Articles

What Happens If An Electric Motor Gets Wet

Modified: May 6, 2024

Discover the consequences of exposing an electric motor to water in this informative article. Learn how water can damage electrical components and how to prevent it.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Electric motors play a vital role in various industries and everyday appliances, powering everything from vehicles to household appliances. However, these machines are susceptible to damage, especially when exposed to water. Water poses a significant threat to the proper functioning of electric motors as it can cause corrosion, short circuits, and irreversible damage.

In this article, we will explore the risks associated with a wet electric motor, the steps to take if it gets wet, how to assess potential damage, drying techniques, when to seek professional help, and preventive measures to avoid water damage to electric motors.

Understanding the vulnerability of electric motors to water can help us mitigate the risks and ensure their longevity and optimal performance.

Key Takeaways:

- Protecting electric motors from water damage is crucial to prevent corrosion, short circuits, and mechanical failures. Immediate action, thorough assessment, and preventive measures are essential for ensuring their longevity and optimal performance.

- When an electric motor gets wet, prompt disconnection, careful inspection, and proper drying techniques are vital. Seeking professional help in complex cases and implementing preventive measures can safeguard motors from water damage.

Read more: What Happens When Insulation Gets Wet

Understanding Electric Motors and Their Vulnerability to Water

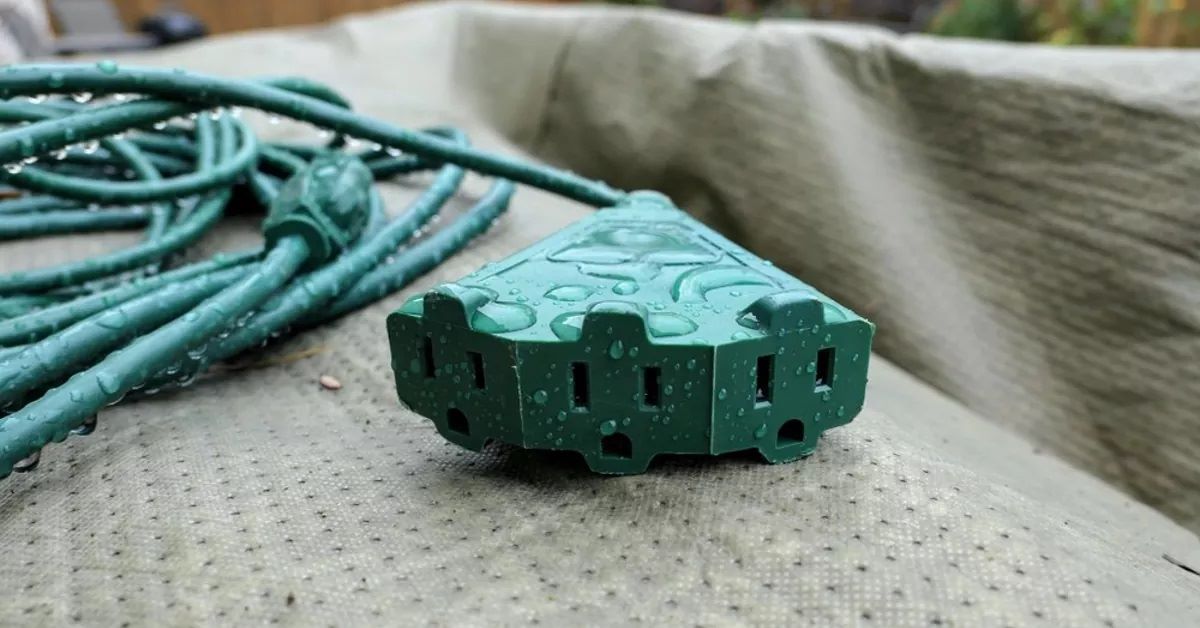

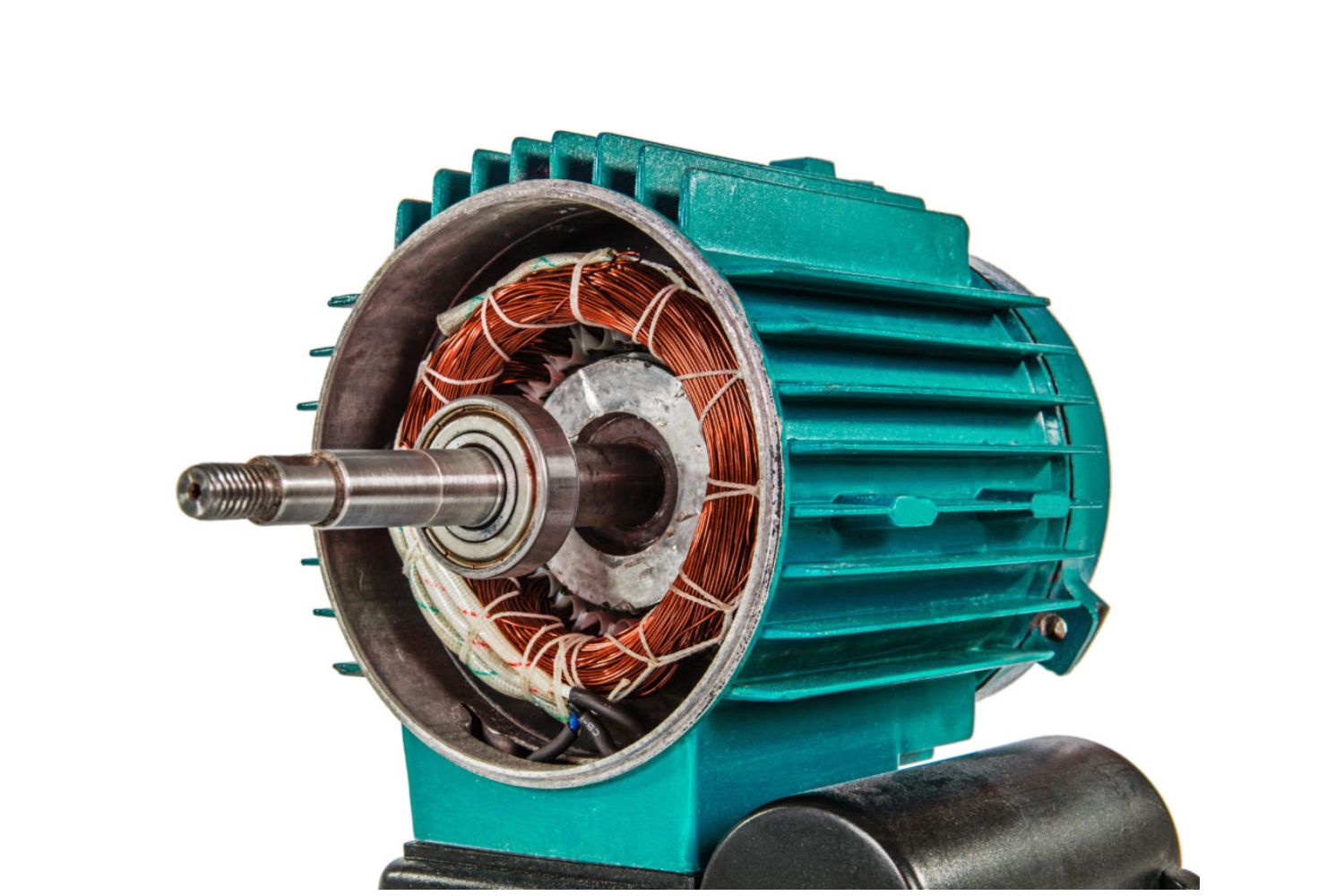

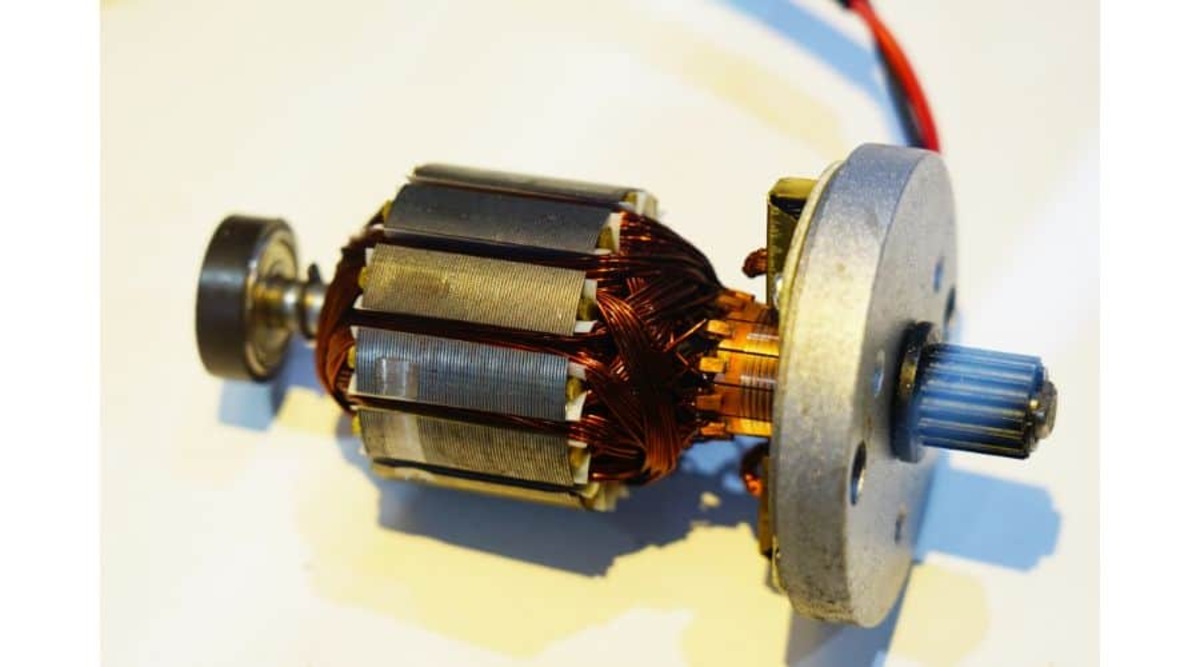

Electric motors are intricate machines that convert electrical energy into mechanical energy. They consist of several components, including a stator, rotor, bearings, and an enclosure. The enclosure, typically made of metal or plastic, provides protection to the internal components from external elements.

However, despite their robust design, electric motors are vulnerable to water damage. Water can enter the motor through various means, such as leaks, splashes, or submersion. When water infiltrates the motor, it can disrupt the delicate balance of electrical components and cause significant harm.

The vulnerability of electric motors to water stems from the fact that water is a conductor of electricity. When water comes into contact with electrical components, it can create a path for the flow of electricity, leading to short circuits. These short circuits can damage the insulation, compromise the motor’s performance, and even pose a safety risk.

Moreover, water can cause corrosion on the metal parts of the motor, including the stator, rotor, and bearings. Corrosion weakens the structural integrity of the motor and can lead to mechanical failures. Additionally, water can mix with lubricants or oils inside the motor, diluting them and reducing their effectiveness in preventing friction and wear.

It’s crucial to note that not all electric motors are equally vulnerable to water damage. Motors designed for specific environments, such as those used in outdoor applications like pumps or industrial machinery, are often built with additional protection, like waterproof enclosures or seals, to resist water ingress. However, even these motors have limitations and may succumb to water damage under extreme conditions.

Understanding the vulnerability of electric motors to water is essential in order to take appropriate steps to prevent and address potential damage. By being aware of the risks, we can better protect these valuable machines and prolong their lifespan.

Risks of a Wet Electric Motor

When an electric motor gets wet, it faces several risks that can lead to damage and malfunction. It’s important to be aware of these risks to take prompt action and minimize the potential consequences.

1. Corrosion: Water is a catalyst for corrosion, especially when it comes into contact with metal components of the motor. Corrosion can weaken the structural integrity of the motor, cause rust, and lead to mechanical failures. This can result in reduced efficiency, increased wear and tear, and ultimately the need for costly repairs or replacement.

2. Short circuits: Water is a conductor of electricity, and when it enters the motor, it can create a path for the flow of electrical current. This can cause short circuits, where electricity flows through unintended pathways, bypassing the intended circuitry. Short circuits can damage electrical components, including the insulation, and may even lead to the motor overheating or catching fire.

3. Insulation breakdown: Electric motors rely on insulation to prevent the flow of electricity through unintended pathways. When water enters the motor, it can seep into the insulation material and weaken it. This can compromise the insulation’s ability to withstand high voltages and result in electrical failures.

4. Mechanical failures: Water can cause lubricants and oils in the motor to dilute, leading to inadequate lubrication of moving parts. This can increase friction, wear, and the likelihood of mechanical failures. Additionally, water can damage bearings, causing them to seize or fail, further compromising the motor’s performance.

5. Safety hazards: A wet electric motor can pose significant safety risks. Short circuits, overheating, or mechanical failures caused by water damage can lead to electrical shocks, fires, or other accidents. These hazards can jeopardize the safety of individuals working near the motor or using equipment powered by the motor.

It’s crucial to address these risks promptly and effectively when an electric motor gets wet. Ignoring or neglecting the potential damage can result in more severe consequences, including irreversible damage to the motor or hazardous situations. Next, we will discuss the steps to take if an electric motor gets wet to mitigate these risks.

Steps to Take if an Electric Motor Gets Wet

If an electric motor gets wet, it’s important to take immediate action to minimize the risks and prevent further damage. Follow these steps to properly address the situation:

- Disconnect the power: Before doing anything else, ensure that the motor is completely disconnected from the power source. This will prevent any accidental electric shocks or further damage due to live electrical currents.

- Remove the motor from the water source: If the motor is submerged in water, carefully remove it from the water source. Use caution to avoid any unnecessary physical strain or damaging the motor further.

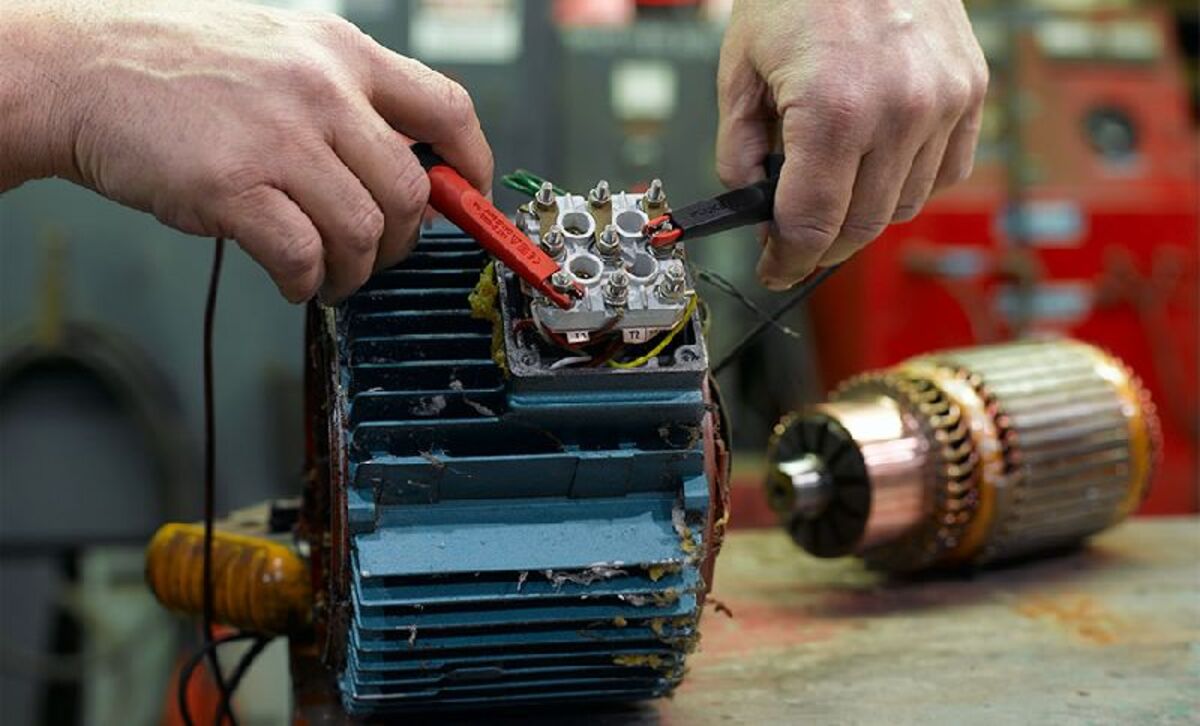

- Inspect the motor: Once the motor is out of the water, visually inspect it for any signs of water accumulation. Look for areas where water may have entered, such as openings or gaps in the enclosure. This will help in assessing the potential damage and determining the necessary steps to address it.

- Allow the motor to dry: If the motor is only damp and not fully submerged, you can allow it to dry naturally. Place it in a well-ventilated area and let the air circulate around it. Ensure that no direct heat sources, such as heaters or blow dryers, are used, as excessive heat can cause further damage to the motor.

- Disassemble if necessary: If water has entered the motor and caused significant damage, you may need to disassemble it for a thorough inspection and cleaning. Refer to the manufacturer’s instructions or seek professional advice if you are unsure about disassembly procedures.

- Clean and dry the components: If you have disassembled the motor, clean the components using a gentle cleaner or warm water and mild detergent. Ensure that all parts are thoroughly dried before reassembling the motor. You can use compressed air or a soft cloth to aid in the drying process.

- Inspect for any damage: Once the motor and its components are dry, carefully inspect them for any visible damage, such as corrosion, melted insulation, or burned components. If you notice any significant damage or if the motor does not function properly, it may require professional repair or replacement.

- Test the motor: Reconnect the motor to the power source and perform a test run to check if it operates smoothly and without any abnormal noises or behaviors. If you observe any issues, it is advisable to seek professional assistance.

Remember, these steps are general guidelines, and the specific actions to take may vary depending on the type and size of the motor, as well as the extent of the water damage. When in doubt, consult the manufacturer’s instructions or seek professional help to ensure proper handling and repair of the wet electric motor.

Potential Damage and How to Assess it

When an electric motor gets wet, it is essential to assess the potential damage to determine the necessary actions for repair or replacement. Here are some common types of damage that can occur and how to assess them:

- Corrosion: Check for signs of corrosion on metal components, such as the stator, rotor, and bearings. Look for rust, discoloration, or any deterioration of the metal surfaces. If there is significant corrosion, it may weaken the structural integrity and require repair or replacement.

- Insulation breakdown: Insulation breakdown can be assessed by inspecting the insulation material for any visible damage, such as cracks, swelling, or brittleness. Additionally, conducting insulation resistance tests can provide more accurate measurements of the insulation’s integrity. If the insulation is compromised, it may lead to electrical failures and require professional repair.

- Short circuits: Perform a thorough visual inspection of the electrical components, looking for any burned or charred areas. Use a multimeter to check for continuity and resistance between electrical connections. If there are signs of short circuits or abnormal electrical readings, it may indicate damage that needs to be addressed.

- Mechanical failures: Check for any unusual noise, grinding, or resistance when rotating the shaft by hand. Test the bearings for smooth rotation and proper function. If there are any issues with mechanical parts or bearings, it may require repair or replacement.

- Functional testing: After addressing visible damage and conducting initial assessments, reconnect the motor to the power source and perform a test run. Pay attention to the motor’s performance, such as speed, vibration, or temperature. If it operates smoothly and without issues, the damage may have been minimal. However, if there are continued problems or abnormalities, it is advisable to seek professional assistance.

It’s important to note that while these assessments can provide a general indication of the damage, a thorough evaluation by a professional technician is recommended for a more accurate diagnosis. They have the expertise and specialized tools to identify hidden or internal damage that may not be immediately apparent.

Remember, safety should always come first when assessing potential damage. If you are unsure or uncomfortable with any aspect of assessing the damage or handling the motor, it is best to seek professional help. A qualified technician can provide a comprehensive assessment and guide you on the appropriate steps to repair or replace the wet electric motor.

If an electric motor gets wet, immediately disconnect the power source and allow it to dry completely before attempting to use it again. Inspect for any damage or corrosion before reapplying power.

Read more: What Happens If Fake Grass Gets Wet?

Drying Techniques for Wet Electric Motors

When an electric motor gets wet, proper drying techniques are crucial to prevent further damage and restore its functionality. Here are some effective methods to dry a wet electric motor:

- Allow for natural drying: If the motor is only slightly damp and not fully submerged, you can simply allow it to dry naturally. Remove the motor from the water source and place it in a well-ventilated area. Ensure there is proper air circulation around the motor to facilitate drying. Avoid using direct heat sources, such as heaters or blow dryers, as excessive heat can cause damage to the motor’s delicate components.

- Use desiccant or moisture-absorbing materials: Desiccant materials, such as silica gel packets or moisture-absorbing crystals, can help absorb moisture from the motor. Place the motor in a sealed container or bag with the desiccant materials and leave it for a period of time. The desiccants will gradually draw out the moisture, aiding in the drying process.

- Utilize compressed air: If the motor has visible moisture or is difficult to dry naturally, you can use compressed air to blow out the excess water. Use a low-pressure setting and ensure that you do not blow air directly onto sensitive components like the bearings or electrical connections. Keep a distance to avoid causing any damage or displacing water to other areas within the motor.

- Apply a gentle heat source: In some cases, when natural drying is not sufficient, a gentle heat source can be used to aid in the drying process. You can place the motor in a warm, low-heat environment, such as an oven set to the lowest temperature or using heat lamps. However, exercise caution to avoid overheating the motor, as excessive heat can cause damage.

- Consider using a dehumidifier: If you have access to a dehumidifier, you can place the motor in an enclosed space with the dehumidifier running. The dehumidifier will help remove excess moisture from the surrounding air, expediting the drying process.

- Consult with a professional: If the motor has been heavily saturated, submerged for an extended period, or if you are uncertain about the appropriate drying methods, it is advisable to consult a professional technician. They will have the expertise and specialized equipment to safely and effectively dry the motor to avoid potential damage.

Remember, the drying process requires patience, and it may take some time for the motor to fully dry. Rushing the drying process or using improper techniques can lead to further damage. If you are unsure or uncomfortable with any aspect of drying the motor, it is best to seek professional assistance to ensure the proper restoration of the wet electric motor.

When to Seek Professional Help

While there are steps you can take to address a wet electric motor on your own, there are certain situations where it is necessary to seek professional help. Here are some instances where it is advisable to consult a qualified technician:

- Extensive water damage: If the motor has been fully submerged or exposed to a significant amount of water, it is crucial to seek professional assistance. Extensive water damage can lead to severe internal damage, corrosion, and insulation breakdown that may require specialized expertise to properly diagnose and repair.

- Electrical failures: If the motor exhibits signs of electrical failures, such as short circuits, tripping breakers, or abnormal readings, it is best to leave the troubleshooting and repair work to a professional. Handling electrical issues without proper knowledge and skills can result in safety hazards or further damage to the motor.

- Unusual noises or vibrations: If the motor produces unexpected noises or vibrations after drying, it may indicate mechanical failures or damaged components. These issues require professional evaluation and repair to ensure the motor’s safe operation and prevent further damage.

- Complex motor systems: If the motor is part of a complex system, such as an industrial or commercial setup, it is advisable to involve professionals who specialize in that specific motor system. They have the expertise and knowledge to handle the intricacies of the system, ensuring proper repair and functionality.

- Manufacturer’s recommendations: If the manufacturer specifically recommends seeking professional help in the event of water damage, it is important to follow their instructions. Manufacturers often have authorized repair centers or service technicians who are trained to handle their specific motor models.

- Lack of experience or expertise: If you are unsure or lack experience in handling electric motors or electrical systems, it is best to err on the side of caution and seek professional help. Trying to repair a wet electric motor without the necessary knowledge can lead to further damage or safety risks.

By seeking professional assistance in these situations, you can ensure that the wet electric motor is properly assessed, repaired if necessary, and restored to its optimal functionality. Professionals have the knowledge, experience, and specialized tools to handle water damage effectively, minimizing the risk of further damage and ensuring the safety and long-term performance of the motor.

Remember that prevention is key, and taking proactive measures to protect electric motors from water damage can help avoid the need for extensive repairs or replacements. Implementing preventive measures will be discussed in the next section.

Preventive Measures to Avoid Electric Motor Damage from Water

Water damage to electric motors can be costly and time-consuming to repair. To avoid these issues, it is important to implement preventive measures to protect electric motors from water damage. Here are some preventive measures you can take:

- Proper motor enclosure: Ensure that the electric motor is housed in an appropriate enclosure. The enclosures should be designed to protect the motor from water ingress. Depending on the application, you may need an enclosure that is waterproof, weatherproof, or at least resistant to splashes or moisture.

- Regular equipment maintenance: Implement a routine maintenance schedule for your equipment, including inspecting the motor and its surroundings for any potential water leaks or sources of moisture. Address any issues promptly to prevent water damage from occurring.

- Seal openings and gaps: Check for any openings, gaps, or cracks in the motor’s enclosure and seal them with appropriate materials, such as gaskets or sealants. This helps to prevent water from seeping into the motor and causing damage.

- Elevate motor installation: If possible, install the motor in an elevated position to reduce the risk of it coming into contact with standing water or floodwaters. This is particularly important in areas prone to flooding or during construction projects where water infiltration is a possibility.

- Proper wiring insulation: Ensure that the electrical wiring connected to the motor is properly insulated and protected from water exposure. Use waterproof conduit, sealant, or other appropriate measures to safeguard the wiring from moisture.

- Keep motor surroundings dry: Maintain a dry and clean environment around the electric motor. Avoid storing or using equipment or materials that can leak or generate excess moisture in close proximity to the motor. This helps to prevent accidental water exposure and potential damage.

- Regular inspections: Regularly inspect the motor for signs of water damage or wear and tear. Look for corrosion, rust, or any other visible indications of moisture intrusion. Timely detection allows for prompt repairs and prevents further damage.

- Training and education: Ensure that personnel working with the electric motor are properly trained and educated on best practices for preventing water damage. They should understand the importance of maintaining a dry environment, recognizing signs of water damage, and knowing when to seek professional help.

- Protective covers: In certain situations, such as during temporary shutdowns or construction work, consider using protective covers or temporary enclosures to shield the motor from potential water exposure.

- Monitor weather conditions: Pay attention to weather forecasts and take necessary precautions during periods of heavy rain, storms, or flooding. If there is a risk of water damage, consider temporarily shutting down or taking additional protective measures for the electric motor.

Implementing these preventive measures can significantly reduce the risk of water damage to electric motors. By investing time and effort in safeguarding your motors, you can prolong their lifespan, minimize repair costs, and ensure consistent performance.

Remember, prevention is always better than the cure when it comes to protecting electric motors from water damage. By taking proactive steps and addressing potential risks, you can enjoy the peace of mind that your motors are well-protected and reliable.

Conclusion

Electric motors are essential components in various industries and everyday appliances, and their vulnerability to water damage is a significant concern. Water can cause corrosion, short circuits, insulation breakdown, and mechanical failures in electric motors, leading to reduced performance, safety hazards, and costly repairs or replacements.

In this article, we have explored the risks associated with a wet electric motor, the steps to take if it gets wet, how to assess potential damage, drying techniques, when to seek professional help, and preventive measures to avoid water damage. By understanding these aspects, we can better protect electric motors and ensure their longevity.

When an electric motor gets wet, it is crucial to take immediate action. Disconnecting the power, removing the motor from the water source, and inspecting it for water accumulation are the initial steps. Depending on the extent of the damage, allowing natural drying, using desiccants, or employing gentle heat sources can aid in the drying process.

Assessing the potential damage involves checking for corrosion, insulation breakdown, short circuits, mechanical failures, and conducting functional testing. While assessing the damage yourself can provide initial insights, it is recommended to involve a professional technician for a comprehensive evaluation and repair.

Prevention is key to avoiding water damage to electric motors. Implementing preventive measures, such as ensuring proper enclosures, regular maintenance, sealing openings, elevating motor installations, and keeping the surroundings dry, can significantly reduce the risk. Regular inspections, proper training of personnel, using protective covers when necessary, and monitoring weather conditions all contribute to safeguarding electric motors.

In conclusion, being aware of the risks, taking prompt action when a motor gets wet, properly assessing potential damage, and implementing preventive measures are all essential for protecting electric motors from water damage. By following these guidelines, you can ensure the longevity, safety, and optimal performance of electric motors, saving you time, money, and headaches in the long run.

Curious about keeping your electric motors in top shape? If you've found our guide on what happens when motors get wet useful, you'll definitely want to check out our upcoming piece on the latest motor repair techniques and strategies for 2024. This article promises to offer valuable insights and tips for maintaining and repairing electric motors, ensuring they run smoothly and efficiently. Don’t miss out on these expert recommendations to extend the life of your machinery.

Frequently Asked Questions about What Happens If An Electric Motor Gets Wet

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Happens If An Electric Motor Gets Wet”