Articles

What Element Makes Plumbing Pipes

Modified: August 31, 2024

Discover the key element that makes plumbing pipes sturdy and reliable. Read our informative articles to learn more about different types of plumbing materials and their advantages.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Plumbing systems play a crucial role in our daily lives, providing us with clean water for drinking, bathing, and washing, as well as efficiently removing wastewater from our homes and buildings. Behind the scenes, there are various types of plumbing pipes that make up these systems, each with its own unique characteristics and applications. Understanding the different types of plumbing pipes is essential for homeowners, contractors, and plumbers alike.

In this article, we will explore the most common types of plumbing pipes used in residential and commercial settings. We will delve into the features, benefits, and limitations of each type, helping you make informed decisions when it comes to your plumbing needs.

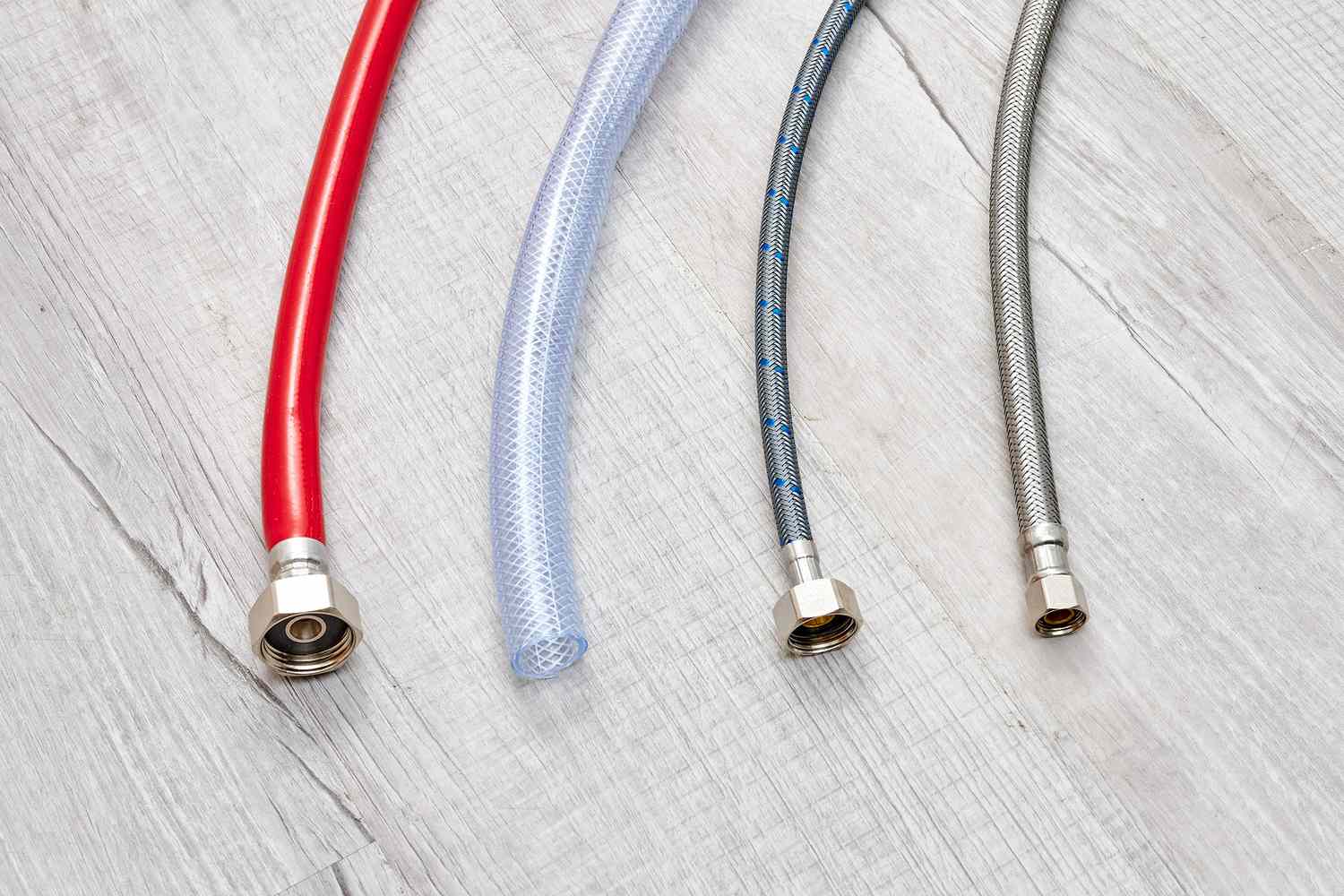

Before we dive into the details, it’s important to note that plumbing pipes are typically classified based on the material they are made from. The most common materials include copper, PVC (Polyvinyl Chloride), galvanized steel, cast iron, and PEX (Cross-linked Polyethylene).

Now, let’s take a closer look at each of these types and discover what makes them unique.

Key Takeaways:

- Copper pipes offer durability, versatility, and antimicrobial properties, making them a popular choice for clean water supply in residential and commercial plumbing systems.

- PEX pipes provide flexibility, durability, and easy installation, making them ideal for cold climates and radiant heating systems, despite being more expensive than other materials.

Read more: What Is A Drain Pipe In Plumbing

Copper Pipes

Copper pipes have been used in plumbing systems for centuries, and for good reason. They are known for their durability, reliability, and excellent performance. Copper pipes are typically made from pure copper or a combination of copper and other materials such as brass or bronze.

One of the main advantages of copper pipes is their resistance to corrosion. This means that they have a long lifespan and can withstand the test of time. Copper pipes are also highly resistant to heat and can handle high temperatures without melting or deforming. This makes them an ideal choice for hot water plumbing systems.

Another benefit of copper pipes is their versatility. They can be easily shaped and bent to fit various plumbing configurations, reducing the need for additional fittings. Copper pipes are also relatively lightweight, making them easier to handle and install compared to other types of plumbing pipes.

In addition to their durability and versatility, copper pipes have excellent antimicrobial properties. They inhibit the growth of bacteria and fungi, ensuring cleaner water supply and reducing the risk of waterborne illnesses. This is particularly important for drinking water systems and healthcare facilities.

However, it is worth noting that copper pipes can be more expensive compared to other materials. The initial cost of installation may be higher, but considering their longevity and resistance to corrosion, they can be a cost-effective choice in the long run.

In terms of maintenance, copper pipes require minimal upkeep. They are not prone to scaling or clogging and do not require regular cleaning. However, it is important to ensure that the water chemistry is compatible with copper, as certain water conditions can cause corrosion and lead to pipe damage over time.

Overall, copper pipes are a popular choice for plumbing systems due to their durability, versatility, and antimicrobial properties. Whether in residential or commercial settings, copper pipes provide a reliable and long-lasting solution for all plumbing needs.

PVC Pipes

PVC pipes, short for Polyvinyl Chloride pipes, are widely used in plumbing systems for both residential and commercial applications. They are known for their affordability, versatility, and ease of installation.

One of the main advantages of PVC pipes is their resistance to corrosion. Unlike metal pipes, PVC pipes do not rust or corrode when exposed to water or other corrosive substances. This makes them highly durable and long-lasting, even in harsh environments.

PVC pipes are also lightweight, making them easy to handle and install. They are available in a range of sizes and can be easily cut and joined using solvent cement or compression fittings. This flexibility in installation allows for efficient and cost-effective plumbing systems.

Another benefit of PVC pipes is their smooth interior surface. This smooth surface helps to prevent scaling and the buildup of debris, ensuring a continuous and unrestricted flow of water. This also means that PVC pipes require minimal maintenance and are less prone to clogging compared to other types of pipes.

PVC pipes are highly resistant to chemicals, making them suitable for a wide range of applications. They can safely transport both hot and cold water and are commonly used in drainage systems, irrigation systems, and underground piping.

One limitation of PVC pipes is their lower tolerance for high temperatures. While they can handle hot water, extremely high temperatures can cause PVC pipes to warp or deform. Therefore, it is important to consider the maximum temperature requirements when using PVC pipes in hot water systems.

It is worth mentioning that PVC pipes are not suitable for outdoor applications in areas with extreme cold temperatures. The material can become brittle in freezing conditions and may crack or break. In such cases, alternative materials like PEX or CPVC pipes may be a better choice.

In summary, PVC pipes are an affordable and versatile option for plumbing systems. Their corrosion resistance, ease of installation, and low maintenance make them a popular choice among homeowners, contractors, and plumbers.

Galvanized Steel Pipes

Galvanized steel pipes are known for their strength and durability, making them a popular choice for plumbing systems in both residential and industrial applications. These pipes are made of steel that has been coated with a layer of zinc to protect against corrosion.

One of the key advantages of galvanized steel pipes is their resistance to rust and corrosion. The zinc coating acts as a barrier, preventing the steel from coming into direct contact with water or moisture that can cause rust. This makes galvanized steel pipes ideal for plumbing systems that are exposed to high levels of moisture or corrosive substances.

Galvanized steel pipes are also known for their strength and durability. They have a high tensile strength, which means they can withstand high pressure and heavy loads. This makes them suitable for applications where durability and strength are paramount, such as in large-scale water supply systems or industrial plumbing projects.

In addition to their strength, galvanized steel pipes are fire-resistant. They have a high melting point, which makes them less susceptible to fire damage. This feature is especially important for plumbing systems in buildings where fire safety is a top priority.

However, it’s important to note that galvanized steel pipes have some limitations. Over time, the zinc coating can deteriorate, leading to corrosion and eventual pipe failure. This is especially true in areas with highly acidic or alkaline water conditions. Regular inspection and maintenance are crucial to ensure the integrity of galvanized steel pipes.

Another consideration is the potential for scaling and mineral buildup inside the pipes. Galvanized steel pipes can accumulate sediment and mineral deposits over time, which can restrict water flow and lead to reduced water pressure. Regular cleaning or descaling may be required to maintain optimal performance.

Due to their weight and rigidity, galvanized steel pipes may also be more challenging to install compared to other types of pipes. Special care must be taken during installation to ensure proper alignment and support.

In summary, galvanized steel pipes offer excellent strength, durability, and fire resistance. They are commonly used in plumbing systems where corrosion resistance and robustness are essential. However, regular maintenance and consideration of water conditions are necessary to prolong their lifespan and ensure optimal performance.

Copper is a common element used to make plumbing pipes due to its corrosion resistance and ability to be easily formed and joined.

Cast Iron Pipes

Cast iron pipes, known for their durability and longevity, have been used in plumbing systems for over a hundred years. These pipes are made from molten iron that is poured into molds, resulting in a strong and resilient material.

One of the main advantages of cast iron pipes is their resistance to high pressure and heavy loads. They have exceptional strength and can withstand the weight of soil, making them suitable for underground plumbing systems and sewer lines. This durability also allows cast iron pipes to have a long lifespan, often lasting over 100 years.

Cast iron pipes have excellent noise reduction properties. The dense material helps to dampen water flow noises, making them ideal for multi-story buildings or areas where noise control is important, such as hospitals or hotels.

Another benefit of cast iron pipes is their resistance to fire. They have a high melting point and are non-combustible, providing an added layer of fire protection to the plumbing system. This is especially crucial in commercial buildings and industrial settings where fire safety is paramount.

However, there are a few considerations when it comes to cast iron pipes. Firstly, they can be heavy and difficult to handle during installation. Specialized equipment and skilled labor may be required to properly maneuver and connect these pipes.

Cast iron pipes are prone to corrosion over time, especially in areas with acidic or corrosive water conditions. Internal and external corrosion can lead to reduced water flow, leaks, and ultimately the need for pipe replacement. Regular inspections and maintenance are essential to prevent issues and extend the lifespan of cast iron pipes.

It’s also important to note that due to their material and weight, cast iron pipes may be more expensive compared to other types of pipes. Additionally, they are not as flexible as some other options, which can limit their use in certain plumbing configurations.

Overall, cast iron pipes are a reliable and durable choice for plumbing systems, particularly in applications where strength, longevity, and sound reduction are important. Regular maintenance and consideration of water conditions are necessary to ensure their optimal performance over the years.

PEX Pipes

PEX pipes, short for Cross-linked Polyethylene pipes, have gained popularity in recent years for their versatility, durability, and ease of installation. These pipes are made from a flexible plastic material that is capable of withstanding high temperatures and pressure.

One of the main advantages of PEX pipes is their flexibility. They can be easily bent and shaped, allowing for hassle-free installation around tight corners and obstacles. This flexibility also reduces the need for additional fittings, reducing the risk of leaks and improving overall system efficiency.

PEX pipes are also known for their durability. They have excellent resistance to corrosion, scale, and chlorine, ensuring long-lasting performance and reliability. These pipes can withstand extreme temperature variations, making them suitable for both hot and cold water applications.

Another benefit of PEX pipes is their resistance to freezing. Unlike some other materials, PEX pipes can expand and contract without cracking or bursting in freezing temperatures. This makes them well-suited for plumbing systems in cold climates where freezing pipes can be a concern.

PEX pipes are lightweight and easy to handle, making them ideal for DIY installations. They can be installed using various connection methods, including crimping, compression, or push-fit fittings. This versatility allows for quick and efficient installation, saving both time and labor costs.

It’s important to note that PEX pipes are not suitable for outdoor applications where they are exposed to direct sunlight for long periods. UV radiation can degrade the material over time, reducing its lifespan and performance. In such cases, installing the pipes in protective conduits or using UV-resistant PEX would be recommended.

PEX pipes are also commonly used in radiant heating systems due to their ability to efficiently distribute hot water throughout the floor. They have excellent heat retention properties, reducing heat loss and improving energy efficiency.

However, it’s worth mentioning that PEX pipes can be more expensive than other materials such as PVC or copper. Despite the higher upfront cost, the benefits of easy installation, durability, and versatility often outweigh the initial investment.

In summary, PEX pipes offer flexibility, durability, and ease of installation. They are a popular choice for plumbing systems, especially in applications where bending and versatile installation options are required. Whether for residential or commercial use, PEX pipes provide a reliable and efficient solution for various plumbing needs.

Conclusion

Plumbing pipes are the backbone of every plumbing system, ensuring the reliable delivery of water and the efficient removal of wastewater. Understanding the different types of plumbing pipes available is crucial when it comes to selecting the right material for your specific needs.

In this article, we have explored some of the most common types of plumbing pipes, including copper, PVC, galvanized steel, cast iron, and PEX. Each type has its own unique features, advantages, and limitations.

Copper pipes are renowned for their durability, versatility, and antimicrobial properties. They are a popular choice for both residential and commercial plumbing systems, ensuring a long lifespan and clean water supply.

PVC pipes, on the other hand, offer affordability, ease of installation, and resistance to corrosion. They are lightweight, versatile, and suitable for various plumbing applications.

Galvanized steel pipes are known for their strength, durability, and fire resistance. They provide excellent protection against corrosion and are commonly used in plumbing systems that require high pressure and heavy loads.

Cast iron pipes, while heavy and more challenging to install, offer exceptional durability and noise reduction properties. They are ideal for applications where strength and longevity are paramount.

Lastly, PEX pipes provide flexibility, durability, and easy installation. They are resistant to freezing, making them suitable for cold climates, and are commonly used in radiant heating systems.

When selecting the right plumbing pipe for your needs, it’s important to consider factors such as budget, application, water conditions, and installation requirements. Regular maintenance and inspections are crucial for all types of pipes to ensure optimal performance and prevent issues.

Ultimately, there is no one-size-fits-all solution when it comes to plumbing pipes. It is recommended to consult with plumbing professionals or contractors to determine the best choice for your specific project or plumbing system requirements.

By understanding the different types of plumbing pipes and their unique characteristics, you can make informed decisions to ensure the longevity, efficiency, and reliability of your plumbing system for years to come.

Frequently Asked Questions about What Element Makes Plumbing Pipes

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Element Makes Plumbing Pipes”