Articles

What Does A Vacuum Pump Do In HVAC

Modified: February 23, 2024

Learn about the role of a vacuum pump in HVAC systems in our insightful articles. Discover how this crucial component ensures efficient and effective operations.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When it comes to HVAC (Heating, Ventilation, and Air Conditioning) systems, there are various components that work together to ensure optimal performance. One crucial component that plays a vital role in maintaining efficient HVAC operations is the vacuum pump.

In this article, we will delve into the basics of HVAC systems and explore the significance of vacuum pumps in ensuring their smooth functioning. We will also discuss the operating principles of vacuum pumps, their applications in HVAC systems, and the importance of proper maintenance.

Understanding the role of a vacuum pump in HVAC is essential for homeowners, technicians, and anyone seeking to maximize the efficiency and longevity of their HVAC systems. So, let’s dive in and discover the fascinating world of vacuum pumps in HVAC systems.

Key Takeaways:

- Vacuum pumps are essential for HVAC systems, removing air and moisture to optimize performance, prevent damage, and ensure efficient heating and cooling.

- Proper maintenance, including regular inspection, cleanliness, and oil maintenance, is crucial for maximizing the lifespan and effectiveness of vacuum pumps in HVAC systems.

Read more: What Does HVAC Do?

Basics of HVAC

HVAC stands for Heating, Ventilation, and Air Conditioning. It refers to the technology and systems used to control indoor environmental conditions, including temperature, humidity, and air quality. HVAC systems are found in residential, commercial, and industrial buildings, providing comfort and maintaining a healthy living or working environment.

The primary function of an HVAC system is to regulate the temperature, ensuring that it remains comfortable regardless of the weather conditions outside. It accomplishes this through the use of heating and cooling mechanisms. During colder months, the system utilizes a heating unit to warm the air, while in hotter months, it employs a cooling unit to cool the air. These units can be in the form of furnaces, heat pumps, or air conditioners.

Another crucial aspect of HVAC systems is ventilation. Ventilation involves the exchange of indoor and outdoor air to maintain air quality and prevent the buildup of pollutants, moisture, and odors. Proper ventilation also helps regulate humidity levels, which is important for occupant comfort and prevents the growth of mold and mildew.

Additionally, HVAC systems incorporate air filtration systems to remove dust, pollutants, and allergens from the air. These filters ensure the circulation of clean and healthy air throughout the space, promoting better indoor air quality and reducing respiratory issues.

The overall operation of an HVAC system involves a combination of different components, including ducts, thermostats, sensors, and controls. These components work together to ensure the proper distribution of conditioned air to various zones or rooms within the building.

Now that we have a basic understanding of HVAC systems, let’s explore the role of a vacuum pump in maintaining their efficiency and performance.

What is a Vacuum Pump?

A vacuum pump is a mechanical device that removes gas molecules from a sealed chamber to create a vacuum or low-pressure environment. It is an essential component in various industries, including HVAC systems.

In the context of HVAC, a vacuum pump is used to evacuate and remove unwanted air and moisture from the refrigeration circuit. It plays a crucial role in preparing the system for refrigerant charging and ensuring the system operates at peak efficiency.

Vacuum pumps work by using mechanical energy to create a partial vacuum within a chamber. This creates a pressure difference between the chamber and its surroundings, causing air and other gases to flow from areas of higher pressure to areas of lower pressure, ultimately leading to the evacuation of the chamber.

There are different types of vacuum pumps used in HVAC systems, including rotary vane pumps, diaphragm pumps, and scroll pumps. Each type operates based on different principles and offers varying levels of efficiency and performance.

Vacuum pumps used in HVAC systems are typically designed to handle the specific demands of refrigeration circuits. They are capable of creating deep vacuums, removing both air and moisture from the system to ensure its reliability and longevity.

Overall, a vacuum pump is a vital tool in HVAC systems as it helps achieve the necessary vacuum level to ensure the proper operation of refrigeration circuits. It ensures the removal of air, moisture, and any other contaminants that could hinder the system’s efficiency and performance.

Now that we understand the basics of a vacuum pump, let’s explore its importance in HVAC systems in more detail.

Importance of Vacuum Pump in HVAC Systems

A vacuum pump plays a crucial role in the proper functioning and efficiency of HVAC systems. Let’s explore the key reasons why a vacuum pump is essential in HVAC systems:

- Removing Air and Moisture: One of the primary purposes of a vacuum pump in HVAC systems is to remove air and moisture from the refrigeration circuit. Air and moisture can have detrimental effects on the system. Air causes pressure imbalance and reduces system efficiency, while moisture leads to the formation of ice, corrosion, and reduced heat transfer. A vacuum pump ensures that the system is properly evacuated, eliminating air and moisture to create a clean and efficient environment for the refrigerant to operate.

- Preventing Contamination: Vacuum pumps help prevent contamination within the HVAC system. During installation, repair, or maintenance, contaminants such as dirt, debris, and foreign particles can enter the system. These contaminants can negatively impact system performance and lead to component failure. By using a vacuum pump, technicians can thoroughly evacuate the system, removing any contaminants and ensuring a clean and properly functioning system.

- Optimizing System Performance: By removing air and moisture, a vacuum pump helps optimize the performance of HVAC systems. Air and moisture can hinder heat transfer, reduce energy efficiency, and potentially damage system components. Proper evacuation with a vacuum pump ensures that the refrigerant operates under optimal conditions, allowing the system to provide efficient cooling or heating to the desired space.

- Preventing System Damage: Air and moisture within the HVAC system can cause damage to various components such as compressors, valves, and evaporators. The presence of moisture can lead to corrosion and rust, compromising the integrity of these components. Using a vacuum pump to evacuate the system reduces the risk of damage, extends the lifespan of the equipment, and minimizes the need for costly repairs or replacements.

- Ensuring Proper Refrigerant Charging: In HVAC systems, the refrigerant must be accurately charged in order to achieve optimal performance. Overcharging or undercharging the refrigerant can lead to reduced efficiency, increased energy consumption, and system malfunctions. A vacuum pump is crucial in removing air from the system, allowing for accurate refrigerant charging. This ensures that the system operates at designed specifications, maximizing energy efficiency and overall performance.

In summary, a vacuum pump is of utmost importance in HVAC systems. It ensures the removal of air, moisture, and contaminants, thereby optimizing system performance, preventing damage, and providing efficient heating or cooling. Proper evacuation with a vacuum pump is a critical step in HVAC installation, repair, and maintenance to ensure the longevity and reliability of the system.

Now that we understand the importance of a vacuum pump, let’s explore its operating principles and how it removes air and moisture from HVAC systems.

Operating Principle of Vacuum Pump

The operating principle of a vacuum pump revolves around creating a pressure difference that allows the removal of air and other gases from a sealed chamber, creating a vacuum or low-pressure environment. Understanding the operating principle is essential in grasping how a vacuum pump effectively removes air and moisture from HVAC systems.

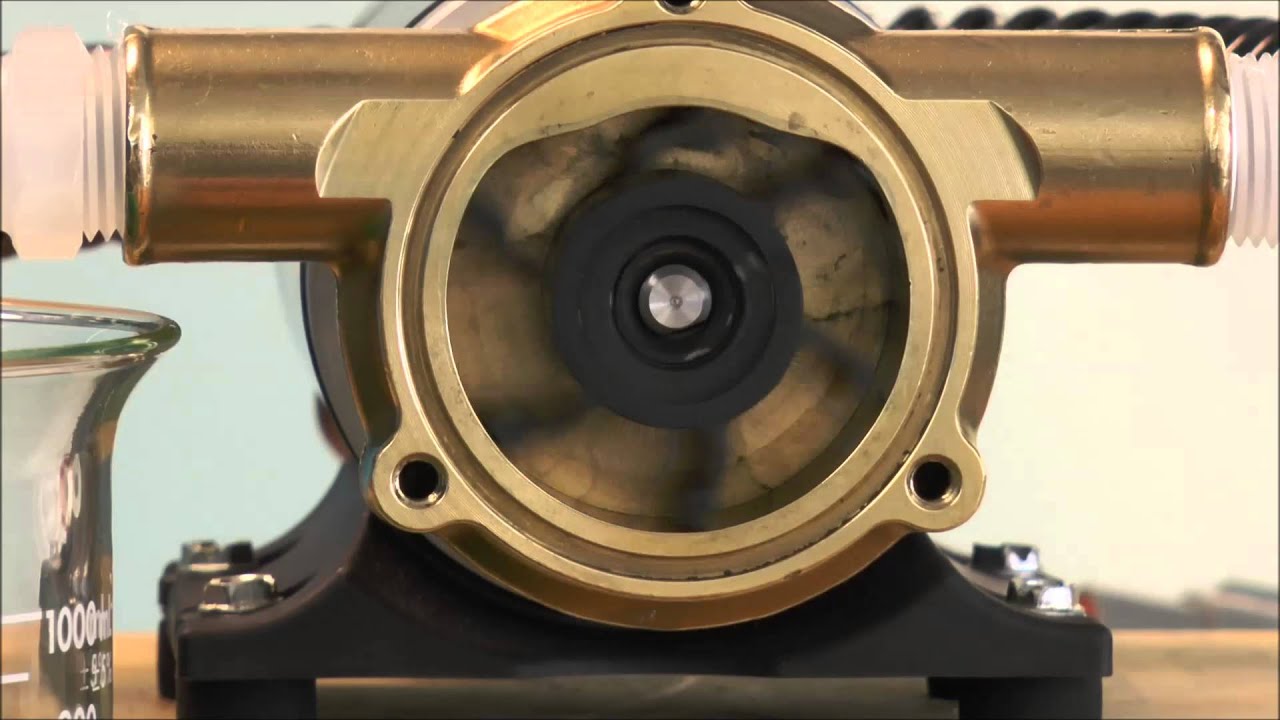

Vacuum pumps utilize various mechanisms to achieve this pressure difference and create a vacuum. The most common types of vacuum pumps used in HVAC systems include rotary vane pumps, diaphragm pumps, and scroll pumps.

In a rotary vane pump, the operating principle involves the use of rotating vanes within a cylindrical chamber. As the vanes spin, they come into contact with the chamber walls, creating discrete spaces or chambers. These chambers progressively increase in size as the vanes rotate, drawing in gas molecules from the inlet and trapping them within the chambers. As the vanes continue to rotate, the trapped gas is carried to the outlet of the pump, and the process repeats, creating a continuous flow of gas from the chamber to the outlet. This mechanism creates the pressure difference required to create a vacuum.

Diaphragm pumps operate by using a flexible diaphragm that moves up and down, creating alternating high and low-pressure regions within the pump chamber. As the diaphragm moves downward, it creates a low-pressure region, drawing in gas molecules through the inlet. When the diaphragm moves upward, it compresses the gas, increasing the pressure and expelling it through the outlet. This cyclic process continues, providing a continuous flow to maintain the vacuum level.

Scroll pumps utilize two interleaved spirals or scrolls to create the pressure difference. The outer scroll remains stationary, while the inner scroll moves in an eccentric motion. As the inner scroll moves, it traps and compresses the gas, forcing it towards the center of the scrolls. The compressed gas is then expelled through the center outlet, while new gas molecules enter from the outer edges of the scrolls, repeating the process to create a vacuum.

Regardless of the specific mechanism, all vacuum pumps work based on the principle of moving gas molecules from an area of higher pressure to an area of lower pressure. By repeatedly trapping and compressing the gas, they create a pressure differential that enables the evacuation of air and moisture from the HVAC system.

Now that we have explored the operating principle of vacuum pumps, let’s dive deeper into how they effectively remove air and moisture from HVAC systems.

A vacuum pump in HVAC is used to remove air and moisture from the system to create a vacuum. This is essential for proper refrigerant charging and preventing system contamination. Regular maintenance and proper use of a vacuum pump are crucial for the efficient operation of HVAC systems.

Read more: What Does An HVAC Installer Do

How Vacuum Pump Removes Air and Moisture

A vacuum pump is a vital tool in HVAC systems for removing air and moisture from within the refrigeration circuit. Proper removal of air and moisture is essential to ensure the system’s efficiency, prevent damage, and optimize performance. Let’s delve into the process of how a vacuum pump effectively removes air and moisture from HVAC systems.

1. Evacuation Process: The first step in removing air and moisture is to connect the vacuum pump to the HVAC system’s service port. The service port allows access to the refrigeration circuit. Once connected, the vacuum pump starts to operate, creating a low-pressure environment within the system.

2. Pressure Differential: The vacuum pump creates a pressure difference between the HVAC system and the surrounding atmosphere. This pressure differential causes air and moisture in the system to flow towards the low-pressure area created by the vacuum pump.

3. Removal of Air: As the vacuum pump operates, it continuously evacuates the system, drawing air molecules from the refrigeration circuit and moving them towards the vacuum pump. The trapped air is then expelled from the system through the vacuum pump’s exhaust.

4. Elimination of Moisture: In addition to air, a vacuum pump also removes moisture from the HVAC system. Moisture within the refrigeration circuit can lead to various issues, including ice formation, corrosion, and reduced performance. The vacuum pump creates a low-pressure environment that allows the moisture to evaporate, converting it into vapor. This vapor is then expelled from the system through the vacuum pump’s exhaust, effectively eliminating the moisture from the HVAC system.

5. Continuous Evacuation: The process of removing air and moisture through the vacuum pump is an ongoing and continuous process. It requires sufficient time to achieve the desired level of evacuation. The duration of the evacuation process can vary depending on factors such as the size of the HVAC system and the amount of moisture present. Technicians typically monitor the evacuation process using manifold gauges or electronic vacuum meters to ensure the system reaches the required vacuum level.

6. Refrigerant Charging: Once the air and moisture have been effectively removed from the HVAC system, it is ready for refrigerant charging. With the vacuum pump’s assistance, the system can be accurately charged with the appropriate amount of refrigerant, ensuring optimal performance and efficiency.

By utilizing a vacuum pump and following proper evacuation procedures, HVAC systems can be prepared for refrigerant charging and operation, ensuring the removal of air and moisture. This results in improved system performance, energy efficiency, and longevity.

Now that we understand how a vacuum pump removes air and moisture from HVAC systems, let’s explore the various applications of vacuum pumps in the HVAC industry.

Applications of Vacuum Pump in HVAC

Vacuum pumps play a vital role in various applications within the HVAC industry. With their ability to create a vacuum and remove air and moisture, they are essential tools for ensuring the proper functioning and efficiency of HVAC systems. Let’s explore some of the key applications of vacuum pumps in HVAC:

- System Evacuation: One of the primary applications of vacuum pumps in HVAC is system evacuation. Before charging the refrigerant, HVAC systems need to be evacuated to remove any air or moisture present in the refrigeration circuit. Vacuum pumps efficiently remove the air and moisture, creating a clean and low-pressure environment for optimal system performance.

- Installation and Repair: During HVAC system installation or repair, vacuum pumps are used to evacuate the system before introducing refrigerant. Whether it’s a new installation or a repair that requires opening the refrigeration circuit, vacuum pumps ensure the removal of air, moisture, and contaminants, preventing performance issues and potential damage.

- Refrigerant Recovery: Vacuum pumps are also used for refrigerant recovery in HVAC systems. When systems need to be serviced or decommissioned, the refrigerant must be properly collected and recycled. Vacuum pumps facilitate the removal of refrigerant from the system, ensuring compliance with environmental regulations and promoting sustainability.

- Leak Detection: Vacuum pumps are employed in leak detection processes in HVAC systems. By creating a vacuum, any leaks in the refrigeration circuit can be identified and located. Vacuum pumps help assess the integrity of the system, allowing technicians to pinpoint and repair leaks, preventing efficiency losses and minimizing environmental impact.

- Moisture Removal: Moisture is a common contaminant in HVAC systems that can lead to various issues such as corrosion, ice formation, and reduced performance. Vacuum pumps effectively remove moisture from the refrigeration circuit, ensuring a dry system and preventing related problems.

- Brazing and Soldering: Vacuum pumps are utilized in HVAC applications that involve brazing or soldering. By creating a vacuum, they remove air from the system, preventing oxidation and ensuring strong and leak-free joints. Vacuum pumps help maintain the integrity of connections during the brazing or soldering process.

These are just a few examples of the applications of vacuum pumps in HVAC systems. Their versatility and ability to create a vacuum make them indispensable tools for technicians working with refrigeration circuits. By effectively removing air and moisture, vacuum pumps contribute to the proper operation, energy efficiency, and longevity of HVAC systems.

Now that we have explored the applications of vacuum pumps in HVAC, let’s shift our focus to the maintenance and care required to ensure the optimal performance of these essential tools.

Maintenance of Vacuum Pump

Maintaining a vacuum pump is essential to ensure its optimal performance, longevity, and reliability. Proper maintenance practices not only extend the lifespan of the vacuum pump but also enhance its efficiency and effectiveness. Let’s explore some key maintenance tips to keep vacuum pumps in top condition:

- Regular Inspection: Conduct regular visual inspections of the vacuum pump to check for any signs of wear, damage, or leaks. Inspect the seals, O-rings, hoses, and connections to ensure they are in good condition. Address any issues immediately to prevent further damage.

- Cleanliness: Keep the vacuum pump clean to prevent the accumulation of debris, dust, and contaminants. Regularly clean the exterior surfaces and ensure that no foreign particles enter the intake or exhaust ports.

- Oil Maintenance: If the vacuum pump operates with oil, check and change the oil regularly according to the manufacturer’s recommendations. Dirty or degraded oil can impact the pump’s performance, so it’s crucial to maintain clean and high-quality oil.

- Filter Replacement: If the vacuum pump has filters, ensure they are regularly cleaned or replaced. Filters help prevent contaminants from entering and damaging the pump. Clogged or dirty filters can reduce the pump’s efficiency and performance.

- Proper Storage: When the vacuum pump is not in use, store it in a clean and dry environment. Protect it from extreme temperatures, humidity, and direct sunlight. Ensure the pump is properly secured and protected from any potential damage.

- Scheduled Maintenance: Follow the manufacturer’s recommended maintenance schedule for the vacuum pump. This may include regular servicing, lubrication, and professional inspection. Adhering to the recommended maintenance intervals helps identify and address any potential issues before they become major problems.

- Operator Training: Ensure that the individuals operating the vacuum pump are properly trained. Proper training includes understanding the operating instructions, safety protocols, and maintenance procedures. Well-trained operators can use the vacuum pump correctly and reduce the risk of damage or improper use.

- Professional Service: Engage the services of a qualified technician for any major repairs or servicing of the vacuum pump. Professional technicians have the expertise and tools necessary to diagnose and address complex issues, ensuring the vacuum pump operates at its best.

By following these maintenance practices, you can significantly prolong the life of the vacuum pump, optimize its performance, and avoid costly repairs or replacements.

Remember, each vacuum pump may have specific maintenance requirements, so always refer to the manufacturer’s guidelines for the best practices for your specific model.

Now that we have covered the maintenance of vacuum pumps, let’s examine some common types of vacuum pumps used in HVAC systems.

Common Types of Vacuum Pumps Used in HVAC

Various types of vacuum pumps are used in HVAC systems to achieve the necessary level of evacuation and removal of air and moisture. Each type of pump offers its own advantages and is suitable for different applications. Let’s explore some common types of vacuum pumps used in HVAC:

- Rotary Vane Pumps: Rotary vane pumps are widely used in HVAC systems due to their reliability and efficiency. They operate using rotating vanes that create chambers, allowing the gas to be trapped and then expelled. These pumps are capable of achieving relatively high vacuums and have a compact design, making them popular for residential and small commercial HVAC applications.

- Diaphragm Pumps: Diaphragm pumps are often used for smaller HVAC systems or in applications where oil-free operation is required. They use a diaphragm to generate the pumping action, creating pressure differentials that evacuate the system. Diaphragm pumps are known for their low maintenance requirements and are less prone to oil contamination. They are also quieter compared to some other pump types.

- Scroll Pumps: Scroll pumps are gaining popularity in HVAC applications due to their high performance and reliability. These pumps use two spiral-shaped scrolls that interlock and rotate to create a vacuum. They are known for their oil-free operation and high pumping speed. Scroll pumps have a compact design, making them suitable for space-constrained HVAC systems.

- Vacuum Ejectors: Vacuum ejectors, also known as venturi pumps, utilize a pressurized fluid, such as steam or compressed air, to create suction and evacuate the system. They are often used in large-scale HVAC applications, such as industrial or commercial systems, where high suction capacities are required.

- Turbo Molecular Pumps: Turbo molecular pumps are used in specific HVAC applications that require very high vacuum levels. These pumps utilize high-speed rotating blades to generate a molecular drag, effectively evacuating the system. Turbo molecular pumps are commonly used in industries with advanced vacuum applications, such as semiconductor manufacturing.

Each type of vacuum pump has its own advantages and is selected based on the specific requirements of the HVAC system. Factors such as system size, vacuum level needed, noise level, and maintenance considerations influence the choice of vacuum pump.

It’s important to consult with HVAC professionals or manufacturers to determine the most suitable type of vacuum pump for your specific HVAC application.

Now that we have explored the common types of vacuum pumps used in HVAC, let’s wrap up our discussion.

Read more: What Does An HVAC Technician Do

Conclusion

Vacuum pumps play a crucial role in the efficient and reliable operation of HVAC systems. They are responsible for removing air and moisture from the refrigeration circuit, ensuring optimal performance and preventing potential issues. By creating a vacuum or low-pressure environment, vacuum pumps facilitate the evacuation of HVAC systems, allowing for accurate refrigerant charging and maintaining clean and efficient operation.

In this article, we have covered the basics of HVAC systems, including their function in regulating temperature, ventilation, and air quality. We explored what a vacuum pump is and its importance in HVAC systems. We learned about the operating principles of vacuum pumps and how they effectively remove air and moisture from the system.

We also discussed the various applications of vacuum pumps in the HVAC industry, such as system evacuation, refrigerant recovery, leak detection, and moisture removal. Vacuum pumps are valuable tools in HVAC installations, repairs, and maintenance processes, ensuring the system operates at peak efficiency and minimizing the risk of damage or component failure.

To ensure the optimal performance and longevity of vacuum pumps, proper maintenance is essential. Regular inspection, cleanliness, oil maintenance, and filter replacement are among the key maintenance practices. Adhering to the manufacturer’s recommended maintenance schedule and engaging professional technicians for major repairs or servicing are crucial for maximizing the lifespan and efficiency of the vacuum pump.

Lastly, we explored some common types of vacuum pumps used in HVAC systems, including rotary vane pumps, diaphragm pumps, scroll pumps, vacuum ejectors, and turbo molecular pumps. Each type offers its own advantages and is selected based on specific HVAC requirements, such as size, vacuum level, and noise considerations.

In conclusion, vacuum pumps are indispensable components in HVAC systems, ensuring proper air and moisture removal, optimizing system performance, and promoting energy efficiency. By understanding the importance of vacuum pumps, their operating principles, maintenance requirements, and applications in HVAC, homeowners and technicians can make informed decisions to keep their HVAC systems running smoothly and effectively.

So, whether you’re installing, repairing, or maintaining an HVAC system, don’t overlook the significance of a vacuum pump in ensuring its efficiency and longevity.

Frequently Asked Questions about What Does A Vacuum Pump Do In HVAC

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Does A Vacuum Pump Do In HVAC”