Articles

How Much Does It Cost To Run Electrical Wire

Modified: January 19, 2024

Discover the average cost of running electrical wire in this informative article. Get the details you need to plan your electrical project budget.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

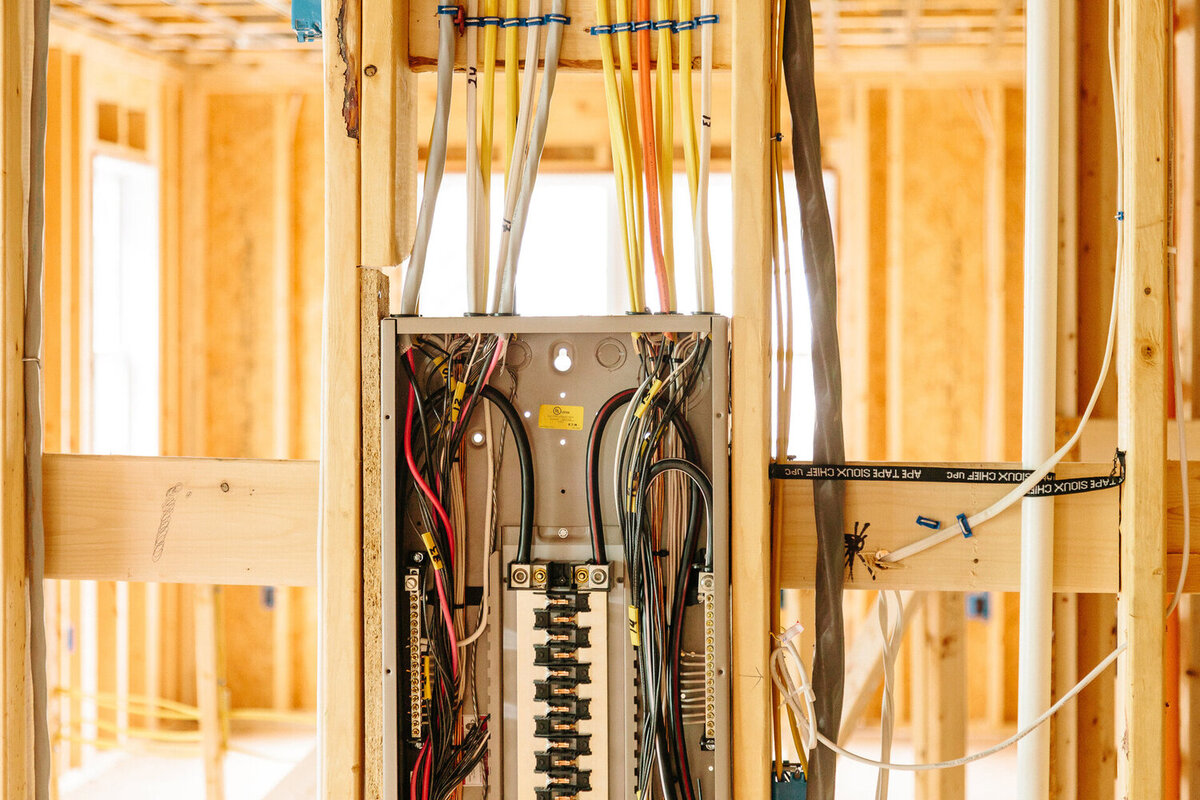

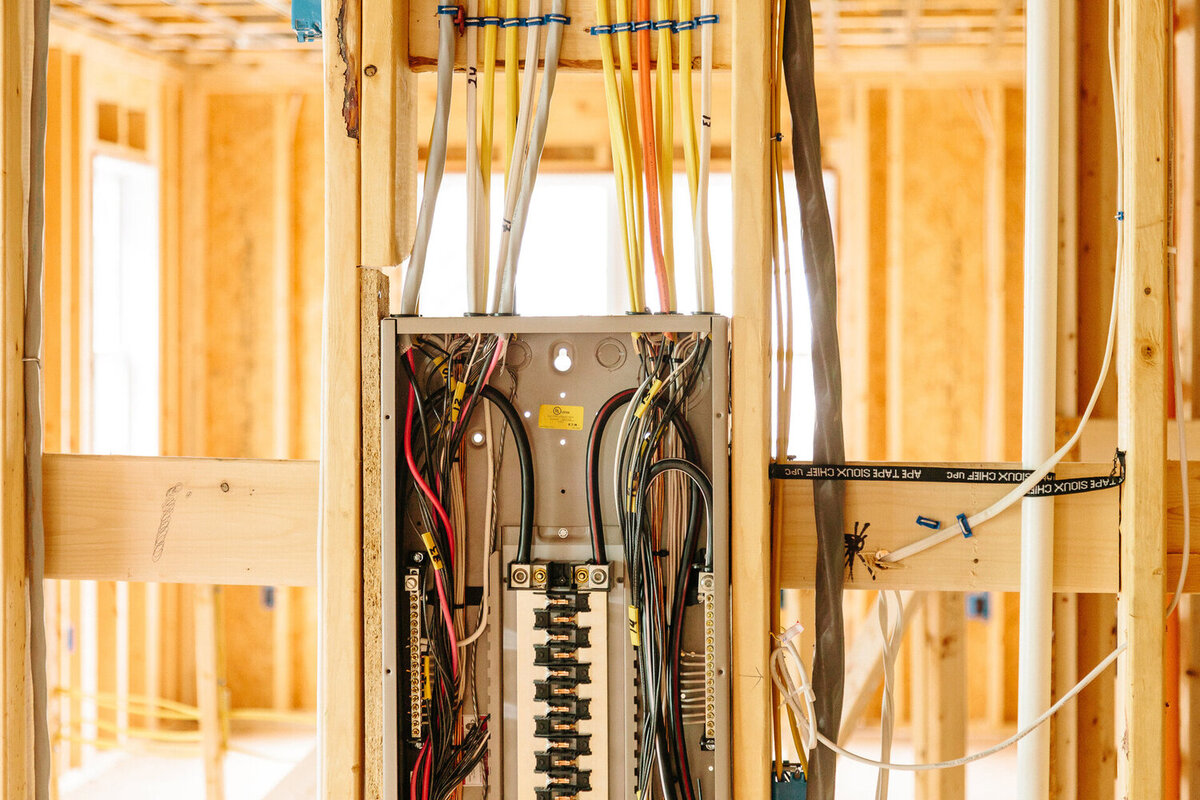

Running electrical wire is an essential part of any electrical installation or renovation project. Whether you’re adding outlets, installing lighting fixtures, or upgrading your electrical system, understanding the cost of running electrical wire is crucial for planning and budgeting.

Electrical wire not only carries electricity throughout your home or office, but it also ensures safety and reliability. The cost of running electrical wire can vary depending on several factors, such as the type of wire, the length of the run, and the complexity of the installation.

In this article, we will explore the factors that affect the cost of running electrical wire, the types of electrical wire available, the cost of materials and labor, and additional costs to consider. Whether you’re a homeowner tackling a DIY project or a business owner looking to hire a professional electrician, this information will help you understand the expenses involved in running electrical wire.

Before we delve into the details, it’s important to note that electrical work can be dangerous and should only be done by individuals with the necessary knowledge and expertise. If you’re not confident in your abilities, it’s always recommended to hire a licensed electrician to ensure proper installation and compliance with electrical codes and regulations.

Now, let’s explore the factors that can affect the cost of running electrical wire.

Key Takeaways:

- Understanding the factors that influence the cost of running electrical wire, such as length of the run, wire type, and labor costs, is crucial for accurate budgeting and planning of electrical installation projects.

- While DIY electrical projects offer cost savings, hiring a professional electrician ensures expertise, compliance with safety standards, and quality workmanship, providing peace of mind for complex installations.

Factors Affecting Cost of Running Electrical Wire

Several factors can influence the cost of running electrical wire. Understanding these factors will help you estimate and plan your electrical installation or renovation project more effectively. Here are some key considerations:

- Length of the Run: The total length of the wire needed to complete the installation will have a significant impact on the cost. Longer runs will require more wire, resulting in higher material costs.

- Location: The location where the electrical wire needs to be installed can affect the cost. For example, running wire through walls, floors, or ceilings that require additional drilling or cutting may require more labor, increasing the overall cost.

- Wire Type and Gauge: The type and gauge of the electrical wire you choose will also impact the cost. Different wire types, such as copper or aluminum, have different price points. The gauge refers to the thickness of the wire, with lower gauge numbers representing thicker wires. Thicker wires generally cost more but can handle higher electrical loads.

- Complexity of the Installation: The complexity of the electrical installation can affect the labor costs. For instance, if the project involves multiple outlets, switches, or fixtures, it will require more time and expertise from the electrician, resulting in higher labor costs.

- Accessibility: The accessibility of the installation site plays a role in the cost. If the location is difficult to reach, such as a crawl space or attic, it may require additional effort and time to run the electrical wire, contributing to increased labor costs.

It’s essential to consider these factors when estimating the cost of running electrical wire. Keep in mind that each project is unique, and the actual cost may vary depending on your specific requirements and local market conditions.

In the following sections, we will explore the different types of electrical wire available, the cost of materials, labor costs, and additional expenses you should consider when calculating the total cost of running electrical wire.

Types of Electrical Wire

When it comes to electrical wire, there are various types to choose from, each designed for specific applications and environments. Understanding the different types of electrical wire will help you select the appropriate wire for your project. Here are the most common types:

- Non-Metallic Sheathed Cable (NM): NM cable, also known as Romex, is one of the most commonly used types of electrical wire. It consists of two or more insulated conductors surrounded by a plastic sheath. NM cable is commonly used for residential wiring, such as powering outlets, switches, and lighting fixtures.

- Armored Cable (AC): Armored cable, often referred to as BX cable, is a type of electrical wire with a flexible metal armor jacket. It provides mechanical protection and is commonly used in areas where the wire may be exposed to physical damage or in outdoor installations.

- Metal-Clad Cable (MC): Metal-clad cable is similar to armored cable but has a solid metal sheath rather than a flexible armor jacket. It offers excellent protection against fire and physical damage and is commonly used in commercial and industrial applications.

- THHN/THWN Wire: THHN (Thermoplastic High Heat-resistant Nylon-coated) and THWN (Thermoplastic Heat and Water-resistant Nylon-coated) wires are commonly used for wiring in conduit systems. They have a single, solid copper conductor covered with a thermoplastic insulation. THHN/THWN wires are suitable for both indoor and outdoor applications.

- Direct Burial Cable: As the name suggests, direct burial cable is designed to be buried directly in the ground without the need for conduit. It is highly durable and has insulation that protects against moisture and other environmental factors. Direct burial cable is commonly used for outdoor electrical installations such as landscape lighting or underground circuits.

- Low Voltage Wire: Low voltage wire is specifically designed for low-voltage applications, typically 24 volts or less. It is commonly used for doorbells, thermostats, security systems, and audio systems. Low voltage wire is often smaller in gauge and does not require conduit.

These are just a few examples of the types of electrical wire available. It’s important to consult with a professional electrician or reference local electrical codes to determine the appropriate wire type for your specific installation.

Next, we will explore the cost of materials required for running electrical wire.

Cost of Materials

When estimating the cost of running electrical wire, it’s important to consider the materials required for the installation. The cost of materials can vary depending on the type and quantity of wire needed. Here are the key components to consider:

- Electrical Wire: The cost of the electrical wire itself will depend on the type, gauge, and length required for the installation. Copper wire is generally more expensive than aluminum wire due to its superior conductivity. Additionally, thicker gauge wires typically cost more than thinner gauge wires.

- Conduit: If you’re running wire in a conduit system, you’ll need to factor in the cost of the conduit itself. Conduit is a protective tubular structure that houses the electrical wire. Conduit can be made of metal or plastic, and its cost will depend on the material and size needed for the installation.

- Connectors and Fittings: Connectors and fittings are essential components that allow for proper connections and terminations in the electrical system. These could include wire nuts, electrical tape, crimp connectors, and conduit connectors. The cost of connectors and fittings will depend on the quantity and type needed for your specific installation.

- Other Miscellaneous Materials: Depending on the complexity of the installation, you may need additional materials such as junction boxes, switches, outlets, and light fixtures. These materials will incur additional costs and should be factored into your overall material expenses.

To estimate the cost of materials, it’s recommended to consult with your local supplier or retailer for accurate pricing. They can provide you with specific costs based on the type and quantity of materials needed for your project.

Next, we will explore the labor costs associated with running electrical wire.

Labor Costs

When running electrical wire, labor costs typically make up a significant portion of the overall project expenses. Hiring a professional electrician ensures that the installation is done properly and in compliance with electrical codes and regulations. Here are some factors that can influence the labor costs:

- Hourly Rates: Electricians charge an hourly rate for their services. The rates can vary depending on factors such as location, experience, and the complexity of the project. It’s important to obtain multiple quotes from reputable electricians to compare and determine the average hourly rate in your area.

- Project Size and Complexity: The size and complexity of the electrical installation will directly impact the labor costs. A simple project, such as installing a single outlet, will require less time and labor compared to rewiring an entire house or commercial building.

- Preparation and Planning: Before starting the installation, electricians may need to conduct site visits and prepare a detailed plan. This includes determining the best routing for the electrical wire and identifying any obstacles or challenges. The time spent on preparation and planning will be factored into the labor costs.

- Required Permits: Some electrical installations may require permits from the local authorities. Electricians may need to obtain these permits on your behalf, which will add to the labor costs. Additionally, the time spent on permit acquisition and inspections will also be factored into the overall labor expenses.

- Travel and Transportation: If the electrician needs to travel a significant distance to your location, travel expenses may be included in the labor costs. This can include fuel costs, tolls, and other transportation expenses.

It’s important to note that labor costs can vary greatly depending on your location and the specific electrician you hire. Always choose a licensed and reputable electrician who can provide a detailed breakdown of their labor costs.

Now, let’s explore additional costs that you should consider when estimating the total expenses of running electrical wire.

When running electrical wire, consider the length of the wire needed, the type of wire required for the project, and any additional materials such as conduit or junction boxes. It’s also important to factor in the cost of labor if hiring a professional electrician.

Additional Costs to Consider

When calculating the cost of running electrical wire, it’s important to consider additional expenses that may arise throughout the installation process. These costs can vary depending on your specific project requirements and circumstances. Here are some common additional costs to keep in mind:

- Permit Fees: In many jurisdictions, electrical work requires permits. The cost of these permits can vary depending on your location and the scope of the project. Be sure to factor in any permit fees when estimating your overall expenses.

- Upgrades or Repairs: If you’re upgrading an existing electrical system or addressing any repairs, there may be additional costs involved. For example, if the wiring in your home is outdated or doesn’t meet current safety standards, you may need to make necessary upgrades, which can increase your expenses.

- Debris Removal: During the installation process, there may be debris generated from cutting, drilling, or removing old wiring. Disposing of this debris may require additional expenses, such as hiring a waste removal service or renting a dumpster.

- Unexpected Issues: Electrical installations can sometimes come across unforeseen issues that require additional work and expenses. For example, if the electrician discovers faulty wiring or hidden damages, they may need to address these issues, resulting in additional labor and material costs.

- Finishing Touches: After the installation of electrical wire, you may need to invest in finishing touches such as painting or patching walls and ceilings. These costs should be factored into your budget as they contribute to the overall project expenses.

It’s essential to have a contingency fund or buffer in your budget to account for any unforeseen expenses that may arise during the electrical wire installation.

Now that we’ve explored the additional costs, let’s discuss the pros and cons of DIY versus hiring a professional for running electrical wire.

DIY vs Hiring a Professional

When it comes to running electrical wire, you have the option of either doing it yourself (DIY) or hiring a professional electrician. Each option has its own set of advantages and considerations. Let’s examine both options to help you make an informed decision:

DIY (Do-It-Yourself)

Pros:

- Cost Savings: One of the major advantages of DIY is the potential cost savings. By running the electrical wire yourself, you can eliminate the labor costs associated with hiring a professional.

- Learning Experience: Taking on a DIY electrical project can be a great learning opportunity. It allows you to gain knowledge and skills in electrical work that can be valuable for future projects and repairs.

- Flexibility and Control: DIY projects give you the flexibility to work at your own pace and make adjustments as needed. You have complete control over the installation process and can ensure it meets your specific requirements.

Cons:

- Safety Concerns: Electrical work can be dangerous if not done properly. Working with live wires and circuits poses the risk of electrocution or electrical fires. If you’re not experienced or confident in your abilities, it’s best to leave the job to professionals.

- Code Compliance: Electrical installations must comply with local electrical codes and regulations to ensure safety and legal compliance. DIY installations may not meet these standards, leading to potential hazards and code violations.

- Time and Effort: Running electrical wire can be a time-consuming task, especially if you’re unfamiliar with the process. DIY projects often require more time and effort compared to hiring a professional who has the knowledge and expertise to complete the job efficiently.

Hiring a Professional

Pros:

- Expertise and Experience: Professional electricians have the necessary expertise and experience to complete electrical installations safely and efficiently. They are knowledgeable about local codes and regulations, ensuring compliance with all necessary requirements.

- Time Savings: Hiring a professional saves you time and effort. Electricians can complete the job faster due to their experience and access to the necessary tools and equipment.

- Quality and Warranty: Professional electricians provide quality workmanship and often offer warranties on their installations. This gives you peace of mind knowing that the electrical system is properly installed and protected.

Cons:

- Higher Costs: Hiring a professional comes with labor costs, which can significantly increase the overall project expenses. However, the investment in a professional ensures the safety and reliability of the electrical system.

- Limited Control: When hiring a professional, you have less control over the installation process compared to doing it yourself. You’ll need to communicate your requirements and trust the electrician’s expertise to achieve the desired outcome.

Ultimately, the decision between DIY and hiring a professional depends on your level of expertise, comfort with electrical work, and the complexity of the project. While DIY may be suitable for minor tasks, it’s always recommended to hire a licensed electrician for complex or large-scale installations to ensure safety and compliance.

Now that you have a comprehensive understanding of the factors and costs involved in running electrical wire, you can make an informed decision and plan for your project accordingly.

Read more: How Much Does A Fan Cost To Run

Conclusion

Running electrical wire is a crucial aspect of any electrical installation or renovation project. Understanding the factors that affect the cost of running electrical wire and considering the types of wire, materials, labor costs, and additional expenses involved will help you plan and budget effectively.

The length of the run, location, wire type and gauge, complexity of the installation, and accessibility are all factors that can influence the cost. By carefully considering these factors, you can estimate the expenses more accurately.

Choosing the right type of electrical wire, such as non-metallic sheathed cable (NM), armored cable (AC), or metal-clad cable (MC), ensures the safety and effectiveness of your electrical system. Additionally, factoring in the cost of materials, including the wire itself, conduit, connectors, and other miscellaneous items, is essential for accurate budgeting.

Labor costs, including hourly rates, site preparation, required permits, and transportation, should be taken into account when running electrical wire. Although hiring a professional electrician may come at a higher cost, their expertise, efficiency, and compliance with electrical codes offer peace of mind and quality workmanship.

It’s also important to consider additional costs, such as permit fees, upgrades or repairs, debris removal, and unexpected issues that may arise during the installation process. Having a contingency fund and factoring in these additional expenses will ensure that you are prepared for any unexpected costs.

Lastly, the choice between DIY and hiring a professional depends on your level of expertise, safety concerns, and project complexity. While DIY may offer cost savings and a learning experience, hiring a professional electrician guarantees expertise, time savings, and adherence to safety standards and electrical codes.

In conclusion, running electrical wire requires careful planning, consideration of costs, and adherence to safety and regulatory standards. Whether you’re embarking on a DIY project or hiring a professional, ensuring the safe and efficient installation of electrical wire will provide a reliable and functional electrical system for your home or business.

Frequently Asked Questions about How Much Does It Cost To Run Electrical Wire

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Much Does It Cost To Run Electrical Wire”