Articles

What Kind Of Copper Is Electrical Wire

Modified: May 6, 2024

Discover the different types of copper used in electrical wire and their characteristics. Gain insights into copper articles and their significance in electrical applications.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

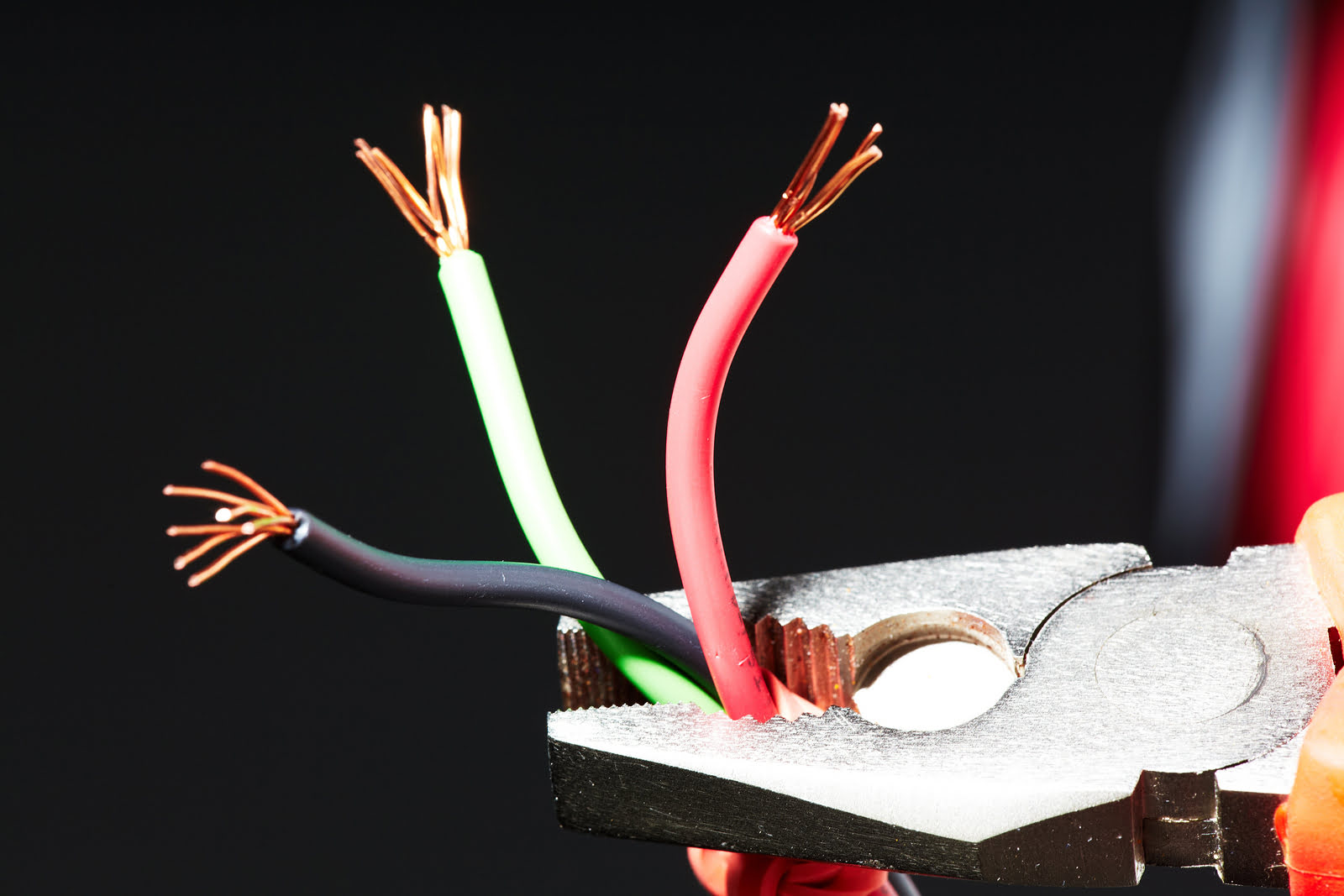

Copper is one of the most commonly used materials in electrical wiring due to its excellent conductivity and durability. It has been a staple in the electrical industry for decades, providing a reliable and efficient means of transmitting electricity. But have you ever wondered what kind of copper is used in electrical wire? In this article, we will explore the different types of copper used in electrical wire and their unique properties.

Before delving into the various types, it’s important to understand why copper is chosen as the conductor material in electrical wire. Copper has a high electrical conductivity, which means it allows electricity to flow through it easily. This property makes it ideal for conducting electrical currents with minimal resistance and energy loss. Additionally, copper is highly durable and resistant to corrosion, ensuring the longevity and reliability of electrical systems.

Now let’s dive into the different types of copper used in electrical wire:

Key Takeaways:

- Copper wire types include bare, tinned, copper-clad aluminum, and oxygen-free copper. Each type offers unique properties such as conductivity, corrosion resistance, and cost-effectiveness, catering to specific electrical and audio applications.

- Understanding the characteristics of different copper wire types is crucial for selecting the most suitable option based on conductivity, durability, and environmental factors. Consulting with industry professionals can provide valuable guidance for optimal performance and safety.

Read more: What Type Of Electrical Cord Has Copper Wire

Copper as a Conductor

Copper is widely recognized as one of the best materials for conducting electricity. Its high electrical conductivity, second only to silver, makes it an ideal choice for electrical wiring. When a current flows through a copper wire, the electrons move freely, creating a continuous flow of electricity. This is due to the copper atoms’ ability to easily lose and gain electrons, allowing for the efficient transmission of electrical energy.

In addition to its excellent conductivity, copper also offers other advantages as a conductor. It has a low resistance, meaning that it minimizes the amount of energy lost as heat during electrical transmission. This property is crucial for ensuring efficient power distribution and reducing energy wastage. Copper is also a malleable metal, making it easy to shape into thin wires without compromising its electrical properties.

Copper is also highly resistant to corrosion. It forms a thin protective oxide layer on its surface, which prevents further oxidation and corrosion. This is especially important in electrical applications where exposure to moisture and harsh environments is common. The corrosion resistance of copper ensures the longevity and reliability of electrical systems.

Furthermore, copper is a sustainable choice for wiring due to its recyclability. It can be easily recycled and reused, reducing the need for new copper mining and minimizing the environmental impact. Using recycled copper in electrical wire production helps conserve natural resources and reduce carbon emissions.

Overall, copper’s superior conductivity, low resistance, corrosion resistance, and recyclability make it the preferred choice for electrical conductors. Its combination of physical, electrical, and environmental properties sets the standard for efficient and reliable electrical wiring.

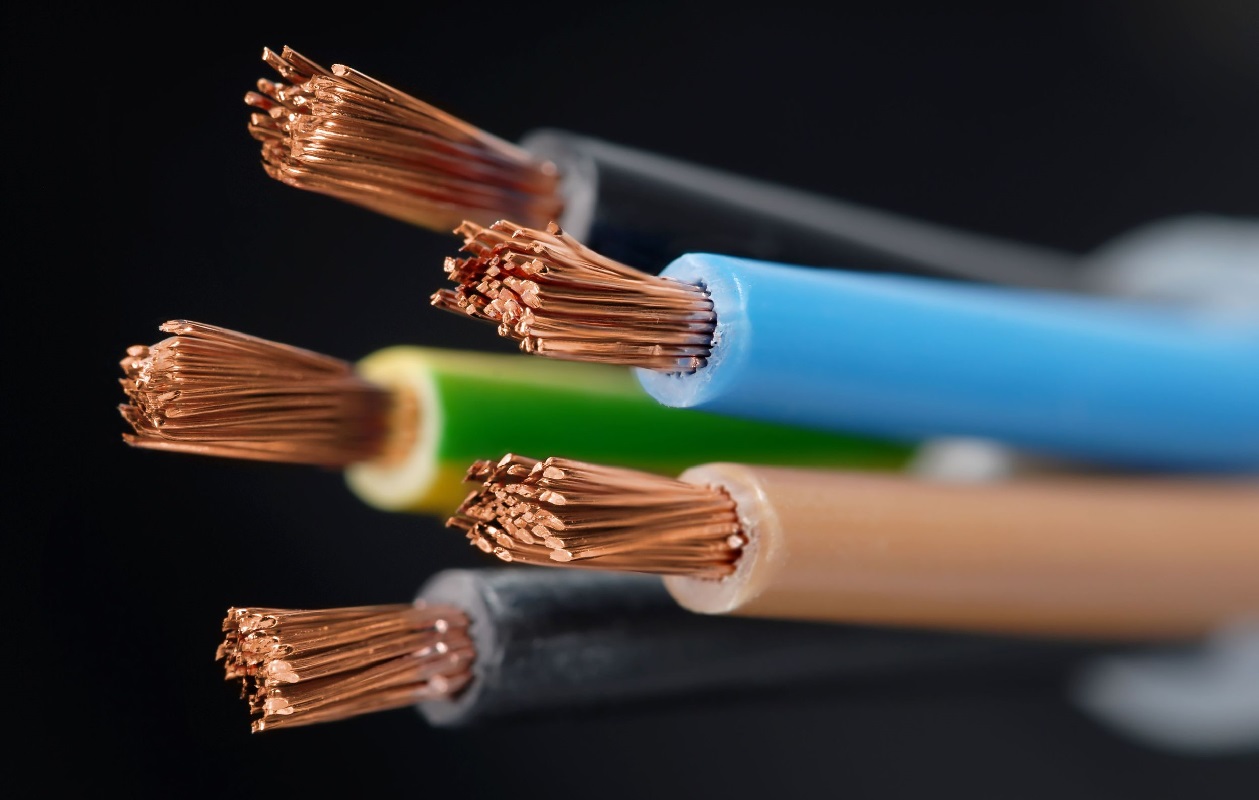

Types of Copper Used in Electrical Wire

When it comes to electrical wire, there are several types of copper that are commonly used. Each type has its own unique characteristics and is suited to different applications. Understanding these different types can help you choose the right copper wire for your specific needs. Let’s explore the most common types of copper used in electrical wire:

- Bare Copper Wire: As the name suggests, bare copper wire is made of pure copper without any additional coatings. It is the most basic and widely used type of copper wire. It is often used in indoor electrical installations, grounding applications, and overhead power lines. Bare copper wire offers excellent conductivity, durability, and affordability.

- Tinned Copper Wire: Tinned copper wire is coated with a thin layer of tin. This coating provides several benefits, including improved resistance to corrosion, enhanced solderability, and increased conductivity. Tinned copper wire is commonly used in marine and automotive applications, as well as in areas with high humidity or exposure to harsh conditions.

- Copper-Clad Aluminum (CCA) Wire: Copper-clad aluminum wire is made by bonding a layer of copper to an aluminum core. This type of wire combines the conductivity of copper with the lightweight and cost-effectiveness of aluminum. CCA wire is commonly used in low-voltage applications, such as speaker wires and telecommunications cables. However, it is important to note that CCA wire has slightly higher resistance compared to pure copper wire.

- Oxygen-Free Copper (OFC) Wire: Oxygen-free copper wire is manufactured through a process that removes oxygen and other impurities from the copper. This results in a high-purity copper wire with superior conductivity. OFC wire is used in high-end audio systems, professional audio equipment, and other applications where the highest level of signal transmission is required.

These are just a few examples of the different types of copper used in electrical wire. Each type has its advantages and is suited to specific applications. It is important to consider factors such as conductivity, corrosion resistance, cost, and specific environmental conditions when selecting the appropriate type of copper wire for your project.

Now that you have a better understanding of the different types of copper used in electrical wire, you can make an informed decision when choosing the right wire for your specific needs. Consider the requirements of your project and consult with a professional if necessary to ensure the best performance and safety.

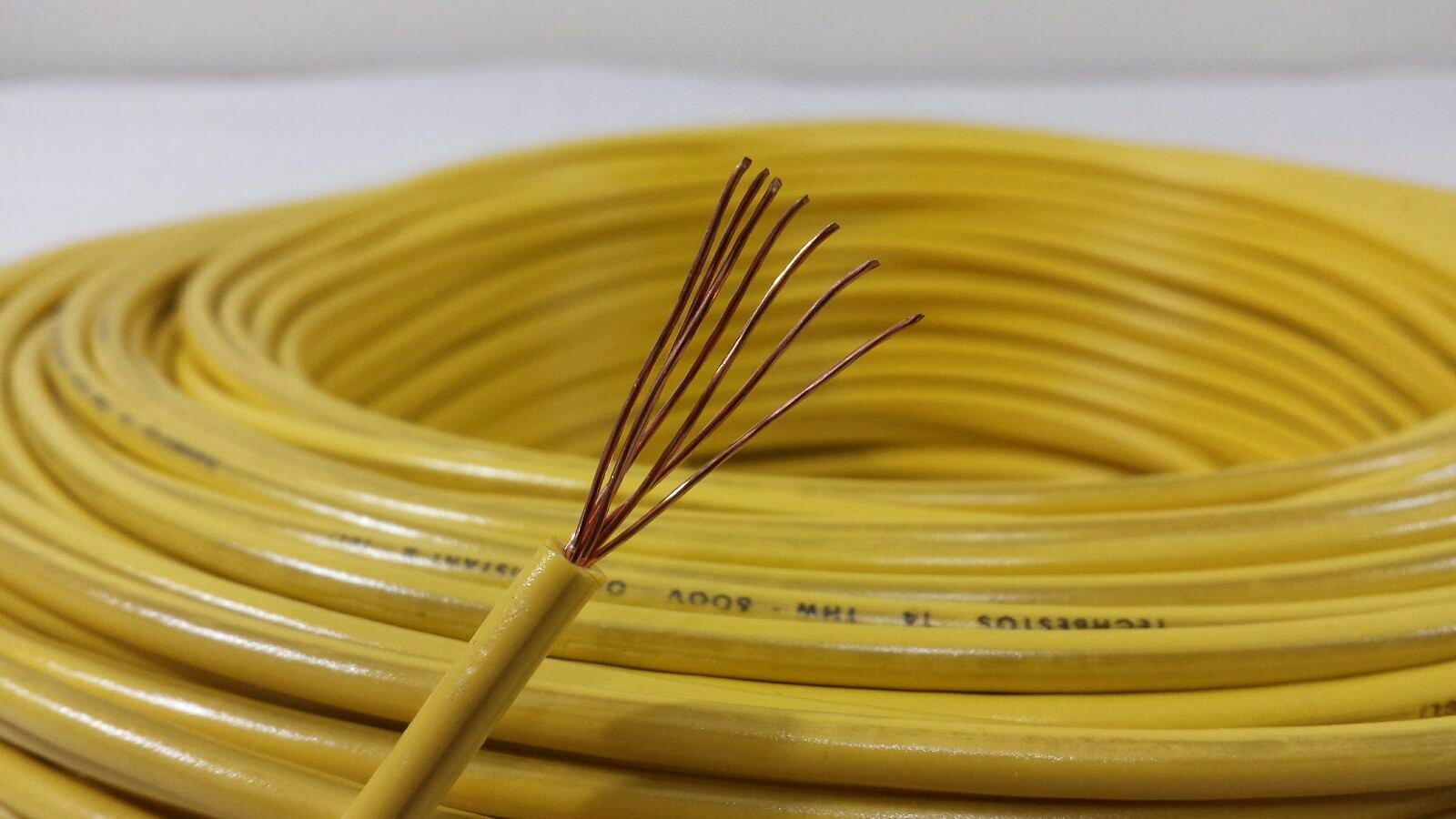

Bare Copper Wire

Bare copper wire is the most common and widely used type of copper wire in electrical applications. As the name suggests, it is made of pure copper without any additional coatings or cladding. This type of wire is highly regarded for its excellent conductivity and durability, making it an ideal choice for various electrical installations.

One of the primary advantages of bare copper wire is its high electrical conductivity. Copper is known for its exceptional ability to conduct electricity, second only to silver. This means that when a current flows through a bare copper wire, minimal energy is lost as heat, resulting in efficient power transmission. The high conductivity of bare copper wire is particularly beneficial in applications that require low resistance and minimal energy loss, such as in power distribution systems.

In addition to its electrical conductivity, bare copper wire is also preferred for its durability. Copper is a highly resilient metal that is resistant to corrosion, which helps extend the lifespan of electrical systems. The natural oxide layer formed on the surface of bare copper wire provides a protective barrier against moisture and other environmental factors that can cause corrosion. This makes it suitable for both indoor and outdoor applications.

Bare copper wire is commonly used for grounding applications. Grounding is an essential safety measure in electrical systems, as it provides a path of low electrical resistance for stray currents and faults, protecting both individuals and equipment from electrical hazards. The high conductivity and durability of bare copper wire make it an ideal choice for grounding purposes.

Furthermore, bare copper wire is cost-effective compared to other types of copper wire. The absence of coatings or cladding reduces manufacturing costs, making it more affordable for a wide range of electrical applications. This makes it a popular choice for residential, commercial, and industrial projects where cost-effectiveness is an important consideration.

It is worth noting that bare copper wire is not suitable for all applications. In environments with high humidity or corrosive substances, the lack of protective coatings may result in accelerated corrosion. In such cases, tinned copper wire or other types of coated copper wire may be more appropriate.

In summary, bare copper wire is a reliable and cost-effective option for electrical wiring needs. Its high electrical conductivity, durability, and affordability make it suitable for a wide range of applications. However, it is important to consider the specific requirements of your project and consult with an electrical professional to ensure that bare copper wire is the most suitable choice for your specific needs.

When it comes to electrical wire, look for copper that is specifically designated as “electrical grade” or “bare copper” to ensure it meets the necessary conductivity and safety standards for electrical applications.

Tinned Copper Wire

Tinned copper wire is a type of copper wire that is coated with a thin layer of tin. This additional coating provides several benefits and enhances the performance of the wire in various electrical applications. Tinned copper wire is widely used in industries such as marine, automotive, and electrical engineering.

One of the primary advantages of tinned copper wire is its improved resistance to corrosion. The tin coating acts as a protective layer, preventing the copper wire from direct contact with moisture and other corrosive elements. This makes tinned copper wire highly suitable for applications where exposure to moisture, humidity, or corrosive substances is common, such as marine environments or outdoor electrical installations.

Another benefit of the tin coating is enhanced solderability. Tin is a highly solderable material, meaning it readily bonds with solder when heated. This makes tinned copper wire easier to join with other components during manufacturing or repairs. The solderability of tinned copper wire ensures secure and reliable connections, reducing the risk of loose or faulty connections in electrical systems.

In addition to corrosion resistance and solderability, tinned copper wire also retains the excellent electrical conductivity of bare copper wire. Copper is renowned for its high electrical conductivity, and the addition of a thin layer of tin does not significantly impact this property. As a result, tinned copper wire provides efficient transmission of electrical currents, ensuring minimal energy loss and maintaining the overall performance of electrical systems.

Tinned copper wire is commonly used in the marine industry due to its ability to withstand the harsh conditions of saltwater environments. It is often utilized for wiring applications on boats, ships, and other marine vessels. The corrosion resistance provided by the tin coating helps protect the wire against the corrosive effects of saltwater, ensuring reliable and long-lasting electrical connections.

Automotive applications also benefit from the use of tinned copper wire. It is used in automotive wiring harnesses, connectors, and other electrical components. The corrosion resistance of tinned copper wire helps prevent issues caused by moisture, road salt, and other environmental factors that can lead to electrical failures.

Overall, tinned copper wire offers the combined advantages of corrosion resistance, enhanced solderability, and excellent electrical conductivity. These properties make it an ideal choice for applications that require reliable performance and longevity in challenging environments. When selecting tinned copper wire, it is important to consider the specific requirements of the application and consult with industry professionals to ensure proper compatibility and performance.

Read more: What Kind Of Electrical Wire To Use Outside

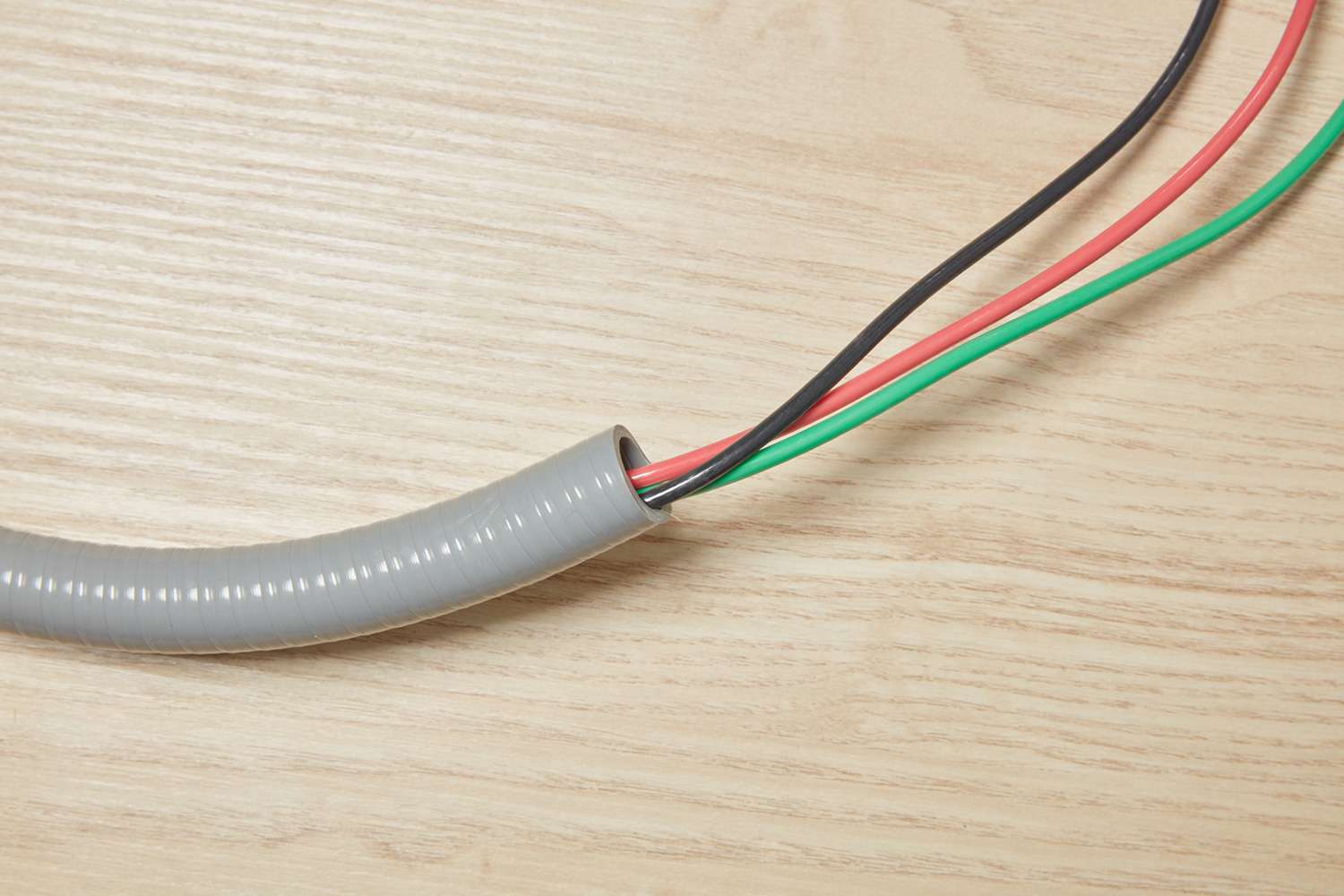

Copper-Clad Aluminum Wire

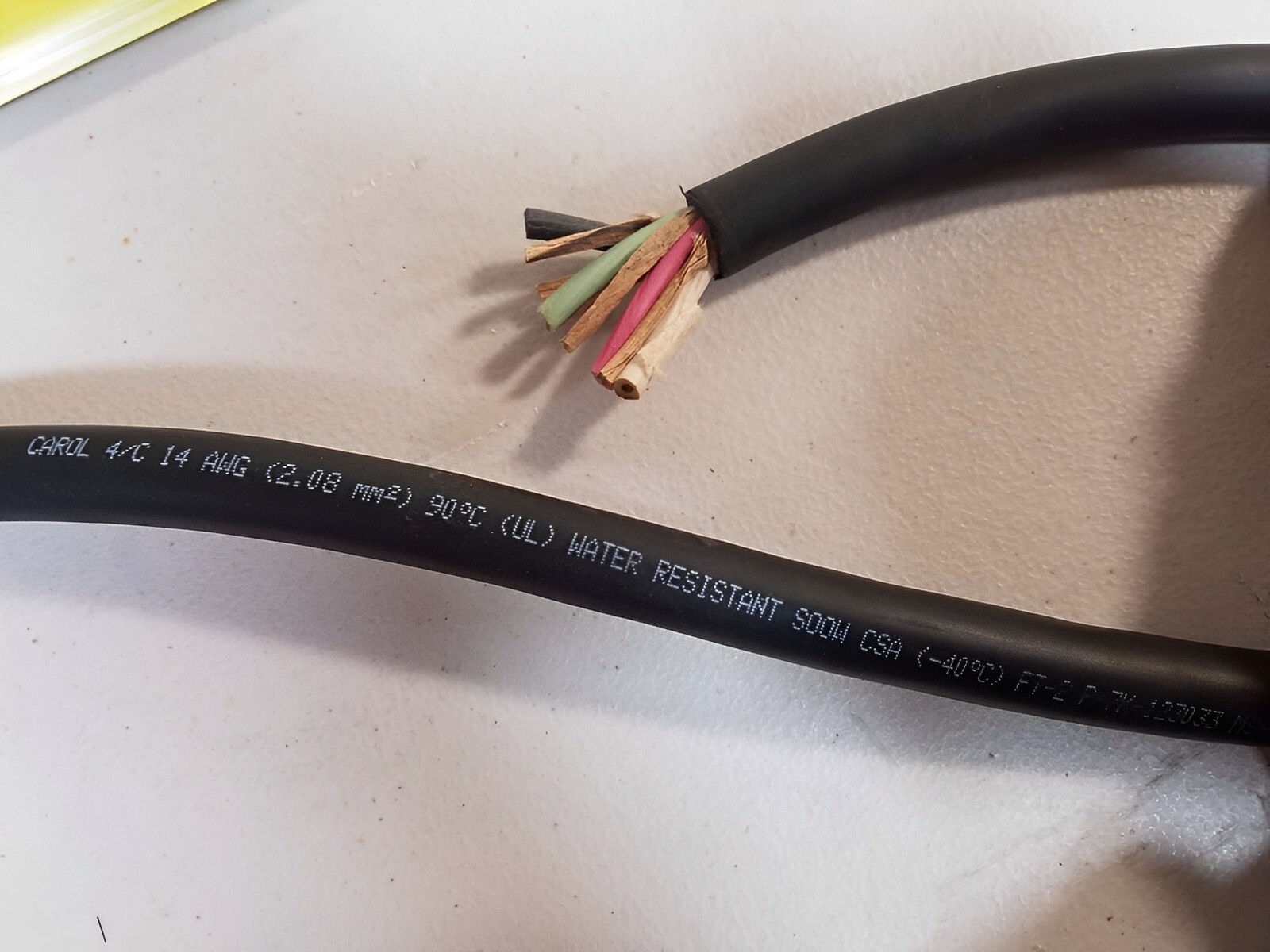

Copper-clad aluminum wire, also known as CCA wire, is a type of electrical wire that consists of an aluminum core with a thin layer of copper coating. This combination of materials provides a unique set of properties and makes it a popular choice for various applications in the electrical industry.

One of the key advantages of copper-clad aluminum wire is its weight savings compared to pure copper wire. Aluminum is a lighter metal than copper, which means that the overall weight of the wire is reduced. This makes it particularly beneficial in applications where weight considerations are important, such as in aerospace or automotive industries.

In addition to weight savings, copper-clad aluminum wire offers cost benefits. Aluminum is less expensive than copper, which means that CCA wire can be produced and sold at a lower price point. This makes it a more cost-effective option for electrical wiring projects, allowing for potential cost savings without compromising performance.

Despite the weight and cost advantages, it’s important to note that copper-clad aluminum wire has slightly higher resistance compared to pure copper wire. Aluminum has a higher resistance than copper, which means that CCA wire has a slightly lower conductivity. However, this slight decrease in conductivity does not significantly impact its performance in many common electrical applications.

Copper-clad aluminum wire is commonly used in low-voltage applications, such as speaker wires and telecommunications cables. In these applications, the resistance of CCA wire can be balanced with appropriate wire gauges to ensure optimal performance.

It’s worth mentioning that copper-clad aluminum wire is not recommended for high-current or high-temperature applications. The higher resistance of aluminum can result in more significant heat generation compared to pure copper, which may cause issues in certain situations. For such applications, it is generally recommended to use pure copper wire to ensure safe and reliable operation.

When considering the use of copper-clad aluminum wire, it is important to carefully assess the specific requirements of the application. Factors such as weight, cost, voltage, and temperature considerations should be taken into account. Consulting with professionals in the electrical industry can help ensure the appropriate selection and safe use of copper-clad aluminum wire for your specific project.

Oxygen-Free Copper Wire

Oxygen-free copper (OFC) wire is a type of copper wire that is manufactured through a process that eliminates or significantly reduces the amount of oxygen present in the copper. This results in a high-purity copper wire with unique properties that make it suitable for specific applications, particularly in the audio and electrical industries.

One of the primary advantages of oxygen-free copper wire is its superior conductivity compared to standard copper wire. The presence of oxygen in copper can form oxides that impede the flow of electrical currents. By removing or minimizing oxygen content, OFC wire achieves a higher level of electrical conductivity, allowing for more efficient transmission of electrical signals. This property is especially beneficial in audio applications, where the preservation of signal integrity is crucial.

In the field of high-end audio equipment, oxygen-free copper wire is often preferred due to its ability to minimize resistance and signal loss. It helps preserve the accuracy, clarity, and details of sound reproduction, delivering a superior audio experience. The high conductivity of OFC wire allows for cleaner, noise-free signals and helps reproduce the nuances of the original audio source.

Another advantage of oxygen-free copper wire is its exceptional malleability. OFC wire is highly ductile, allowing it to be easily shaped and bent without compromising its structural integrity or electrical conductivity. This flexibility makes it convenient to handle during installation or when used in applications that require intricate wire routing, such as custom audio systems or electronic devices.

In addition to its electrical properties, OFC wire also offers excellent corrosion resistance. This is due to its high purity and absence of impurities that can contribute to corrosion. The corrosion resistance of oxygen-free copper wire ensures the long-term reliability and durability of electrical systems, even in demanding environments or locations with high levels of moisture or humidity.

It is important to note that oxygen-free copper wire is typically more expensive than standard copper wire due to the additional manufacturing processes involved in removing oxygen. However, for applications where signal integrity is paramount, the investment in OFC wire can deliver noticeable improvements in audio performance.

Oxygen-free copper wire finds applications in various audio systems, including high-end speaker cables, interconnect cables, and audio connectors. It is also used in specialized electronic equipment, signal transmission devices, and other applications where the highest level of electrical conductivity and signal fidelity is required.

In summary, oxygen-free copper wire offers superior electrical conductivity, malleability, and corrosion resistance compared to standard copper wire. Its unique properties make it a highly sought-after choice in the audio industry and other applications that demand the highest level of signal transmission and performance. When choosing oxygen-free copper wire, it is essential to consider the specific requirements of your project and consult with audio professionals or experts in the field to ensure the best results.

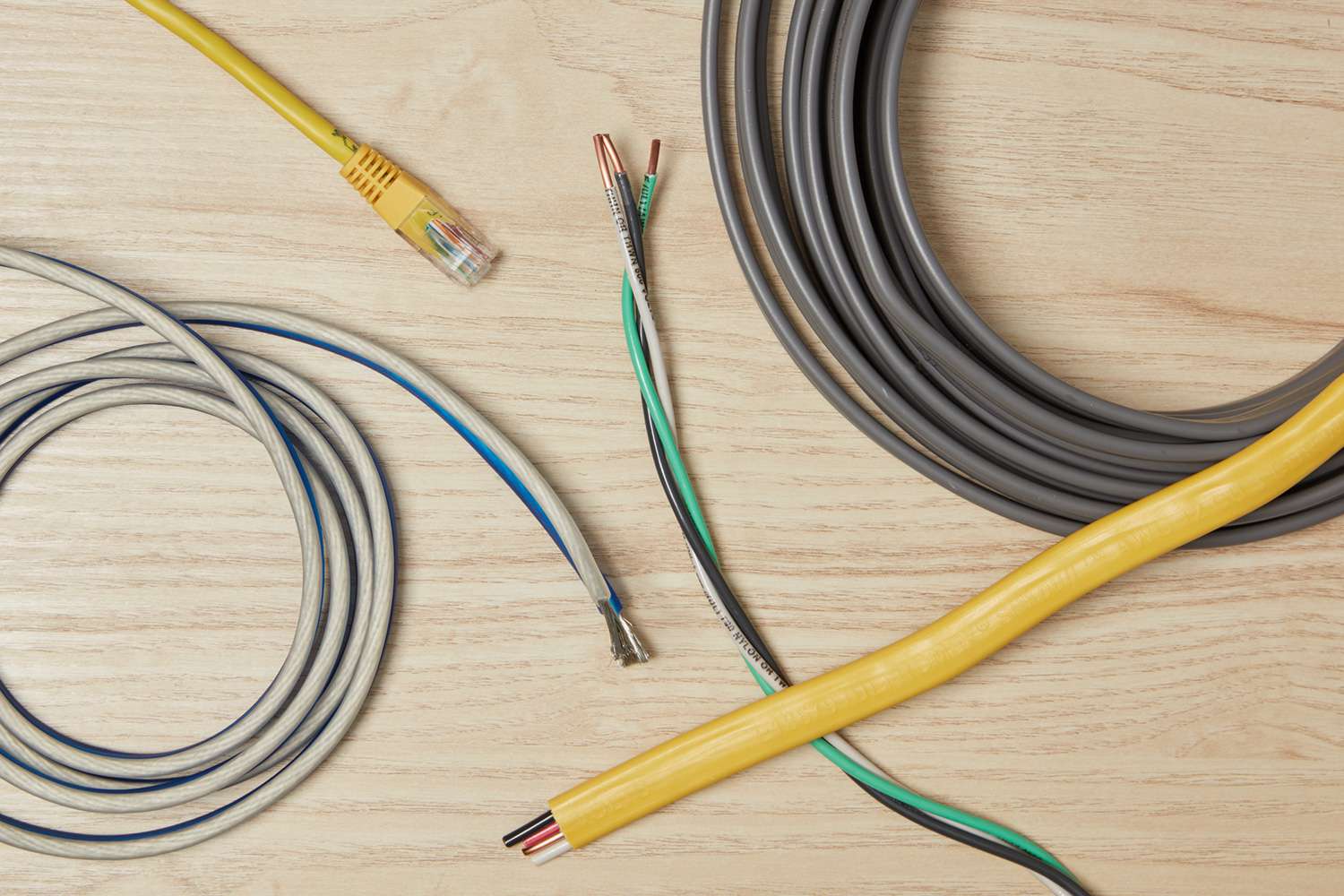

Conclusion

Copper wire is a vital component in electrical systems and is widely recognized for its excellent conductivity and durability. Understanding the different types of copper used in electrical wire can help you make informed decisions when choosing the right wire for your specific needs.

Bare copper wire, the most common type, offers high conductivity and durability. It is suitable for grounding, indoor installations, and overhead power lines. Tinned copper wire provides enhanced corrosion resistance and solderability, making it ideal for marine, automotive, and humid environments.

Copper-clad aluminum wire combines the lightweight and cost-effectiveness of aluminum with the conductivity of copper. It is commonly used in low-voltage applications, but caution should be taken for high-current or high-temperature applications.

Oxygen-free copper wire, with its high purity and superior conductivity, excels in audio applications where signal integrity is crucial. It delivers exceptional audio performance and is sought after in high-end audio systems and professional equipment.

In conclusion, the selection of the right type of copper wire depends on the specific requirements of your project. Consider factors such as conductivity, corrosion resistance, weight, cost, and environmental conditions when making your decision. Consulting with professionals in the electrical or audio industry can provide valuable guidance in choosing the appropriate wire for optimal performance and safety.

Whether it’s for powering your home, transmitting audio signals, or any other electrical application, understanding the different types of copper wire and their characteristics ensures the efficiency, reliability, and longevity of your electrical systems.

Curious about the latest innovations in electrical wiring? Our upcoming articles will dive into exciting options for your projects. One feature will highlight standout copper wire choices, perfect for those seeking reliability and efficiency in their electrical setups. Another piece will focus on the best wire gauge selections, providing detailed recommendations for various applications. Whether upgrading old systems or starting fresh, these articles offer valuable insights for making informed decisions.

Frequently Asked Questions about What Kind Of Copper Is Electrical Wire

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Kind Of Copper Is Electrical Wire”