Articles

What Does An Electric Motor Do

Modified: October 20, 2024

Learn about the role of electric motors in various applications. Read informative articles and gain insights into how these motors work and their practical uses.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

In today’s fast-paced world, electric motors have become an essential part of our daily lives. From powering machines to propelling vehicles, these ingenious devices play a crucial role in various industries and sectors. Understanding what an electric motor does and how it works is the first step towards appreciating their importance in modern society.

An electric motor is a device that converts electrical energy into mechanical energy. It is a fundamental component found in a wide range of applications, from household appliances to industrial machinery. By harnessing the power of electricity, electric motors have revolutionized our ability to automate tasks, create efficient transportation systems, and drive technological advancements.

Electric motors have replaced traditional combustion engines in many areas due to their numerous advantages. They provide clean, reliable, and efficient operation, reducing noise pollution and minimizing environmental impact. Moreover, electric motors are highly versatile and can be precisely controlled, allowing for optimal performance and energy utilization.

Understanding how an electric motor works is essential to grasp its capabilities and potential applications. By converting electrical energy into mechanical energy, electric motors enable the movement and operation of various devices. Whether it’s spinning the blades of a fan, propelling a car forward, or driving industrial machinery, electric motors power the modern world.

This article will delve into the inner workings of electric motors, exploring their components, types, applications, advantages, and disadvantages. By the end, you’ll have a comprehensive understanding of what an electric motor does and why it is such a crucial part of our everyday lives.

Key Takeaways:

- Electric motors are essential in modern society, powering everything from household appliances to industrial machinery. Their energy efficiency, quiet operation, and precise control make them indispensable in our daily lives.

- While electric motors offer numerous advantages, such as environmental friendliness and long lifespan, they also come with limitations like dependence on electricity supply and initial cost. Ongoing research and development efforts are addressing these challenges, making electric motors more accessible and efficient.

Read more: What Electric Motor Does Tesla Use

How Does an Electric Motor Work?

At the heart of an electric motor is a simple yet ingenious principle: electromagnetic induction. This principle, discovered by Michael Faraday in the 19th century, forms the foundation for the operation of electric motors.

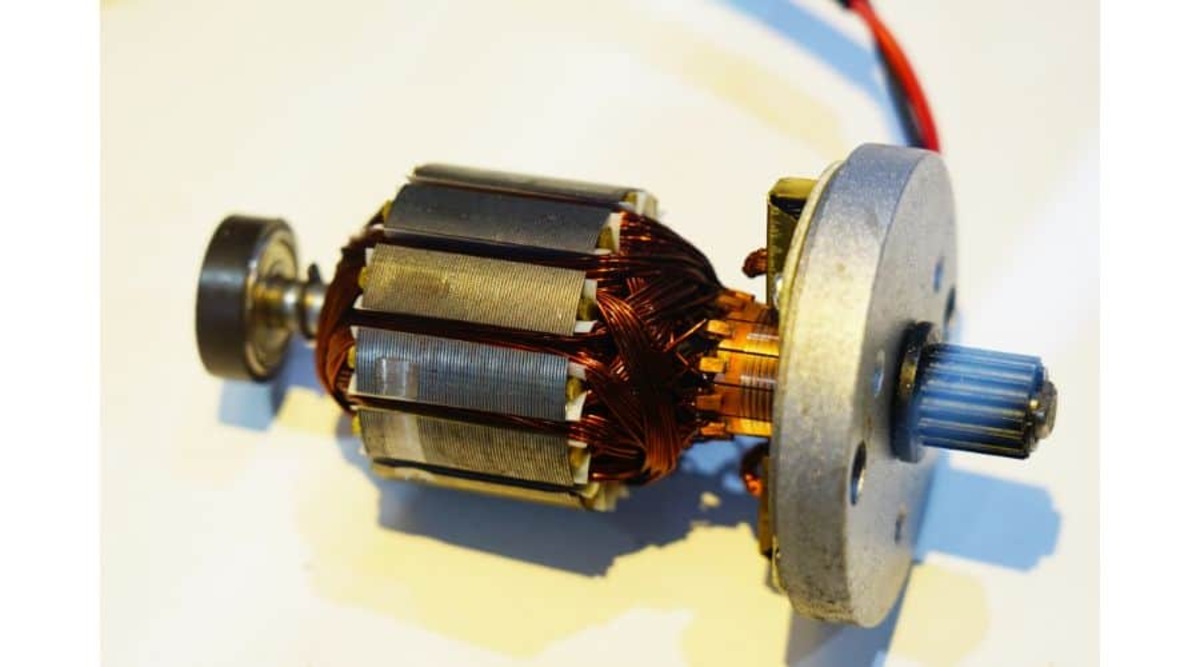

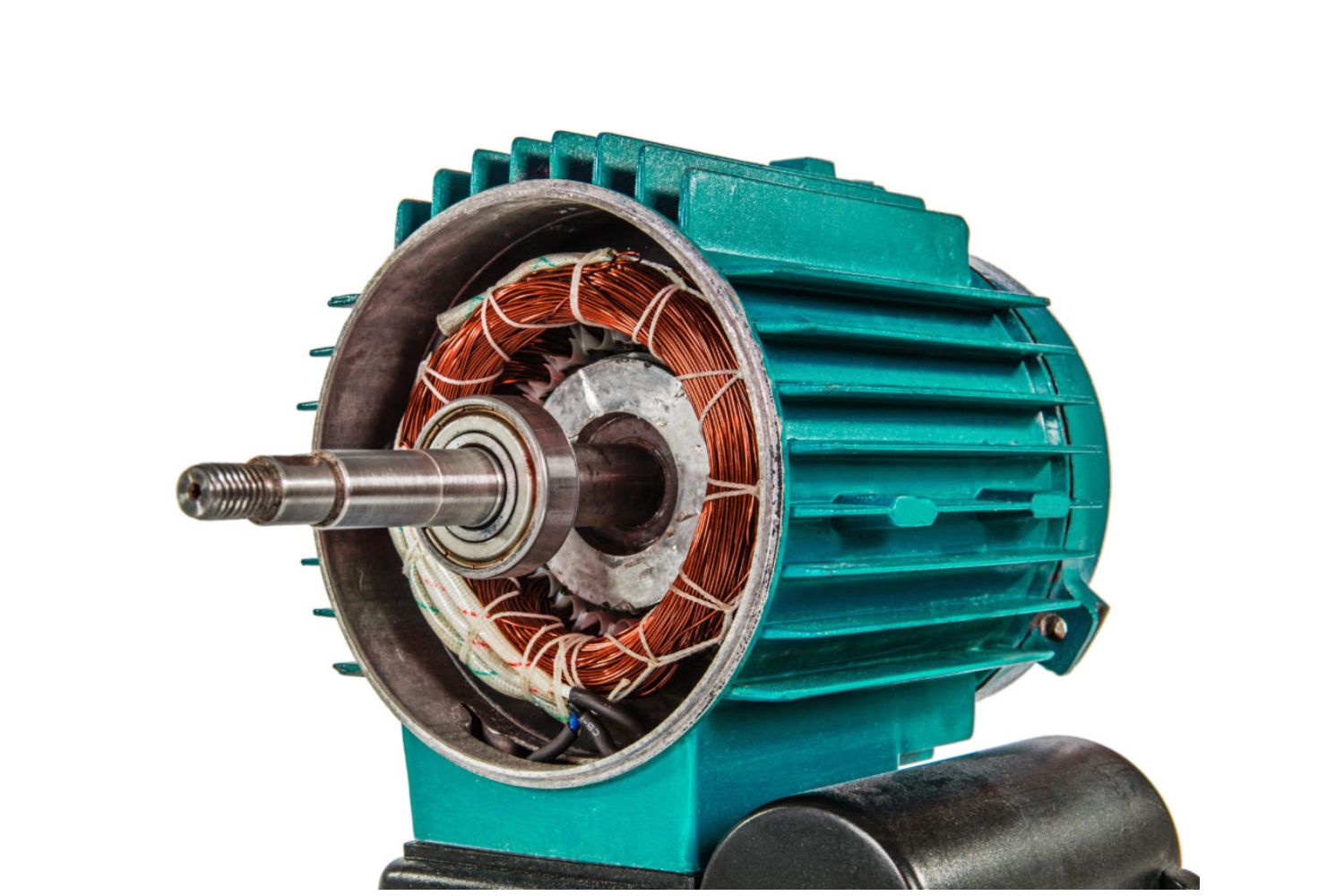

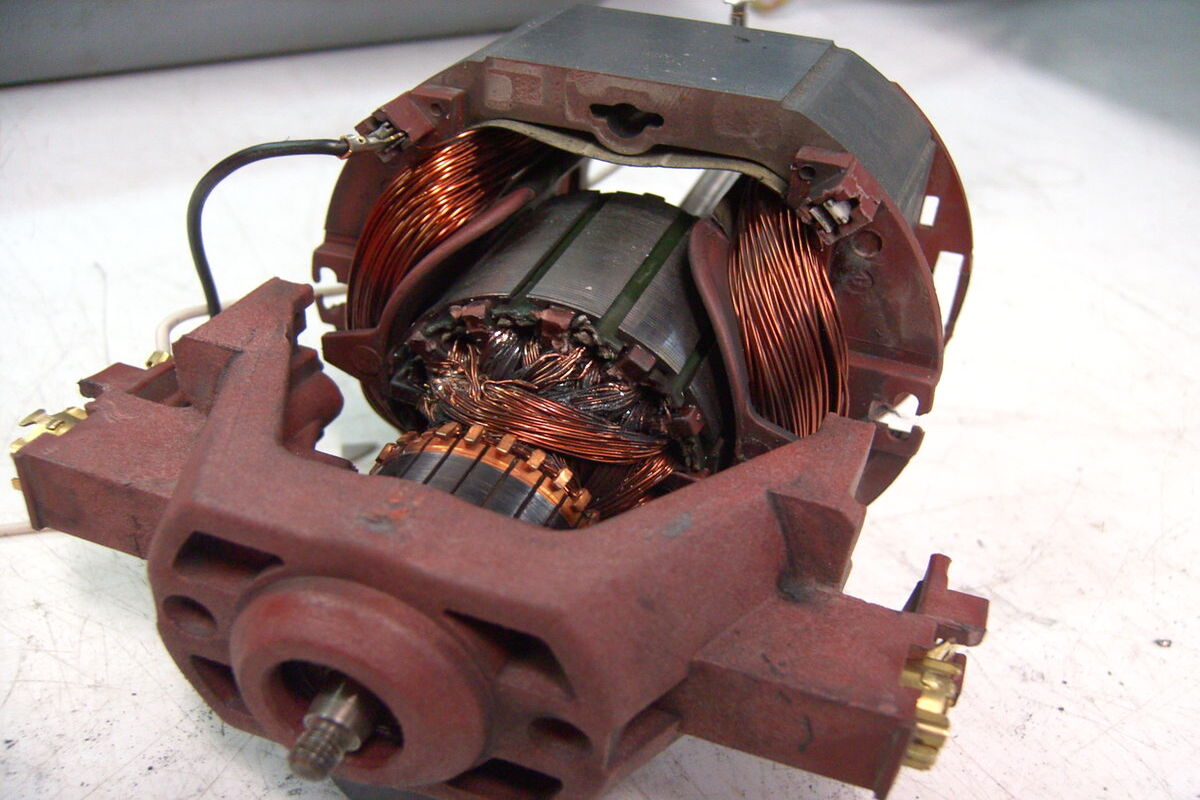

An electric motor consists of two main components: the stator and the rotor. The stator is the stationary part of the motor, while the rotor is the moving part. The stator contains a series of coils, known as windings, which are made of insulated copper wire. These windings are arranged in a specific pattern to create a magnetic field when an electrical current flows through them.

When an electric current is supplied to the motor, it flows through the windings in the stator. This electric current generates a magnetic field that induces a force on the rotor, causing it to spin. The rotor is made up of a series of electromagnets or permanent magnets, depending on the type of motor.

As the rotor begins to spin, it interacts with the magnetic field created by the stator. The magnetic fields repel or attract each other, depending on the polarity of the magnets and windings. This interaction creates a rotational force, known as torque, which drives the rotor to continue spinning.

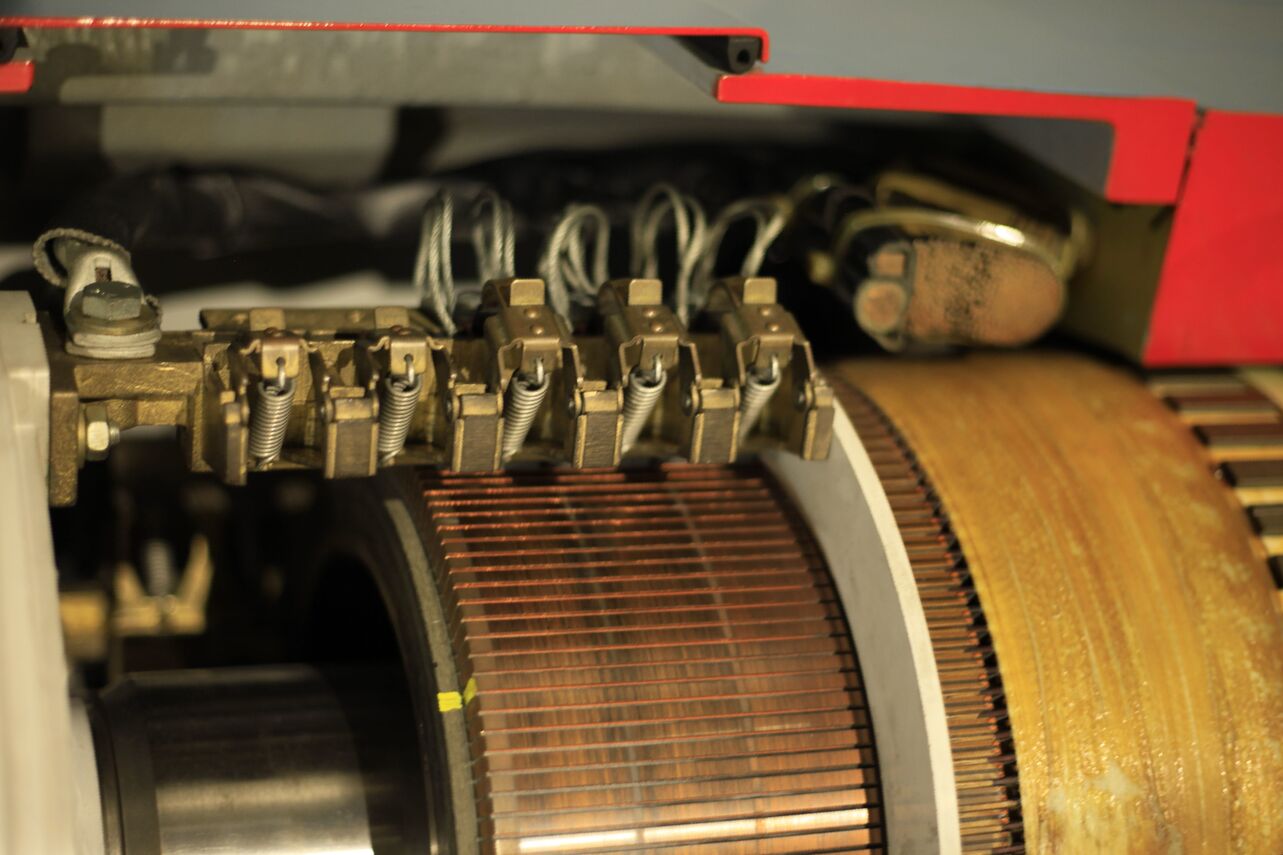

The direction of the rotation can be reversed by changing the polarity of the current flow in the windings. This is typically achieved by using a device called a commutator for direct current (DC) motors or an electronic controller for alternating current (AC) motors.

By controlling the flow of electric current and the strength of the magnetic field, the speed and torque of the motor can be adjusted. This allows for precise control and efficient operation in various applications.

It is worth mentioning that electric motors can also work in reverse. By subjecting the rotor to an external mechanical force, it can induce an electric current in the windings, effectively acting as a generator. This principle, known as regenerative braking, is commonly used in electric vehicles to convert kinetic energy into electrical energy, which can then be stored in batteries for later use.

Overall, the operation of an electric motor is a complex interplay between electrical currents, magnetic fields, and mechanical forces. Through careful design and engineering, electric motors have become highly efficient and versatile devices capable of powering a wide range of machinery and applications.

Components of an Electric Motor

An electric motor is composed of several key components working together to convert electrical energy into mechanical energy. Each component plays a crucial role in the motor’s performance and functionality. Let’s explore these components in more detail:

- Stator: The stator is the stationary part of the motor and houses the windings. It is typically constructed with a series of stacked laminations to reduce energy losses due to eddy currents. The windings, made of insulated copper wire, are arranged in specific patterns to create a magnetic field.

- Rotor: The rotor is the moving part of the motor and is responsible for generating mechanical motion. It can be either an electromagnet or a permanent magnet, depending on the motor type. The rotor interacts with the magnetic field created by the stator, causing it to spin.

- Windings: The windings are coils of insulated wire that reside in the stator. These windings carry the electrical current that creates the magnetic field. The number and arrangement of windings determine the motor’s characteristics, such as torque and speed.

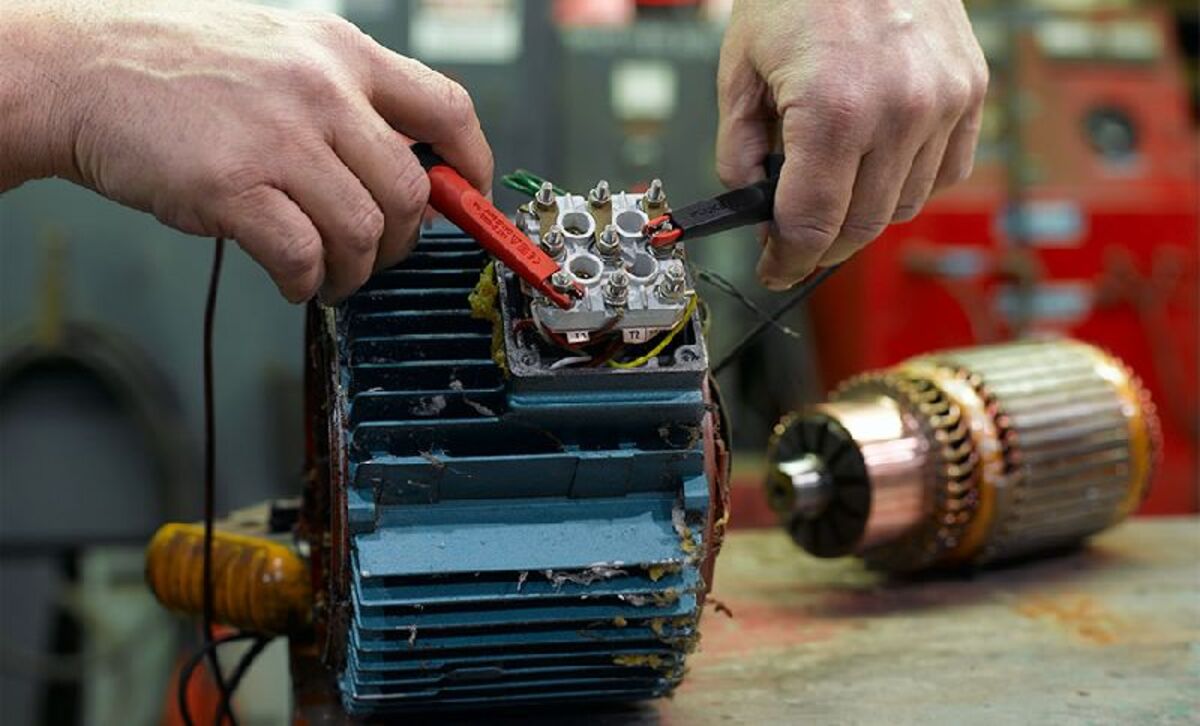

- Commutator (DC Motors): In DC motors, the commutator is a device that switches the direction of the electric current in the windings. It consists of metal segments that are insulated from each other and connected to different windings. The commutator ensures that the rotor continues to rotate in the same direction.

- Brushes (DC Motors): Brushes are conductive contacts that make physical contact with the commutator. They are responsible for delivering the electric current to the windings in a DC motor. The brushes typically consist of carbon or graphite material to provide smooth contact and minimize wear.

- Bearings: Bearings are essential for reducing friction and allowing smooth rotation of the motor’s shaft. They support the weight of the rotor and enable its movement. Common types of bearings used in electric motors include ball bearings and sleeve bearings.

- Enclosure: The enclosure protects the internal components of the motor from external factors such as dust, moisture, and physical damage. It also helps to dissipate heat generated during operation and provides a mounting surface for the motor.

- Cooling System: Larger electric motors often incorporate a cooling system to regulate the motor’s temperature during operation. This can be achieved through the use of cooling fans, heat sinks, or liquid cooling systems. Proper cooling is essential to ensure optimal performance and prevent overheating.

These components work together seamlessly to enable the conversion of electrical energy into mechanical energy. The precise design and selection of these components depend on the specific application and requirements of the motor.

Types of Electric Motors

Electric motors come in various types, each designed to meet specific application requirements. Different motor types offer distinct advantages and suitable performance characteristics. Let’s explore some common types of electric motors:

- DC Motors: Direct Current (DC) motors are widely used in applications where precise speed control is required. They consist of a stator with windings and a rotor with permanent magnets. DC motors are known for their simplicity, reliability, and high torque at low speeds. They are commonly used in electric vehicles, robotics, and small appliances.

- AC Motors: Alternating Current (AC) motors are the most widely used type of electric motor. They run on AC power and can be further categorized into various subtypes, including induction motors, synchronous motors, and brushless DC motors. AC motors are known for their simplicity, low maintenance, and efficiency. They are used in a wide range of applications such as pumps, fans, compressors, and industrial machinery.

- Induction Motors: Induction motors are the workhorses of the industrial world. They are robust, reliable, and suitable for a wide range of applications. Induction motors work on the principle of electromagnetic induction, where the rotating magnetic field generated by the stator induces a current in the rotor. These motors are widely used in manufacturing, HVAC systems, and conveyor belts.

- Synchronous Motors: Synchronous motors operate at a fixed speed that is synchronized with the frequency of the power source. They are often used in applications that require precise control and positioning, such as robotics, CNC machines, and synchronous generators.

- Brushless DC Motors: Brushless DC motors, also known as BLDC motors, offer the advantages of high efficiency, compact size, and long lifespan. They are similar in operation to DC motors but use electronic commutation instead of brushes and a commutator. BLDC motors are commonly found in drones, electric vehicles, and computer cooling fans.

- Stepper Motors: Stepper motors are designed for precise control and positioning. They can rotate in small, fixed incremental steps and provide accurate motion control. Stepper motors are commonly used in 3D printers, CNC machines, and robotics.

Each type of electric motor has its own unique characteristics and is suited for specific applications. The choice of motor type depends on factors such as speed requirements, load characteristics, efficiency, cost, and control requirements.

Applications of Electric Motors

Electric motors are used in a vast array of applications across various industries, revolutionizing the way we live and work. From household appliances to complex industrial machinery, electric motors power a wide range of devices. Let’s explore some common applications of electric motors:

- Home Appliances: Electric motors are integral to numerous household appliances, including refrigerators, air conditioners, washing machines, and vacuum cleaners. They drive the compressors, fan motors, and agitators, providing essential functionality and convenience in our daily lives.

- Transportation: Electric motors play a significant role in the transportation sector, particularly in electric vehicles (EVs). They power the propulsion system, converting electrical energy into mechanical energy to drive the wheels. Electric motors are also used in hybrid vehicles, electric bikes, and trains, offering a cleaner and more sustainable alternative to traditional combustion engines.

- Industrial Machinery: Electric motors are extensively used in various industrial applications. They power conveyor belts, pumps, compressors, and industrial fans. Electric motors are also found in manufacturing equipment such as machine tools, robots, and assembly line systems, improving efficiency and automation capabilities.

- Aerospace and Defense: Electric motors are utilized in aerospace applications, including aircraft systems such as flight control actuators, landing gear mechanisms, and auxiliary power units. In the defense sector, electric motors are used in missile systems, guidance systems, and military vehicles.

- Renewable Energy: Electric motors play a crucial role in renewable energy generation systems. They are used in wind turbines to convert wind energy into electrical power. Electric motors are also found in solar tracking systems, ensuring efficient alignment of solar panels with the sun’s position for maximum energy capture.

- Medical Devices: Electric motors are essential components of medical devices and equipment. They power the operation of surgical tools, diagnostic equipment, prosthetic devices, and MRI machines. Electric motors enable precise and controlled movements in medical robotics and assistive devices.

- Entertainment and Gaming: Electric motors enhance the entertainment experience in various ways. They power amusement park rides, conveyor systems in theme parks, and motion simulators. Electric motors are also found in gaming consoles, enabling force feedback in controllers and enhancing immersion in virtual reality systems.

These are just a few examples of the countless applications of electric motors. With advancements in motor technology, the possibilities for their use continue to expand, paving the way for innovative solutions in various industries.

When using an electric motor, make sure to provide proper maintenance by keeping it clean and lubricated to ensure optimal performance and longevity.

Advantages and Disadvantages of Electric Motors

Electric motors offer numerous advantages that have made them a popular choice in various industries and applications. However, like any technology, they also have their own limitations. Let’s explore the advantages and disadvantages of electric motors:

Advantages:

- Energy Efficiency: Electric motors have high energy efficiency, especially when compared to combustion engines. They convert a significant portion of electrical energy into mechanical energy, reducing energy wastage and operating costs.

- Environmentally Friendly: Electric motors produce zero or reduced emissions during operation, making them environmentally friendly alternatives to combustion engines. They contribute to lower air pollution levels and help combat climate change.

- Quiet Operation: Electric motors operate with less noise compared to internal combustion engines. This makes them ideal for applications where noise reduction is important, such as household appliances and electric vehicles.

- Instantaneous Torque: Electric motors provide high torque at low speeds, allowing for quick startup and acceleration. This feature is particularly beneficial in applications that require precise control and rapid response, such as robotics and electric vehicles.

- Long Lifespan: Electric motors are durable and can have a long operational lifespan with proper maintenance. They have fewer moving parts compared to combustion engines, reducing the risk of mechanical failure.

- Flexibility and Control: Electric motors offer precise control over speed, torque, and direction of rotation. This flexibility allows for optimized performance and efficient operation in various applications. Additionally, electric motors can be integrated with advanced control systems for enhanced automation and monitoring capabilities.

Disadvantages:

- Initial Cost: Electric motors can have a higher upfront cost compared to traditional combustion engines. However, the cost of electric motors has been decreasing over the years, making them more accessible.

- Dependence on Electricity: Electric motors rely on a steady and reliable electricity supply. In case of power outages or inadequate infrastructure, the functionality of electric motors can be affected.

- Limited Energy Storage: Electric motors require a power source, typically batteries, to operate independently. The limited energy storage capacity of current battery technology can impact the range and runtime of electric motor-powered devices.

- Charging Infrastructure: Electric vehicles, in particular, may face challenges due to the need for a well-developed charging infrastructure. Lack of charging stations can limit the adoption and convenience of electric vehicles.

- Environmental Impact of Battery Production and Disposal: The production and disposal of electric vehicle batteries can have environmental implications. Proper recycling and responsible disposal methods are essential to mitigate these impacts.

- Weight and Size: Electric motors, especially those with high power output, can be heavier and larger than their combustion engine counterparts. This can pose challenges in applications where space and weight restrictions are a concern.

Despite these limitations, the advantages of electric motors, such as energy efficiency, environmental friendliness, and precise control, make them an increasingly attractive choice for a wide range of applications.

Conclusion

Electric motors have revolutionized the way we live and work, powering a wide range of devices and industries. Understanding what an electric motor does and how it works provides a deeper appreciation for their significance in our daily lives.

Electric motors have become indispensable components in various applications, from household appliances to industrial machinery. Their energy efficiency, environmental friendliness, and versatility make them a preferred choice over traditional combustion engines. Electric motors offer precise control, high torque at low speeds, and quiet operation, enabling enhanced performance and efficiency.

Advancements in electric motor technology continue to expand their potential applications. From electric vehicles that reduce emissions and dependence on fossil fuels to renewable energy systems that harness the power of wind and sun, electric motors are driving a sustainable future.

While electric motors have numerous advantages, they also come with certain limitations, such as the dependence on electricity supply and initial cost. However, ongoing research and development efforts are addressing these challenges, making electric motors more accessible and efficient.

In conclusion, electric motors have transformed the way we harness energy and power our world. Their ability to convert electrical energy into mechanical energy has paved the way for innovation and progress. As technology continues to evolve, electric motors will undoubtedly play a crucial role in shaping a greener, more sustainable future.

Frequently Asked Questions about What Does An Electric Motor Do

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Does An Electric Motor Do”