Articles

What Does HVAC Mean In Construction

Modified: January 6, 2024

"Discover the meaning of HVAC in construction with our informative articles. Learn how this essential system keeps buildings comfortable and efficient."

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

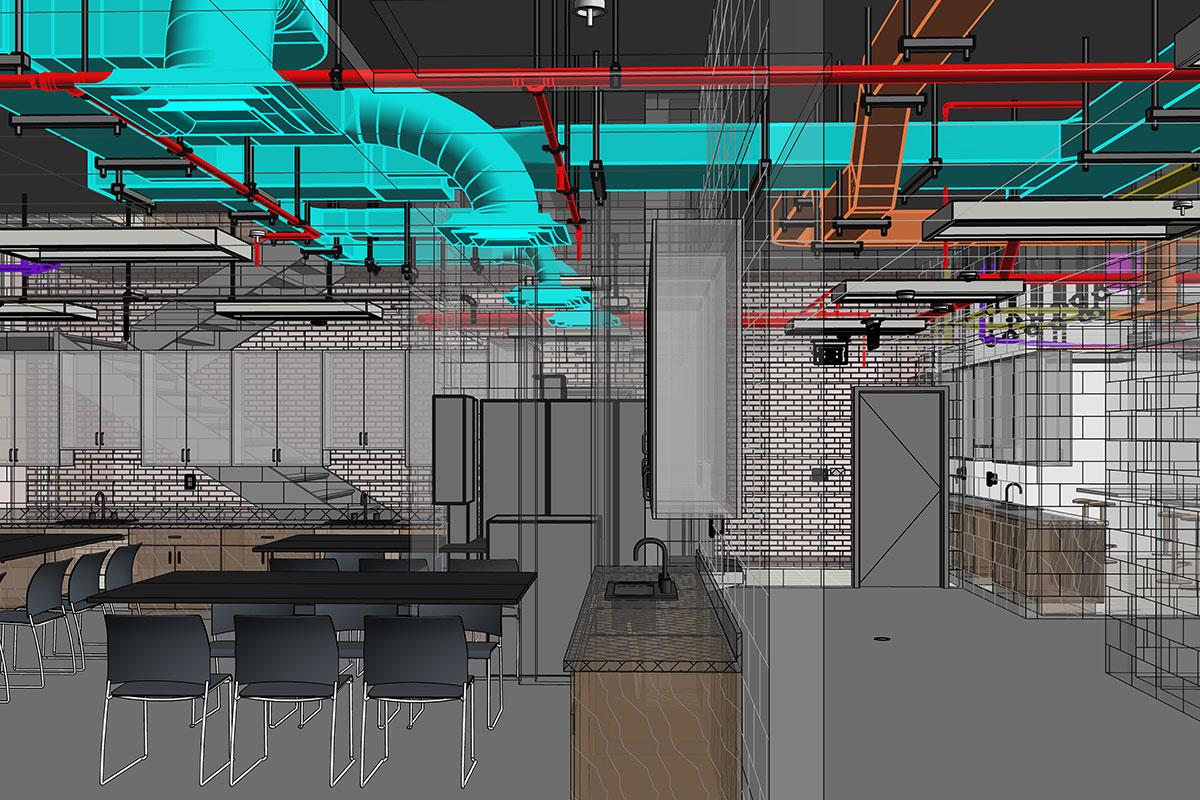

Welcome to the world of construction, where the acronym HVAC is commonly used. But what does HVAC actually mean? In the construction industry, HVAC stands for Heating, Ventilation, and Air Conditioning, and it plays a crucial role in creating comfortable and safe environments for buildings.

HVAC systems are integral to any construction project, whether it’s a residential building, commercial complex, or industrial facility. They go beyond just creating a comfortable temperature; they regulate air quality, humidity levels, and ensure proper air circulation. Understanding the importance and components of HVAC systems is essential for anyone involved in construction, whether you’re a contractor, architect, or homeowner.

In this article, we will delve into the world of HVAC in construction. We’ll explore its definition, discuss its importance, break down its components, and look at the different types of HVAC systems available. Additionally, we’ll touch on design considerations, energy efficiency, and maintenance practices to keep these systems running smoothly.

So, strap in as we embark on a journey to uncover the wonders of HVAC in the construction industry.

Key Takeaways:

- HVAC systems are essential in construction for providing comfort, maintaining air quality, and ensuring energy efficiency. Understanding their components, types, and design considerations is crucial for creating sustainable and healthy indoor environments.

- Energy efficiency is a top priority in HVAC systems, with factors such as high-efficiency equipment, zoning strategies, and smart controls playing a key role. Regular maintenance and consideration of renewable energy sources further enhance sustainability.

Read more: What Does Ecm Mean In HVAC

Definition of HVAC

HVAC, as mentioned earlier, stands for Heating, Ventilation, and Air Conditioning. It refers to the technology, systems, and equipment used to control the indoor environment of a building, including temperature, airflow, humidity, and air quality. HVAC systems are designed to provide a comfortable and healthy living or working environment by regulating these factors.

Heating: The heating component of HVAC systems is responsible for maintaining optimal temperatures during colder months. It involves the use of heating equipment such as boilers, furnaces, or heat pumps to generate heat. The heated air is then distributed throughout the building to keep it warm and comfortable.

Ventilation: Ventilation is the process of replacing stale indoor air with fresh outdoor air. It plays a vital role in maintaining indoor air quality by removing pollutants, such as carbon dioxide, odors, and moisture, and introducing clean air. Ventilation systems can consist of mechanical fans, natural airflows, or a combination of both.

Air Conditioning: The air conditioning component of HVAC systems is responsible for cooling the indoor environment during hotter months. It involves the use of cooling equipment, such as central air conditioners or heat pumps, to remove heat from the air. The cooled air is then distributed throughout the building to maintain a comfortable temperature.

Combined, these three components work together to create a comfortable, healthy, and controlled indoor environment in buildings of all types and sizes.

Now that we have a clear understanding of what HVAC entails, let’s explore why it is so important in the construction industry.

Importance of HVAC in Construction

HVAC systems play a vital role in construction projects, and their importance cannot be overstated. Here are some of the key reasons why HVAC is crucial in the construction industry:

- Comfort: One of the primary reasons for incorporating HVAC systems in buildings is to provide comfort to occupants. Whether it’s a home, office, or commercial space, maintaining optimal temperature levels is essential for the well-being and productivity of people inside. HVAC systems ensure that indoor spaces are neither too hot nor too cold, creating a comfortable environment throughout the year.

- Indoor Air Quality: HVAC systems also contribute to maintaining good indoor air quality. They help remove pollutants, allergens, and contaminants from the air, providing clean and fresh air to breathe. This is especially important for individuals with respiratory issues or allergies, as well as in spaces where occupants spend a significant amount of time, such as offices or schools.

- Moisture Control: HVAC systems regulate humidity levels, preventing excessive moisture buildup. By controlling humidity, these systems help inhibit the growth of mold, mildew, and bacteria, which can cause health issues and damage the building structure. Proper moisture control is particularly crucial in areas with high humidity or where moisture-prone activities take place, such as bathrooms or kitchens.

- Energy Efficiency: HVAC systems contribute to energy efficiency in buildings. With advancements in technology, modern HVAC systems are designed to be energy-efficient, reducing energy consumption and lowering utility costs. Energy-efficient HVAC systems not only benefit the environment but also result in long-term cost savings for property owners.

- Building Durability: Proper HVAC systems help maintain the structural integrity of buildings. By controlling temperature and humidity levels, HVAC systems contribute to preserving materials such as wood, drywall, and furniture. They minimize the risk of damage caused by extreme temperature fluctuations and excessive moisture, extending the lifespan of the building and reducing the need for costly repairs.

Overall, HVAC systems provide a multitude of benefits in the construction industry, ensuring comfort, indoor air quality, moisture control, energy efficiency, and building durability. Integrating HVAC systems into construction projects is essential for creating safe, healthy, and sustainable built environments.

Components of HVAC System

HVAC systems consist of various components working together to achieve their objectives of heating, ventilation, and air conditioning. Let’s take a closer look at the key components of an HVAC system:

- Thermostat: The thermostat serves as the control center for the HVAC system. It allows users to set and regulate the desired temperature in the building. Modern thermostats often come with programmable features, enabling users to schedule temperature adjustments throughout the day for energy efficiency.

- Furnace: The furnace is a crucial component for heating in HVAC systems. It generates heat by burning fuel (such as gas or oil) or using electric resistance. The heated air is then circulated through the ductwork to warm the indoor space.

- Air Conditioner/Heat Pump: Air conditioners and heat pumps are responsible for cooling the air in HVAC systems. They remove heat from the indoor environment and transfer it outside. Air conditioners use refrigerant and a condenser to achieve this, while heat pumps can reverse the process to provide both cooling and heating capabilities.

- Ductwork: Ductwork is a network of pipes or channels that distribute conditioned air throughout the building. It includes supply ducts that deliver heated or cooled air to various rooms and return ducts that draw the air back to the HVAC system for reconditioning.

- Vents/Registers: Vents, also known as registers, are the visible openings in walls, ceilings, or floors where conditioned air enters or exits a room. They can be adjusted to control the airflow, enabling occupants to customize the temperature in individual spaces.

- Air Filters: Air filters capture dust, dirt, and other airborne particles to ensure good indoor air quality. Filters prevent these particles from entering the HVAC system and being circulated back into the building. Regular cleaning or replacement of air filters is essential for maintaining optimal system performance.

- Evaporator Coil/Heat Exchanger: The evaporator coil, commonly located in the indoor unit, cools the air by absorbing heat from it. In heat pumps, the evaporator coil can also extract heat from the outside air for heating purposes. In contrast, the heat exchanger in a furnace or boiler transfers heat from fuel combustion to the circulating air.

- Condenser: The condenser is the outdoor unit of an air conditioner or heat pump. It releases the heat absorbed from the indoor air into the outdoor environment. The condenser also helps convert the refrigerant from a high-pressure gas to a liquid state.

- Blower Motor: The blower motor powers the fan that circulates air throughout the HVAC system. It ensures that conditioned air is distributed evenly to all areas of the building.

These are the primary components that make up an HVAC system. The proper installation, integration, and maintenance of these components are essential for the efficient and effective operation of HVAC systems in construction projects.

Heating Systems in HVAC

Heating is a fundamental component of HVAC systems, especially in regions with cold climates or during winter months. Let’s explore some of the common heating systems used in HVAC:

- Furnaces: Furnaces are the most widely used heating systems in residential and commercial buildings. They can be fueled by natural gas, oil, or propane. The furnace heats the air through combustion and then distributes it throughout the building via ductwork. Modern furnaces are highly efficient and equipped with features like variable speed blowers and programmable thermostats for improved energy efficiency.

- Boilers: Boilers use hot water or steam to provide heating. They are commonly fueled by natural gas, oil, or electricity. The heated water or steam is circulated through pipes to radiators or baseboard heaters, emitting heat into the surrounding space. Boilers are often preferred for larger buildings or homes with hydronic-based heating systems.

- Heat Pumps: Heat pumps are versatile systems that can provide both heating and cooling. They work by transferring heat from one location to another. In heating mode, a heat pump extracts heat from the outside air, even when it’s cold, and transfers it indoors. Heat pumps are energy-efficient and can provide significant cost savings, especially in moderate climates.

- Radiant Heating: Radiant heating systems involve heating objects or surfaces in the space rather than the air. This type of heating is achieved through electric radiant panels, radiant floor heating, or hydronic radiant systems. Radiant heating offers consistent warmth, reduces dust circulation, and allows for zoning, providing customized heating in specific areas.

- Solar Heating: Solar heating systems utilize the sun’s energy to provide heat. Solar collectors, typically installed on the roof, absorb the sun’s radiation and transfer the heat to a heat exchanger or thermal mass. Solar heating can supplement traditional heating systems and reduce reliance on fossil fuels.

While these are the commonly used heating systems in HVAC, it’s important to consider factors such as energy efficiency, cost-effectiveness, space availability, and specific heating requirements when selecting the right system for a construction project. Additionally, proper maintenance and regular servicing of heating systems are essential to ensure optimal performance, energy efficiency, and longevity.

Read more: What Does Seer Mean For HVAC

Cooling Systems in HVAC

Cooling systems are an essential component of HVAC systems, especially in regions with hot climates or during the summer months. Let’s explore some of the common cooling systems used in HVAC:

- Central Air Conditioning: Central air conditioning systems are widely used in residential and commercial buildings. They consist of an outdoor unit, containing a compressor and condenser, and an indoor unit that circulates cool air. The system uses refrigerant to absorb heat from indoor air and release it outdoors, cooling the indoor space through a network of ducts and vents.

- Window Air Conditioners: Window air conditioners are compact units designed to cool individual rooms. They are self-contained and installed in a window or a dedicated opening on the wall. Window ACs work by pulling in warm air, cooling it with a refrigeration cycle, and expelling the cool air into the room while venting hot air outside.

- Split Air Conditioning: Split air conditioning systems consist of two components: an outdoor unit and an indoor unit. The outdoor unit houses the compressor and condenser, while the indoor unit contains the evaporator and blower. Split ACs are efficient, quiet, and provide targeted cooling to specific areas or rooms without the need for ductwork.

- Ductless Mini-Split Systems: Ductless mini-split systems operate similarly to split air conditioners but without the need for ductwork. They consist of an outdoor unit connected to one or more indoor units, each serving a specific zone. Ductless systems offer flexibility in zoning and temperature control, making them ideal for retrofitting existing buildings or adding cooling to specific areas.

- Evaporative Coolers: Evaporative coolers, often referred to as swamp coolers, are mainly used in dry climates. They use the natural process of evaporation to cool the air. Water is evaporated and passed over cooling pads, lowering the temperature of the air, which is then circulated throughout the building. Evaporative coolers are energy-efficient and provide a cost-effective alternative to traditional air conditioning.

When selecting a cooling system for a construction project, factors such as energy efficiency, cooling capacity, noise levels, and space availability should be considered. Regular maintenance and cleaning of filters and coils are essential to ensure proper functioning and efficiency of cooling systems. Additionally, integrating programmable thermostats and optimizing airflow can further enhance the performance and energy efficiency of cooling systems in HVAC.

HVAC stands for Heating, Ventilation, and Air Conditioning. In construction, it refers to the systems used to control temperature, humidity, and air quality in buildings. Proper HVAC design is essential for comfort and energy efficiency.

Ventilation Systems in HVAC

Ventilation is a critical component of HVAC systems that ensures the flow of fresh and clean air throughout a building. It plays a crucial role in maintaining indoor air quality, controlling humidity levels, and preventing the buildup of pollutants. Let’s explore some common ventilation systems used in HVAC:

- Mechanical Ventilation: Mechanical ventilation systems use fans and ductwork to bring in fresh outdoor air and remove stale indoor air. There are several types of mechanical ventilation systems, including:

- Exhaust Ventilation: This system uses fans to exhaust stale air from areas such as bathrooms, kitchens, or storage rooms. Fresh air enters the building through natural leakage or dedicated supply vents.

- Supply Ventilation: Supply ventilation systems introduce outdoor air into the building through fans and ductwork. This helps maintain a positive pressure, preventing the infiltration of outdoor pollutants. Stale air is expelled through natural leakage or exhaust vents.

- Balanced Ventilation: Balanced ventilation systems use both supply and exhaust fans to ensure a balanced airflow. They bring in fresh air while simultaneously expelling stale air from the building.

- Natural Ventilation: Natural ventilation relies on natural air movement to provide fresh air and remove indoor pollutants. It utilizes openings such as windows, doors, or vents to facilitate the exchange of air. Natural ventilation can be enhanced through the use of strategically placed windows, louvers, or vents to create cross ventilation and promote air movement.

- Hybrid Ventilation: Hybrid ventilation systems combine both mechanical and natural ventilation strategies. They use mechanical ventilation when necessary (during periods of extreme temperatures or when indoor air quality is poor) and rely on natural ventilation during milder weather conditions to minimize energy consumption.

- Heat Recovery Ventilation (HRV) and Energy Recovery Ventilation (ERV): HRV and ERV systems are designed to recover heat or coolness from the exhaust air while providing fresh air. These systems use heat exchangers to transfer heat or energy from the outgoing air to the incoming fresh air, improving energy efficiency and reducing heating or cooling loads.

- Spot Ventilation: Spot ventilation refers to the localized extraction of air in specific areas prone to high moisture or pollutant levels, such as bathrooms or kitchens. It involves the use of exhaust fans or range hoods to remove stale or contaminated air directly from the source, helping to maintain indoor air quality.

Properly designed and installed ventilation systems are essential for ensuring healthy indoor environments. They help remove pollutants, control moisture levels, and provide a constant supply of fresh air, contributing to the overall well-being and comfort of occupants. Regular maintenance, including cleaning or replacing filters, is necessary to ensure the effective operation of ventilation systems in HVAC.

Types of HVAC Systems

HVAC systems can vary in design and operation depending on the specific needs and requirements of a building. Here are some of the common types of HVAC systems used in construction:

- Single-Split System: The single-split system is the most common type of HVAC system used in residential buildings or small commercial spaces. It consists of a single indoor unit, such as an air conditioner or heat pump, connected to an outdoor unit via refrigerant lines. This system is ideal for individual rooms or small areas where zoning is not a requirement.

- Multi-Split System: The multi-split system is similar to the single-split system but allows for multiple indoor units to be connected to a single outdoor unit. Each indoor unit can be independently controlled, providing zoning capabilities and customized temperature control in various areas or rooms. This system is suitable for buildings with different temperature requirements for different spaces.

- VRF/VRV System: Variable Refrigerant Flow (VRF) or Variable Refrigerant Volume (VRV) systems are highly flexible and energy-efficient HVAC systems. They use a single outdoor unit that connects to multiple indoor units. The system dynamically adjusts refrigerant flow to each indoor unit, allowing for individualized temperature control in different zones simultaneously. VRF/VRV systems are commonly used in larger commercial buildings or multi-story complexes.

- Packaged HVAC System: Packaged HVAC systems are self-contained units that house all necessary components in a single unit. These components include the compressor, condenser, evaporator, and sometimes the heating equipment. Packaged systems are typically installed outdoors or on rooftops. They are commonly used in small commercial buildings, modular constructions, or residential homes with limited indoor space.

- Chilled Water System: Chilled water systems use chilled water as a medium to provide cooling. They consist of a chiller, which cools the water, and a network of pipes that distribute the chilled water throughout the building. Air handling units or fan coil units are used in individual spaces to cool the air by passing it over the chilled water coils. Chilled water systems are commonly found in larger commercial buildings or facilities with high cooling demands.

- Geothermal Heat Pump System: Geothermal heat pump systems leverage the constant temperature of the earth to provide heating and cooling. They use underground pipes, called geothermal loops, to exchange heat with the earth. In winter, the system extracts heat from the ground for heating, while in summer, it removes heat from the building and transfers it to the ground for cooling. Geothermal systems are energy-efficient and environmentally friendly.

Each type of HVAC system has its advantages and considerations, including installation costs, energy efficiency, space requirements, and maintenance needs. The selection of the appropriate HVAC system should be based on the specific requirements and objectives of the construction project.

Design Considerations for HVAC Systems

Designing an effective HVAC system requires careful consideration of various factors to meet the specific requirements of a construction project. Here are some important design considerations to keep in mind:

- Building Size and Layout: The size and layout of the building play a crucial role in determining the HVAC system’s capacity, ductwork sizing, and equipment placement. Proper analysis of the building’s square footage, number of rooms, and floor plan is essential to ensure adequate heating and cooling distribution throughout the space.

- Insulation and Building Envelope: A well-insulated building envelope is crucial for energy efficiency and optimal HVAC performance. The insulation levels in walls, roofs, and floors should be carefully considered to minimize heat gain or loss. Proper sealing of air leaks and using energy-efficient windows and doors can also improve the overall effectiveness of the HVAC system.

- Energy Efficiency: Energy efficiency should be a key consideration in the design of HVAC systems. Opt for high-efficiency equipment, such as Energy Star-rated appliances, to reduce energy consumption and lower operational costs. Incorporating programmable thermostats, occupancy sensors, and zoning strategies can further enhance energy efficiency and comfort.

- Zoning and Controls: Zoning allows for customized temperature control in different areas or rooms based on occupancy and usage patterns. By dividing the building into distinct zones with separate controls, you can optimize energy usage and provide personalized comfort. Utilizing advanced control systems and automated sensors can help monitor and adjust the HVAC system based on real-time conditions.

- Ventilation Requirements: Proper ventilation is critical for maintaining good indoor air quality. Consider the required airflow rates, outdoor air intake, and filtration systems to ensure proper ventilation and remove contaminants. Compliance with local building codes and regulations for ventilation is essential for occupant health and safety.

- Noise Control: HVAC systems can generate noise during operation. It’s important to consider noise control measures to maintain a comfortable and quiet indoor environment. Strategic placement of equipment, vibration isolation, and ductwork insulation can help minimize noise levels and prevent disruptions.

- Equipment Selection and Sizing: Choosing the right equipment and properly sizing it is crucial for efficient HVAC operation. Oversized equipment can lead to short cycling and unnecessary energy consumption, while undersized equipment may struggle to meet the heating or cooling demands. Conduct a proper load calculation to determine the accurate equipment size and consider factors such as climate, insulation levels, occupancy, and building orientation.

- Maintenance and Accessibility: Design HVAC systems with maintenance and accessibility in mind. Ensure that equipment, filters, and ductwork are easily accessible for cleaning, inspections, and repairs. Incorporating smart maintenance features, such as filter change indicators and remote diagnostics, can facilitate regular upkeep and prolong the lifespan of the system.

It’s important to consult with HVAC professionals, engineers, and designers during the construction phase to ensure the design meets the specific requirements and goals of the building project. A well-designed HVAC system will not only provide optimal comfort but also enhance energy efficiency, indoor air quality, and overall sustainability.

Energy Efficiency in HVAC

Energy efficiency is a crucial consideration when it comes to HVAC systems in construction projects. Improving the energy efficiency of your HVAC system not only reduces environmental impact but also helps lower utility costs and increase overall sustainability. Here are some key factors to consider for energy-efficient HVAC:

- High-Efficiency Equipment: Selecting high-efficiency HVAC equipment is essential for optimizing energy consumption. Look for equipment with energy efficiency ratings, such as SEER (Seasonal Energy Efficiency Ratio) for cooling and AFUE (Annual Fuel Utilization Efficiency) for heating. Energy Star-certified appliances indicate that they meet strict guidelines for energy efficiency, making them a good choice.

- Proper Equipment Sizing: Oversized or undersized HVAC equipment can lead to inefficiencies and increased energy consumption. Properly sizing the equipment based on the building’s heating and cooling load is crucial. Conducting a load calculation that takes into account factors such as insulation, windows, doors, and occupancy can help determine the appropriate size of the equipment.

- Zoned Heating and Cooling: Implementing zoning strategies allows for customized temperature control in different areas or rooms. This prevents the need to heat or cool the entire building uniformly, leading to energy savings. By utilizing programmable thermostats and zone controls, occupants have the ability to adjust temperatures based on their specific needs, optimizing comfort and energy usage.

- Smart Thermostats and Controls: Installing smart thermostats and controls can significantly improve energy efficiency. These devices allow for automated temperature adjustments, adaptive learning, and remote access, enabling users to optimize energy usage based on occupancy patterns and preferences.

- Optimized Ventilation: Proper ventilation is essential for maintaining good indoor air quality, but it can also impact energy efficiency. Use energy recovery ventilation (ERV) or heat recovery ventilation (HRV) systems to transfer heat or energy from the exhaust air to the incoming fresh air, reducing the load on the HVAC system and conserving energy.

- Regular Maintenance: Routine maintenance is crucial for the efficient operation of HVAC systems. Regularly inspect and clean air filters, coils, and ductwork to ensure optimal airflow and minimize energy loss. Performing annual maintenance, such as checking refrigerant levels, lubricating motors, and calibrating thermostats, can also help identify and address any issues that may affect energy efficiency.

- Proper Insulation and Air Sealing: A well-insulated building envelope and proper air sealing can greatly contribute to energy efficiency. Insulation minimizes heat transfer through walls, roofs, and floors, reducing the workload on the HVAC system. Additionally, sealing air leaks and ensuring proper insulation around doors and windows can prevent drafts and heat loss.

- Consider Renewable Energy Sources: Integrating renewable energy sources, such as solar panels or geothermal systems, can further enhance energy efficiency. Solar panels can generate electricity to power the HVAC system, while geothermal systems utilize the constant temperature of the earth for heating and cooling, reducing reliance on traditional energy sources.

By implementing these energy-efficient strategies, you can reduce energy consumption, lower carbon emissions, and create a more sustainable and cost-effective HVAC system. Consulting with HVAC professionals and energy experts can help you make informed decisions and optimize the energy efficiency of your HVAC system during the construction process.

Maintenance of HVAC Systems

Regular maintenance is crucial for ensuring the proper functioning, efficiency, and longevity of HVAC systems in construction projects. Neglecting maintenance can lead to decreased performance, increased energy consumption, higher repair costs, and reduced indoor air quality. Here are some key maintenance tasks to keep HVAC systems running smoothly:

- Filter Cleaning or Replacement: Air filters in HVAC systems collect dust, dirt, and other airborne particles. Dirty filters restrict airflow, reduce system efficiency, and worsen indoor air quality. Clean or replace filters regularly, following manufacturer recommendations. Some filters may need cleaning or replacement monthly, while others may last for several months.

- Duct Cleaning: Over time, dust, debris, and mold can accumulate in the ductwork, impairing airflow and contaminating indoor air. Periodic duct cleaning helps remove these contaminants, improving indoor air quality and system efficiency. Professional duct cleaning should be considered every few years, or more frequently in high-dust environments.

- Coil Cleaning: Evaporator and condenser coils can accumulate dirt and debris, hindering heat transfer and reducing system efficiency. Clean coils annually or as needed to remove dirt buildup. Ensure coils are free of obstructions, such as vegetation or debris, to ensure proper airflow and optimal system performance.

- Lubrication: Moving parts in HVAC systems, such as fan motors and bearings, may require periodic lubrication. Lubricate these components as recommended by the manufacturer to reduce friction and extend their lifespan. Improper lubrication can lead to increased energy consumption and premature system failure.

- Condensate Drain Cleaning: HVAC systems generate condensate, which needs to drain properly to prevent water damage and the growth of mold or bacteria. Check condensate drains regularly to ensure they are clear of blockages. Clean or unclog drains to allow proper drainage to prevent overflow or water damage.

- Electrical Components and Connections: Inspect electrical connections, control panels, and wiring for signs of wear, damage, or loose connections. Faulty electrical components can lead to poor system performance, increased energy consumption, or safety hazards. Tighten connections and replace damaged components as necessary.

- Thermostat Calibration: Regularly calibrate and test thermostats to ensure temperature accuracy and proper functioning. Incorrect thermostat readings can lead to inefficient heating or cooling and discomfort for occupants. Replace batteries in thermostats as needed.

- Professional Maintenance: Regular professional maintenance by trained technicians is crucial for HVAC systems. Schedule annual maintenance visits with HVAC professionals to conduct thorough inspections, cleanings, and tune-ups. Professional technicians can identify any potential issues or inefficiencies, ensuring optimal system performance.

- Record Keeping: Keep a detailed record of maintenance activities, including dates of filter replacements, cleaning tasks, and professional service visits. This record helps track maintenance schedules, identify trends, and provide important information for future system maintenance or inspections.

By following a proactive maintenance schedule and addressing issues promptly, you can ensure the efficient and reliable operation of HVAC systems in construction projects. Regular maintenance not only saves energy and extends the system’s lifespan but also enhances indoor air quality, occupant comfort, and overall satisfaction.

Conclusion

HVAC systems play a crucial role in the construction industry, providing heating, ventilation, and air conditioning to create comfortable, healthy, and efficient indoor environments. By understanding the definition, importance, components, and types of HVAC systems, stakeholders in construction projects can make informed decisions that maximize comfort, energy efficiency, and sustainability.

The design process of HVAC systems requires careful consideration of factors such as building size, insulation, ventilation requirements, and energy efficiency. Proper equipment sizing, zoning strategies, and smart controls are essential for optimizing energy usage and providing customized comfort to occupants. Additionally, regular maintenance, including filter cleaning or replacement, coil cleaning, and electrical inspections, helps ensure the longevity and optimal performance of HVAC systems.

Energy efficiency should be a top priority when it comes to HVAC systems. Choosing high-efficiency equipment, implementing zoning strategies, and utilizing smart thermostats and controls are effective ways to reduce energy consumption and lower utility costs. Additionally, considering renewable energy sources and optimizing ventilation systems can further enhance energy efficiency and sustainability.

In conclusion, HVAC systems are an integral part of construction projects, providing thermal comfort, air quality control, and energy efficiency. By prioritizing proper design, regular maintenance, and energy-saving strategies, stakeholders can create buildings that are not only comfortable and healthy but also environmentally friendly and cost-effective.

Frequently Asked Questions about What Does HVAC Mean In Construction

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Does HVAC Mean In Construction”