Articles

What Is Bibs Insulation

Modified: August 16, 2024

Discover the benefits and uses of Bibs insulation with our informative articles. Learn how this eco-friendly material can improve energy efficiency and enhance comfort in your home.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of insulation! Whenever we think about making our homes more energy-efficient, insulation is a crucial factor to consider. It helps to keep our homes warm in the winter and cool in the summer, reducing our energy consumption and ultimately saving money on utility bills. In this article, we will explore the world of Bibs insulation, its definition, how it works, the benefits it offers, the installation process, its efficiency and cost, maintenance and longevity, and how it compares to other insulation types.

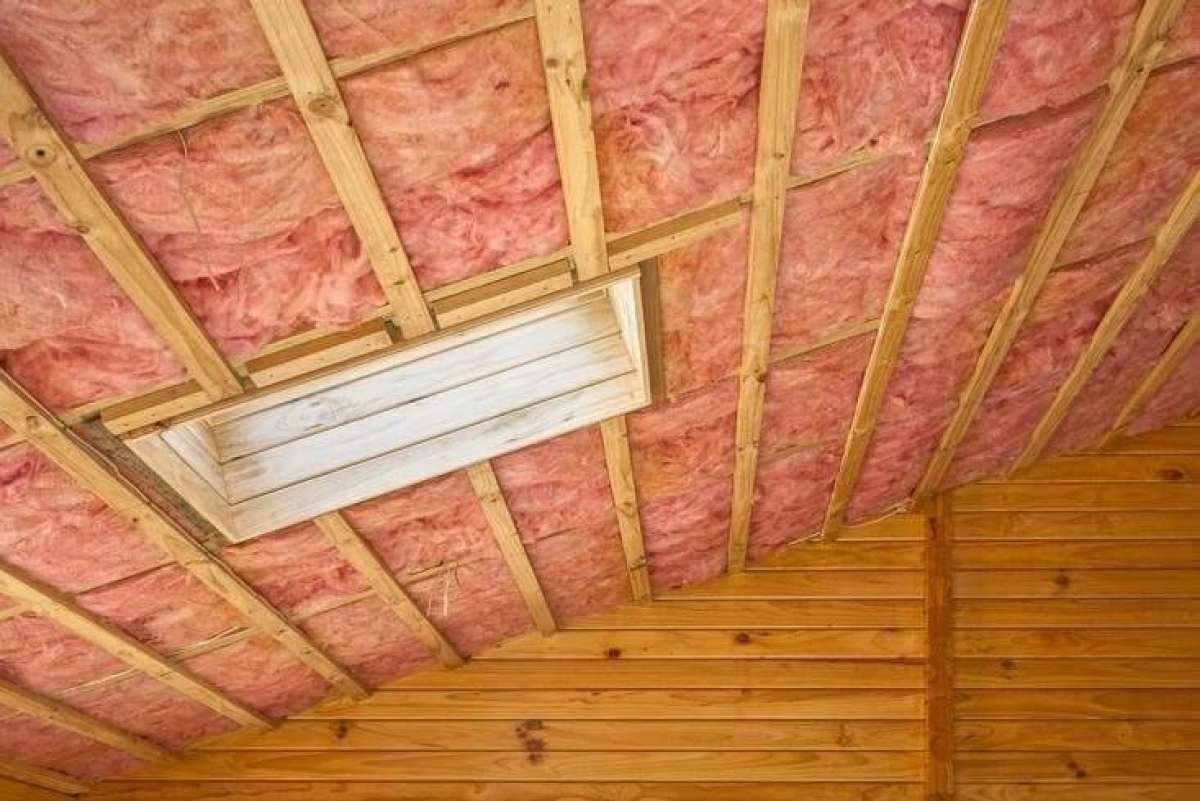

So, what exactly is Bibs insulation? Bibs, which stands for Blown-in Blanket System, is a type of insulation that is highly effective in providing thermal protection for residential and commercial buildings. It is designed to fill cavities in walls, floors, and ceilings, creating a seamless layer of insulation.

Bibs insulation is made up of tightly packed fibrous material, typically fiberglass or cellulose, which is blown into the designated area using specialized equipment. It forms a continuous barrier that helps to prevent heat loss or gain, improving the overall energy efficiency of the building. Let’s explore how Bibs insulation works and how it can benefit your home or business.

Key Takeaways:

- Bibs insulation, also known as Blown-in Blanket System, offers seamless and continuous coverage, eliminating gaps and providing superior energy efficiency and thermal performance compared to other insulation types.

- With Bibs insulation, homeowners and building owners can enjoy enhanced energy efficiency, improved comfort, soundproofing capabilities, and long-term insulation performance, making it a cost-effective and efficient insulation solution.

Read more: What Is A Hose Bib In Plumbing

Definition of Bibs Insulation

Bibs insulation, also known as Blown-in Blanket System, is a type of insulation that is installed by blowing loose-fill insulation material into wall cavities, attics, and floors. Unlike traditional insulation methods that involve the use of pre-cut batts or rigid foam panels, Bibs insulation provides a seamless blanket of insulation that conforms perfectly to the space it is installed in.

The insulation material used in Bibs insulation is typically fiberglass or cellulose, both of which have excellent thermal performance and soundproofing properties. Fiberglass consists of small, fine fibers made from molten glass, while cellulose is made from recycled paper products that are treated with fire-retardant chemicals.

The installation process of Bibs insulation involves the use of specialized equipment, including blowing machines and hoses. The insulation material is loaded into the blowing machine, which breaks it up and propels it through the hoses into the desired area. The material fills the cavities evenly and densely, creating a seamless layer of insulation that fills every nook and cranny.

The key advantage of Bibs insulation is its ability to eliminate gaps and voids, which can occur with traditional insulation methods. Gaps and voids can cause thermal bridging, where heat or cold can bypass the insulation and transfer between the interior and exterior of a building. By ensuring consistent and complete coverage, Bibs insulation minimizes thermal bridging and improves the overall energy efficiency of a structure.

The thickness of Bibs insulation can be adjusted to achieve the desired R-value, which measures the insulation’s resistance to heat flow. The higher the R-value, the greater the insulation’s effectiveness. By customizing the thickness of Bibs insulation, it can be tailored to meet the specific energy efficiency needs of different regions and climates.

Overall, Bibs insulation is a cost-effective and efficient insulation solution that offers excellent thermal performance, soundproofing capabilities, and ease of installation. Its ability to provide consistent coverage and fill every nook and cranny sets it apart from traditional insulation methods, making it an excellent choice for residential and commercial applications.

How Bibs Insulation Works

Bibs insulation works by creating a seamless and continuous layer of insulation that fills the cavities in walls, floors, and ceilings. The process involves the use of specialized equipment to blow loose-fill insulation material into the desired area.

The first step in the Bibs insulation process is to prepare the area where the insulation will be installed. This involves sealing any air leaks and ensuring proper ventilation. Once the area is prepared, the insulation material can be loaded into the blowing machine.

The insulation material used in Bibs insulation is typically fiberglass or cellulose. Fiberglass insulation consists of small glass fibers that trap air pockets, providing excellent thermal resistance. Cellulose insulation, on the other hand, is made from recycled paper products treated with fire-retardant chemicals. It offers superior thermal performance and soundproofing capabilities.

With the insulation material loaded into the blowing machine, the next step is to direct the material into the cavities. A hose connected to the machine is used to blow the insulation material into the walls, floors, or ceilings. The material is propelled into the cavities, filling them evenly and densely.

As the insulation material is blown into the cavities, it creates a seamless layer that conforms to the shape of the space. This ensures that every nook and cranny is filled, eliminating gaps and voids that can occur with traditional insulation methods.

By filling the cavities completely, Bibs insulation minimizes the occurrence of thermal bridging. Thermal bridging is when heat or cold bypasses the insulation and transfers between the interior and exterior of a building. The seamless layer of Bibs insulation creates a continuous thermal barrier, improving the energy efficiency of the structure.

Bibs insulation also provides excellent soundproofing capabilities. The dense layer of insulation material absorbs and dampens sound waves, reducing noise transmission between rooms and from the outside environment.

One of the advantages of Bibs insulation is its ability to adapt to various types of construction, including wood framing, steel framing, and masonry. It can be installed in both new construction and retrofit projects, making it a versatile insulation option.

Overall, Bibs insulation works by blowing loose-fill insulation material into cavities, creating a seamless and continuous layer of insulation. By eliminating gaps and voids, Bibs insulation provides excellent thermal performance, soundproofing capabilities, and energy efficiency for residential and commercial buildings.

Benefits of Bibs Insulation

Bibs insulation offers numerous benefits for homeowners and building owners alike. Let’s explore some of the key advantages of choosing Bibs insulation for your insulation needs:

1. Enhanced Energy Efficiency: Bibs insulation creates a seamless and continuous layer of insulation that fills cavities, eliminating gaps and voids. This ensures maximum thermal efficiency and reduces energy waste by preventing heat transfer between the interior and exterior of a building.

2. Improved Comfort: With its superior insulation properties, Bibs insulation helps to maintain a consistent indoor temperature. It keeps homes warm in the winter and cool in the summer, providing a comfortable living environment all year round.

3. Soundproofing: The dense layer of Bibs insulation material effectively absorbs and dampens sound waves, reducing noise transmission from outside sources and between rooms. This can greatly improve the peace and quiet within your home or commercial space.

4. Increased Energy Savings: By minimizing heat loss and gain, Bibs insulation reduces the workload on heating and cooling systems. This results in lower energy consumption and can lead to significant savings on utility bills over time.

5. Eco-Friendly Solution: Bibs insulation is typically made from recycled materials, such as fiberglass or cellulose. By choosing Bibs insulation, you are contributing to a more sustainable future by reducing waste and promoting the use of recycled materials.

6. Quick and Non-Invasive Installation: Installing Bibs insulation is a relatively quick and hassle-free process. The insulation material is blown into the designated areas using specialized equipment, which minimizes disruption and saves time compared to traditional insulation methods.

7. Versatility: Bibs insulation can be installed in various types of construction, including wood framing, steel framing, and masonry. It can be used in both new construction projects and retrofit applications, making it a versatile insulation option for different building types.

8. Longevity: Properly installed Bibs insulation can last for decades, providing long-lasting insulation performance and energy efficiency. It requires minimal maintenance, making it a durable and cost-effective solution.

9. Fire Resistance: Cellulose Bibs insulation is treated with fire-retardant chemicals, adding an extra layer of fire protection to your building. This can help to improve the overall safety of your home or commercial space.

Overall, Bibs insulation offers a wide range of benefits, from enhanced energy efficiency and comfort to soundproofing capabilities and eco-friendliness. It is a versatile and cost-effective insulation solution that can greatly improve the overall performance and sustainability of your residential or commercial building.

Installation Process of Bibs Insulation

The installation process of Bibs insulation involves several steps to ensure proper and effective coverage. Here is a breakdown of the installation process:

1. Preparation: Before the installation begins, the area where the insulation will be installed needs to be prepared. This may involve sealing any air leaks, ensuring proper ventilation, and protecting any electrical or mechanical components in the area.

2. Equipment Set-up: Specialized equipment is used to install Bibs insulation. This includes a blowing machine and hoses. The blowing machine is loaded with the insulation material, such as loose-fill fiberglass or cellulose.

3. Insulation Material Distribution: The insulation material is fed through the hoses from the blowing machine to the designated area. The installer carefully directs the hose to reach the cavities in walls, floors, or ceilings.

4. Blowing Process: The blowing machine propels the insulation material into the cavities with controlled air pressure. The material fills the cavities evenly, ensuring a seamless layer of insulation. The installer monitors the process to ensure consistent coverage.

5. Settling and Fluffing: After the installation, the insulation material may settle and compact slightly. To optimize its thermal performance, the insulation is typically fluffed using special tools. This helps to create a more effective thermal barrier.

6. Inspection: Once the installation is complete, the area is inspected to ensure that all cavities have been properly filled with insulation material. Any areas that require additional insulation are addressed to ensure proper coverage.

7. Clean-up: After the installation, any excess insulation material or debris is cleaned up and removed from the work area. This ensures a clean and safe environment.

8. Completion: The installation process of Bibs insulation is considered complete once the designated areas have been filled with the insulation material. The installer may provide a final inspection to ensure that the installation meets the required standards and specifications.

It is important to note that Bibs insulation installation should be carried out by trained professionals who have experience in handling the equipment and materials. This ensures proper installation and optimal performance of the insulation.

The installation process of Bibs insulation is relatively quick and non-invasive compared to other insulation methods. It allows for efficient insulation coverage, providing enhanced energy efficiency, comfort, and soundproofing for residential and commercial buildings.

BIBS insulation, or Blown-In Blanket System, is a type of insulation that is blown into walls, floors, attics, and ceilings. It provides a seamless, thermal barrier that can help improve energy efficiency and reduce noise.

Read more: How To Install A Hose Bib

Cost and Efficiency of Bibs Insulation

When considering insulation options, it is important to assess both the cost and efficiency of the chosen method. Bibs insulation offers a balance between cost-effectiveness and energy efficiency. Let’s delve into the cost and efficiency factors of Bibs insulation:

1. Cost: The cost of Bibs insulation can vary depending on factors such as the size of the project, location, and the insulation material used. However, in general, Bibs insulation is considered a cost-effective solution compared to other insulation methods. The installation process is relatively quick and non-invasive, which can help reduce labor costs. Additionally, Bibs insulation is known for its ability to eliminate gaps and voids, making it highly efficient and cost-effective in the long run.

2. Energy Efficiency: Bibs insulation is known for its high energy efficiency. By filling cavities with a dense layer of insulation material, Bibs insulation minimizes heat loss or gain through thermal bridging. The seamless and continuous insulation layer creates an effective thermal barrier, helping to maintain a consistent indoor temperature and reducing the workload on heating and cooling systems. This results in increased energy savings and lower utility bills over time.

3. R-Value: The R-value measures the thermal resistance of an insulation material. The higher the R-value, the greater the insulation’s effectiveness. Bibs insulation can achieve high R-values, providing excellent thermal performance and energy efficiency. The R-value of the insulation can be customized by adjusting the thickness of the material during the installation process.

4. Comfort: Bibs insulation not only improves energy efficiency but also enhances comfort levels within a building. By minimizing heat transfer, Bibs insulation helps maintain a consistent indoor temperature throughout the year. This reduces drafts and cold spots, creating a comfortable living or working environment for occupants.

5. Soundproofing: In addition to its thermal benefits, Bibs insulation also offers soundproofing capabilities. The dense layer of insulation material helps absorb and dampen sound waves, reducing noise transmission from outside sources and between rooms. This can significantly improve the acoustic quality of a space, creating a quieter and more peaceful environment.

6. Longevity: Bibs insulation, when properly installed and maintained, can last for several decades. It does not settle or sag over time, ensuring long-term insulation performance. This longevity reduces the need for frequent insulation replacement or upgrades, saving on future costs.

7. Environmental Impact: Bibs insulation is an environmentally friendly choice. It is often made from recycled materials, such as fiberglass or cellulose. By using recycled materials, Bibs insulation helps reduce waste and promote sustainability.

It’s important to note that while Bibs insulation offers numerous benefits, including cost-effectiveness and energy efficiency, the overall cost and efficiency will vary depending on factors such as the size of the project, insulation material chosen, and the local climate conditions. It is advisable to consult with a professional insulation contractor to assess the specific needs of your building and determine the cost and efficiency of Bibs insulation for your project.

Maintenance and Longevity of Bibs Insulation

Bibs insulation is known for its durability and longevity, requiring minimal maintenance to continue performing efficiently. Here’s a breakdown of the maintenance and longevity aspects of Bibs insulation:

1. Minimal Maintenance: Bibs insulation is a low-maintenance insulation option. Once installed, it typically requires little to no maintenance. Unlike some other insulation materials, Bibs insulation does not settle or sag over time, ensuring consistent performance without the need for frequent adjustments.

2. Insulation Integrity: Properly installed Bibs insulation maintains its integrity for many years, providing continued thermal insulation performance. It does not degrade or break down easily, even in high-humidity environments. This stability ensures long-lasting energy efficiency and comfort within a building.

3. Pest Resistance: Bibs insulation, especially cellulose insulation, is treated with fire-retardant chemicals that also act as a pest deterrent. These chemicals make the insulation unappealing to rodents, insects, and other pests, reducing the risk of infestation. This enhances the longevity of the insulation and reduces the need for remedial measures.

4. Moisture Management: Proper moisture management is crucial for maintaining the longevity of any insulation material. Bibs insulation, when installed correctly, helps to manage moisture within the building envelope. It allows for moisture vapor to escape, preventing the accumulation of condensation and reducing the risk of mold or mildew growth. This ensures the insulation remains effective and extends its lifespan.

5. Inspection: Periodic inspections of the Bibs insulation can help identify any issues or areas of concern. Inspections should include a visual inspection of the insulation throughout the building to check for signs of damage or displacement. Addressing any issues promptly can help maintain the insulation’s effectiveness and prevent potential energy loss.

6. Professional Maintenance: While maintenance needs for Bibs insulation are minimal, it can be beneficial to consult a professional insulation contractor for periodic maintenance check-ups. They can assess the insulation’s condition, identify any potential issues, and provide recommendations for maintenance or repairs if needed.

7. Lifespan: Bibs insulation, when properly installed and maintained, can last for several decades. The exact lifespan depends on various factors, including the insulation material, installation quality, and environmental conditions. With proper care, Bibs insulation can provide long-term thermal insulation and energy efficiency benefits to a building.

It is important to note that while Bibs insulation is known for its longevity, routine inspections and maintenance are still recommended to ensure optimal performance. Regular assessments and timely repairs can help extend the lifespan of the insulation, enhance energy efficiency, and maintain a comfortable indoor environment.

Comparison with Other Insulation Types

When choosing insulation for your home or building, it’s essential to consider the different options available. Let’s compare Bibs insulation with other common insulation types to understand their differences and benefits:

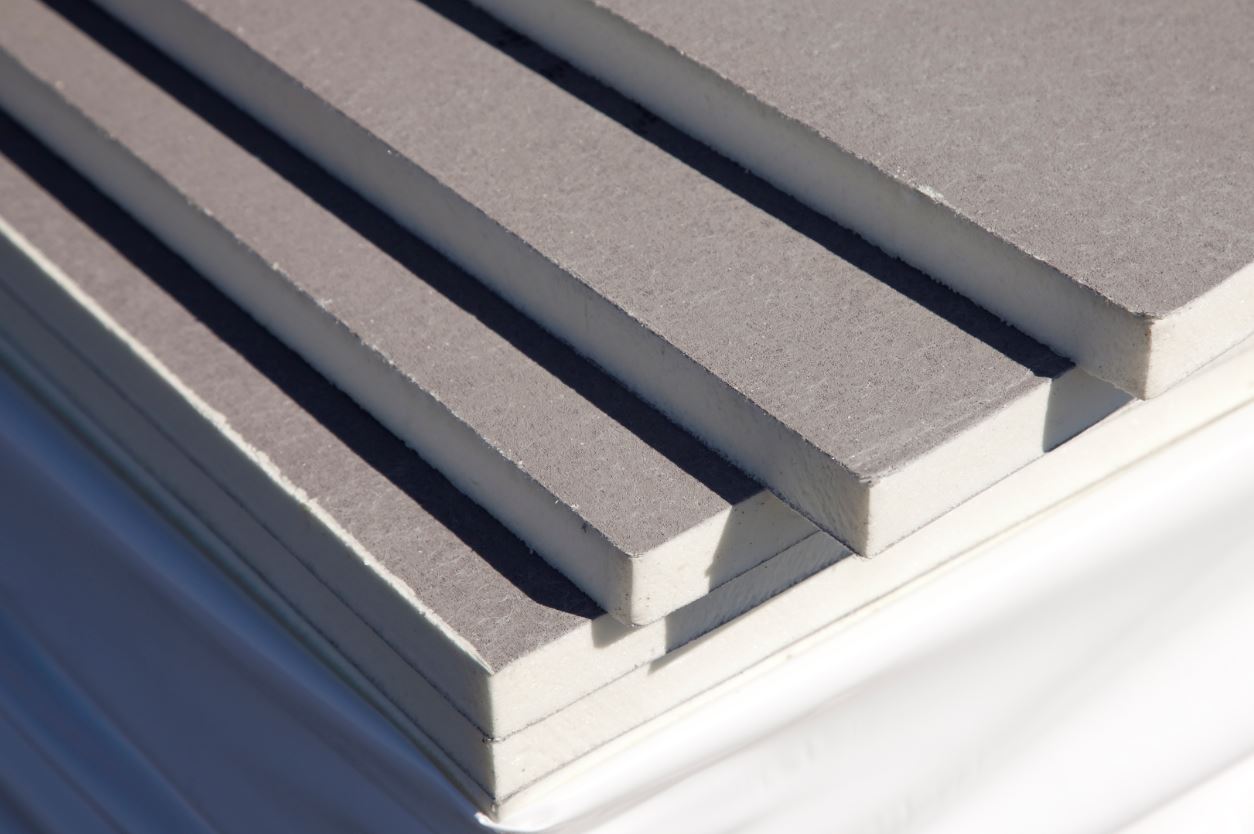

1. Fiberglass Batt Insulation: Fiberglass batt insulation consists of pre-cut fiberglass panels that are fitted between wall studs or ceiling joists. While batt insulation is a popular choice due to its affordability, it often leaves gaps and voids, leading to thermal bridging. In contrast, Bibs insulation provides seamless coverage and eliminates gaps, offering superior energy efficiency and reduced heat transfer.

2. Cellulose Loose-fill Insulation: Both Bibs insulation and cellulose loose-fill insulation involve blowing insulation material into the desired area. However, Bibs insulation uses a more controlled blowing process, resulting in a denser and more consistent layer of insulation. Cellulose insulation may settle over time, reducing its effectiveness. Bibs insulation, on the other hand, maintains its integrity and thermal performance over the long term.

3. Spray Foam Insulation: Spray foam insulation is a versatile and efficient option. It expands to fill cavities, providing an airtight seal and excellent thermal insulation. However, spray foam insulation can be more expensive compared to Bibs insulation. It also requires professional installation and can be challenging to apply evenly in certain areas. Bibs insulation offers a cost-effective alternative with easier and faster installation.

4. Rigid Foam Insulation: Rigid foam insulation panels are solid sheets of insulation that are installed on walls or roofs. While it provides excellent insulation properties, rigid foam can be more expensive and challenging to install compared to Bibs insulation. Bibs insulation offers a seamless solution that conforms to the specific space, ensuring complete coverage and minimizing thermal bridging.

5. Reflective Insulation: Reflective insulation consists of a reflective material, such as aluminum foil, that reflects heat radiation. It is typically used in attics and crawlspaces. While reflective insulation can be effective in reducing radiant heat, it does not provide as much insulation against conductive or convective heat transfer as Bibs insulation does. Bibs insulation offers comprehensive thermal protection by creating a continuous insulation layer that tackles all forms of heat transfer.

6. Blown-in Fiberglass Insulation: Blown-in fiberglass insulation is similar to Bibs insulation in terms of the installation process. However, the main difference lies in the method of application. While both use a blowing machine, Bibs insulation is designed to eliminate gaps and voids more effectively. This results in improved energy efficiency and enhanced thermal performance compared to blown-in fiberglass insulation.

When comparing insulation types, it’s important to consider factors such as cost, installation process, thermal performance, and long-term effectiveness. While each insulation type has its own advantages, Bibs insulation stands out for its seamless and dense coverage, superior energy efficiency, and cost-effectiveness in the long run.

Conclusion

Bibs insulation, also known as Blown-in Blanket System, offers a comprehensive and efficient solution for insulating residential and commercial buildings. With its seamless and continuous coverage, Bibs insulation eliminates gaps and voids, providing superior energy efficiency and thermal performance compared to other insulation types.

Throughout this article, we explored the definition and working principle of Bibs insulation. We discussed its benefits, including enhanced energy efficiency, improved comfort, soundproofing capabilities, and eco-friendliness. Bibs insulation offers excellent long-term insulation performance, requiring minimal maintenance and providing insulation integrity for many years.

The installation process of Bibs insulation involves the use of specialized equipment to blow loose-fill insulation material into the designated areas. The cost of Bibs insulation is generally affordable compared to other insulation types, and it offers high energy efficiency, resulting in long-term energy savings and reduced utility bills.

When compared to other insulation types, Bibs insulation offers distinct advantages. Its seamless coverage eliminates gaps and provides consistent thermal protection. Bibs insulation is also durable, maintaining its performance and insulation integrity for decades.

In conclusion, Bibs insulation is a cost-effective and efficient insulation solution that offers numerous benefits, including enhanced energy efficiency, improved comfort, soundproofing capabilities, and long-term performance. Its installation process is relatively quick and non-invasive, making it suitable for various construction projects.

If you are considering insulation options for your home or building, consult with a professional insulation contractor to determine if Bibs insulation is the right choice for your project. They can provide guidance based on your specific needs and help ensure a successful insulation installation that will enhance the energy efficiency and comfort of your space for years to come.

Frequently Asked Questions about What Is Bibs Insulation

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is Bibs Insulation”