Articles

What Does CTS Stand For In Plumbing

Modified: December 7, 2023

Find out the meaning of CTS in the context of plumbing with our informative articles. Explore the world of plumbing and enhance your knowledge.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When it comes to plumbing, there are a myriad of terms and acronyms that can be quite confusing to the average homeowner. One such term that you may have come across is CTS. But what does CTS stand for in plumbing?

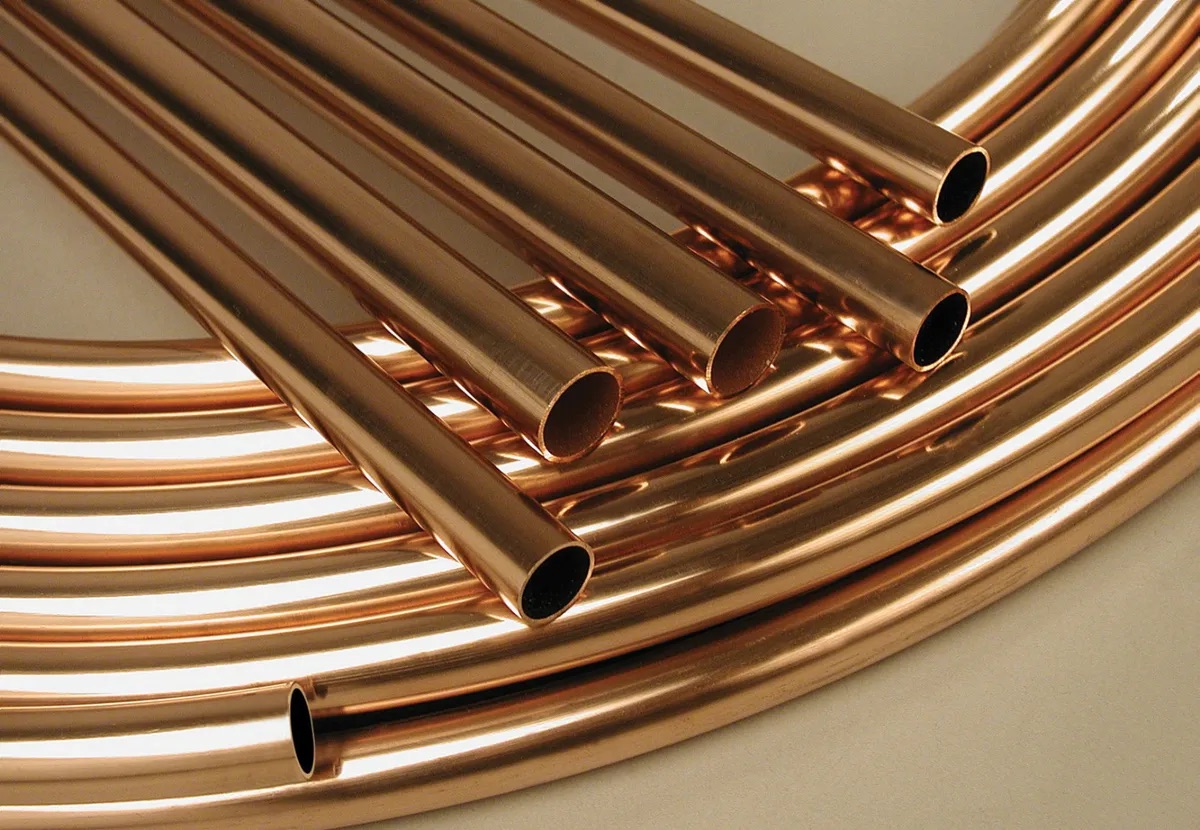

CTS stands for Copper Tube Size. It refers to a specific sizing system used for copper tubing in plumbing applications. This system is based on the outside diameter (OD) of the tubing, rather than the inside diameter (ID). Understanding CTS is essential for anyone involved in plumbing, whether you are a homeowner, a plumber, or a DIY enthusiast.

In this article, we will delve deeper into the concept of CTS in plumbing. We will explore its definition, common uses, advantages, disadvantages, and how it differs from IPS (Iron Pipe Size). By the end, you will have a comprehensive understanding of what CTS stands for in plumbing and how it impacts your plumbing system.

Key Takeaways:

- CTS, or Copper Tube Size, is a crucial standard for copper tubing in plumbing. It ensures compatibility, ease of installation, and seamless transitions between plumbing components, making it a go-to choice for various applications.

- While CTS plumbing systems offer durability, excellent flow characteristics, and compatibility, they also come with potential drawbacks such as higher cost, susceptibility to theft, and risk of freezing. Understanding the differences between CTS and IPS is essential for successful plumbing projects.

Read more: What Does Television Stand For

Definition of CTS

In plumbing, CTS refers to Copper Tube Size. It is a standardized sizing system used for copper tubing in plumbing applications. Unlike other pipes that are measured based on their inside diameter (ID), CTS is measured based on the outside diameter (OD) of the tubing.

The CTS measurement is typically stated in fractions of an inch, such as 1/2″, 3/4″, 1″, and so on. These measurements represent the outside diameter of the copper tubing. For example, a 1/2″ CTS pipe will have an actual outside diameter of around 5/8″. Similarly, a 3/4″ CTS pipe will have an actual outside diameter of around 7/8″.

It is important to note that CTS is specific to copper tubing and is not applicable to other types of pipes, such as PVC or PEX.

The use of CTS in plumbing is important for several reasons. Firstly, it allows standardized sizing for copper tubing, ensuring compatibility and ease of installation. Secondly, CTS sizing provides a seamless transition between different plumbing components, such as fittings, valves, and connectors, which are specifically designed to work with CTS pipes.

Now that we understand the definition of CTS, let’s explore some of its common uses in plumbing.

Common Uses of CTS in Plumbing

CTS pipes find a wide range of applications in plumbing systems. Here are some of the most common uses:

- Water Supply Lines: CTS pipes are commonly used for water supply lines in residential and commercial buildings. The standardized sizing of CTS allows for easy installation and replacement of water lines.

- Hot and Cold Water Distribution: CTS pipes are suitable for both hot and cold water distribution systems. The copper material has excellent thermal conductivity, making it ideal for carrying hot water without significant heat loss.

- Inline Appliances: CTS pipes are used to connect inline appliances such as water heaters, washing machines, and dishwashers. The CTS sizing ensures a secure and leak-free connection between the appliance and the plumbing system.

- Hydronic Heating Systems: CTS pipes are also utilized in hydronic heating systems that use hot water to generate heat. The copper material is resistant to corrosion and can withstand high temperatures, making it a reliable choice for these systems.

- Underground Water Service Lines: CTS pipes are commonly used for underground water service lines connecting a building to the municipal water supply. The durability and resistance to corrosion of copper make it an ideal choice for these applications.

- Residential Plumbing Installations: CTS pipes are preferred in residential plumbing installations due to their ease of installation, compatibility with various fittings, and longevity. They are commonly used for water supply lines, kitchen and bathroom plumbing, and outdoor irrigation systems.

The versatility and reliability of CTS pipes make them a popular choice in the plumbing industry. Now, let’s explore some of the advantages of using CTS plumbing systems.

Advantages of CTS Plumbing Systems

CTS plumbing systems offer several advantages that make them a preferred choice for many plumbing applications. Here are some key benefits:

- Durability: CTS pipes are made from copper, which is a highly durable material. Copper has excellent resistance to corrosion and can withstand high temperatures and pressures, making it a reliable option for long-lasting plumbing systems.

- Excellent Flow Characteristics: Copper pipes have smooth internal surfaces that promote excellent water flow. They offer low resistance to flow, meaning there are minimal pressure drops, allowing for efficient water distribution throughout the plumbing system.

- Longevity: Copper pipes have a long lifespan, often lasting more than 50 years with proper installation and maintenance. This longevity reduces the need for frequent replacements, saving homeowners and businesses on repair and replacement costs in the long run.

- Safe for Drinking Water: Copper is a naturally occurring material that is safe for drinking water. It is non-toxic and prevents the growth of bacteria, ensuring the delivery of clean and safe drinking water to households and buildings.

- Flexible and Easy to Install: CTS pipes are flexible and can be easily bent to fit around corners or obstacles, making installation simpler and more efficient. They can be joined using various methods such as soldering, compression fittings, or push-fit fittings, providing flexibility in installation techniques.

- Compatibility: CTS pipes are designed to work seamlessly with a wide range of fittings, valves, and connectors. This compatibility simplifies the installation process and ensures a secure and leak-free connection between different plumbing components.

The advantages of CTS plumbing systems contribute to their popularity in residential, commercial, and industrial applications. However, it is important to consider the potential disadvantages of using CTS pipes as well. Let’s explore these drawbacks in the next section.

CTS stands for “copper tube size” in plumbing. When purchasing pipes or fittings, make sure to match the CTS to ensure a proper fit and avoid any installation issues.

Disadvantages of CTS Plumbing Systems

While CTS plumbing systems have numerous advantages, they also come with a few disadvantages that should be considered. Here are some common drawbacks:

- Higher Cost: CTS pipes, especially those made of copper, tend to be more expensive compared to other piping materials like PVC or PEX. The cost of the material itself, as well as the additional fittings and connectors required for installation, can significantly increase the overall project cost.

- Susceptible to Theft: Copper pipes have a higher scrap value, making them attractive to thieves. In certain areas, there have been instances of copper pipe theft, leading to disruptions in water supply and costly repairs for homeowners.

- Risk of Freezing: Copper pipes have less tolerance to freezing temperatures compared to other pipe materials. If exposed to extremely cold temperatures, CTS pipes may freeze and potentially crack or burst, leading to water damage and costly repairs.

- Hardness and Rigidity: Copper pipes are relatively harder and less flexible compared to materials like PEX. This rigidity can make installation in tight spaces or around obstacles more challenging. It may also require additional fittings and connectors to accommodate changes in direction.

- Greater Heat Transfer: Copper is an excellent conductor of heat, which can lead to heat loss in hot water plumbing systems. This may result in increased energy consumption and higher utility bills, especially in long pipe runs.

- Potential for Water Quality Issues: In areas with acidic or aggressive water, copper pipes may be prone to corrosion over time. This can lead to water discoloration, taste issues, and potentially affect the overall quality of the water supply.

Despite these disadvantages, CTS plumbing systems continue to be widely used due to their overall durability, longevity, and compatibility. However, it’s important to weigh these drawbacks against your specific plumbing needs and budget before making a decision.

Read more: What Does TV Stand For In Television

CTS vs. IPS: Understanding the Difference

When it comes to plumbing, you may come across two different sizing systems: CTS (Copper Tube Size) and IPS (Iron Pipe Size). Understanding the difference between these two systems is essential for proper installation and compatibility. Let’s explore the distinctions between CTS and IPS:

CTS (Copper Tube Size):

- CTS refers to the sizing system used for copper tubing in plumbing applications.

- CTS uses the outside diameter (OD) of the tubing for measurement.

- Typical CTS measurements are stated in fractions of an inch, such as 1/2″, 3/4″, 1″, etc.

- CTS is commonly used for water supply lines, hot and cold water distribution systems, and inline appliances.

- CTS pipes are compatible with fittings and connectors specifically designed for CTS.

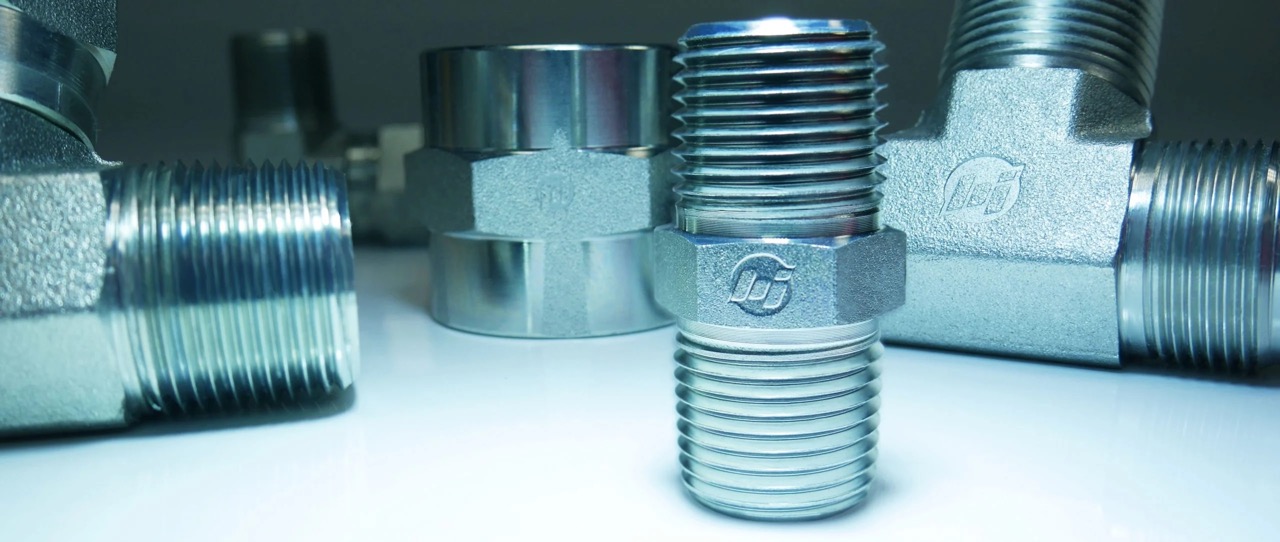

IPS (Iron Pipe Size):

- IPS refers to the sizing system used for iron and plastic pipes, such as PVC (Polyvinyl Chloride) and CPVC (Chlorinated Polyvinyl Chloride).

- IPS uses the inside diameter (ID) of the pipe for measurement.

- Typical IPS measurements are stated in inches, such as 1″, 1.5″, 2″, etc.

- IPS is commonly used for rigid water supply lines, drainage systems, and irrigation systems.

- IPS pipes are compatible with fittings and connectors specifically designed for IPS.

It’s important to note that CTS and IPS pipes are not interchangeable. Their sizing systems and corresponding fittings are different, which means you cannot connect a CTS pipe directly to an IPS fitting or vice versa. Mixing the two systems can lead to leaks, improper connections, and potential plumbing issues.

When working on a plumbing project, it’s crucial to determine whether you need CTS or IPS materials based on the specific requirements and plumbing codes in your area. Consulting with a plumbing professional or referencing building codes can ensure that you choose the correct system for your project.

Now that we have a better understanding of CTS and IPS, let’s conclude our discussion.

Conclusion

Understanding CTS (Copper Tube Size) is essential for anyone involved in plumbing, whether you are a homeowner, a plumber, or a DIY enthusiast. CTS refers to a standardized sizing system used for copper tubing in plumbing applications, where the measurement is based on the outside diameter (OD) of the tubing.

CTS pipes find common uses in water supply lines, hot and cold water distribution, inline appliances, hydronic heating systems, underground water service lines, and residential plumbing installations. They offer advantages such as durability, excellent flow characteristics, longevity, safety for drinking water, and compatibility with various fittings.

However, CTS plumbing systems also have some disadvantages to consider, such as higher cost, susceptibility to theft, risk of freezing, hardness and rigidity, greater heat transfer, and potential water quality issues. These drawbacks should be weighed against your specific needs and budget before deciding on the suitability of CTS pipes for your plumbing project.

It’s important to note that CTS pipes differ from IPS (Iron Pipe Size) pipes, which use a different sizing system for iron and plastic pipes. Mixing CTS and IPS systems can lead to compatibility issues and improper connections. Understanding the difference between CTS and IPS is crucial for proper installation and adherence to plumbing codes.

In conclusion, CTS plays a significant role in plumbing systems, especially when it comes to copper tubing. By understanding CTS and its application, advantages, disadvantages, and the distinction from IPS, you can make informed decisions and ensure the success of your plumbing projects.

Frequently Asked Questions about What Does CTS Stand For In Plumbing

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Does CTS Stand For In Plumbing”