Home>Articles>Why Are Permanent Magnets Needed In An Electric Motor

Articles

Why Are Permanent Magnets Needed In An Electric Motor

Modified: December 7, 2023

Discover the importance of permanent magnets in an electric motor. Read our informative articles to understand why these magnets are necessary for efficient motor operation.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Electric motors have become an integral part of our everyday lives, powering various devices and machines that we rely on. Whether it’s the motor in your washing machine, your car’s starter motor, or the motors used in industrial applications, they all have one thing in common – the need for magnets. Magnets play a crucial role in the operation of electric motors, providing the necessary magnetic field for the motor to function efficiently.

In this article, we will explore why magnets are essential in electric motors and delve into the types of magnets used. We will focus particularly on permanent magnets and their advantages over temporary magnets in electric motor applications.

By understanding the importance of magnets and their role in electric motors, we can gain a better appreciation for the technology that powers our modern world.

Key Takeaways:

- Permanent magnets are crucial for efficient electric motor performance, offering high magnetic strength, energy efficiency, and reliability. Understanding factors affecting their performance is essential for optimizing motor operation.

- Magnets, especially permanent ones, play a vital role in electric motors, providing stability, controllability, and long operational lifespan. Their impact on motor efficiency and reliability cannot be overstated.

Read more: Why You Need A Electric Pressure Cooker

How do Electric Motors Work?

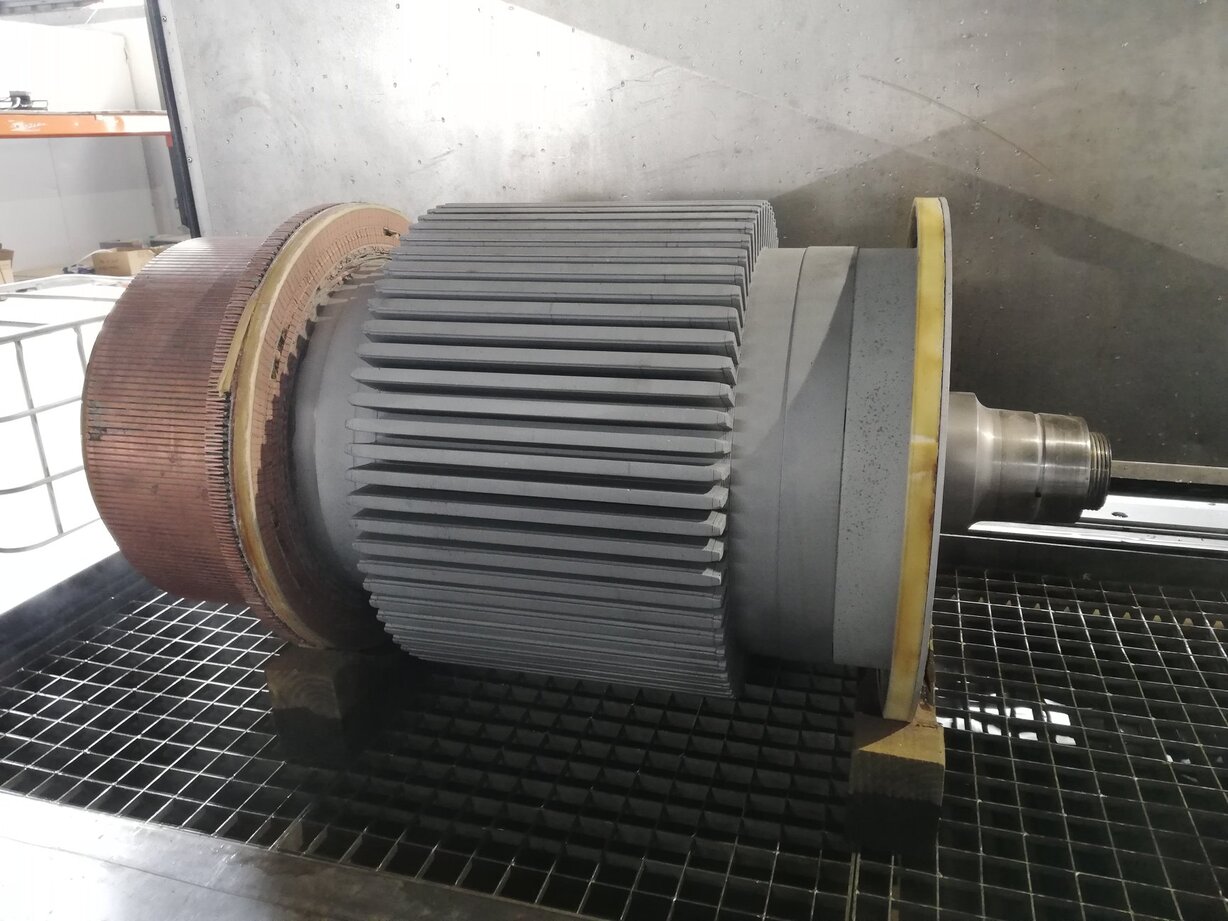

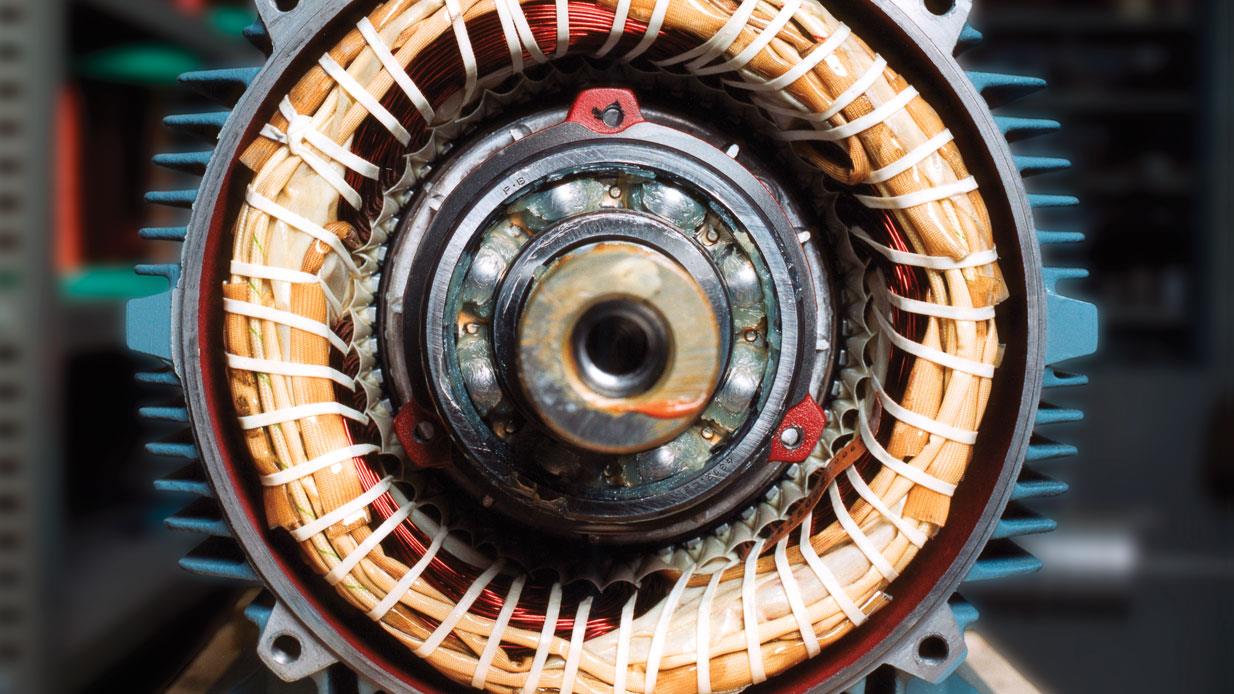

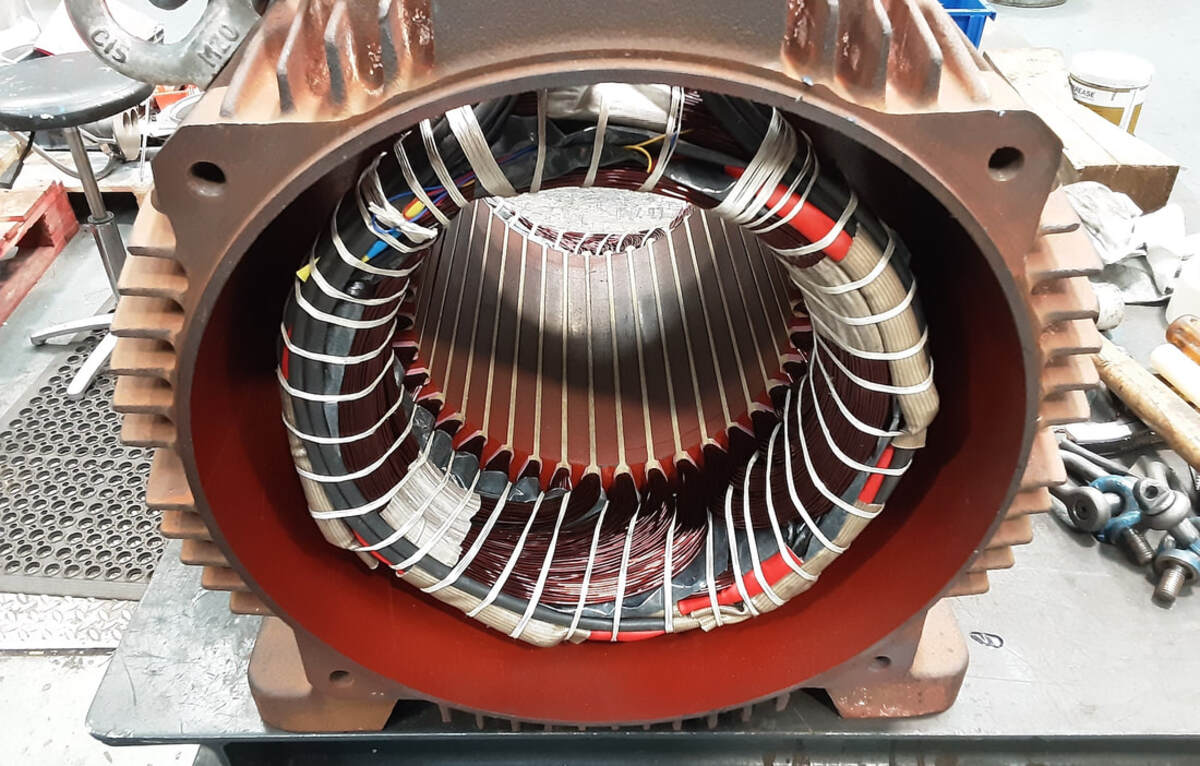

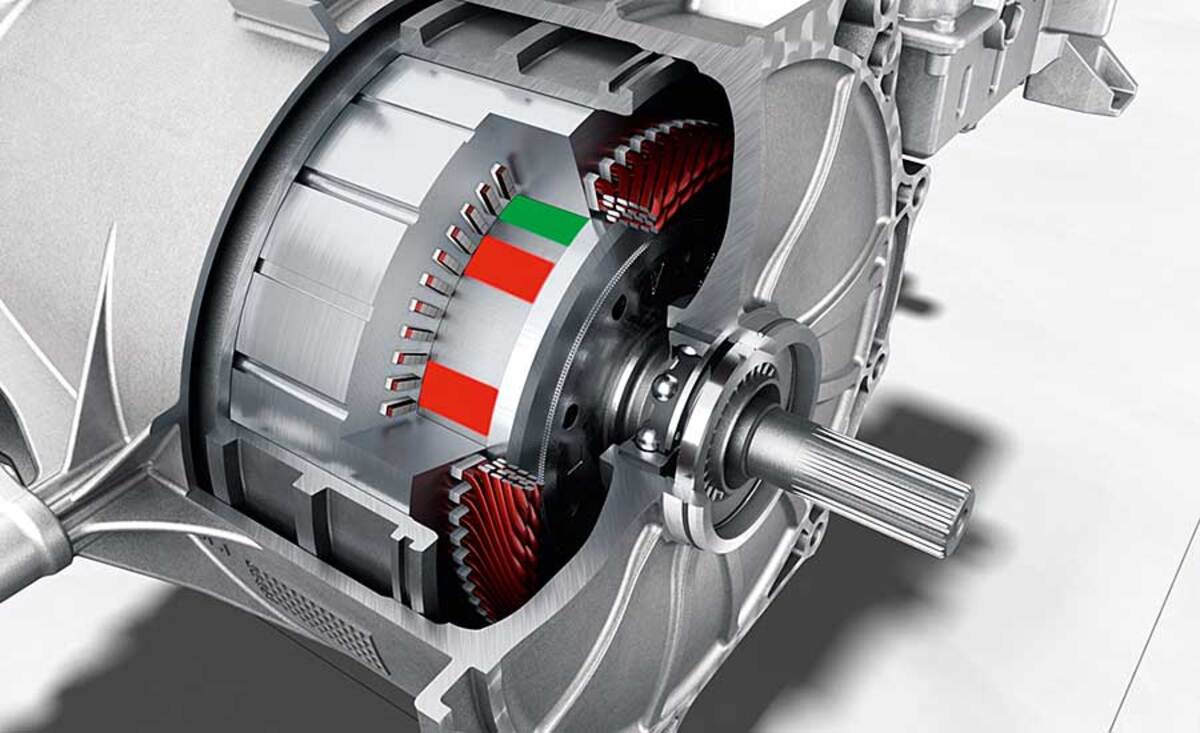

Electric motors are devices that convert electrical energy into mechanical energy. They rely on the interaction between magnetic fields and electric currents to generate motion. At their core, electric motors consist of two essential components: a stator and a rotor.

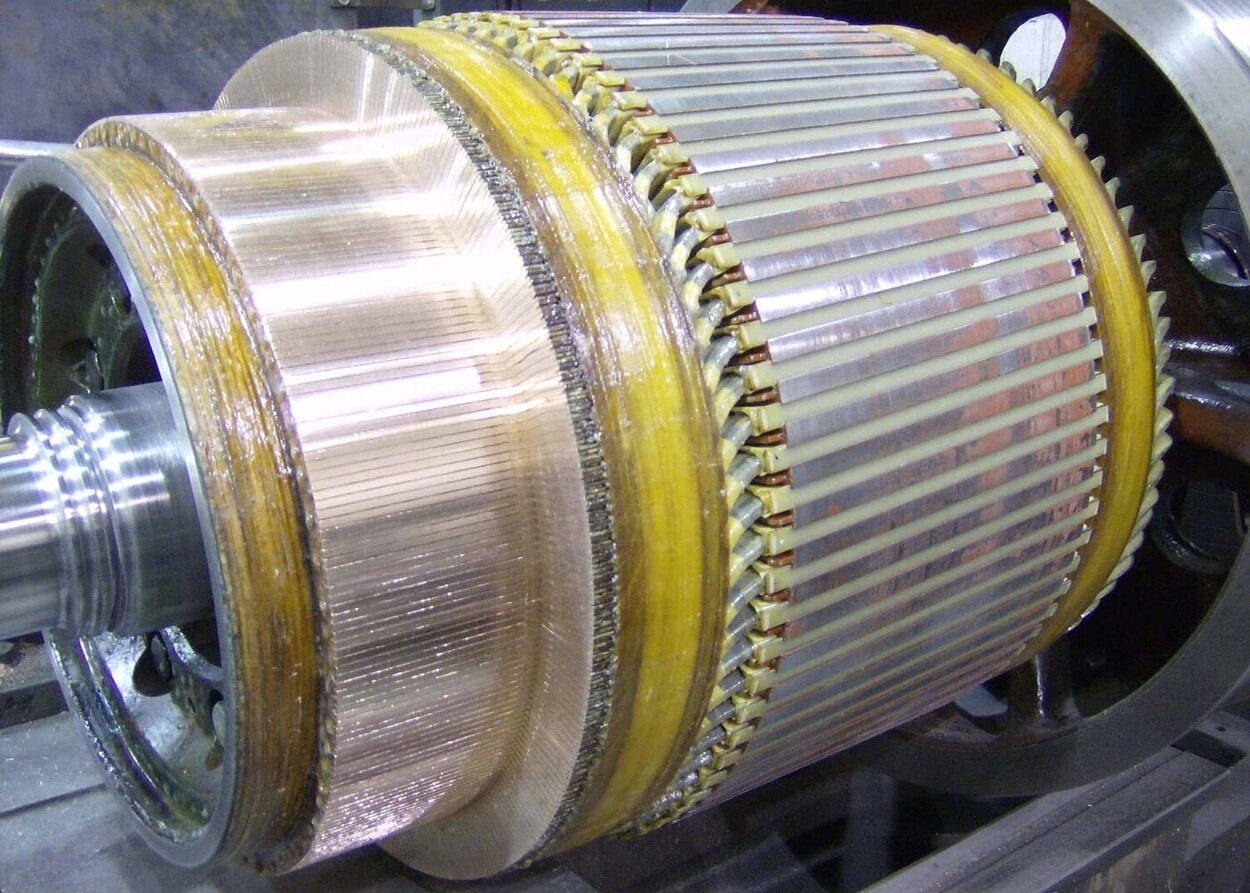

The stator is the stationary part of the motor and contains a series of wire windings arranged in a specific pattern. When an electric current is applied to these windings, they create a magnetic field. The rotor, on the other hand, is the moving part of the motor and is usually equipped with permanent magnets or electromagnets.

When the electric current flows through the windings in the stator, it produces a magnetic field that interacts with the magnetic field of the rotor. This interaction causes a force to be exerted on the rotor, causing it to rotate. The rotation of the rotor then drives the mechanical output of the motor, such as spinning a fan or propelling a vehicle.

To ensure smooth and efficient operation, electric motors require magnets to create and maintain the magnetic field. The magnets provide a permanent source of magnetic flux, eliminating the need for an external power source to generate the field. This leads us to the importance of magnets in electric motors.

Importance of Magnets in Electric Motors

Magnets play a critical role in the operation and performance of electric motors. They are responsible for creating the magnetic field necessary for the motor to function effectively. Here are some key reasons why magnets are important in electric motors:

- Magnetic Field Generation: Magnets generate a magnetic field that interacts with the electric current flowing through the motor’s windings. This interaction creates a torque or rotational force that drives the motion of the motor. Without magnets, there would be no magnetic field and no rotating force to drive the motor’s output.

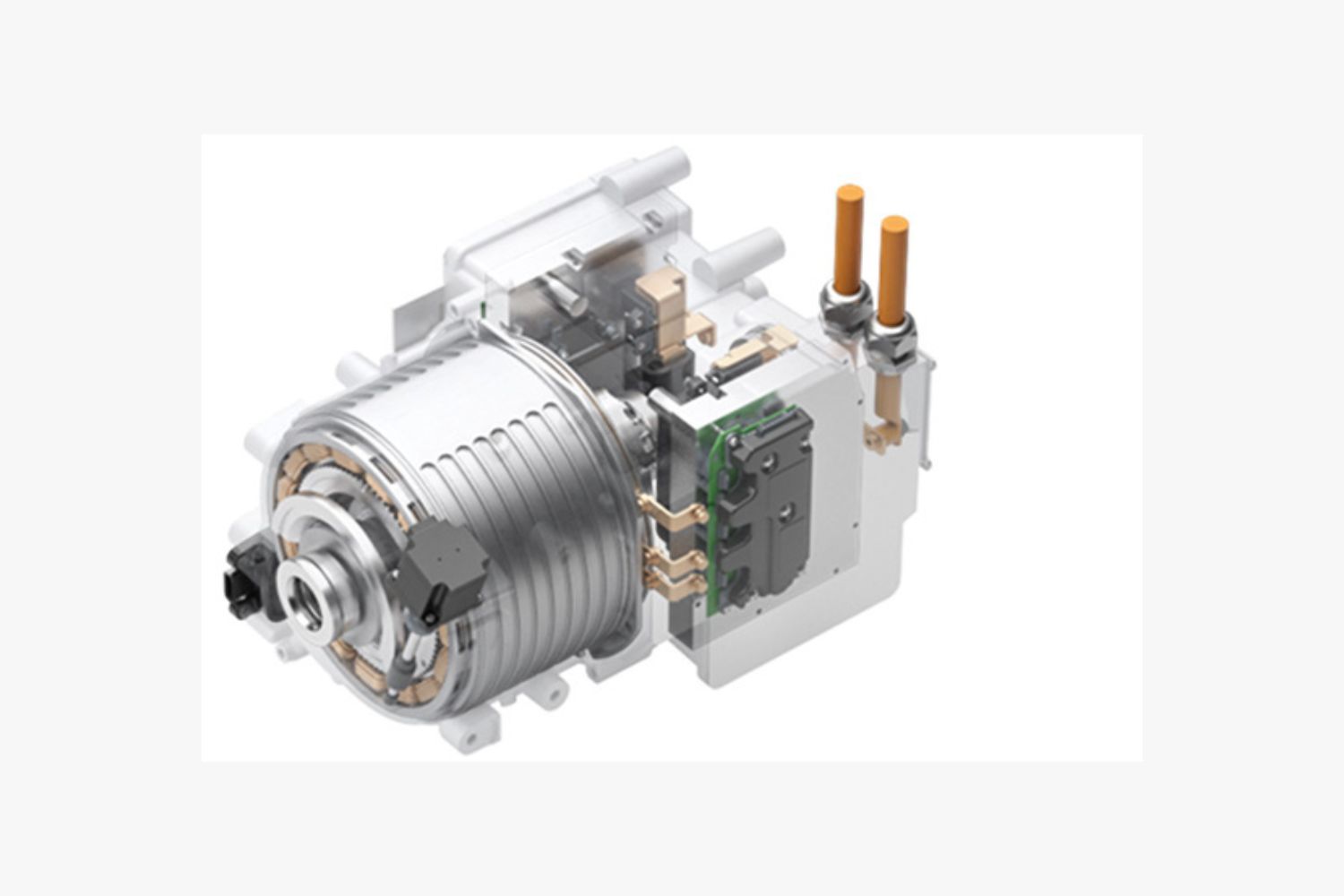

- Efficiency: Permanent magnets used in electric motors offer high levels of efficiency. They have a strong magnetic field that allows for greater torque production with less energy consumption. This improves the overall efficiency of the motor, reducing energy loss and making it more cost-effective to operate.

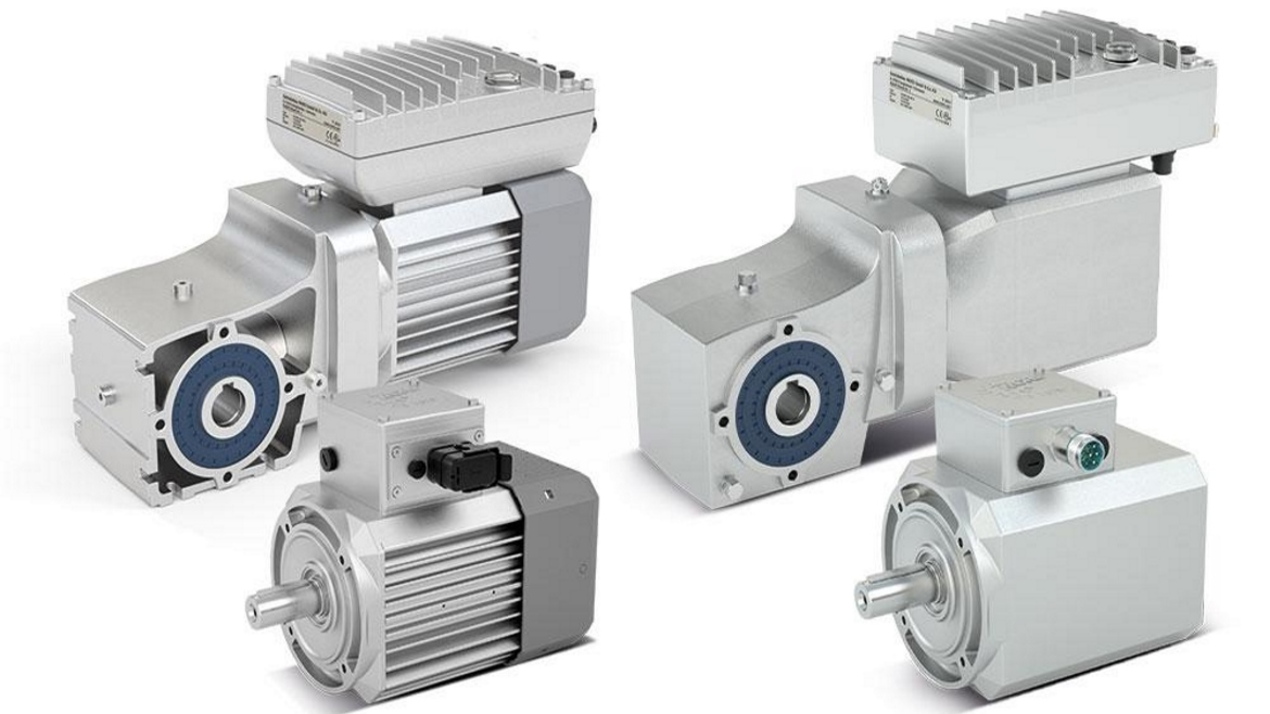

- Compact Size: Permanent magnets are compact and lightweight, making them ideal for use in electric motors. Their small size enables motors to be more compact and lightweight themselves, making them suitable for various applications where space is limited, such as in consumer electronics or automotive systems.

- Reliability and Durability: Permanent magnets are known for their durability and stability. They can withstand high temperatures and harsh operating conditions without significant loss of magnetism. This makes them reliable in long-term motor operation and reduces the need for frequent maintenance or replacement.

- Controllability: Magnets allow for precise control of the motor’s speed and direction. By altering the magnetic field, the motor’s performance can be adjusted to meet specific requirements. This feature is crucial in applications where the speed and precision of motor operation are critical, such as in robotics or industrial automation.

In summary, magnets are of utmost importance in electric motors as they create the necessary magnetic field, contribute to energy efficiency, enable compact designs, ensure reliability, and allow for precise control of the motor’s operation. Without magnets, electric motors as we know them would not exist, and the technology-driven world we live in today would be dramatically different.

Types of Magnets Used in Electric Motors

Electric motors utilize different types of magnets to generate the necessary magnetic field for their operation. The choice of magnet depends on the specific requirements of the motor application, such as performance, cost, and temperature range. Let’s explore some of the commonly used magnets in electric motors:

- Permanent Magnets: Permanent magnets, as the name implies, retain their magnetism over time without the need for an external magnetic field. They are typically made of materials like neodymium, samarium cobalt, or ferrite. Permanent magnets offer high magnetic strength, making them ideal for applications that require strong torque output and high efficiency.

- Electromagnets: Unlike permanent magnets, electromagnets require an electrical current to generate a magnetic field. They are made by wrapping a coil of wire around a core material, which intensifies the magnetic field when the current flows through the coil. Electromagnets offer the advantage of controllability, allowing the motor’s magnetic field to be adjusted by varying the current. However, they require a constant power supply to maintain the magnetic field.

- Hybrid Magnets: Hybrid magnets combine the characteristics of permanent magnets and electromagnets. They typically consist of a core material with a permanent magnet attached to it, along with a coil of wire that can produce an additional magnetic field when current is applied. This combination allows for enhanced controllability and flexibility in motor performance.

- Soft Magnetic Materials: Soft magnetic materials, such as iron, nickel, and cobalt alloys, are often used in the core of electric motor designs. While they are not permanent magnets on their own, they help guide and concentrate the magnetic field generated by the permanent magnets or electromagnets. Soft magnetic materials have low magnetic coercivity, allowing for efficient magnetization and demagnetization.

The type of magnet used in an electric motor depends on factors such as the desired performance, cost, temperature range, and specific application requirements. Permanent magnets are most commonly used due to their high magnetic strength and efficiency. However, hybrid magnets and electromagnets are preferred in certain applications where adjustability and control are crucial.

Permanent magnets are needed in an electric motor to create a constant magnetic field, which interacts with the changing magnetic field produced by the motor’s coils to generate motion. This allows for efficient and reliable operation of the motor.

Permanent Magnets vs. Temporary Magnets

Magnets used in electric motors can be categorized into two main types: permanent magnets and temporary magnets. Each type has its own characteristics and applications. Let’s explore the differences between these two types:

Permanent Magnets:

- Permanent magnets, as the name suggests, retain their magnetism over time without the need for an external magnetic field.

- They are made from materials like neodymium, samarium cobalt, or ferrite, which have high magnetic strength.

- Permanent magnets provide a constant and stable magnetic field, ensuring consistent motor performance.

- They offer high energy density, meaning they can generate strong magnetic fields with relatively small sizes.

- Permanent magnets require minimal maintenance and do not rely on a continuous power supply to maintain their magnetism.

- Permanent magnets are commonly used in electric motors due to their high efficiency, compact size, and reliability.

Temporary Magnets:

- Temporary magnets, also known as electromagnets, require an electric current to produce a magnetic field.

- They are made by wrapping a coil of wire around a core material, such as iron or steel.

- The magnetic field of temporary magnets can be controlled by adjusting the current flowing through the coil.

- Temporary magnets are typically used in applications where adjustability and controllability of the magnetic field are necessary.

- They can be turned on or off by controlling the current, allowing for precise control of the motor’s operation.

- Temporary magnets are widely used in various industries, including robotics, automation, and magnetic levitation systems.

While permanent magnets are the preferred choice for most electric motor applications due to their stability and efficiency, temporary magnets offer advantages in specific situations where adjustability and fine-tuning of the magnetic field are required. Both types of magnets have their unique characteristics and play crucial roles in the operation of electric motors.

Advantages of Permanent Magnets in Electric Motors

Permanent magnets play a vital role in the efficient and reliable operation of electric motors. These magnets offer several advantages that make them the preferred choice in many motor applications. Let’s explore some of the key advantages of permanent magnets in electric motors:

- High Magnetic Strength: Permanent magnets, such as neodymium or samarium cobalt magnets, have a high magnetic strength. This allows for the generation of strong magnetic fields, leading to greater torque production and improved motor performance.

- Energy Efficiency: Permanent magnets offer high energy density, which means they can generate strong magnetic fields with relatively small sizes. This allows for the design of compact and lightweight motors. Additionally, permanent magnets have low energy loss, resulting in higher overall motor efficiency and reduced power consumption.

- Stability and Reliability: Permanent magnets are known for their stability and durability. They can withstand high temperatures, vibrations, and harsh operating conditions without significant loss of magnetism. This ensures long-term reliability and reduces the need for frequent maintenance or magnet replacement.

- Controllability: While permanent magnets have a fixed magnetic field, their performance can still be controlled by adjusting other motor parameters, such as the number of turns in the stator windings or the shape of the rotor. This allows for precise control of the motor’s speed and torque characteristics without the need for external control devices.

- No External Power Supply: Permanent magnets do not require an external power supply to maintain their magnetic field. Once magnetized, they create a constant magnetic flux, eliminating the need for additional energy input. This simplifies the motor design and reduces dependence on external power sources.

- Long Operational Lifespan: Due to their stability and durability, permanent magnets have a long operational lifespan. They do not experience significant degradation over time, resulting in reliable and consistent motor performance throughout the motor’s lifespan.

The advantages of permanent magnets in electric motors, including high magnetic strength, energy efficiency, stability, controllability, and long lifespan, make them the preferred choice for various motor applications. By harnessing the capabilities of these magnets, electric motors can provide optimal performance, reduce energy consumption, and contribute to a more sustainable and efficient future.

Factors Affecting Permanent Magnet Performance in Electric Motors

The performance of permanent magnets in electric motors depends on various factors that can affect their magnetic properties and overall efficiency. Understanding these factors is crucial for optimizing the performance and longevity of the magnets. Let’s explore some of the key factors that can affect permanent magnet performance in electric motors:

- Temperature: Temperature has a significant impact on permanent magnet performance. High temperatures can cause a permanent magnet to lose its magnetism or reduce its magnetic strength. Therefore, it is important to ensure that the operating temperature of the motor is within the recommended range specified by the magnet manufacturer to maintain optimal performance.

- Demagnetization: Demagnetization can occur under certain conditions, such as exposure to external magnetic fields or physical shocks. Exceeding the maximum operating temperature or subjecting the magnet to high mechanical stress can also lead to demagnetization. To prevent demagnetization, proper design considerations, such as selecting suitable magnet materials and adequate magnetic shielding, should be implemented.

- Humidity and Corrosion: Moisture and corrosive environments can degrade the performance of permanent magnets over time. It is important to protect the magnets from moisture and corrosion by employing suitable coatings or encapsulation materials. Regular maintenance and inspection can also help detect any signs of degradation and ensure the longevity of the magnets.

- Mechanical Stress: Excessive mechanical stress, such as vibration, shock, or physical deformation, can impact the performance of permanent magnets. High-stress levels can lead to cracks or fractures in the magnet material, compromising its magnetic properties. Proper design considerations, including robust mechanical support and vibration damping strategies, are essential to minimize the impact of mechanical stress on the magnets.

- Magnet Purity and Manufacturing Quality: The purity and manufacturing quality of permanent magnets play a crucial role in their overall performance. Impurities or defects in the magnet material can affect its magnetic properties and durability. It is important to source magnets from reputable suppliers and ensure strict quality control measures during the manufacturing process.

- Magnetic Field Orientation: The orientation of the magnetic field generated by permanent magnets can impact the motor performance. Proper alignment and positioning of the magnets within the motor design are important to optimize the magnetic field distribution and maximize the motor’s torque output.

By considering and addressing these factors, motor designers and manufacturers can optimize the performance of permanent magnets and ensure their long-term reliability and efficiency. Implementing appropriate measures to protect against temperature, demagnetization, humidity, corrosion, mechanical stress, and maintaining high magnet purity and manufacturing quality will contribute to the overall performance and lifespan of the magnets in electric motors.

Conclusion

Magnets are an essential component in electric motors, providing the magnetic field necessary for their operation. Permanent magnets, in particular, offer numerous advantages that make them the preferred choice in many motor applications.

Permanent magnets, with their high magnetic strength, contribute to efficient motor performance by generating strong magnetic fields that result in greater torque production. They also offer high energy density, enabling the design of compact and lightweight motors that consume less power.

Furthermore, permanent magnets exhibit stability and reliability, with the ability to withstand high temperatures, vibrations, and harsh operating conditions without significant loss of magnetism. They require no external power supply to maintain their magnetic field, simplifying motor design and reducing dependence on external control devices.

However, there are several factors that can impact the performance of permanent magnets in electric motors. Temperature, demagnetization, humidity, corrosion, mechanical stress, and magnet purity and manufacturing quality must be carefully managed to ensure optimal magnet performance and longevity.

In conclusion, the importance of magnets in electric motors cannot be understated. The use of permanent magnets brings significant advantages, such as high magnetic strength, energy efficiency, stability, controllability, and long operational lifespan. By understanding the factors that affect permanent magnet performance and implementing proper design and maintenance strategies, motor manufacturers can maximize the potential of these magnets, leading to more efficient and reliable electric motors.

Frequently Asked Questions about Why Are Permanent Magnets Needed In An Electric Motor

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “Why Are Permanent Magnets Needed In An Electric Motor”