Articles

What Is Pinning Loading For Hand Tools

Modified: December 7, 2023

Discover the essential articles on pinning loading and hand tools. Learn what pinning loading is and how it is used in the world of hand tools.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

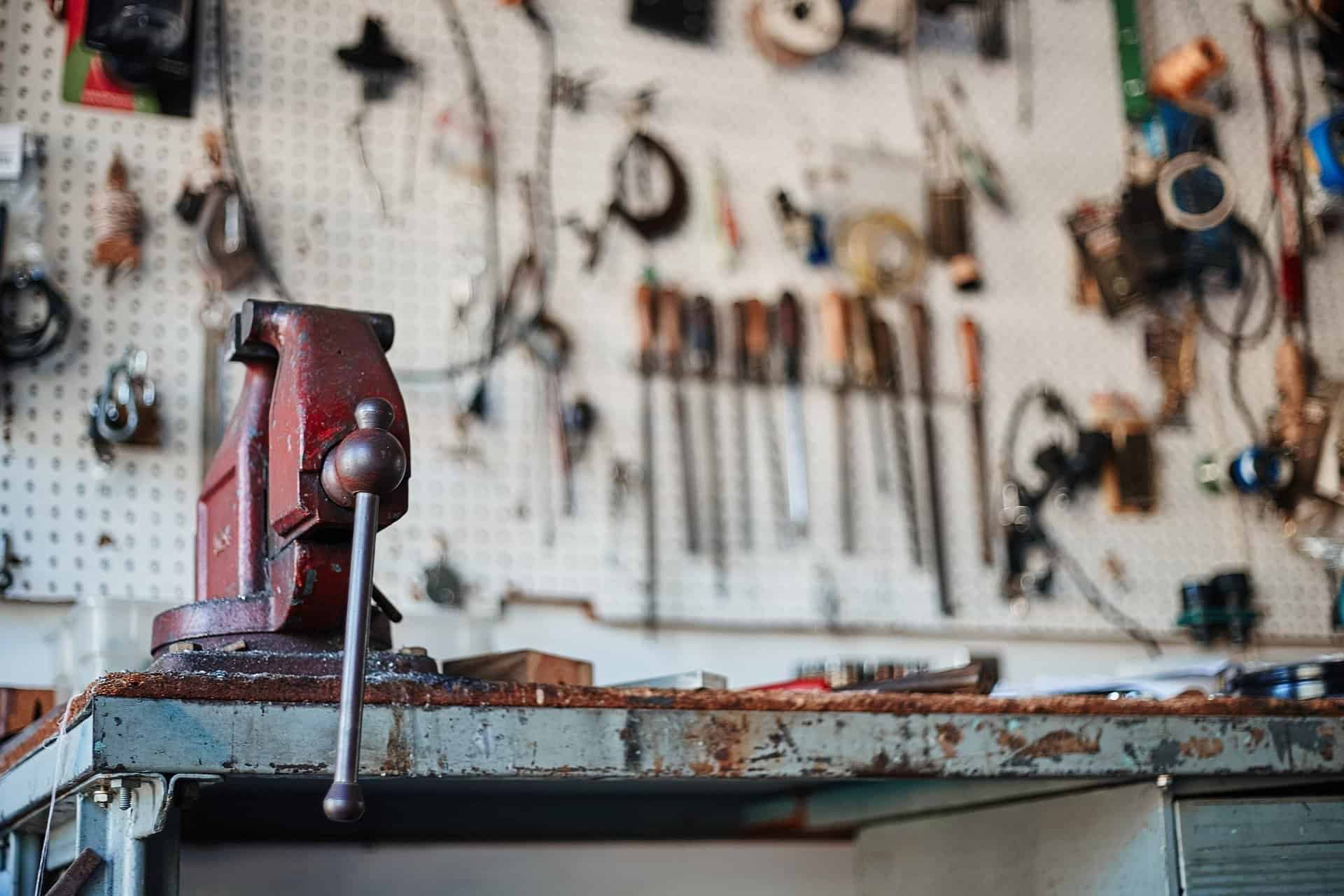

Welcome to the fascinating world of hand tools! Whether you are a DIY enthusiast, a professional tradesperson, or simply someone who appreciates the art of craftsmanship, hand tools are an essential part of your toolkit. From hammers to screwdrivers, wrenches to pliers, hand tools play a vital role in various tasks, from repairing household items to constructing complex structures.

In this article, we will delve into the concept of pinning loading – a technique commonly used in hand tools to enhance their functionality and performance. We will explore what pinning loading entails, discuss the different types of hand tools that utilize this technique, and highlight the benefits and challenges associated with its use. Additionally, we will also provide some important safety measures that need to be taken into consideration when using pinning loaded hand tools.

So, let’s roll up our sleeves, grab our favorite hand tool, and dive into the world of pinning loading!

Key Takeaways:

- Pinning loading enhances hand tools by providing increased gripping power, improved stability, and better control, leading to greater efficiency, versatility, and durability in various applications.

- While pinning loading offers significant benefits, users must be mindful of potential challenges such as overloading, maintenance requirements, and safety considerations to ensure safe and effective usage of pinning loaded hand tools.

Read more: What Are The Hazards Of Hand Tools

Definition of Hand Tools

Hand tools are manual devices that are designed to be operated by hand. They are primarily used for performing various tasks that range from maintenance and repair work to construction and woodworking. Hand tools are typically compact, portable, and easy to handle, allowing users to have precise control over their actions.

Unlike power tools that require an external power source to operate, hand tools rely solely on the physical force exerted by the user. This direct interaction between the user and the tool gives a unique sense of connection and control, making hand tools a preferred choice for many professionals and DIY enthusiasts.

There are countless types and varieties of hand tools available, each designed for a specific purpose. These tools are made from durable materials such as steel, aluminum, or hardened plastic to withstand the rigors of everyday use. From the basic essentials like hammers, screwdrivers, and wrenches, to specialized tools like saws, planes, and chisels, hand tools come in a wide range of shapes and sizes, catering to different tasks and requirements.

Hand tools provide numerous advantages over their power tool counterparts. For starters, they are often more affordable, making them accessible to a wider range of users. They are also quieter and generate less vibration, making them ideal for tasks where precision and finesse are crucial. Additionally, hand tools require minimal maintenance and do not rely on electricity or batteries, making them reliable companions in remote or outdoor settings.

In the next section, we will explore the concept of pinning loading and how it enhances the performance of hand tools.

Overview of Pinning Loading

Pinning loading is a technique used in the design and construction of certain hand tools to improve their performance and functionality. It involves adding pins or springs to the tool mechanism, which enhances its gripping power, stability, and overall effectiveness.

One of the primary purposes of pinning loading is to provide additional torque or force during operation. By incorporating pins or springs, the hand tool can exert greater pressure or leverage, allowing users to exert more force with less effort. This is particularly useful when dealing with stubborn or tightly fastened elements that require extra power to loosen or tighten.

In addition to improved torque, pinning loading also enhances the stability and precision of the hand tool. The pins or springs ensure that the components of the tool remain in the desired position, minimizing movement and reducing the risk of slippage or accidental mishaps. This stability is crucial in tasks that demand accuracy, such as drilling, cutting, or fastening.

Pinning loading is commonly used in various types of hand tools, including wrenches, pliers, and clamps. For example, in a wrench, the addition of a pinned joint between the handle and the head increases the gripping power of the tool, allowing it to securely fasten or loosen bolts and nuts. Similarly, in a pair of pliers, pinning loading provides a stronger grip, enabling users to handle objects with greater ease and control.

It is important to note that not all hand tools incorporate pinning loading. The decision to use this technique depends on the intended function and design of the tool. While some hand tools can benefit greatly from pinning loading, others may not require it due to their specific purpose or construction.

Now that we have explored the concept of pinning loading, let’s take a closer look at some common types of hand tools that utilize this technique.

Common Types of Hand Tools

Hand tools come in a wide variety of types and designs, each tailored to specific tasks and applications. While not all hand tools utilize pinning loading, there are several common types that incorporate this technique to enhance their performance. Let’s explore some of these hand tools:

- Adjustable Wrench: Also known as a spanner wrench, an adjustable wrench features a pinning loaded mechanism that allows the user to adjust the jaw size to fit different sizes of nuts and bolts. The pins or springs provide a secure grip, preventing the wrench from slipping during use.

- Pliers: Pliers are versatile tools used for gripping, bending, and cutting various materials. Many types of pliers, such as locking pliers and needle-nose pliers, incorporate pinning loading to provide a stronger and more secure grip on objects.

- Clamps: Clamps are commonly used for holding objects together firmly. Whether it’s woodworking, metalworking, or construction, clamps are essential tools. Pinning loading in clamps ensures a tight grip and prevents slippage, allowing for precise and reliable clamping.

- Vise Grips: Vise grips, also known as locking pliers, utilize pinning loading to lock the grip in place, providing a firm hold on objects. This locking feature makes vise grips ideal for applications that require sustained force or hands-free operation.

- Screwdrivers: While not all screwdrivers incorporate pinning loading, some models, such as ratcheting screwdrivers, utilize this technique. The pins or springs in these screwdrivers allow for easier and faster switching between clockwise and counterclockwise rotation, increasing efficiency and convenience.

- Saws: Hand saws, including hacksaws and coping saws, may incorporate pinning loading to secure the blade to the handle. This ensures stability and improves cutting accuracy, especially in demanding tasks where precision is important.

These are just a few examples of hand tools that often incorporate pinning loading. It’s important to note that the specific design and construction of hand tools can vary among manufacturers, so it’s always advisable to read the manufacturer’s instructions and guidelines for optimal and safe usage.

Now that we have explored some common types of hand tools, let’s move on to discussing the benefits of pinning loading.

When using hand tools, be mindful of pinning loading, which occurs when a tool is levered against a fixed object, causing excessive force on the tool and potential damage. Always use tools as intended to avoid pinning loading.

Benefits of Pinning Loading

Pinning loading in hand tools offers several notable benefits, enhancing their functionality and providing users with an improved user experience. Let’s explore some of the key advantages of using pinning loaded hand tools:

- Increased gripping power: Pinning loading provides hand tools with a greater gripping power. The addition of pins or springs allows for a stronger hold, enabling users to exert more force and torque, particularly important when dealing with stubborn fasteners or tightly secured objects.

- Improved stability: By incorporating pinning loading, hand tools offer improved stability during use. The pins or springs help keep the components of the tool in the desired position, reducing movement and minimizing the risk of slippage or accidents. This enhanced stability is especially beneficial for tasks that require precision and accuracy.

- Enhanced control: Pinning loading allows for better control over the hand tool’s actions. The increased gripping power and stability translate into improved handling and maneuverability, allowing users to work with confidence and precision.

- Efficiency and productivity: With the added force and stability provided by pinning loading, hand tools can accomplish tasks more efficiently. Users can exert less effort while achieving the desired results faster, saving time and energy in the process.

- Versatility: Pinning loading can make hand tools more versatile. The ability to adjust the gripping power or switch between different settings or functions enhances the tool’s adaptability to different tasks and applications, reducing the need for multiple specialized tools.

- Durability: The added strength and stability offered by pinning loading can contribute to the overall durability and longevity of the hand tools. By minimizing the risk of slippage or wear, these tools are built to withstand the rigors of regular use, allowing for prolonged and reliable performance.

These benefits make pinning loaded hand tools essential for various industries and applications. However, it’s important to recognize that while pinning loading enhances the functionality of hand tools, proper usage and adherence to safety measures are equally crucial. Let’s explore some of the challenges associated with pinning loading in the next section.

Read more: What To Look For In Hand Tools

Challenges of Pinning Loading

While pinning loading offers numerous benefits to hand tools, it also presents some challenges that users should be aware of. Understanding these challenges can help ensure safe and effective use of pinning loaded hand tools. Let’s explore some of these challenges:

- Overloading: One of the primary challenges of pinning loading is the risk of overloading the hand tool. Applying excessive force or torque beyond the tool’s capacity can strain the pins or springs, leading to deformation or failure. It’s important to understand the limitations of the tool and use it within the recommended parameters.

- Maintenance: Pinning loaded hand tools may require more maintenance compared to non-pinning loaded tools. The pins or springs can be subject to wear and tear over time, and periodic inspections and lubrication may be needed to ensure their proper functioning.

- Complexity: Pinning loading can add complexity to the design and construction of hand tools. This can result in increased manufacturing costs and potentially higher product prices. Users should consider the specific needs and requirements of their tasks before opting for pinning loaded hand tools.

- Safety considerations: The increased gripping power and torque provided by pinning loading can pose potential safety risks if not used correctly. Users must observe proper handling techniques, wear appropriate protective gear, and be mindful of their surroundings to avoid accidents or injuries.

- Limitations on certain tasks: While pinning loading enhances the performance of hand tools in many applications, there are certain tasks where it may not be suitable or necessary. Users should assess the specific requirements of their tasks and choose the appropriate hand tool accordingly.

By understanding these challenges, users can make informed decisions about the use of pinning loaded hand tools. It’s important to follow safety guidelines, engage in regular maintenance, and exercise caution while using these tools to ensure efficient and safe operation.

Next, let’s explore some important safety measures that should be taken into consideration when using pinning loaded hand tools.

Safety Measures for Pinning Loading

When working with pinning loaded hand tools, it is essential to prioritize safety to prevent accidents and injuries. Here are some important safety measures to keep in mind:

- Read and follow the manufacturer’s instructions: Familiarize yourself with the specific guidelines and recommendations provided by the manufacturer for the pinning loaded hand tool. This includes information on usage, maintenance, and safety precautions.

- Inspect the tool before use: Before using a pinning loaded hand tool, carefully inspect it for any damage, such as bent pins, worn springs, or loose components. Do not use the tool if any defects or issues are identified. Report and address any damage promptly.

- Understand the tool’s capacity: Be aware of the tool’s limitations in terms of torque and force. Avoid applying excessive pressure or overloading the tool beyond its recommended capacity. Pay attention to any specified torque limits or warnings provided by the manufacturer.

- Use appropriate protective gear: Depending on the task and the nature of the tool, use personal protective equipment (PPE) such as safety goggles, gloves, and ear protection. This protects you from potential hazards such as flying debris, sharp edges, or excessive noise.

- Maintain a secure grip: Ensure that you have a firm and comfortable grip on the tool. Make sure your hands are dry and free of any oil or grease that could cause the tool to slip during use. Take breaks as needed to prevent hand fatigue and maintain control over the tool.

- Keep a safe working area: Clear your work area of any clutter, obstructions, or distractions that may interfere with the safe use of the pinning loaded hand tool. Ensure adequate lighting to have a clear view of the task at hand.

- Store the tool properly: After use, store the pinning loaded hand tool in a secure and dry location, away from moisture and extreme temperatures. This helps to prolong its lifespan and minimize the risk of damage or accidents.

- Regularly maintain and inspect the tool: Periodically check the pins, springs, and overall condition of the pinning loaded hand tool. Lubricate the moving parts as recommended by the manufacturer. This ensures smooth operation and reduces the likelihood of unexpected failures or malfunctions.

Remember, safety should always be a top priority when working with any hand tool, including those with pinning loading. By following these safety measures, you can minimize the risk of accidents and injuries and ensure a safe and successful work environment.

Finally, let’s wrap up our discussion on pinning loading in hand tools.

Conclusion

Hand tools are indispensable companions for DIY enthusiasts, tradespeople, and anyone who enjoys working with their hands. The concept of pinning loading, which involves adding pins or springs to enhance gripping power and stability, has greatly improved the functionality and performance of various hand tools.

In this article, we have explored the definition of hand tools and delved into the world of pinning loading. We learned that hand tools are manual devices used for a wide range of tasks, and pinning loading is a technique employed to increase torque, improve stability, and enhance control.

We discussed some common types of hand tools that utilize pinning loading, including adjustable wrenches, pliers, clamps, screwdrivers, and saws. Each of these tools benefits from pinning loading, offering improved gripping power, stability, and versatility.

We then examined the advantages of pinning loading, such as increased gripping power, improved stability, enhanced control, efficiency and productivity gains, versatility, and improved durability. These benefits make pinning loaded hand tools invaluable in various industries and applications.

However, we also highlighted some of the challenges associated with pinning loading, such as the risk of overloading, increased maintenance requirements, added complexity, safety considerations, and limitations on certain tasks. By understanding these challenges, users can effectively mitigate risks and maximize the benefits of pinning loaded hand tools.

To ensure safe usage, we provided essential safety measures, including reading and following manufacturer instructions, inspecting the tool before use, understanding the tool’s capacity, using appropriate protective gear, maintaining a secure grip, keeping a safe working area, storing the tool properly, and regularly maintaining and inspecting the tool.

In conclusion, pinning loading has revolutionized the world of hand tools, offering improved functionality, stability, and control. By understanding the benefits, challenges, and safety measures associated with pinning loaded hand tools, users can make informed decisions and work safely and efficiently, leading to successful outcomes in their various projects and tasks.

So, let’s harness the power of pinning loaded hand tools and continue to create, build, and innovate with confidence!

Frequently Asked Questions about What Is Pinning Loading For Hand Tools

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is Pinning Loading For Hand Tools”