Articles

What Does An HVAC Actuator Do

Modified: December 7, 2023

Learn about the role of HVAC actuator in regulating temperature and airflow. Access informative articles on how actuators function and their importance in HVAC systems.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When it comes to managing the temperature and air flow in our homes or commercial buildings, HVAC systems play a crucial role. Within these systems, HVAC actuators serve as the unsung heroes, responsible for controlling and regulating the various components that make up the heating, ventilation, and air conditioning functions.

The term HVAC actuator may sound unfamiliar to some, but it refers to a critical component that helps ensure our comfort and well-being. In this article, we will delve into the world of HVAC actuators, exploring their definition, functions, types, how they work, their importance in HVAC systems, and common issues and troubleshooting methods.

So, if you’ve ever wondered about the inner workings of your HVAC system or have been in need of a solution to an HVAC actuator problem, read on to discover everything you need to know about HVAC actuators.

Key Takeaways:

- HVAC actuators are like conductors of an orchestra, directing the components of HVAC systems to create a harmonious indoor environment by controlling dampers, valves, fan speed, and more.

- HVAC actuators are essential for precise control, energy efficiency, zone control, system balancing, improved air quality, and overall optimal performance within HVAC systems.

Read more: What Does A Door Lock Actuator Do

Definition of HVAC Actuator

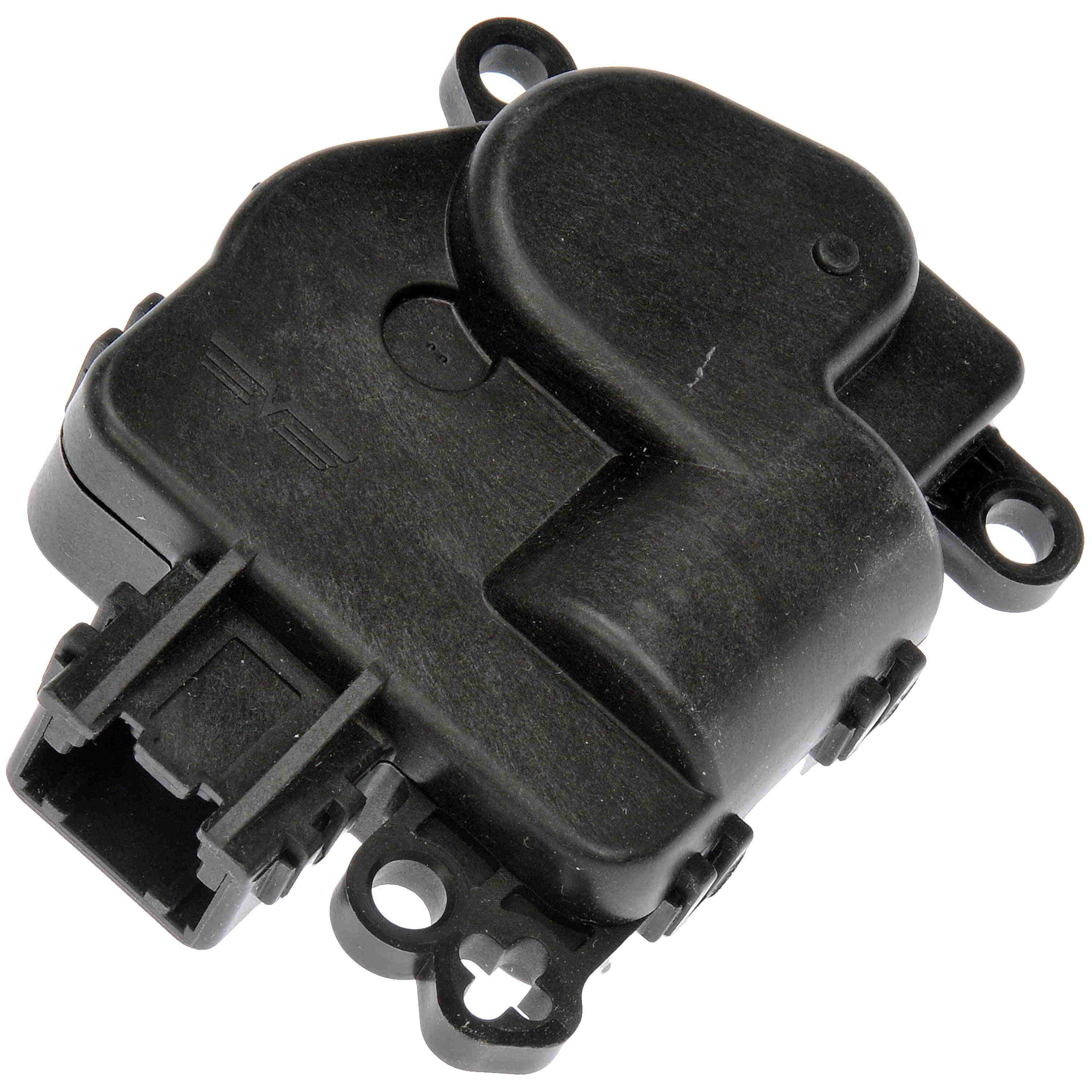

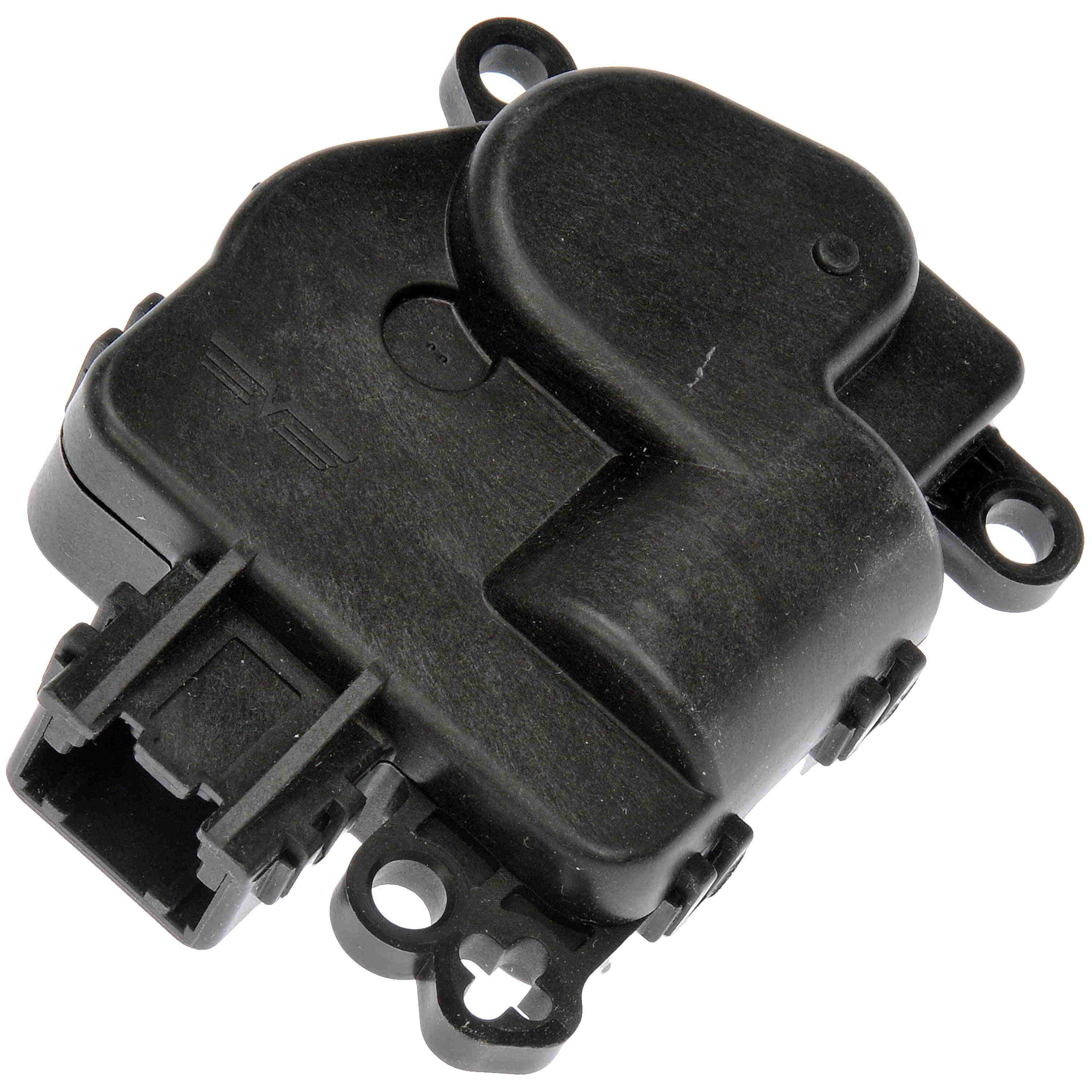

An HVAC actuator is a mechanical or electrical device that is responsible for controlling the operation of various components within an HVAC system. It acts as a “middleman” between the HVAC system controls and the components, allowing for the precise adjustment of temperature, air flow, and other parameters.

Think of an HVAC actuator as the conductor of an orchestra, directing the actions of the different instruments (components) to create a harmonious symphony (comfortable indoor environment). Without the actuator, the HVAC system would lack the ability to regulate and modulate its functions effectively.

Actuators are designed to receive signals from the HVAC system’s control unit or thermostat and then initiate the appropriate actions by moving mechanical parts or adjusting electrical settings. They are responsible for opening and closing dampers, adjusting valve positions, controlling fan speed, and modulating the operation of other system components.

In simpler terms, an HVAC actuator interprets the “commands” from the system controls and carries out the necessary actions to maintain the desired indoor air conditions. They are essential for achieving energy efficiency, occupant comfort, and optimal system performance.

It’s important to note that HVAC actuators are highly adaptable and can be found in a wide range of applications, including residential, commercial, and industrial HVAC systems. They may vary in size, configuration, and technologies used, but their fundamental purpose remains the same: to control and regulate HVAC system components.

Functions of HVAC Actuator

HVAC actuators perform a variety of essential functions within an HVAC system, all aimed at ensuring efficient and precise control of temperature, air flow, and other parameters. Let’s explore some of the primary functions of HVAC actuators:

- Damper Control: One of the key functions of an HVAC actuator is to control dampers. Dampers are movable plates or blades within the ductwork that regulate the flow of air. Actuators are responsible for opening and closing dampers to control the amount of air entering different zones or rooms. By adjusting damper positions, HVAC actuators help maintain the desired temperature levels and distribute air evenly throughout the building.

- Valve Control: HVAC actuators also play a crucial role in controlling valves within the HVAC system. Valves are responsible for regulating the flow of hot or cold water, refrigerant, or other fluids in heating and cooling systems. Actuators can open and close valves, allowing for precise control of fluid flow and temperature modulation.

- Fan Speed Control: Another important function of HVAC actuators is controlling fan speed. HVAC systems often include fans that circulate air throughout the building. By adjusting the speed of these fans, actuators can regulate the volume of air being delivered to different areas, ensuring optimal comfort and efficiency.

- Zone Control: HVAC actuators are instrumental in achieving zone control within a building. With the help of multiple actuators, each controlling different dampers and valves, the HVAC system can maintain different temperature settings in various zones or rooms. This allows for personalized comfort and energy savings by only conditioning occupied areas.

- Temperature and Humidity Control: Actuators are responsible for precisely maintaining the desired temperature and humidity levels in a building. They work in conjunction with sensors and thermostats to receive and interpret temperature and humidity signals, then initiate the necessary actions to control heating and cooling components accordingly.

By performing these functions, HVAC actuators allow for precise control, energy efficiency, occupant comfort, and optimal performance of HVAC systems. They are crucial components that work behind the scenes to ensure our indoor environments are comfortable and conducive to our needs.

Types of HVAC Actuators

HVAC actuators come in various types, each designed to suit specific control requirements and system configurations. Let’s explore some of the common types of HVAC actuators:

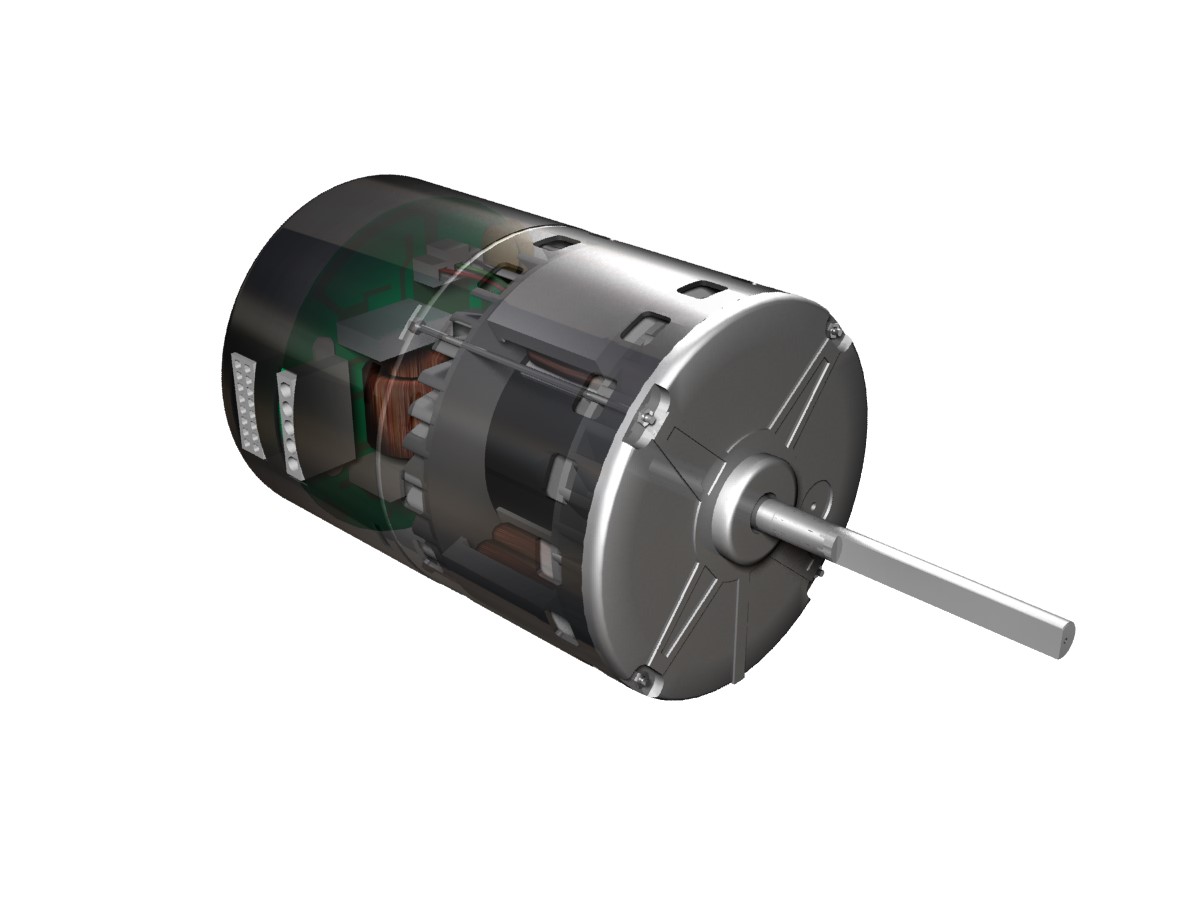

- Electric Actuators: Electric actuators are one of the most widely used types. They utilize electric power to drive the motion of mechanical components, such as dampers and valves. Electric actuators are known for their precise control and quick response, making them suitable for applications that require high accuracy and fast adjustments.

- Pneumatic Actuators: Pneumatic actuators rely on compressed air to create the necessary mechanical movement. They are commonly used in HVAC systems that already have a compressed air supply. Pneumatic actuators are valued for their simplicity, reliability, and cost-effectiveness in controlling dampers, valves, and other components.

- Hydraulic Actuators: Hydraulic actuators use hydraulic fluid to transfer and control mechanical force. They are typically used in larger HVAC applications that require high force output, such as in industrial settings. Hydraulic actuators excel in providing strong and precise motion control.

- Thermal Actuators: Thermal actuators utilize thermal expansion properties to control movement. They consist of a wax or liquid-filled chamber that expands or contracts with temperature changes, causing the actuator to move. Thermal actuators are commonly used in heating systems for zone control and temperature regulation.

- Direct-Coupled Actuators: Direct-coupled actuators are designed to be connected directly to the moving components they control, such as dampers and valves. They offer a simplified installation process and provide a direct and reliable mechanical connection between the actuator and the component.

It’s worth noting that these types of HVAC actuators may also come in different sizes, operating voltages, and control methods (e.g., on/off or proportional control). The choice of the appropriate type depends on factors such as system requirements, control strategy, available resources, and budget.

Overall, the different types of HVAC actuators offer flexibility and versatility, enabling system designers to select the most suitable option based on the specific needs of each HVAC application.

A HVAC actuator is responsible for controlling the flow and temperature of air in your vehicle’s heating, ventilation, and air conditioning system. If you notice inconsistent airflow or temperature, it may be a sign that the actuator needs to be checked or replaced.

How HVAC Actuators Work

HVAC actuators may have different designs and technologies, but they all follow a similar operating principle. Let’s take a closer look at how HVAC actuators work:

- Receiving Input Signals: HVAC actuators receive input signals from the HVAC system’s control unit or thermostat. These signals indicate the desired temperature, airflow, or other parameters that need to be maintained.

- Interpreting the Signals: The actuator interprets the input signals and determines the necessary actions to achieve the desired settings. This may involve opening or closing dampers, adjusting valve positions, modulating fan speed, or a combination of actions.

- Generating Mechanical or Electrical Movement: Depending on the type of actuator, it generates a mechanical or electrical movement to perform the required actions. Electric actuators use motors or solenoids to drive mechanical components, while pneumatic actuators use compressed air or gas pressure to create motion. Hydraulic actuators use hydraulic fluid for force transmission, and thermal actuators use thermal expansion properties to initiate movement.

- Controlling System Components: HVAC actuators control various components within the HVAC system. For example, they can open or close dampers to regulate air intake or adjust valve positions to control fluid flow. By performing these actions, the actuators maintain the desired temperature, airflow, or other parameters.

- Feedback and Sensing: To ensure accurate control, many HVAC actuators incorporate feedback mechanisms and sensing capabilities. They use sensors to monitor the actual position, temperature, or other relevant parameters and provide feedback to the control system. This allows for continuous adjustment and correction based on the actual conditions.

- Communication and Integration: In advanced HVAC systems, actuators often have communication capabilities, allowing for integration with building automation systems or other control networks. This enables centralized monitoring, control, and coordination of the entire HVAC system.

Overall, HVAC actuators act as the crucial link between the HVAC system controls and the various components that regulate temperature, airflow, and other parameters. By interpreting input signals, generating movement, and controlling system components, they work to maintain a comfortable and efficient indoor environment.

Read more: What Does HVAC Do?

Importance of HVAC Actuators in HVAC Systems

HVAC actuators play a significant role in the proper functioning and efficiency of HVAC systems. Let’s explore the importance of HVAC actuators in more detail:

- Precise Control: HVAC actuators enable precise control over the various components within the HVAC system, such as dampers, valves, and fans. This level of control allows for accurate adjustment of temperature, air flow, and other parameters, ensuring optimal comfort and energy efficiency.

- Energy Efficiency: By effectively regulating the operation of HVAC system components, actuators contribute to energy efficiency. They help reduce energy consumption by ensuring that heating, cooling, and ventilation are only provided when and where needed. This leads to energy savings and lower utility bills.

- Zone Control: HVAC actuators are essential for implementing zone control within a building. They allow for the independent regulation of temperature and airflow in different zones or rooms. This enables occupants to personalize their comfort settings and further enhances energy efficiency by conditioning only occupied spaces.

- System Balancing: Actuators assist in system balancing by properly adjusting dampers and valves to ensure balanced air distribution and refrigerant flow. This helps maintain uniform temperature and comfort throughout the building and avoids issues such as hot and cold spots.

- Improved Air Quality: HVAC actuators contribute to improved indoor air quality. By controlling dampers and airflow, they ensure proper ventilation and filtration, reducing the presence of pollutants, allergens, and odors in the air. This creates a healthier and more comfortable indoor environment.

- Integration and Automation: Modern HVAC systems often rely on integration and automation for optimal performance. HVAC actuators with communication capabilities can seamlessly integrate into building automation systems, allowing for centralized control, monitoring, and coordination of the entire HVAC system. This simplifies operation and maintenance and enhances overall system efficiency.

- Enhanced System Performance: The proper functioning of HVAC actuators is crucial for achieving optimal system performance. Actuators that are well-maintained and calibrated ensure the accurate response and operation of heating, cooling, and ventilation components. This results in a reliable and effective HVAC system.

In summary, HVAC actuators are vital components in HVAC systems. They provide precise control, energy efficiency, zone control, system balancing, improved air quality, integration, and automation, as well as enhance overall system performance. Without HVAC actuators, HVAC systems would lack the ability to efficiently regulate temperature, airflow, and other parameters, compromising comfort, energy savings, and indoor air quality.

Common Issues and Troubleshooting of HVAC Actuators

While HVAC actuators are essential for the proper functioning of HVAC systems, they can experience issues from time to time. Understanding common issues and troubleshooting methods can help identify and resolve problems efficiently. Here are some of the common issues with HVAC actuators and possible solutions:

- Faulty Actuator Motor: A faulty actuator motor can result in the actuator not responding or moving correctly. In this case, the motor may need to be replaced or repaired by a professional technician.

- Stuck or Jammed Actuator: If the actuator gets stuck or jammed in a specific position, it can affect the proper functioning of the HVAC system. Try manually loosening any obstructions or debris around the actuator and ensuring that it moves freely. If the issue persists, it may require professional inspection and repair.

- Actuator Calibration Issues: Calibration problems can lead to inaccurate positioning or control of the HVAC system components. Consult the manufacturer’s instructions to recalibrate the actuator properly. If the issue persists, a technician may need to assess and adjust the calibration settings.

- Electrical or Wiring Problems: Electrical or wiring issues can cause the actuator to malfunction or not receive proper signals. Check for loose connections, damaged wiring, or faulty electrical components. Repair or replace any damaged parts, ensuring proper electrical connections to resolve the issue.

- Incorrect Actuator Sizing: If an actuator is undersized or oversized for the application, it can affect its performance and reliability. Verify that the actuator is the correct size and capacity based on the HVAC system’s requirements. If necessary, consult with a professional to determine the appropriate actuator size for the specific application.

- Sensor or Control System Malfunction: Faulty sensors or control system components can result in incorrect signals being sent to the actuator, leading to improper operation. Check the sensors and control system for any issues, such as loose connections or damaged components. Repair or replace any faulty parts to ensure proper communication with the actuator.

- Dirt or Debris Build-Up: Accumulation of dirt, dust, or debris around the actuator can hinder its movement and cause operational problems. Regularly inspect and clean the actuator and its surrounding area to prevent build-up and ensure smooth operation.

It is important to note that HVAC actuator issues can vary depending on the specific type, model, and application. If troubleshooting steps are unsuccessful or if you are unsure about how to resolve the issue, it is recommended to seek assistance from a qualified HVAC technician who can diagnose and address the problem effectively.

By identifying and resolving common issues with HVAC actuators promptly, you can ensure the continuous and reliable operation of your HVAC system, maintaining optimal comfort and energy efficiency.

Conclusion

HVAC actuators are the unsung heroes of HVAC systems, playing a crucial role in regulating temperature, airflow, and other parameters. These mechanical or electrical devices work behind the scenes, ensuring our comfort, energy efficiency, and indoor air quality.

We started by understanding the definition of HVAC actuators and their functions within the system. We explored the different types of actuators available, including electric, pneumatic, hydraulic, thermal, and direct-coupled actuators, each with its own advantages and applications.

We then discussed how HVAC actuators work, from receiving input signals to generating mechanical or electrical movement and controlling system components. Through their precise control and integration capabilities, actuators contribute to maintaining consistent comfort, energy savings, and optimal performance within HVAC systems.

The importance of HVAC actuators cannot be overstated. They enable precise control, zone control, energy efficiency, system balancing, improved air quality, and enhanced system performance. By properly maintaining and troubleshooting common issues related to actuators, we ensure their continued and reliable operation.

In conclusion, HVAC actuators are integral components of HVAC systems, working tirelessly to ensure our comfort and well-being. Whether it’s adjusting dampers, regulating valves, or controlling fan speeds, these small yet powerful devices are the key to achieving optimal indoor environments.

As technology continues to evolve, we can expect advancements in HVAC actuators, enabling even smarter and more efficient control over our heating, ventilation, and air conditioning systems. So, the next time you enjoy a comfortable indoor environment, take a moment to appreciate the role that HVAC actuators play in making it all possible.

Frequently Asked Questions about What Does An HVAC Actuator Do

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Does An HVAC Actuator Do”