Articles

How To Store Acetone

Modified: January 6, 2024

Learn the proper way to store acetone and keep your articles safe with these helpful storage tips.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Acetone is a commonly used chemical compound in various industries and households. It is a volatile, colorless liquid with a distinct odor and is highly flammable. Due to its flammable nature and potential health hazards, proper storage of acetone is crucial to ensure safety and prevent accidents.

In this article, we will discuss the necessary precautions and guidelines for safely storing acetone. By following these recommendations, you can minimize the risks associated with handling and storing acetone, protecting both yourself and the surrounding environment.

Key Takeaways:

- Proper storage of acetone requires safety precautions, suitable materials, and a well-ventilated location to minimize risks and ensure a safe environment for handling and storage.

- Adhering to temperature considerations, ventilation requirements, and emergency response measures is crucial for safe and responsible storage of acetone, protecting individuals and the environment.

Read more: Why Use Acetone To Clean Glassware

Safety Precautions

Before delving into the specifics of storing acetone, it is essential to understand the safety precautions that should be taken when working with this chemical.

First and foremost, always wear appropriate personal protective equipment (PPE) when handling acetone. This includes safety goggles, gloves, and a lab coat or protective clothing. These measures will help protect your eyes, skin, and respiratory system from potential harm.

Additionally, ensure that you are working in a well-ventilated area. Acetone vapors can be hazardous if inhaled in high concentrations. Open windows or use exhaust fans to allow fresh air to circulate and remove any fumes.

Keep acetone away from sources of ignition, such as open flames, sparks, or heat sources. Acetone is highly flammable, and even a small spark can ignite it, leading to a fire or explosion.

When transferring acetone from one container to another, use appropriate tools such as a funnel or a transfer pump to reduce the risk of spillage. Always work on a stable surface and avoid unnecessary movements that could lead to accidents.

Lastly, it is crucial to familiarize yourself with the Material Safety Data Sheet (MSDS) for acetone. The MSDS contains important information about the chemical’s properties, hazards, and emergency procedures. Make sure you know how to respond in case of a spill, fire, or exposure to acetone.

By adhering to these safety precautions, you can minimize the potential risks associated with working with acetone and ensure a safe environment for yourself and those around you.

Required Materials

When it comes to storing acetone safely, having the appropriate materials is essential. Here is a list of items you will need:

- Approved Storage Containers: Select containers that are specifically designed for storing chemicals and are compatible with acetone. Options include high-density polyethylene (HDPE) bottles, metal cans, or glass bottles. Ensure that the containers are in good condition, with secure lids or caps.

- Labeling Materials: You will need labels to clearly mark the containers holding acetone. These labels should specify the contents, and include hazard symbols, warnings, and any required safety information. Use durable labels that won’t easily fade or peel off.

- Funnel or Transfer Pump: For transferring acetone from one container to another, a funnel or a transfer pump can be handy. This will help minimize spills and ensure a smooth and controlled transfer process.

- Personal Protective Equipment (PPE): As mentioned earlier, it is essential to have proper PPE, including safety goggles, gloves, and a lab coat or protective clothing. These items will protect you from potential exposure to acetone.

- Storage Space: Allocate a dedicated storage space for acetone that is cool, dry, and well-ventilated. Make sure the space is away from sources of ignition and incompatible substances.

Having these materials readily available will make the task of storing acetone more efficient and safe. Always remember to regularly inspect and replace any damaged or worn-out containers or equipment to maintain the integrity of the storage system.

Storage Container Selection

Selecting the right storage containers is crucial when it comes to storing acetone safely. The containers should be able to withstand the chemical’s properties and prevent leaks or spills. Here are some factors to consider when choosing storage containers for acetone:

- Material Compatibility: Acetone is best stored in containers made of high-density polyethylene (HDPE) or metal, such as aluminum or stainless steel. These materials are resistant to the corrosive nature of acetone and provide a secure barrier, preventing leakage or evaporation.

- Container Size: Consider the quantity of acetone you need to store and choose containers of an appropriate size. Large quantities are typically stored in drums or safety cans, while smaller quantities can be stored in bottles or cans with screw-top lids.

- Tight Seal: Ensure that the containers have tight-fitting lids or caps that can be securely closed. This prevents evaporation and reduces the risk of accidental spills or exposure to the chemical.

- Opaque or UV-Blocking Containers: Acetone is sensitive to light and can degrade over time when exposed to ultraviolet (UV) rays. Choose containers that are opaque or have UV-blocking properties to minimize light exposure and maintain the chemical’s stability.

- Secondary Containment: Consider using secondary containment, such as spill trays or containment pallets, to provide an additional layer of protection in case of a spill or leak. This helps prevent the spread of the chemical and minimizes the risk of contamination.

It is important to note that using glass containers for acetone storage is generally not recommended due to the risk of breakage. However, if glass containers are used, select those made of borosilicate glass, which offers better resistance to chemicals and thermal shock.

Always follow the manufacturer’s guidelines and recommendations when selecting storage containers for acetone. Additionally, regularly inspect the containers for any signs of damage or degradation, and replace them as necessary to maintain the integrity of the storage system.

Proper Labeling

Properly labeling containers that store acetone is crucial for safety and organizational purposes. Clear and accurate labeling helps prevent confusion, ensures proper handling, and provides essential information to those who may come in contact with the chemical. Here are some guidelines for proper labeling:

- Content Identification: Clearly state that the container holds acetone. Use descriptive labels that are easily readable and understandable. This helps prevent accidental use or mixing with incompatible substances.

- Hazard Symbols: Include hazard symbols or pictograms that convey the dangers associated with acetone. These symbols can be obtained from safety standards organizations or regulatory agencies.

- Warnings and Safety Information: Display relevant warnings and safety information, such as “Flammable,” “Keep away from heat sources,” or “Use in well-ventilated areas.” Convey any necessary precautions that need to be taken when handling or storing acetone.

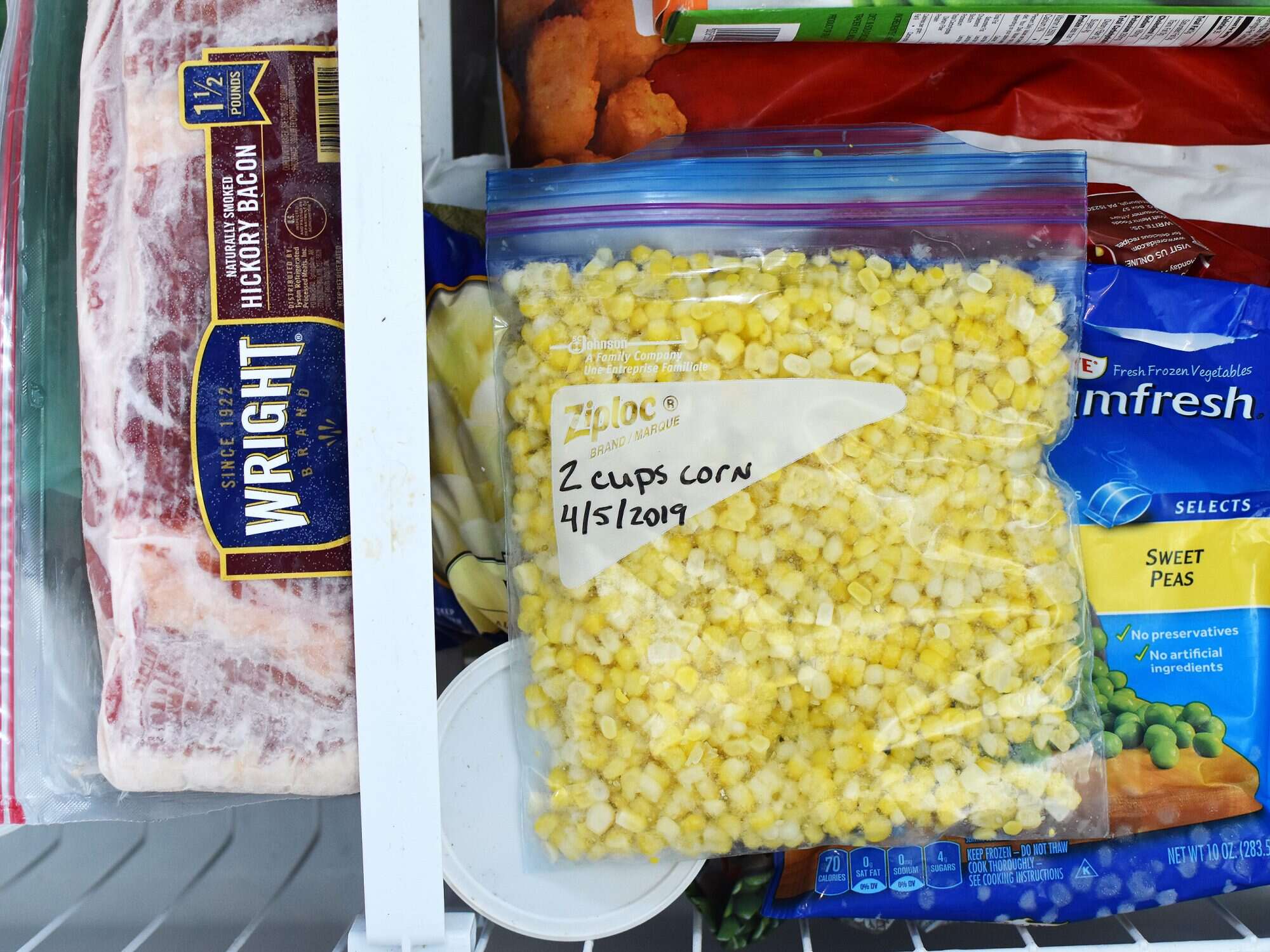

- Date of Storage: It is also helpful to indicate the date of storage on the label. This ensures that older containers are used first, reducing the chances of acetone degradation or expiration.

- Emergency Contact Information: Include emergency contact numbers, such as poison control or local emergency services, on the label. This information should be readily accessible in case of spills, accidents, or exposure.

Use durable labels that can withstand the storage conditions and won’t easily fade or peel off. Consider using waterproof or chemical-resistant labels for added durability.

Proper labeling should be applied to both the primary storage container and any secondary containment, such as spill trays or pallets. This ensures that the contents and associated hazards are clearly communicated, even if the container is placed within a larger containment system.

Regularly inspect the labels for any wear or damage, and replace them as needed to maintain the clarity and legibility of the information.

Following these labeling guidelines ensures that anyone who comes in contact with the acetone containers can quickly and accurately identify the chemical, understand its hazards, and take the necessary precautions for safe handling and storage.

Read more: How To Store Store-Bought Bread

Suitable Storage Location

Choosing a suitable storage location for acetone is crucial to minimize risks and ensure the safety of individuals and the surrounding environment. Here are some considerations when determining the ideal storage location:

- Ventilation: Acetone should be stored in a well-ventilated area. Ensure that the storage space has adequate airflow to prevent the accumulation of acetone vapors, which can be hazardous if inhaled.

- Temperature: Acetone should be stored in a cool area, away from direct sunlight or sources of heat. Extreme temperatures can negatively affect the stability of acetone and increase the risk of vaporization or degradation.

- Avoidance of Ignition Sources: To minimize the risk of fire or explosion, ensure that the storage location is free from open flames, sparks, or sources of heat. Store acetone away from electrical equipment, appliances, or pilot lights.

- Incompatible Materials: Acetone should be stored away from incompatible substances, such as oxidizers, strong acids, or bases. Chemical reactions or reactions caused by spills can lead to dangerous situations or the release of toxic gases.

- No Smoking Policy: Prohibit smoking in the storage area and enforce a strict no-smoking policy. Smoking near acetone can ignite the flammable vapors present in the area.

- Secure Storage: Store acetone in secure cabinets or storage racks that prevent accidental tipping or breakage. This helps to minimize the risk of spills or leaks and ensures that the containers are safely stored.

Remember to keep the storage area clean and free from clutter. This reduces the risk of accidental spills or contamination and allows for easier inspection and maintenance of the storage area.

It is also important to properly segregate and separate acetone storage from other chemicals or hazardous materials. Use appropriate barriers or partitions to ensure that incompatible substances are stored separately, minimizing the risk of accidental mixing or reactions.

Regularly inspect the storage area for any signs of leaks, spills, or damage to containers. Promptly clean up any spills or leaks using proper procedures and equipment.

By carefully selecting a suitable storage location and adhering to these guidelines, you can ensure the safe and proper storage of acetone, reducing the risks associated with its handling and storage.

Store acetone in a cool, dry, well-ventilated area away from heat, sparks, and open flame. Keep it tightly sealed in its original container and away from incompatible materials.

Temperature Considerations

Proper temperature control is essential when storing acetone to ensure its stability and prevent potential hazards. Acetone should be stored within a specific temperature range to maintain its integrity and reduce the risk of fire, evaporation, or degradation. Here are some temperature considerations to keep in mind:

- Recommended Storage Temperature: The ideal storage temperature for acetone is between 15 to 25 degrees Celsius (59 to 77 degrees Fahrenheit). Storing acetone within this range helps maintain its chemical properties and stability.

- Avoid Extreme Temperatures: Acetone should be kept away from extreme heat or cold. High temperatures can increase the volatility of acetone, increasing the risk of vaporization and potential fire hazards. Low temperatures can cause acetone to solidify or crystallize, rendering it less usable.

- Protection from Direct Sunlight: Direct exposure to sunlight can affect the stability of acetone. It is important to store acetone in a well-shaded area or in opaque containers to minimize light exposure and prevent any adverse effects on the chemical’s composition.

- Temperature Monitoring: Installing temperature monitoring devices, such as thermometers or data loggers, in the storage area can provide real-time information on temperature fluctuations. Regularly monitor and record the temperature to ensure it remains within the recommended range.

- Emergency Temperature Controls: In case of a temperature-related emergency, such as a rapid increase in temperature or a fire, ensure that appropriate fire suppression and temperature control systems, such as sprinklers or ventilation, are in place to mitigate the situation.

It is important to note that changes in temperature can cause pressure buildup within sealed containers, which may lead to container failure or rupture. Ensure that containers are properly vented or designed to handle any pressure changes.

Always store acetone in a dedicated storage area away from heat sources, open flames, direct sunlight, and incompatible substances. Regularly inspect the storage area and containers for any signs of temperature-related issues, leaks, or damage.

By understanding and controlling the temperature conditions, you can maintain the stability and safety of acetone during storage, ensuring its usability for its intended purposes.

Ventilation Requirements

Proper ventilation is essential when storing acetone to ensure a safe and healthy environment. Adequate ventilation helps to minimize the build-up of acetone vapors, reducing the risk of inhalation and potential health hazards. Here are some ventilation requirements to consider:

- Natural Ventilation: Utilize natural ventilation by opening windows, doors, or vents to allow fresh air to circulate within the storage area. This helps to dissipate any acetone vapors that may be present.

- Mechanical Ventilation: In areas where natural ventilation is insufficient, consider installing mechanical ventilation systems such as exhaust fans or ventilation ducts. These systems help to remove and replace the air within the storage area, maintaining a safe and well-ventilated environment.

- Ventilation Rate: Ensure that the ventilation rate is adequate based on the size of the storage area and the quantity of acetone being stored. The specific ventilation requirements may vary depending on local regulations, so consult applicable guidelines or authorities for guidance on the necessary ventilation rate.

- Avoid Confined Spaces: Never store acetone in confined spaces with limited airflow, such as small rooms or cabinets without proper ventilation. This can lead to the accumulation of acetone vapors and increase the risk of exposure.

- Hazardous Environment Monitoring: Consider installing gas monitors or detectors to continuously monitor the acetone vapor concentration in the storage area. These devices can provide real-time information and trigger alarm systems if the vapor concentration exceeds acceptable limits.

It’s important to note that ventilation serves two purposes when storing acetone: it helps to remove vapors and maintain a safe environment, and it also aids in preventing the build-up of flammable vapors that could potentially ignite in the presence of an ignition source.

Regularly inspect the ventilation systems to ensure they are functioning properly. Clean or replace filters as necessary to maintain optimal airflow and prevent any blockages.

By following proper ventilation requirements, you can effectively control the concentration of acetone vapors in the storage area, ensuring the safety of individuals working in the vicinity and reducing the risk of potential health hazards.

Handling and Transfer Techniques

Proper handling and transfer techniques are essential to ensure the safe and efficient storage of acetone. By following these guidelines, you can minimize the risk of spills, exposures, and accidents. Here are some key considerations:

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety goggles, gloves, and a lab coat or protective clothing, when handling acetone. This protects you from potential contact with the chemical and reduces the risk of skin irritation or chemical burns.

- Secure Containers: Ensure that the storage containers are properly sealed and secure to prevent any leaks or spills. Use containers with tight-fitting lids or caps, and avoid overfilling them to allow for expansion and prevent accidental spills.

- Use Transfer Tools: When transferring acetone from one container to another, use appropriate tools such as a funnel or a transfer pump. This helps to minimize the risk of spills and allows for controlled and precise transfer.

- Stable Work Surface: Always work on a stable surface, such as a sturdy table or countertop. This reduces the chances of accidental tipping or knocking over of containers during the handling process.

- Spill Containment: Place absorbent materials, such as spill mats or absorbent pads, around the area where acetone is being handled or transferred. These materials can help contain and absorb spills, minimizing the spread of the chemical and making cleanup easier.

- Proper Cleaning: In the event of a spill, promptly clean it up using appropriate spill cleanup procedures. Use absorbent materials specifically designed for chemical spills and follow the necessary safety precautions to prevent contact with the chemical.

- No Eating or Drinking: Avoid eating, drinking, or smoking in the storage or handling area to prevent accidental ingestion of acetone. Keep food and beverages away from the storage area to prevent contamination.

Proper handling and transfer techniques are crucial to avoid accidental exposures, protect yourself and others, and maintain a safe working environment. Remember to always follow the recommended procedures and use caution when working with acetone.

Read more: How To Store Basil From Store

Emergency Response Measures

Despite taking all necessary precautions, emergencies can still occur when handling and storing acetone. It is essential to have a well-planned emergency response strategy in place to protect yourself, others, and the environment. Here are some key measures to consider:

- Spill and Leak Control: In the event of a spill or leak, immediately contain the area to prevent further spread. Use appropriate absorbent materials to soak up the acetone and prevent it from reaching drains or bodies of water. Follow proper disposal procedures for the used absorbents.

- Fire Safety: If a fire occurs, evacuate the area immediately and activate the nearest fire alarm. Call emergency services and follow established fire safety procedures. Use appropriate fire extinguishing methods, such as carbon dioxide (CO2) or dry chemical extinguishers, specifically labeled for use on flammable liquid fires.

- Emergency Communication: Establish a clear system for communicating emergencies. Make sure all personnel working with acetone are aware of emergency protocols and know how to contact emergency services, such as the fire department or poison control center, if needed.

- First Aid: In the case of accidental exposure to acetone, seek medical attention immediately. Rinse affected areas with plenty of water and remove contaminated clothing if safe to do so. Follow appropriate first aid measures and keep safety data sheets readily accessible for medical professionals.

- Evacuation Plan: Develop and practice an evacuation plan specific to your storage area. Ensure that all personnel are familiar with escape routes, assembly points, and emergency exits. Regularly conduct drills to ensure efficient evacuation in case of an emergency.

- Emergency Contacts: Keep a list of emergency contact numbers readily available, including poison control, local emergency services, and the nearest hospital. Make sure all employees are aware of these contact details and can access them easily in case of an emergency.

Regularly review and update your emergency response measures to account for changes in personnel, equipment, or storage procedures. Provide appropriate training to all employees, ensuring they are knowledgeable about emergency protocols and procedures.

Remember, the safety of individuals and the environment should always be the top priority in any emergency situation. By being prepared and taking prompt and appropriate actions, you can mitigate the risks associated with acetone and ensure a safer working environment.

Disposal Guidelines

Proper disposal of acetone is crucial to protect the environment and comply with local regulations. Acetone is considered a hazardous waste and should not be poured down the drain or disposed of improperly. Here are some important guidelines to follow when disposing of acetone:

- Consult Local Regulations: Check with local regulations and authorities to understand the specific disposal requirements for acetone in your area. Different regions may have different guidelines and restrictions.

- Recycling Options: Explore opportunities for recycling acetone. Some recycling facilities accept certain types of chemicals for reclamation and reuse. Contact waste management companies or recycling centers to inquire about their policies.

- Chemical Treatment: In some cases, it may be possible to chemically treat acetone to render it non-hazardous or less harmful. However, this process should only be conducted by professionals and in compliance with applicable regulations.

- Hazardous Waste Disposal: If recycling or treatment options are not available, dispose of acetone as hazardous waste. Contact licensed hazardous waste disposal companies or local authorities for guidance on proper disposal methods and designated collection sites.

- Container Preparation: Ensure that all acetone containers are completely empty and free of any residue before disposal. Follow appropriate cleaning procedures and eliminate any potential hazards.

- Labeling and Documentation: Clearly label the containers as hazardous waste and include any required information, such as the type of waste and storage duration. Maintain proper documentation and records of disposal activities as required by local regulations.

- Community Collection Events: Check if there are local community collection events or programs that accept hazardous waste. These events provide an opportunity to dispose of acetone and other hazardous materials in a safe and controlled manner.

Remember, improper disposal of acetone can have harmful effects on the environment and human health. Always take the necessary steps to ensure that acetone is disposed of responsibly and in accordance with applicable regulations.

If you are unsure about the specific disposal guidelines in your area, seek guidance from environmental authorities, waste management professionals, or local government agencies to ensure proper and legal disposal of acetone.

Conclusion

Proper storage of acetone is essential to ensure safety and prevent accidents in various settings, including industrial applications, laboratories, and households. By following the guidelines and practices outlined in this article, you can minimize the risks associated with storing acetone and create a safer environment for everyone involved.

Starting with proper safety precautions, such as wearing personal protective equipment (PPE) and working in well-ventilated areas, is crucial. Selecting suitable storage containers, labeling them accurately, and choosing an appropriate storage location are also key considerations to ensure the integrity and stability of acetone.

Temperature control and proper ventilation play key roles in maintaining the quality and safety of acetone. Paying attention to temperature considerations and ensuring adequate ventilation can prevent the build-up of flammable vapors and protect against potential hazards.

Handling and transferring acetone should be done carefully, using proper tools and techniques to minimize the risk of spills and exposures. In the event of emergencies, having a well-designed emergency response plan, including spill control, fire safety measures, and proper communication protocols, is crucial to minimize harm and ensure a swift and effective response.

Lastly, disposing of acetone properly is important to protect the environment. Adhering to local regulations, considering recycling or chemical treatment options, and utilizing designated hazardous waste disposal methods can prevent contamination and negative environmental impacts.

By following these guidelines and best practices for storing acetone, you can create a safer working environment, reduce the risk of accidents, and protect both yourself and the surrounding environment. Prioritizing safety and responsible handling of acetone not only prevents harm, but also promotes good stewardship of the chemical and the overall well-being of those involved.

Frequently Asked Questions about How To Store Acetone

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Store Acetone”