Articles

What Does Ecm Mean In HVAC

Modified: December 7, 2023

Unlock the meaning of ECM in HVAC with our informative articles. Find valuable insights and expert advice on energy-efficient heating and cooling systems.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When it comes to maintaining comfortable indoor temperatures, HVAC systems play a crucial role. These systems are responsible for heating, ventilation, and air conditioning in residential, commercial, and industrial buildings. However, traditional HVAC systems can be energy-intensive, leading to higher utility bills and a negative impact on the environment.

In recent years, there has been a growing focus on energy-efficient solutions in the HVAC industry. One of the key advancements in this regard is the integration of Electronically Commutated Motors (ECMs) in HVAC systems. The use of ECM technology provides numerous benefits, including improved energy efficiency, cost savings, and enhanced comfort.

Understanding what ECM means in the context of HVAC systems and its significance is essential for both homeowners and HVAC professionals. In this article, we will explore the concept of ECM in HVAC, its role, benefits, drawbacks, types, and factors to consider when choosing ECM for HVAC systems.

Key Takeaways:

- ECMs revolutionize HVAC systems by optimizing energy usage, reducing utility bills, and enhancing comfort through variable speed control and precise airflow adjustment. Their benefits outweigh initial costs, offering a sustainable investment for homeowners and businesses.

- When choosing ECMs for HVAC systems, consider factors such as compatibility, speed control range, efficiency ratings, noise levels, control options, warranty, and expert guidance. Consulting with HVAC professionals ensures informed decisions for optimal performance and energy efficiency.

Read more: What Does HVAC Mean In Construction

Definition of ECM

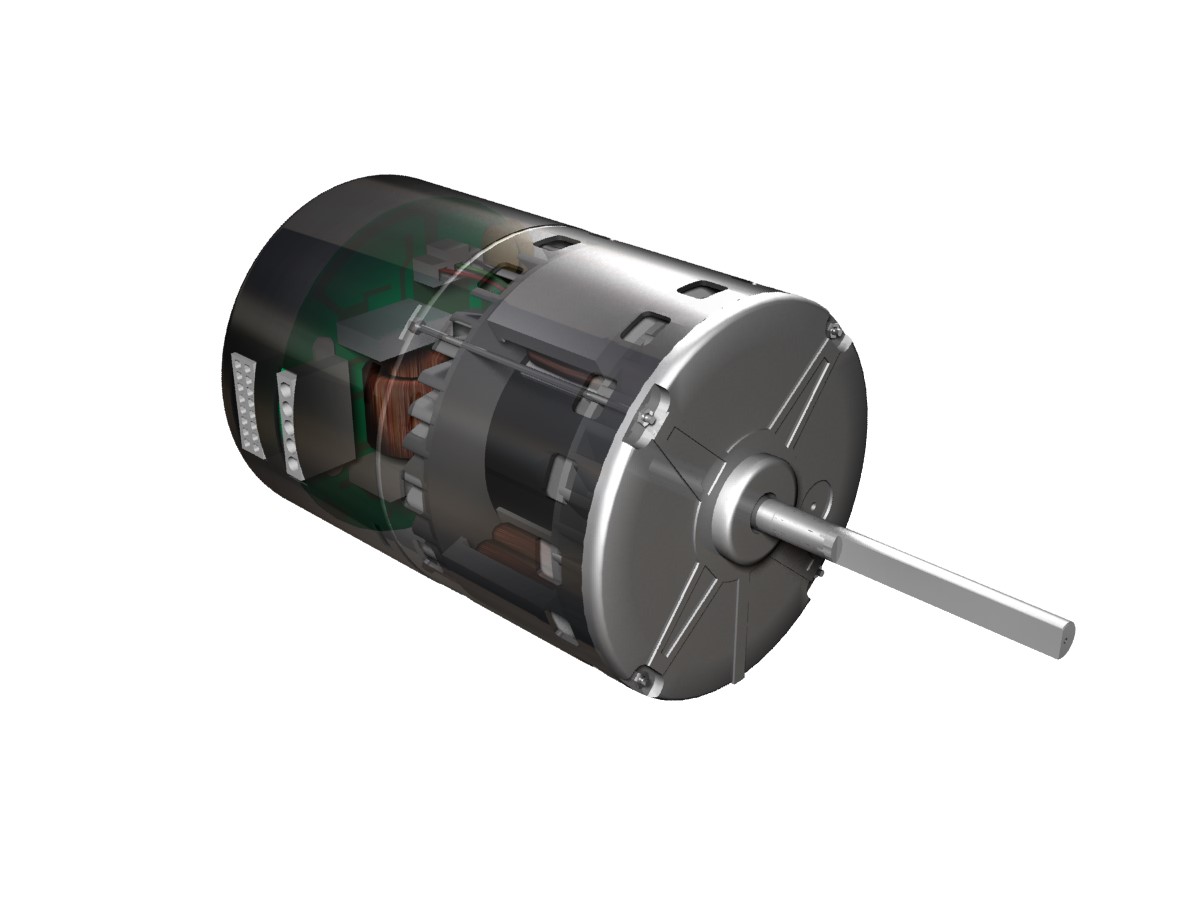

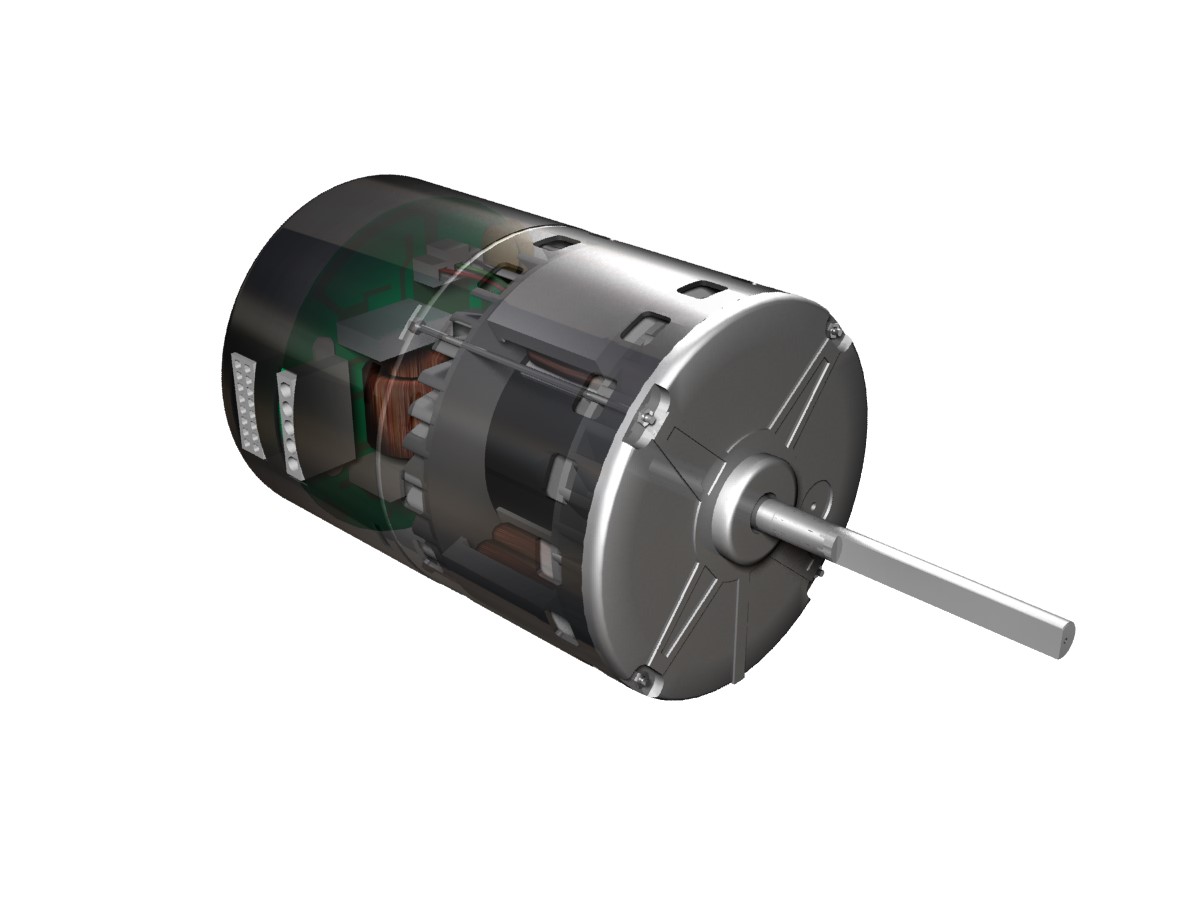

Electronically Commutated Motors (ECMs) are advanced motor technologies that are widely used in HVAC systems. Unlike traditional motors, ECMs use electronic controls to vary their speed and rotational direction. The electronic commutation of ECMs through the use of integrated circuitry allows for precise control of motor performance.

ECMs are designed to be efficient and adaptable, making them an ideal choice for HVAC applications. These motors are also known as brushless DC motors or permanent magnet motors. ECMs utilize a combination of permanent magnets and electronic controls to deliver efficient and reliable performance in HVAC systems.

The key feature of ECMs is their ability to adjust the speed based on the system requirements, which allows for precise temperature control and energy efficiency. This flexibility enables the motor to operate at various speeds, optimizing energy consumption based on the heating or cooling demand.

ECMs are commonly found in various HVAC components, including air handlers, furnaces, condensing units, and heat pumps. They are integrated into these systems to enhance their performance, improve energy efficiency, and reduce operating costs.

In addition to their inherent energy-saving capabilities, ECMs also offer other advantages over traditional motors. These advantages include quieter operation, longer lifespan, and reduced wear and tear due to the absence of brushes and commutators.

Role of ECM in HVAC Systems

ECMs play a crucial role in enhancing the performance and energy efficiency of HVAC systems. They provide variable speed control, allowing the system to adjust the airflow and power consumption based on the specific heating or cooling requirements.

One of the primary functions of ECMs in HVAC systems is to regulate the airflow. By adjusting the speed of the motor, ECMs can deliver the required amount of air to each zone or room, ensuring optimal comfort. This dynamic airflow control helps prevent overcooling or overheating, reducing energy wastage and improving overall system efficiency.

Another essential role of ECMs is in improving the overall energy efficiency of the HVAC system. Traditional motors operate at a fixed speed and consume a constant amount of power, regardless of the system demand. On the other hand, ECMs can modulate their speed and power consumption based on the heating or cooling load, resulting in significant energy savings. This adaptive functionality helps reduce utility bills and minimize the environmental impact of HVAC systems.

ECMs also contribute to enhanced comfort in indoor spaces. By adjusting the airflow and temperature control, these motors can maintain a consistent and even distribution of conditioned air throughout the building. This ensures that each room receives the necessary heating or cooling, eliminating hot or cold spots and improving occupant comfort.

Furthermore, the use of ECMs in HVAC systems leads to quieter operation. Traditional motors can produce noticeable noise and vibration. In contrast, ECMs operate with reduced noise levels, promoting a more peaceful and comfortable environment.

Overall, the role of ECMs in HVAC systems is to optimize energy usage, improve comfort levels, and reduce operating costs. These advanced motors allow for precise control and intelligent adaptation to varying heating and cooling demands, making them an indispensable component in modern HVAC design.

Benefits of ECM in HVAC

The integration of Electronically Commutated Motors (ECMs) in HVAC systems offers a wide range of benefits for both residential and commercial applications. These benefits contribute to improved energy efficiency, enhanced comfort, and cost savings. Let’s explore some of the key advantages of using ECMs in HVAC systems.

- Increased Energy Efficiency: ECMs are highly energy-efficient motors that can reduce power consumption by up to 30% compared to traditional motors. The ability to adjust the motor speed based on system demand allows for precise control of airflow and temperature, resulting in optimal energy usage.

- Cost Savings: The improved energy efficiency of ECMs leads to significant cost savings over time. By using less energy to achieve the desired heating or cooling levels, homeowners and businesses can enjoy reduced utility bills and lower maintenance costs.

- Improved Comfort: ECMs enable precise control of airflow, ensuring a more consistent and even distribution of conditioned air throughout the building. This eliminates temperature fluctuations and hot or cold spots, providing enhanced comfort for occupants.

- Quiet Operation: Traditional motors can be noisy, causing disruptions and discomfort. ECMs operate at reduced noise levels, resulting in quieter HVAC systems and a more peaceful indoor environment.

- Extended Lifespan: ECMs are designed with durable components and have no brushes or commutators that wear out over time. This results in a longer lifespan compared to traditional motors, contributing to cost savings and reduced maintenance requirements.

- Environmental Benefits: The energy savings achieved through the use of ECMs have a positive impact on the environment. By reducing overall power consumption, ECMs help lower greenhouse gas emissions and minimize the carbon footprint associated with HVAC systems.

In summary, the benefits of ECMs in HVAC systems include increased energy efficiency, cost savings, improved comfort, quiet operation, extended lifespan, and environmental advantages. These benefits make ECMs a valuable investment for those seeking to optimize their HVAC systems for optimal performance and sustainability.

ECM stands for Electronically Commutated Motor, which is a type of energy-efficient motor used in HVAC systems. It can help improve the system’s energy efficiency and reduce operating costs.

Drawbacks of ECM in HVAC

While Electronically Commutated Motors (ECMs) offer numerous advantages in HVAC systems, it’s important to also consider their potential drawbacks. Understanding these limitations can help individuals make informed decisions when it comes to integrating ECM technology into their HVAC systems. Let’s explore some of the common drawbacks associated with ECMs in HVAC applications.

- Initial Cost: ECMs generally have a higher upfront cost compared to traditional motors. This cost difference can be a deterrent for some homeowners or businesses, particularly those on a tight budget. However, it’s important to consider the long-term cost savings and energy efficiency benefits that ECMs provide.

- Complexity: ECMs are more complex in design compared to traditional motors. Their integrated circuitry and electronic controls require specialized knowledge and expertise for installation, troubleshooting, and repairs. This can result in higher service costs and a greater reliance on HVAC professionals with experience in ECM technology.

- Compatibility: Retrofitting ECMs into existing HVAC systems can present challenges. Older systems may not be designed to accommodate ECMs, requiring modifications or additional components for proper integration. It’s essential to assess the compatibility of ECMs with existing HVAC equipment before making the switch.

- Limited Application: While ECMs are suitable for a wide range of HVAC applications, there may be specific scenarios where they are not the most practical choice. In certain circumstances, other motor technologies or control methods may be more suitable, depending on the specific needs of the HVAC system.

- Reliability Concerns: While ECMs are built for durability and have a longer lifespan compared to traditional motors, there is still a potential for technical issues and failures. The integrated electronic components can be susceptible to damage from power surges or electrical faults, requiring professional intervention for repairs or replacement.

It’s worth noting that despite these drawbacks, ECMs remain a popular choice in the HVAC industry due to their significant energy savings, improved comfort, and long-term cost benefits. By carefully assessing the specific needs and constraints of the HVAC system, individuals can determine whether the advantages of ECMs outweigh the associated drawbacks.

Read more: What Does Seer Mean For HVAC

Types of ECM in HVAC

When it comes to Electronically Commutated Motors (ECMs) in HVAC systems, there are two main types that are commonly used: constant torque ECMs and constant airflow ECMs. These two types differ in their primary application and performance characteristics.

- Constant Torque ECM: This type of ECM is designed to maintain a consistent torque output as the motor speed varies. Constant torque ECMs are commonly used in HVAC applications that require precise control of fan or blower speed, such as in air handlers or ventilation systems. They offer a wide range of speed control to dynamically adjust the airflow based on system demand. These motors are well-suited for applications where maintaining a specific pressure or static pressure is essential.

- Constant Airflow ECM: As the name suggests, constant airflow ECMs are designed to provide a consistent airflow regardless of changes in static pressure or external factors. These motors are typically used in HVAC systems where maintaining a consistent supply of air to different zones or rooms is important, such as in ducted air conditioning systems. Constant airflow ECMs feature advanced controls that can modulate the motor speed to match the required airflow, ensuring optimal comfort and ventilation efficiency.

Both constant torque ECMs and constant airflow ECMs offer unique benefits in HVAC applications. The selection of the appropriate ECM type depends on the specific requirements of the HVAC system, including the desired level of control, the need for constant airflow, and the nature of the application.

It’s worth noting that advancements in ECM technology have led to the development of hybrid ECMs that combine the characteristics of both constant torque and constant airflow ECMs. These hybrid ECMs offer greater versatility and flexibility in motor performance, allowing for more precise control of airflow and energy efficiency.

When considering the type of ECM to incorporate into an HVAC system, it’s important to consult with HVAC professionals who can assess the specific needs of the system and recommend the most appropriate ECM type to achieve optimal performance and efficiency.

Factors to Consider When Choosing ECM for HVAC Systems

Choosing the right Electronically Commutated Motor (ECM) for your HVAC system is crucial to ensure optimal performance, energy efficiency, and cost-effectiveness. Consider the following factors when selecting an ECM for your HVAC system:

- System Compatibility: Ensure that the ECM you choose is compatible with your existing HVAC system or the system you plan to install. Consider the voltage requirements, physical dimensions, and mounting options to ensure proper integration.

- Speed Control Range: Evaluate the speed control range of the ECM. A wider speed control range allows for more precise and flexible control of the motor, enabling better matching to the heating or cooling demand of the system.

- Efficiency Ratings: Look for ECMs with high efficiency ratings, such as those certified by Energy Star or other recognized organizations. Higher efficiency means lower energy consumption and reduced operating costs over time.

- Noise Levels: Consider the noise levels produced by the ECM. Look for models that operate quietly, especially if the HVAC system is installed in residential or noise-sensitive areas.

- Control Options: Evaluate the availability and compatibility of control options for the ECM. Some ECMs may be compatible with advanced control systems, allowing for integration with building automation systems or remote control capabilities.

- Warranty and Support: Consider the warranty and support provided by the manufacturer. Look for ECMs from reputable manufacturers that offer reliable warranty coverage and provide technical support if needed.

- Cost Considerations: Assess the upfront cost of the ECM along with the long-term energy savings it can provide. While higher efficiency ECMs may have a higher initial investment, they can result in significant cost savings over the life of the HVAC system.

- Expert Guidance: Consult with HVAC professionals who have experience with ECMs. They can assess your specific HVAC needs, recommend suitable ECM options, and ensure proper installation and integration.

Taking these factors into consideration will help you choose an ECM that aligns with your HVAC system requirements, energy efficiency goals, and budget. It’s essential to understand the specific needs of your HVAC system and seek expert advice to make an informed decision.

Conclusion

Electronically Commutated Motors (ECMs) have revolutionized the HVAC industry by providing advanced motor technology that enhances energy efficiency, comfort, and cost savings. ECMs offer variable speed control, allowing for precise adjustment of airflow and power consumption based on the heating or cooling demand. This intelligent adaptation results in optimal energy usage, reduced utility bills, and a positive impact on the environment.

The benefits of ECMs in HVAC systems are extensive. They include increased energy efficiency, cost savings, improved comfort, quieter operation, extended lifespan, and environmental advantages. These benefits make ECMs a valuable investment for homeowners, businesses, and HVAC professionals aiming to optimize the performance and sustainability of their HVAC systems.

While ECMs offer many advantages, it’s important to consider the potential drawbacks, such as the initial cost and complexity of installation and maintenance. However, these limitations are generally outweighed by the long-term benefits and energy savings provided by ECM technology.

When selecting an ECM for your HVAC system, consider factors such as system compatibility, speed control range, energy efficiency ratings, noise levels, control options, warranty and support, and cost considerations. Consulting with HVAC professionals will help ensure that you choose the right ECM for your specific needs and maximize the benefits it offers.

In conclusion, the integration of ECMs in HVAC systems is a game-changer in terms of energy efficiency, comfort, and sustainability. By harnessing the power of ECM technology, we can create more efficient, cost-effective, and environmentally friendly HVAC systems that provide optimal comfort and contribute to a greener future.

Frequently Asked Questions about What Does Ecm Mean In HVAC

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Does Ecm Mean In HVAC”