrounding area. If you notice any signs of overheating, such as smoke or an unpleasant odor, immediately stop applying heat and allow the sealant to cool. Excessive heat can cause irreparable damage to the sealant and compromise its effectiveness.

- Balance with Ambient Conditions: Take into account the ambient temperature and humidity when applying heat. If the surrounding conditions are already warm and dry, applying additional heat may not be necessary or advisable. Strive to create a balance between the use of artificial heat and the natural environment to prevent potential problems.

- Follow Manufacturer’s Guidelines: Always refer to the manufacturer’s instructions for the specific sealant being used. Some sealants may have specific recommendations or restrictions regarding the application of heat. Adhering to these guidelines will ensure the best possible result and preserve the integrity of the sealant.

By applying heat cautiously and following these guidelines, you can help speed up the drying time of sealants. However, it’s important to remember that each sealant has its own characteristics, and the effectiveness of the heat method may vary. It’s always recommended to allow the proper drying and curing time as recommended by the manufacturer to achieve optimal results.

Factors to Consider After Sealing

After sealing your driveway, several factors should be taken into consideration to ensure the longevity and effectiveness of the sealant. Here are some key factors to keep in mind:

- Foot Traffic: Allow sufficient time for the sealant to dry and cure before allowing foot traffic on the driveway. Walking on the sealant too early can cause imprints and disrupt the proper adhesion and drying process. Refer to the manufacturer’s instructions for the recommended drying time.

- Vehicle Traffic: Avoid driving or parking vehicles on the newly sealed driveway until the sealant has fully cured. The weight of vehicles can leave tire marks or indentations on the sealant if it is not fully set. It’s advisable to wait for the recommended curing time before subjecting the driveway to vehicular use.

- Curing Time: While the sealant may feel dry to the touch after the recommended drying time, it’s important to note that curing time can be longer. Curing refers to the process by which the sealant fully hardens and reaches its maximum protective capabilities. Follow the manufacturer’s instructions regarding the recommended curing time before resuming regular activities on the driveway.

- Maintenance: Regularly inspect and maintain the sealed driveway to prolong its lifespan. Sweep away debris, clean any spills or stains, and promptly address any cracks or damage that may occur over time. Routine maintenance will help preserve the integrity of the sealant and ensure long-lasting protection.

- Seasonal Considerations: Keep in mind that extreme weather conditions can impact the durability of the sealant. In areas with harsh winters, salt or chemical deicers can deteriorate the sealant over time. Take appropriate measures to protect the driveway during these seasons, such as using alternative snow removal methods and reapplying sealant as needed.

By considering these factors and taking appropriate measures, you can ensure that the freshly sealed driveway remains in optimal condition and continues to provide protection for an extended period of time.

Foot Traffic

After sealing your driveway, it’s essential to consider foot traffic and allow sufficient time for the sealant to dry and cure properly. Walking on the freshly sealed surface too early can lead to imprints, disrupt the drying process, and compromise the effectiveness of the sealant. Here are some key points to keep in mind regarding foot traffic:

- Drying Time: The drying time of sealants can vary depending on factors such as the type of sealant used, weather conditions, and thickness of the application. It’s important to follow the manufacturer’s instructions for the specific sealant to determine the recommended drying time. Typically, sealants may require at least 24 to 48 hours to dry before foot traffic can be allowed.

- Caution Signs: During the drying period, it’s important to use caution signs or other visible warnings to notify individuals that the driveway has been recently sealed and is not safe for walking. Clearly mark off the area with signs, barricades, or caution tape to prevent accidental foot traffic and ensure the sealant is undisturbed.

- Avoid Heavy Pressure: Even after the recommended drying time, it’s advisable to avoid heavy pressure on the sealed surface. While the sealant may feel dry, it may still be in the process of curing and hardening. To prevent any potential damage, refrain from placing heavy objects or applying excessive force on the driveway for a few days or as recommended by the manufacturer.

- Furniture and Decorations: If you have outdoor furniture, decorations, or other objects on the driveway, remove them or relocate them to prevent damage to the freshly sealed surface. Heavy objects can leave imprints or indentations on the sealant before it has fully cured.

- Frequent Use Areas: If there are specific areas of the driveway that experience frequent foot traffic, such as entryways or pathways, take extra care to ensure these areas have ample time to dry and cure. Consider implementing temporary alternative pathways during the drying period to avoid excessive foot traffic on these areas.

It’s important to be patient and give the sealant adequate time to dry and cure before allowing regular foot traffic on the driveway. Rushing the process can have detrimental effects on the quality and durability of the sealant. Always refer to the manufacturer’s instructions for specific guidelines on drying time and foot traffic recommendations.

By exercising caution and considering foot traffic, you can ensure that the sealant fully adheres and cures, providing long-lasting protection and a beautifully sealed driveway for years to come.

Vehicle Traffic

When it comes to vehicle traffic, it’s crucial to exercise caution and allow sufficient time for the sealant on your driveway to fully cure before driving vehicles over it. Premature vehicle traffic can cause damage to the newly sealed surface, impacting the effectiveness and longevity of the sealant. Here are some important considerations regarding vehicle traffic:

- Curing Time: While the drying time may vary, it’s important to note that drying is different from curing. Drying refers to the evaporation of the solvents in the sealant, while curing involves the chemical reactions that make the sealant harden and reach its full protective capabilities. Follow the manufacturer’s instructions to determine the recommended curing time before allowing vehicle traffic on the driveway. Typically, it can range from a few days to a week.

- Avoid Heavy Vehicles: During the curing period, it is recommended to avoid parking heavy vehicles, such as trucks or SUVs, on the freshly sealed driveway. The weight of these vehicles can create pressure points on the surface, potentially causing indents or marks. Find alternative parking options for these vehicles until the sealant has fully cured.

- Turn Wheels Carefully: When driving vehicles over the sealed surface after the curing period, be cautious when turning the wheels. Sharp turns or sudden movements can potentially scrape or damage the sealant. To minimize any potential harm, make slow, deliberate turns to avoid unnecessary stress on the sealant.

- Stay on the Designated Driveway: It’s important to ensure that vehicles remain on the designated driveway area and avoid driving off onto adjacent grass or landscaping. The sealant is specifically designed for the driveway surface and may not adhere as well or provide the same level of protection on other surfaces. Staying on the driveway will help maintain the integrity of the sealant and preserve its effectiveness.

- Be Mindful of Chemicals: Avoid using harsh chemicals, gasoline, or oil spills on the newly sealed driveway. These substances can damage the sealant and weaken its protective properties. Promptly clean up any spills or leaks to prevent any long-term damage to the sealant.

Always refer to the manufacturer’s guidelines and follow their recommended curing time before driving vehicles on the freshly sealed surface. Prioritizing patience and caution will ensure that the sealant has sufficient time to cure and provide optimum protection for your driveway against everyday vehicle use.

By taking these precautions, you can help preserve the quality and longevity of the sealant, ensuring that your driveway remains well-protected and aesthetically pleasing for an extended period.

Curing Time

The curing time of driveway sealants is a crucial factor to consider. While the drying time refers to the evaporation of solvents, the curing time involves the chemical reactions that result in the sealant fully hardening and providing maximum protection. It’s important to allow sufficient curing time to ensure the sealant’s effectiveness and durability.

Here are some key points to understand about curing time:

- Manufacturer’s Guidelines: Follow the manufacturer’s instructions regarding the recommended curing time for the specific sealant you are using. Different sealants have varying curing requirements, so it’s essential to adhere to the guidelines provided to achieve optimal results.

- Patience is Key: Be patient during the curing process and avoid subjecting the sealed surface to heavy use or vehicle traffic until the sealant has fully cured. Rushing the process can compromise the integrity of the sealant and decrease its effectiveness.

- Weather Considerations: Weather conditions, such as temperature and humidity, can affect the curing time. Warmer temperatures generally promote faster curing, while cooler temperatures may prolong the process. It’s advisable to seal your driveway during a period of favorable weather to ensure the best curing conditions.

- Continuous Protection: Even after the curing period, it’s important to practice regular maintenance to protect the sealant and extend its lifespan. This includes removing debris, cleaning spills, and addressing any cracks or damage promptly to prevent further deterioration.

Conclusion

Properly sealing your driveway is an essential maintenance step that helps protect it from the elements and extend its lifespan. Understanding the drying time, factors that can affect it, and the importance of curing time are key to achieving a successful and long-lasting seal.

Factors such as the type of sealant used, weather conditions, thickness of the application, and surface porosity can impact the drying time of the sealant. It’s important to follow the manufacturer’s instructions for the specific sealant to ensure proper application and drying.

After sealing your driveway, take necessary precautions to protect the sealed surface from foot and vehicle traffic until the sealant has fully dried and cured. Patience is crucial during this time to allow the sealant to harden and provide maximum protection.

Remember to properly maintain your sealed driveway to preserve the integrity of the sealant over time. Regular inspections, prompt repairs, and periodic reapplication of sealant as needed will help keep your driveway in optimal condition.

By understanding the factors affecting drying time, allowing sufficient curing time, and practicing proper maintenance, you can ensure that your sealed driveway remains protected, visually appealing, and functional for years to come.

Frequently Asked Questions about How Long Does It Take After Driveway Sealing

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Long Does It Take After Driveway Sealing”