Home>Articles>What Device Is Like The Reverse Of An Electric Motor?

Articles

What Device Is Like The Reverse Of An Electric Motor?

Modified: December 7, 2023

Discover articles that explore the mysterious device that functions in reverse of an electric motor. Uncover the secrets behind this intriguing technology.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Electric motors are a fundamental part of our modern world, powering everything from household appliances to industrial machinery. These devices convert electrical energy into mechanical energy, enabling them to perform various tasks with efficiency and precision. However, have you ever wondered if there is a device that works in the reverse manner of an electric motor?

In this article, we will explore the intriguing concept of a device that functions in the opposite way of an electric motor. We will delve into the workings of electric motors, their reverse functionality, and ultimately reveal the fascinating counterpart to an electric motor. So, let’s embark on this journey of discovery as we unravel the mystery of the reverse device.

Key Takeaways:

- Electric motors can function in reverse, converting mechanical energy into electrical energy. This reverse functionality, based on electromagnetic induction, allows for energy regeneration and conservation in applications such as regenerative braking and wind turbines.

- Generators, the reverse devices of electric motors, play a vital role in power generation and backup supply. They harness mechanical energy to produce electrical power, serving diverse applications from power plants to off-grid locations and emergency services.

Read more: How To Wire A Reversible Electric Motor

Overview of Electric Motors

Electric motors are electromechanical devices that convert electrical energy into mechanical energy. They operate based on the principles of electromagnetism, with the interaction between magnetic fields and electric currents resulting in the generation of rotational motion.

There are various types of electric motors, including DC (Direct Current) motors and AC (Alternating Current) motors, each with their own distinct characteristics and applications. DC motors are commonly found in devices such as fans, toys, and small appliances, while AC motors are utilized in larger machinery, such as pumps, compressors, and industrial equipment.

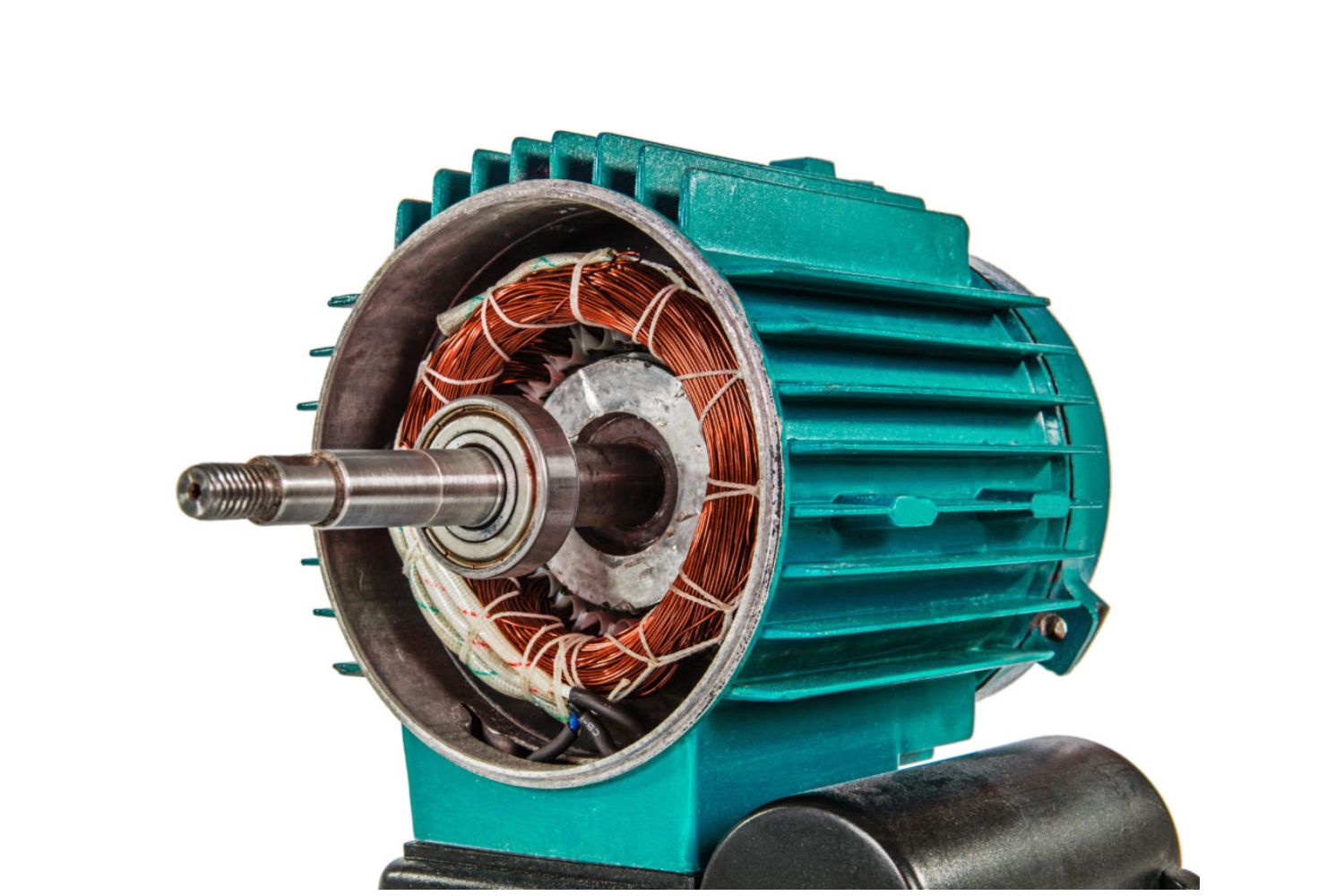

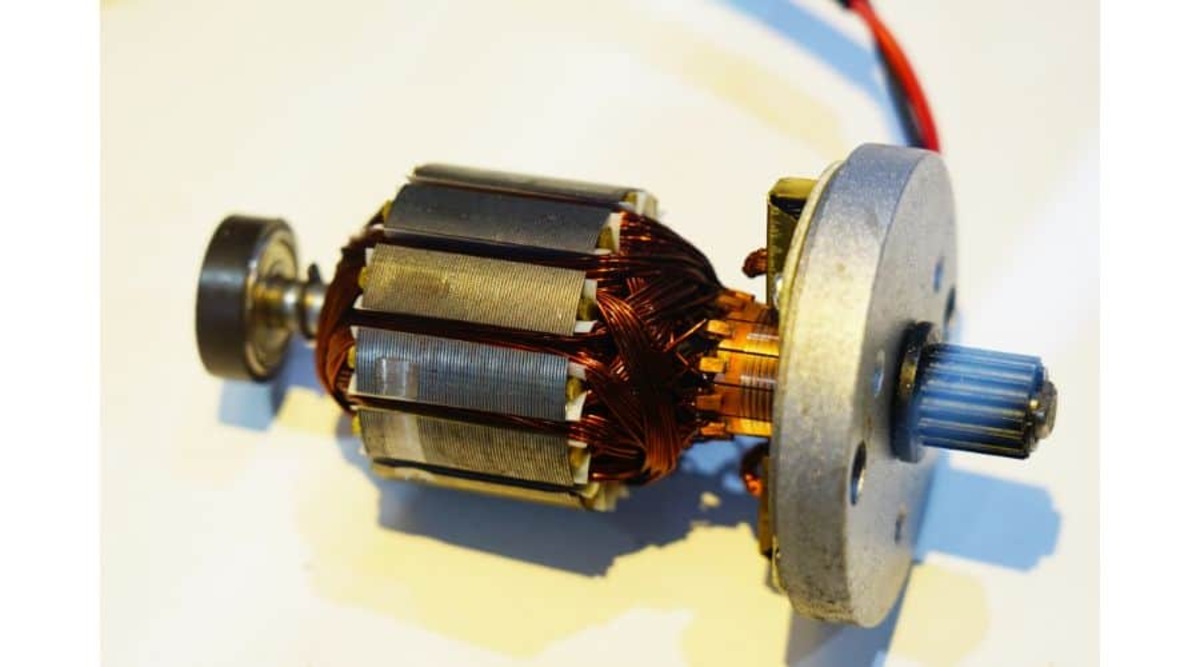

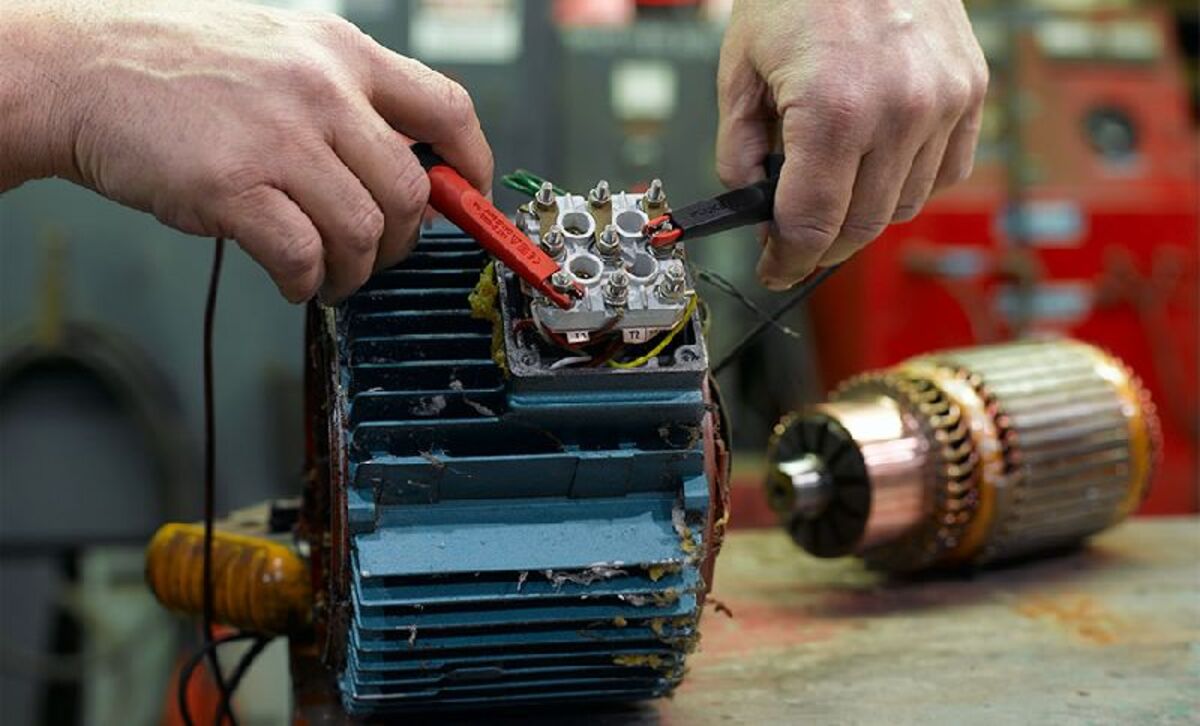

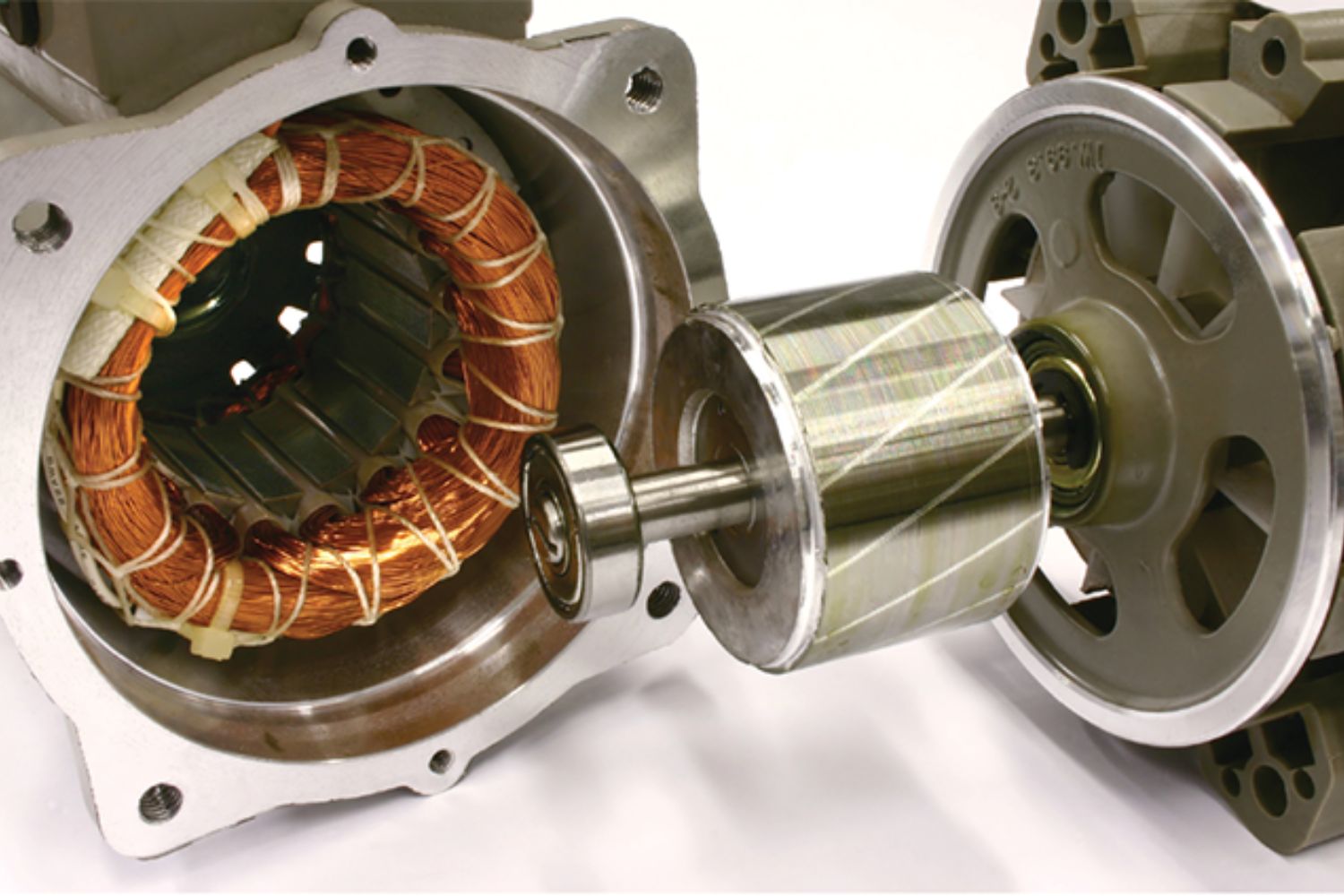

The key components of an electric motor include the stator, rotor, and commutator or slip rings. The stator comprises a set of stationary coils that create a magnetic field, while the rotor consists of a rotating armature or permanent magnets. The commutator or slip rings facilitate the flow of electricity to the coils, ensuring the continuous rotation of the rotor.

Electric motors are known for their efficiency, reliability, and versatility. They offer precise control over speed and torque, making them suitable for a wide range of applications across various industries.

Functioning of Electric Motors

The functioning of electric motors is based on the principles of electromagnetism and electromagnetic induction. When an electric current passes through the coils in the stator, it creates a magnetic field. This magnetic field interacts with the magnetic field of the rotor, resulting in the generation of mechanical motion.

DC motors rely on the commutator to direct the flow of electricity to the stator coils. As the rotor rotates, the commutator switches the direction of the current, ensuring a continuous rotational movement. This mechanism allows DC motors to maintain a constant speed and torque.

On the other hand, AC motors operate based on the principles of alternating current. The alternating current supplied to the stator produces a rotating magnetic field, which induces current in the rotor. The interaction between the rotating magnetic field of the stator and the induced currents in the rotor causes the rotor to rotate.

The speed of an electric motor can be controlled by adjusting the voltage or frequency of the power supply. Lowering the voltage reduces the speed, while increasing the voltage enhances the speed. Similarly, changing the frequency of the power supply can also alter the motor’s speed.

Electric motors exhibit high efficiency, as they can convert a significant amount of electrical energy into mechanical energy. This makes them a preferred choice in various applications, where energy conservation is crucial.

Reverse Functionality of Electric Motors

While the primary purpose of electric motors is to convert electrical energy into mechanical energy, they can also operate in a reverse manner. This reverse functionality allows electric motors to convert mechanical energy into electrical energy, effectively working as generators.

When an external force is applied to the rotating shaft of an electric motor, the rotor spins, generating an electrical current in the coils of the stator. This electrical current can be harnessed and utilized, making electric motors suitable for applications such as regenerative braking in electric vehicles or generating electricity through wind turbines.

The reverse functionality of electric motors is based on the principles of electromagnetism and Faraday’s law of electromagnetic induction. According to Faraday’s law, a change in the magnetic field within a coil induces an electromotive force (EMF) or voltage across the coil.

In the case of a motor operating in reverse, the mechanical energy applied to the rotor causes a change in the magnetic field, which leads to the induction of an electrical current in the stator coils. This current can then be utilized or stored for various purposes.

It is important to note that the reverse functionality of electric motors is not as efficient as their primary function of converting electrical energy into mechanical energy. This is because some energy is lost in the form of heat and resistance during the conversion process.

Nevertheless, the reverse functionality of electric motors expands their range of applications and allows for energy regeneration and conservation. It enables the utilization of mechanical energy to produce electrical power, promoting sustainability and efficient energy usage.

What Device Functions in the Reverse Manner of an Electric Motor?

Now that we have explored the reverse functionality of electric motors, you may be curious about the device that functions in the opposite way. The counterpart to an electric motor, which transforms electrical energy into mechanical energy, is known as a generator or alternator.

Generators are devices that convert mechanical energy into electrical energy. They operate on the principles of electromagnetic induction, similar to electric motors but in reverse. When a mechanical force is applied to the generator’s rotor, it causes the magnetic field to change, resulting in the induction of an electrical current in the stator.

Generators come in different types, including AC generators (alternators) and DC generators. AC generators produce alternating current, while DC generators produce direct current. These devices are essential in power generation systems, where they convert the mechanical energy from turbines, engines, or other sources into electrical energy.

The reverse functionality of a generator allows it to harness various forms of mechanical energy, such as wind, water, or steam, and convert it into usable electrical power. This makes generators a vital component in renewable energy systems, backup power supplies, and portable electricity generation.

Generators play a significant role in maintaining a stable and reliable power supply, especially in situations where the grid is not available or during power outages. They are widely used in industries, construction sites, remote locations, and emergency situations where a constant and independent electrical supply is required.

It’s important to note that while generators can function in the opposite manner of electric motors, they have different designs and operating characteristics. Generators are specifically designed to handle the conversion of mechanical energy into electrical energy, ensuring efficiency and optimal performance.

So, the next time you think about the reverse device of an electric motor, remember the versatile and indispensable generator – the device that works in the opposite way, transforming mechanical energy into electrical energy.

Read more: How To Reverse An Electric Motor Rotation

Working Principle of the Reverse Device

The working principle of the reverse device, also known as a generator or alternator, revolves around the concept of electromagnetic induction. This principle states that a change in the magnetic field within a coil induces an electromotive force (EMF) or voltage across the coil.

In the case of a generator, the mechanical energy supplied to the device is harnessed to produce a change in the magnetic field. This change is achieved by rotating a magnet or a set of magnets inside the generator, creating a rotating magnetic field.

As the magnets rotate, the magnetic field around them changes, inducing an electrical current in the coils of wire that surround the magnets. These coils, known as the stator, are stationary and consist of multiple turns of wire to enhance the induction process.

The induced current in the stator coils is typically alternating current (AC) since the changing magnetic field results in a constantly reversing direction of the current. This AC current can then be used to power electrical devices or can be converted into direct current (DC) using rectifiers.

The output voltage of a generator is determined by various factors, including the speed of rotation, the strength of the magnetic field, and the design of the stator coils. Adjusting these factors allows for the generation of different levels of electrical power.

Additionally, generators are equipped with voltage regulators to maintain a consistent output voltage despite variations in the rotational speed or other external factors. This ensures a stable and reliable power supply from the generator.

Overall, the working principle of a reverse device, such as a generator or alternator, involves the conversion of mechanical energy into electrical energy through the process of electromagnetic induction. By utilizing the change in magnetic fields, these devices enable the production of electrical power from various forms of mechanical energy.

A device that is like the reverse of an electric motor is a generator. Generators convert mechanical energy into electrical energy, while electric motors convert electrical energy into mechanical energy.

Applications of the Reverse Device

The reverse device, or generator/alternator, finds applications in diverse fields where the conversion of mechanical energy into electrical energy is needed. Let’s explore some of the key applications of this versatile device:

- Power Generation: One of the primary applications of generators is power generation. Generators are used in power plants, both conventional and renewable, to convert mechanical energy from sources such as turbines, engines, or wind and water turbines into electrical energy. They play a crucial role in providing electricity for residential, commercial, and industrial purposes.

- Backup Power Supply: In situations where the main power grid fails or during planned power outages, generators serve as reliable backup power sources. They ensure uninterrupted power supply in hospitals, data centers, critical infrastructure, and residential buildings, keeping essential systems, appliances, and equipment functioning.

- Construction and Mining: Construction sites and mining operations often require temporary or remote power sources. Generators provide portable and independent electricity to power tools, lighting, site offices, and machinery in these environments, improving productivity and efficiency.

- Emergency Services: In emergency situations such as natural disasters, generators are essential for emergency services such as hospitals, fire stations, and disaster relief centers. They ensure the availability of power for medical equipment, communication systems, lighting, and other crucial operations.

- Recreational and Outdoor Activities: Generators are commonly used for recreational purposes such as camping, RV trips, and outdoor events. They provide power for lighting, cooking appliances, entertainment systems, and charging electronic devices, enabling a comfortable outdoor experience.

- Telecommunications: The telecommunications industry heavily relies on generators to maintain communication networks during power outages. Generators power cell towers, data centers, and communication facilities, ensuring uninterrupted connectivity and reliable communication services.

- Off-Grid and Remote Areas: In off-grid or remote areas where access to the main power grid is limited or nonexistent, generators serve as primary sources of electricity. They provide power for off-grid homes, research stations, remote agricultural operations, and other establishments, enabling a sustainable and independent power supply.

These are just a few examples of the wide-ranging applications of generators. The versatility and reliability of the reverse device make it indispensable in various industries, emergency situations, and daily life, providing electrical power when and where it is needed.

Advantages and Disadvantages of the Reverse Device

The reverse device, also known as a generator or alternator, offers several advantages in terms of generating electrical energy. However, it also comes with certain disadvantages. Let’s explore the advantages and disadvantages of this versatile device:

Advantages:

- Power Generation: Generators provide a reliable and efficient means of generating electrical power from various mechanical energy sources such as turbines, engines, or renewable energy systems.

- Backup Power Supply: The reverse device serves as an essential backup power supply, ensuring uninterrupted electricity during power outages or in locations where the main power grid is unavailable or unstable.

- Portability: Many generators are designed to be portable, allowing them to be easily transported and deployed in different locations as needed, making them ideal for construction sites, outdoor events, and emergency situations.

- Versatility: Generators can be utilized in a wide range of applications, from small-scale residential use to large-scale industrial operations, providing power for various electrical appliances, tools, and machinery.

- Energy Independence: Generators offer the ability to generate electricity independent of the main power grid, making them valuable in remote areas, off-grid locations, and situations where self-sufficiency is desired.

Disadvantages:

- Fuel Consumption and Emissions: Generators typically consume fuel, such as gasoline, diesel, or natural gas, to generate electricity. This reliance on fuel combustion can result in emissions of greenhouse gases and contribute to air pollution.

- Noise and Environmental Impact: Generators can be noisy during operation, which can be a nuisance in residential areas or other noise-sensitive environments. Additionally, their use and fuel consumption can impact the environment, particularly in terms of air and noise pollution.

- Maintenance and Operating Costs: Generators require regular maintenance to ensure optimal performance and reliability. This includes oil changes, filter replacements, and periodic inspections. Additionally, fuel and maintenance costs can contribute to the overall operating expenses.

- Limited Efficiency: Generators are not 100% efficient in converting mechanical energy into electrical energy. Some energy is lost as heat and non-useful energy during the conversion process. This can result in inefficiencies and additional energy costs.

- Dependence on External Energy Sources: While generators provide a means of generating power, they still rely on external energy sources, such as fossil fuels or renewable energy systems, to generate the initial mechanical energy needed for operation.

It’s important to consider these advantages and disadvantages when evaluating the use of generators. While they offer significant benefits, it’s crucial to mitigate the associated environmental impacts, promote energy efficiency, and weigh the costs against the specific needs and considerations of each application.

Conclusion

The reverse device, also known as a generator or alternator, plays a crucial role in our modern world by transforming mechanical energy into electrical energy. As the counterpart to electric motors, generators provide a reliable and versatile solution for power generation and backup power supply.

By harnessing the principles of electromagnetic induction, generators convert various forms of mechanical energy, such as rotational motion or kinetic energy from wind or water, into usable electrical power. This ability makes generators indispensable in power plants, remote locations, emergency situations, and off-grid areas.

Generators offer numerous advantages, including their ability to generate electricity from different energy sources, their versatility in applications, and their portability for use in various settings. They provide a solution for ensuring continuous power supply during grid failures, powering critical infrastructure, and enabling off-grid living or remote operations.

However, generators also come with certain disadvantages, such as fuel consumption, emissions, noise, and maintenance costs. It is important to mitigate these impacts by considering energy-efficient models, utilizing cleaner fuel sources, and implementing proper maintenance and noise reduction measures.

In conclusion, the reverse device, or generator, serves as a vital component of our electrical infrastructure, empowering us to harness mechanical energy and convert it into usable electrical power. It is an essential tool for industries, emergency services, construction sites, outdoor activities, and areas without access to the main power grid.

Going forward, advancements in generator technology, including the integration of renewable energy sources and energy storage systems, will continue to improve their efficiency, reduce environmental impacts, and make them even more versatile and sustainable. With proper usage and consideration of both advantages and disadvantages, generators will continue to be a reliable and invaluable asset in our quest for accessible, reliable, and sustainable electrical power.

Frequently Asked Questions about What Device Is Like The Reverse Of An Electric Motor?

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Device Is Like The Reverse Of An Electric Motor?”