Articles

How Long To Stay Off The Sealed Driveway

Modified: January 18, 2024

Discover how long you should stay off a sealed driveway after it's been done with our informative articles. Stay informed and protect your investment.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

A sealed driveway not only enhances the aesthetic appeal of your property but also provides protection against weather elements and daily wear and tear. However, once the sealant is applied, it’s important to allow sufficient time for it to dry and cure properly before subjecting it to regular use. The drying time for a sealed driveway can vary depending on several factors, including the type of sealant used, weather conditions, and other environmental factors.

In this article, we will explore the various factors that affect the drying time of a sealed driveway and discuss the recommended periods you should wait before using it. We will also highlight the importance of following the recommended drying period, the impact of weather conditions, and the consequences of not waiting long enough. Additionally, we will provide valuable tips for maintaining a sealed driveway to ensure its long-lasting durability.

Whether you’ve recently sealed your driveway or are planning to do so in the near future, understanding the importance of allowing it to dry properly is crucial. By following the guidelines and recommendations outlined in this article, you can ensure that your sealed driveway remains in top condition for years to come.

Key Takeaways:

- Properly curing a sealed driveway is crucial for durability and protection. Adhering to recommended drying periods and maintenance tips ensures long-lasting results, enhancing the aesthetic appeal of your property.

- Rushing the drying process can lead to poor adhesion, inadequate protection, and compromised durability. Patience and adherence to recommended drying periods are key to maintaining a functional, attractive, and durable sealed driveway.

Read more: How To Seal A Driveway

Factors Affecting Drying Time

Several factors can influence the drying time of a sealed driveway. Understanding these factors will help you determine how long you should wait before using the driveway and ensure that the sealant cures effectively. Here are some key factors that can affect the drying time:

- Type of Sealant: The type of sealant used plays a significant role in determining the drying time. Different sealants have varying compositions and chemical properties, which can impact the curing process. It’s important to follow the manufacturer’s instructions regarding drying times specific to the sealant you’ve chosen.

- Temperature: Temperature has a direct correlation with the drying time of a sealed driveway. Warmer temperatures generally accelerate the drying process, while colder temperatures can slow it down. It’s essential to consider the current and forecasted temperatures before sealing your driveway and factor in the extra drying time required in colder weather.

- Humidity: Humidity levels can also affect the drying time. High humidity can prolong the drying process as it prevents moisture from evaporating quickly. Conversely, low humidity can help expedite the drying time. Pay attention to the humidity levels in your area and adjust your expectations accordingly.

- Thickness of the Sealant Layer: The thickness of the sealant layer applied to the driveway can impact the drying time. A thicker layer will take longer to dry compared to a thinner layer. Ensure that you apply the sealant evenly and in accordance with the manufacturer’s recommended thickness to ensure proper drying.

- Air Circulation: Sufficient air circulation is essential for the drying process. Good airflow aids in the evaporation of moisture from the sealant. If the driveway is located in an area with limited air circulation, such as an enclosed space or surrounded by tall structures, it may require additional drying time.

- Additional Additives: Sometimes, additional additives or enhancers are mixed with the sealant to provide added benefits such as improved durability or color enhancement. These additives can affect the drying time, so it’s important to follow the instructions provided by the manufacturer when using such products.

By considering these factors, you can have a better understanding of the drying time required for your sealed driveway. It’s important to note that these factors may vary based on the specific product used, so always refer to the manufacturer’s guidelines and recommendations for the most accurate drying period.

Recommended Drying Periods

While the drying time for a sealed driveway can vary depending on the factors mentioned earlier, there are some general guidelines to follow. These recommended drying periods allow the sealant to fully cure and achieve its optimal protective qualities. Here are the typical drying periods for different types of sealants:

- Acrylic-Based Sealants: Acrylic-based sealants are commonly used due to their affordability and ease of application. For acrylic sealants, it is generally recommended to wait at least 24 to 48 hours before using the driveway. However, keep in mind that colder temperatures and higher humidity levels may extend the drying time.

- Penetrating Sealers: Penetrating sealers provide deep protection by bonding with the concrete molecules. These sealers usually take longer to dry compared to acrylic sealants. It is advisable to wait around 72 hours before using the driveway after applying a penetrating sealer. Again, factors like temperature and humidity can affect the drying time, so monitor the conditions accordingly.

- Epoxy-Based Sealants: Epoxy-based sealants are highly durable and provide exceptional protection. However, they require a longer drying time due to their thicker consistency. It is recommended to wait at least 48 to 72 hours before using the driveway after applying an epoxy-based sealant. Consider allowing even more drying time if the weather conditions are unfavorable.

- Polyurethane Sealants: Polyurethane sealants offer excellent durability and resistance to harsh weather conditions. They typically require a drying period of 48 to 72 hours. However, depending on the specific product and prevailing weather conditions, it may be necessary to extend the drying time to ensure optimal curing.

It’s important to note that these recommended drying periods may vary depending on the specific product and manufacturer’s instructions. It is always best to follow the guidelines provided by the sealant manufacturer to ensure proper drying and curing.

Additionally, it’s essential to avoid any heavy vehicles or equipment on the driveway during the drying period. This can cause damage to the sealant and compromise its effectiveness. Be patient and allow for the recommended drying time to ensure the best possible results.

Weather Conditions and Their Impact

Weather conditions play a crucial role in the drying time and curing process of a sealed driveway. The various elements, such as temperature, humidity, and precipitation, can significantly impact the effectiveness of the sealant and the overall longevity of the driveway. Here’s a closer look at how different weather conditions can affect the drying process:

- Temperature: Higher temperatures generally speed up the drying time of the sealant. The warmth helps evaporate the moisture from the sealant more quickly, promoting faster curing. On the other hand, colder temperatures can slow down the drying process. In colder climates, it is important to allow for additional drying time to ensure proper curing.

- Humidity: Humidity levels can hinder the drying process as they affect the evaporation of moisture from the sealant. High humidity can extend the drying time, while low humidity can help expedite it. Therefore, it’s important to consider the humidity levels in your area when determining the drying period for your sealed driveway.

- Precipitation: Rain, snow, or any form of precipitation can be detrimental to the curing process of the sealant. Moisture can interfere with the bonding of the sealant to the surface, leading to poor adhesion and potential damage. It is essential to avoid sealing your driveway before or during a period of precipitation and allow for additional drying time if the driveway gets exposed to moisture after sealing.

- Wind: Strong winds can disrupt the drying process by causing uneven drying and potentially blowing debris onto the freshly sealed surface. It is advisable to carefully monitor weather conditions and avoid sealing your driveway on particularly windy days. Additionally. provide some protection against wind by placing temporary barriers or windbreaks if necessary.

To ensure that the sealant cures properly and provides long-lasting protection, it’s crucial to be mindful of weather conditions. Ideally, choose a period of dry, moderate temperatures with low humidity for sealing your driveway. This will help to facilitate optimal drying and curing, ensuring a strong and durable seal.

If unexpected weather conditions arise after sealing your driveway, such as rainfall or extreme temperatures, it’s best to consult with the sealant manufacturer for specific recommendations on how to mitigate the impact and adjust the drying period if necessary.

By considering the weather conditions and their impact, you can make informed decisions and ensure that the sealant on your driveway dries and cures effectively, resulting in a long-lasting and well-protected surface.

Importance of Following the Recommended Period

Following the recommended drying period for a sealed driveway is crucial for several reasons. While it may be tempting to start using the driveway sooner, allowing sufficient drying time is essential to ensure the effectiveness and longevity of the sealant. Here are the key reasons why it’s important to adhere to the recommended period:

- Optimal Curing: The recommended drying period allows the sealant to cure and bond effectively with the surface of the driveway. Curing is a chemical process that involves the hardening of the sealant, making it durable and resistant to damage. Rushing this process by using the driveway too soon can result in a weak or incomplete cure, compromising the overall quality of the sealant.

- Resistance to Wear and Tear: Properly cured sealant provides enhanced protection against regular wear and tear, such as vehicle traffic, foot traffic, and exposure to the elements. By allowing the sealant to dry and cure for the recommended period, you ensure that it develops the necessary strength and durability to withstand these daily stresses, prolonging the life of your driveway.

- Sealant Effectiveness: The performance of the sealant is directly related to its proper drying and curing. Following the recommended period ensures that the sealant can create an effective barrier against moisture, UV rays, oil spills, and other contaminants. This barrier helps preserve the integrity of the driveway, preventing cracks, deterioration, and costly repairs.

- Enhanced Aesthetic Appeal: A well-cured sealed driveway not only provides protection but also enhances the overall appearance of your property. By waiting for the recommended drying period, you give the sealant ample time to settle evenly, providing a smooth and visually appealing surface. This contributes to the curb appeal of your home and creates a welcoming entrance.

- Cost Savings: By adhering to the recommended drying period, you can avoid the potential setbacks and expenses associated with premature use of a sealed driveway. Rushing to use the driveway before the sealant has fully cured can lead to damage, requiring repairs or reapplication of the sealant, which can be both time-consuming and costly.

Ultimately, following the recommended drying period is essential for maximizing the benefits of your sealed driveway. It ensures the optimal curing of the sealant, enhances its durability, and extends the lifespan of your driveway. It also helps maintain the aesthetic appeal of your property while saving you from potential repair expenses and hassles in the long run.

Remember, patience is key when it comes to your sealed driveway. By allowing it to dry and cure properly, you are investing in its long-term performance and protection.

It is recommended to stay off a newly sealed driveway for at least 24-48 hours to allow the sealant to fully cure and harden. This will help prevent any damage or markings on the surface.

Read more: How Long To Stay Off New Grass

Signs of a Properly Cured Driveway

Properly curing a sealed driveway is essential to ensure its durability and effectiveness. Once the recommended drying period has passed, it’s important to look out for certain signs that indicate the sealant has cured properly. These signs confirm that your driveway is ready for regular use. Here are some signs to watch for:

- Surface Appearance: A properly cured driveway will have a smooth and uniform surface. There should not be any tackiness or stickiness when you walk or touch the surface. The sealant should have fully dried and hardened, providing a solid protective layer over the driveway.

- Color Consistency: The color of the sealant should appear consistent across the entire driveway. If you notice any areas where the color appears uneven or different from the rest of the surface, it may indicate that those areas have not fully cured. These areas may require additional drying time or attention to ensure proper curing.

- Resistance to Pressure: A cured sealant should be able to withstand pressure from foot traffic, vehicles, and other common activities. Walk on your driveway and observe if there are any indentations or imprints left behind. If the sealant remains firm and maintains its integrity under pressure, it is a good indication of proper curing.

- Water Beading: Sprinkle some water onto the surface of the driveway and observe how it reacts. A properly cured driveway will cause the water to bead up and roll off the surface. If the water soaks into the sealant or causes it to become soft or discolored, it is a sign that the driveway has not fully cured and is not yet ready for regular use.

- Resistance to Stains: A well-cured sealed driveway should also exhibit resistance to stains and spills. If you accidentally drop oil, gasoline, or other common stains on the surface and they can be easily wiped away without leaving a mark, it indicates that the sealant has cured properly and is providing the desired protection.

- Time Since Application: It is important to keep in mind the recommended drying period specific to the type of sealant you have used. If the recommended drying period has passed, and you have observed the other signs mentioned above, it is a strong indication that your driveway has cured properly and is ready for regular use.

By paying attention to these signs, you can confirm that your driveway has properly cured after sealing. This provides you with the confidence to begin using the driveway as intended, knowing that the sealant is fully functional and capable of providing long-lasting protection against various environmental factors and daily wear and tear.

If you have any doubts about the curing process, it’s always best to consult with the manufacturer or a professional contractor who can assess the condition of your driveway and provide guidance on its readiness for use.

Consequences of Not Waiting Long Enough

Not waiting for the recommended drying period before using a sealed driveway can have several negative consequences. While it may be tempting to start using the driveway sooner, doing so can compromise the effectiveness of the sealant and lead to costly issues down the line. Here are some of the potential consequences of not waiting long enough:

- Poor Adhesion: The primary purpose of sealing a driveway is to create a protective barrier on the surface. If the sealant has not fully cured, it may not adhere properly to the concrete, resulting in poor adhesion. This can lead to the sealant peeling or delaminating from the surface, leaving it vulnerable to damage from UV rays, moisture, and other contaminants.

- Inadequate Protection: A sealant that has not fully cured will not provide the intended level of protection to your driveway. Premature use can result in the sealant being less effective in preventing moisture penetration, oil spills, and other factors that can cause damage to the concrete. This can lead to premature deterioration, staining, cracking, and costly repairs in the future.

- Compromised Durability: Waiting for the recommended drying period allows the sealant to cure properly, making it more durable and resilient. Not allowing sufficient time for curing can weaken the sealant, making it more prone to damage from regular use. This can lead to cracking, chipping, and diminished overall longevity of the driveway.

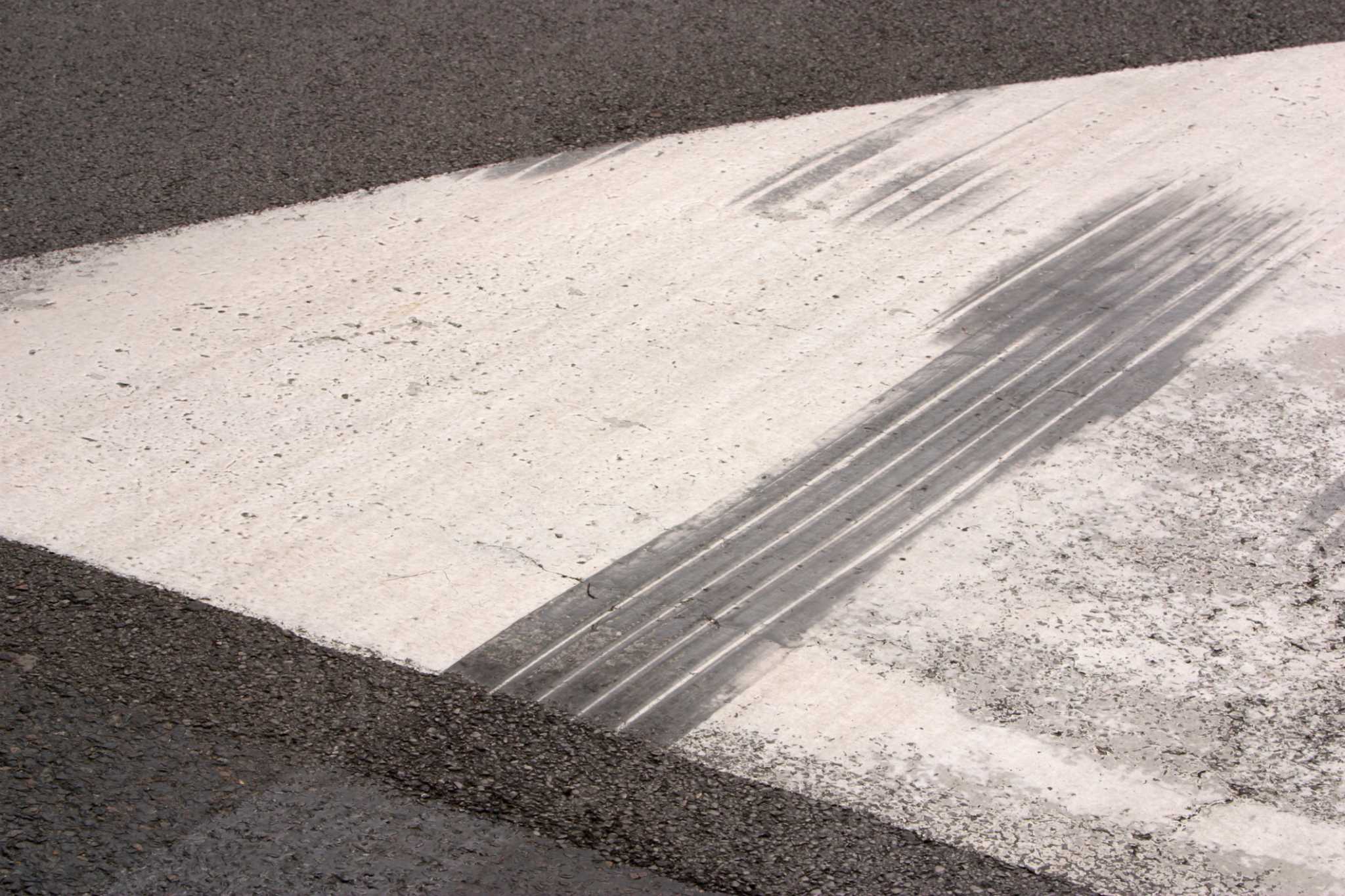

- Unsightly Appearance: Rushing to use a freshly sealed driveway can result in cosmetic issues. The sealant may not have fully settled or hardened, leading to uneven color distribution, tacky surfaces, or even visible footprints or tire marks. These aesthetic issues can detract from the overall appearance of your property and require additional effort to rectify.

- Increased Maintenance: When a sealant has not fully cured, it may require more frequent maintenance and reapplication. Premature use of the driveway can cause the sealant to wear off or abrade more quickly, necessitating more frequent sealing or repairs. This can be time-consuming and add to the overall cost of maintaining your driveway.

By not waiting long enough for the sealant to dry and cure fully, you risk compromising the integrity, effectiveness, and longevity of your sealed driveway. It’s important to exercise patience and follow the recommended drying period to ensure that the sealant can provide optimal protection and maintain its appearance over time.

Remember that the recommended drying period may vary depending on the specific sealant and prevailing weather conditions. Adhering to these guidelines will help you avoid the potential consequences of premature use and ensure that your sealed driveway remains in excellent condition for years to come.

Tips for Maintaining a Sealed Driveway

Proper maintenance is essential to keep your sealed driveway in optimal condition and extend its lifespan. By following these tips, you can ensure that your driveway remains durable, attractive, and well-protected:

- Regular Cleaning: Keep your driveway clean by regularly sweeping away debris, leaves, and dirt. This prevents the buildup of substances that can degrade the sealant over time. Use a broom or leaf blower to remove loose particles, and consider using a mild detergent or driveway cleaner for more stubborn stains.

- Spill and Stain Prevention: Promptly clean up any oil spills, gasoline, or other potential staining substances on your driveway. These can penetrate the sealant and cause discoloration or damage. Use absorbent materials like kitty litter or clean up spills with a degreaser specifically designed for concrete surfaces.

- Avoid Heavy Vehicles and Equipment: Minimize the use of heavy vehicles, such as large trucks or construction equipment, on your sealed driveway. Excessive weight, especially from heavy machinery, can stress and damage the sealant. If unavoidable, use thick plywood or boards to distribute the weight and protect the surface.

- Protect from Sharp Objects: Avoid dragging sharp objects, such as metal shovels or snow blowers, on the sealed surface. These can scratch or gouge the sealant, compromising its effectiveness. Use plastic shovels or snow blowers with rubber blades to minimize potential damage.

- Sealant Reapplication: Over time, the sealant on your driveway will wear off due to weather exposure, UV rays, and regular use. Plan to reseal your driveway every 2-3 years, or as recommended by the manufacturer. This helps maintain the protective layer and prolongs the life of the driveway. Be sure to thoroughly clean the surface before applying a new coat of sealant.

- Address Cracks and Damage Promptly: Inspect your driveway regularly for any cracks or signs of damage. Promptly repair and seal any cracks to prevent them from widening or allowing moisture penetration. Small cracks can be filled with a concrete crack filler, while larger or more extensive damage may require professional repair.

- Be Mindful of Snow Removal: When clearing snow from your driveway, avoid using metal shovels or sharp-edged snow blowers directly on the sealed surface. Instead, use plastic shovels or snow blowers with rubber blades to minimize potential damage. Avoid using excessive force or harsh chemicals that can degrade the sealant.

- Protective Parking: If possible, avoid parking vehicles with hot tires on the sealed driveway, especially during hot summer months. The heat from the tires can soften the sealant and leave imprints or marks on the surface. Use protective pads or mats to prevent direct contact between the tires and the sealed surface.

- Proper Drainage: Ensure that your driveway has proper drainage to prevent the buildup of water or pooling. Poor drainage can lead to water seeping into the sealant and causing damage. Clear out any debris, such as leaves or dirt, that may block the drainage channels or gutters near your driveway.

By implementing these maintenance tips, you can enhance the longevity and appearance of your sealed driveway. Regular cleaning, prevention of stains and damage, reapplication of sealant, and prompt repair of cracks will help preserve the integrity of the surface and keep it in excellent condition for years to come.

Remember to consult the recommendations provided by your sealant manufacturer for specific maintenance guidelines, as different products may require slightly different care. By investing time and effort into proper maintenance, you can enjoy a beautiful, functional, and well-protected driveway for many years.

Conclusion

A sealed driveway can significantly enhance the appearance and longevity of your property. However, allowing the sealant to dry and cure properly is essential to ensure its effectiveness and durability. By following the recommended drying periods, considering the impact of weather conditions, and adhering to proper maintenance practices, you can enjoy a well-protected and long-lasting driveway.

We explored the various factors that affect the drying time of a sealed driveway, including the type of sealant, temperature, humidity, and thickness of the sealant layer. It’s important to consider these factors to determine the appropriate drying period for your specific driveway. Rushing the drying process can lead to poor adhesion, inadequate protection, compromised durability, and other issues that can require costly repairs in the future.

Throughout the article, we highlighted the importance of patience and adherence to the recommended drying period. Proper curing of the sealant ensures optimal protection against moisture, UV rays, oil spills, and regular wear and tear. It also contributes to the overall aesthetic appeal of your property.

We emphasized the consequences of not waiting long enough before using a sealed driveway, including poor adhesion, inadequate protection, compromised durability, unsightly appearance, and increased maintenance needs. By understanding and avoiding these consequences, you can maintain a driveway that remains functional, attractive, and durable over time.

Lastly, we provided valuable tips for maintaining a sealed driveway, such as regular cleaning, spill prevention, avoiding heavy vehicles and sharp objects, and prompt repair of cracks and damage. These maintenance practices help prolong the lifespan of the sealant and ensure the longevity of your driveway.

In conclusion, by exercising patience, following the recommended drying period, and implementing proper maintenance practices, you can enjoy the benefits of a well-cured and well-maintained sealed driveway. Remember, a little care and attention can go a long way in preserving the beauty and functionality of your property’s entrance for years to come.

Frequently Asked Questions about How Long To Stay Off The Sealed Driveway

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Long To Stay Off The Sealed Driveway”