Home>Articles>Which Type Of Condenser Uses A Fan To Push Air Across The Condenser?

Articles

Which Type Of Condenser Uses A Fan To Push Air Across The Condenser?

Modified: October 20, 2024

Looking for articles about condensers? Learn about the type that uses a fan to push air across the condenser. Find all the information you need.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When it comes to cooling systems, condensers play a vital role in heat transfer. They are an essential component of air conditioning, refrigeration, and heat pump systems. A condenser’s primary function is to release heat absorbed by the refrigerant during the cooling process. This allows the refrigerant to return to its liquid state, ready to remove more heat.

There are various types of condensers available, each designed to cater to specific cooling requirements. One popular type is the air-cooled condenser. As the name suggests, these condensers utilize the surrounding air to remove heat from the system. They are an efficient and cost-effective cooling solution for a variety of applications.

In this article, we will explore the different types of condensers, with a specific focus on air-cooled condensers that use a fan to push air across the condenser. We will delve into their working principle, benefits, drawbacks, and applications. By the end, you will have a comprehensive understanding of this particular condenser type and its role in the cooling process.

Key Takeaways:

- Air-cooled condensers with fans offer cost-effective and flexible cooling solutions for various applications, from residential air conditioning to industrial processes. Their independence from water sources and ease of installation make them a practical choice.

- The use of fans to push air across condenser coils enhances heat dissipation, making air-cooled condensers with fans suitable for applications such as refrigeration, heat pumps, data centers, and transportation refrigeration. Regular maintenance is crucial for optimal performance.

Read more: Which Type Of Air Conditioner Is Best?

Definition of a Condenser

A condenser is a heat exchange device that plays a crucial role in various cooling systems. Its primary function is to transfer heat from the refrigerant to the surrounding environment, allowing the refrigerant to condense back into a liquid state. This process is a key step in the refrigeration cycle, as it prepares the refrigerant for further cooling.

Condensers are typically used in air conditioning, refrigeration, and heat pump systems to remove heat from the working fluid or refrigerant. They provide a means of transferring thermal energy from the system to the external environment.

Condensers work by exposing the hot refrigerant vapor to a cool medium, which can be air or water. As the refrigerant comes into contact with the cooler surface, it releases heat energy, causing the vapor to condense into a liquid. The liquid refrigerant can then flow back into the evaporator, where it absorbs heat and restarts the refrigeration cycle.

In essence, a condenser acts as a bridge between the evaporator and the compressor, allowing for the continuous circulation of the refrigerant. It helps to maintain the efficiency and performance of cooling systems by facilitating the transfer of heat and ensuring the proper functioning of the cycle.

Condensers come in various configurations and types, each suited for specific cooling requirements. One commonly used type is the air-cooled condenser, which relies on fans to push air across the condenser coils, facilitating heat transfer to the surrounding atmosphere.

In the next section, we will explore the different types of condensers in more detail, focusing on air-cooled condensers that utilize fans for airflow.

Types of Condensers

Condensers are available in different types, each with its own unique characteristics and applications. The choice of condenser type depends on factors such as cooling requirements, space limitations, and cost considerations. Here are some of the common types of condensers:

- Air-Cooled Condensers: Air-cooled condensers use ambient air to remove heat from the refrigerant. They are typically found in residential and commercial air conditioning systems, as well as small-scale refrigeration units. These condensers employ fans to push air across the condenser coils, facilitating heat transfer and condensation.

- Water-Cooled Condensers: Water-cooled condensers rely on water as the cooling medium. They are commonly used in large-scale refrigeration and air conditioning systems, as well as industrial applications. Water-cooled condensers require a separate water supply and a cooling tower to dissipate heat from the system.

- Evaporative Condensers: Evaporative condensers combine the use of air and water for heat rejection. They incorporate a water spray system to enhance the cooling effect by evaporating water in contact with the condenser coils. Evaporative condensers are often employed in industrial cooling applications and areas with dry climates.

- Shell and Tube Condensers: Shell and tube condensers consist of a series of tubes enclosed within a shell. The refrigerant flows through the tubes, while the cooling medium, such as water or air, surrounds the tubes. This design allows for efficient heat transfer and is commonly used in refrigeration, air conditioning, and heat pump systems.

- Plate Condensers: Plate condensers utilize a stack of metal plates to provide a large surface area for heat transfer. The refrigerant flows between the plates, while the cooling medium flows on the opposite side. Plate condensers are compact and efficient, making them suitable for space-constrained applications.

These are just a few examples of the many types of condensers available in the cooling industry. Each type offers its own advantages and is selected based on the specific cooling requirements and system design.

In the next section, we will focus on air-cooled condensers that use a fan to push air across the condenser, providing efficient and cost-effective cooling solutions.

Overview of Air-Cooled Condensers

Air-cooled condensers are a popular choice in many cooling applications due to their efficiency, simplicity, and cost-effectiveness. These condensers rely on the surrounding air to remove heat from the refrigerant and facilitate the condensation process. They are commonly used in residential and commercial air conditioning systems, as well as small-scale refrigeration units.

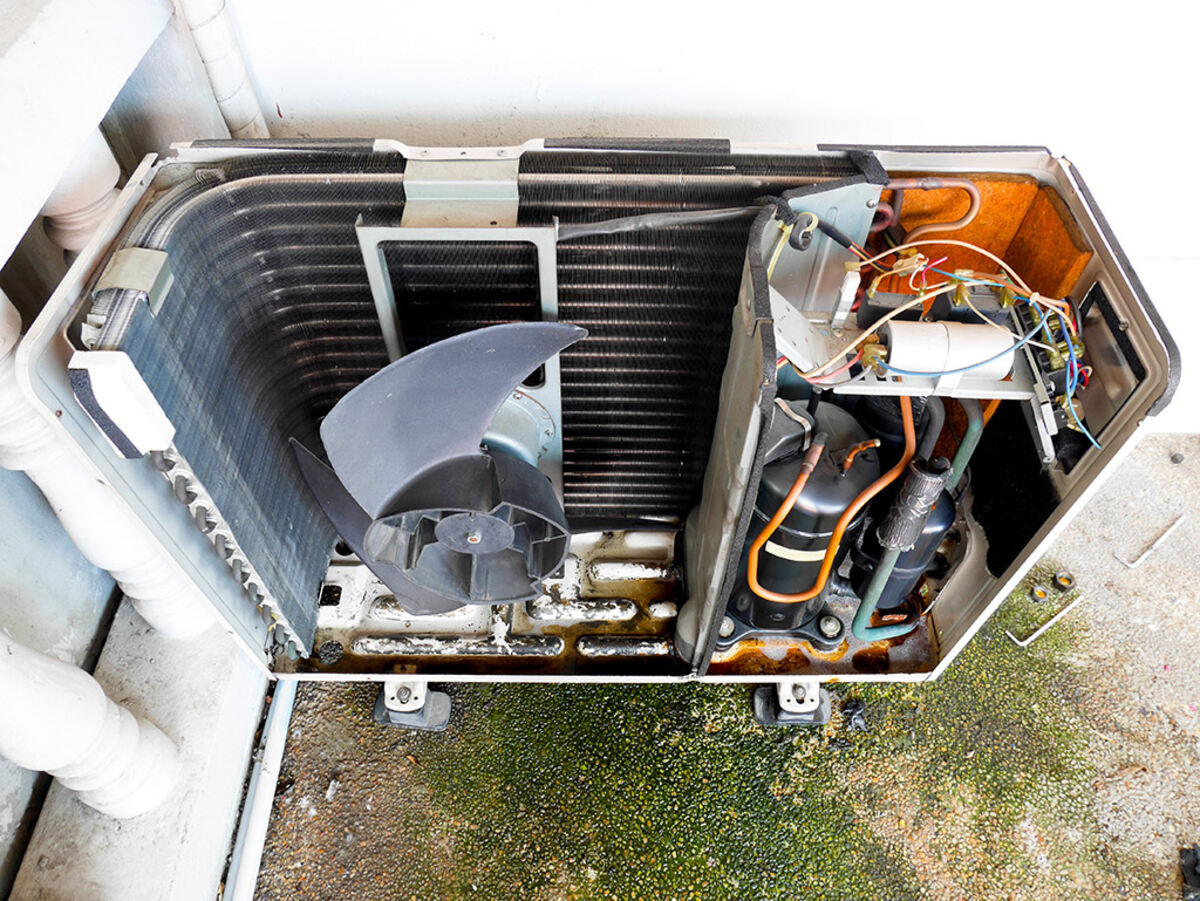

The design of an air-cooled condenser typically consists of a network of copper or aluminum tubes that carry the refrigerant. These tubes are surrounded by a series of aluminum fins, which increase the surface area and enhance heat transfer. To facilitate airflow, the condenser is equipped with one or more fans that create a forced draft, pushing air across the condenser coils.

The primary advantage of air-cooled condensers is their ability to operate independently of external water sources, such as cooling towers or water supplies. This makes them more suitable for applications where water availability is limited or expensive to maintain. Additionally, air-cooled condensers eliminate the need for complex plumbing systems and can be easily installed in various locations.

An important consideration when using air-cooled condensers is the ambient temperature and airflow conditions. The efficiency of the condenser depends on the temperature difference between the refrigerant and the surrounding air. High ambient temperatures or restricted airflow can result in reduced condensing performance.

Regular maintenance of air-cooled condensers is essential to ensure optimal performance. The condenser coils should be cleaned periodically to remove dust, dirt, and debris that can impede airflow and hinder heat transfer. Proper maintenance helps maintain the condenser’s efficiency, prolong its lifespan, and prevent potential equipment failures.

Despite their advantages, air-cooled condensers do have some limitations. Compared to water-cooled condensers, they have a lower heat rejection capacity, which can limit their use in applications that require large cooling loads. Additionally, air-cooled condensers can be noisier due to the operation of the fans, which may need to be taken into account in noise-sensitive environments.

Overall, air-cooled condensers offer a practical and efficient cooling solution for a range of applications. Their simplicity, compactness, and independence from water sources make them a popular choice in the cooling industry. In the next section, we will delve into the working principle of air-cooled condensers and explore how they utilize fans to push air across the condenser coils.

Working Principle of Air-Cooled Condensers

The working principle of air-cooled condensers is based on the fundamental concepts of heat transfer and the refrigeration cycle. These condensers use ambient air as the cooling medium to remove heat from the refrigerant, allowing it to condense back into a liquid state.

When the hot refrigerant vapor enters the air-cooled condenser, it comes into contact with a network of tubes. These tubes, typically made of copper or aluminum, are designed to maximize surface area and enhance heat transfer. The heat contained in the refrigerant vapor is transferred to the metal tubes through conduction.

As the heat is transferred to the tubes, the refrigerant vapor begins to cool down. Simultaneously, one or more fans are activated to create airflow across the condenser coils. The fans draw ambient air into the condenser, which passes over the tubes and absorbs the heat from the refrigerant. This process, known as convection, facilitates the release of heat energy from the refrigerant to the surrounding air.

As the ambient air absorbs the heat, it becomes warmer and is expelled from the condenser. The heated air is vented outside, away from the cooling system. This continuous flow of air across the condenser coils enables the refrigerant to shed heat and undergo the condensation process.

As the refrigerant gives off heat to the ambient air, it experiences a change in temperature and pressure. The high-temperature, high-pressure vapor gradually cools down and condenses into a liquid state within the condenser coils. The now-liquid refrigerant can then flow to the next stage of the refrigeration cycle, where it absorbs heat once again, creating a continuous cooling process.

The efficiency of an air-cooled condenser depends on several factors, including the ambient temperature, available airflow, and the design and condition of the condenser coils. Higher ambient temperatures, restricted airflow, or the presence of dirt and debris on the coils can reduce the condenser’s efficiency and hinder heat transfer.

Regular maintenance, such as cleaning the condenser coils and ensuring proper airflow, is essential to maintain optimal performance. By keeping the condenser clean and ensuring adequate airflow, the cooling system can operate efficiently, consume less energy, and provide effective cooling.

In the next section, we will focus on the specific types of air-cooled condensers that utilize fans to push air across the condenser, enhancing the heat transfer process.

Read more: How To Test Condenser Fan Motor

Condenser Types That Use a Fan to Push Air Across

When it comes to air-cooled condensers, there are several types that utilize fans to push air across the condenser coils, enhancing the heat transfer process. These condensers are designed to efficiently dissipate heat by utilizing forced air circulation. Let’s explore some of the common condenser types that employ fans:

- Axial Fan Condensers: Axial fan condensers feature large axial fans that draw air through the condenser coils and expel it in the same direction. The fans are mounted directly on the condenser and generate a high volume of airflow, making them suitable for applications with high cooling demands. These condensers are commonly used in large commercial air conditioning systems and refrigeration units.

- Centrifugal Fan Condensers: Centrifugal fan condensers utilize centrifugal fans, which pull air into the condenser from the sides and discharge it from the top. The design of these fans allows for increased air pressure and airflow control, making them ideal for applications that require uniform air distribution or where space limitations exist. Centrifugal fan condensers are commonly used in compact air conditioning systems, heat pumps, and refrigeration units.

- Propeller Fan Condensers: Propeller fan condensers use propeller fans that operate at high speeds to create a high volume of airflow. These fans are typically mounted outside the condenser unit and draw air through the condenser coils. Propeller fan condensers are often found in residential air conditioning systems and small-scale refrigeration units, where cost-effectiveness and simplicity are paramount.

- Mixed Flow Fan Condensers: Mixed flow fan condensers combine axial and centrifugal fan elements to create a hybrid airflow pattern. The mixed flow design offers a balance between high airflow rates and increased pressure, making it suitable for medium-sized commercial air conditioning systems and refrigeration units. These condensers provide efficient heat transfer while minimizing noise levels during operation.

- V-Shaped Condensers: V-shaped condensers feature multiple sets of condenser coils placed at an inclined angle, resembling the shape of the letter “V”. The design allows for increased surface area and improved airflow across the coils. V-shaped condensers often utilize axial fans to push air across the coils, making them efficient in cooling systems with limited space or where air circulation needs to be optimized.

These are just a few examples of the condenser types that use fans to push air across the condenser coils. Each type offers its own advantages in terms of cooling efficiency, airflow control, and space requirements. The selection of the appropriate condenser type depends on factors such as cooling requirements, available space, and system design.

In the following sections, we will explore the benefits and drawbacks of air-cooled condensers with fans, as well as their applications in various industries.

The type of condenser that uses a fan to push air across the condenser is called an air-cooled condenser. This type of condenser is commonly used in air conditioning and refrigeration systems.

Benefits and Drawbacks of Air-Cooled Condensers with Fans

Air-cooled condensers with fans offer several advantages that make them a popular choice in many cooling applications. However, they also come with certain drawbacks that should be taken into consideration. Let’s explore the benefits and drawbacks of air-cooled condensers with fans:

Benefits:

- Cost-effective: Air-cooled condensers with fans are generally more cost-effective compared to water-cooled condensers. They do not require additional equipment such as cooling towers or water supplies, reducing installation and maintenance costs.

- Ease of installation: These condensers are relatively easy to install and do not require complex plumbing systems. Their compact design allows for flexible placement in various locations, making them suitable for both residential and commercial applications.

- Independence from water sources: Air-cooled condensers eliminate the need for external water sources, making them ideal for areas where water availability is limited or expensive. This independence also reduces the risk of water-related issues, such as leaks or water treatment requirements.

- Flexibility: Air-cooled condensers can be used in both indoor and outdoor settings, providing flexibility in system design. They are particularly useful in retrofitting existing buildings or when space is limited.

- Energy efficiency: With advances in fan technology, air-cooled condensers have become more energy-efficient. Variable speed fans can be utilized to match the cooling load, reducing energy consumption and enhancing overall system efficiency.

- Lower maintenance requirements: Maintenance for air-cooled condensers is generally simpler compared to water-cooled condensers. Cleaning the condenser coils regularly to remove debris and ensuring proper airflow are key maintenance tasks.

- Durability: Air-cooled condensers are typically more resistant to corrosion compared to water-cooled condensers. They are less prone to damage caused by the quality of water or various chemical treatments.

Drawbacks:

- Reduced heat rejection capacity: Air-cooled condensers have a lower heat rejection capacity compared to water-cooled condensers. This limits their use in applications that require large cooling loads or in high-temperature environments.

- Higher operating temperatures: Air-cooled condensers operate at higher discharge temperatures compared to water-cooled condensers. This can reduce the overall efficiency of the cooling system and potentially impact the longevity of certain system components.

- Potential noise concerns: The operation of fans in air-cooled condensers can generate noise, which may be a concern in noise-sensitive environments. However, advancements in technology have resulted in quieter fans.

- Dependence on ambient conditions: The performance of air-cooled condensers heavily relies on ambient temperature and airflow conditions. High ambient temperatures or restricted airflow can decrease their efficiency and effectiveness.

- Regular maintenance requirements: While maintenance for air-cooled condensers is generally simpler, regular cleaning of the condenser coils is essential. Dust, dirt, and debris can accumulate on the coils and hinder heat transfer, reducing the condenser’s efficiency.

- Environmental impact: Air-cooled condensers contribute to heat release into the surrounding environment, potentially raising outdoor temperatures. This may have a localized impact in urban areas, creating urban heat islands.

Considering the benefits and drawbacks, air-cooled condensers with fans are an efficient and cost-effective cooling solution for various applications. The specific advantages and limitations should be carefully evaluated based on the cooling requirements, space availability, and environmental factors.

In the following section, we will explore the applications of air-cooled condensers with fans in different industries and sectors.

Read more: What Is An Air Conditioner Condenser

Applications of Condensers with Fans

Condensers with fans are widely used in various industries and sectors where efficient heat transfer and cooling are required. The ability to utilize ambient air for heat dissipation makes these condensers suitable for a range of applications. Let’s explore some of the common applications of condensers with fans:

- Air Conditioning: Condensers with fans are extensively used in air conditioning systems, including both residential and commercial applications. They play a key role in extracting heat from the refrigerant, allowing for effective cooling of indoor spaces. These condensers are often found in central air conditioning units, split systems, and window units.

- Refrigeration: Refrigeration units, such as refrigerators, freezers, and walk-in coolers, rely on condensers with fans to remove heat from the refrigerant. The cooling process in these units is essential for preserving food, beverages, and other perishable items. Condensers with fans ensure efficient heat transfer and maintain the desired temperature levels.

- Heat Pumps: Heat pump systems utilize condensers with fans to regulate indoor temperatures by extracting heat from the outside air or ground. Heat pumps are used for both heating and cooling purposes in residential, commercial, and industrial applications. The use of condensers with fans enables the efficient transfer and release of heat for effective heating or cooling.

- Data Centers and Electronics Cooling: Temperature control is crucial in data centers and electronics equipment to prevent overheating and ensure optimal performance. Condensers with fans are employed to dissipate heat generated by servers, networking equipment, and other electronics. These condensers help maintain stable operating temperatures, ensuring the reliability and longevity of critical systems.

- Process Cooling: Many industrial processes require precise cooling to maintain specific temperatures. Condensers with fans are used in industries such as chemical manufacturing, pharmaceuticals, food processing, and oil refineries. They provide efficient cooling solutions for different process applications, ensuring the stability and quality of products.

- HVAC Systems in Buildings: Air-cooled condensers with fans are commonly utilized in HVAC (Heating, Ventilation, and Air Conditioning) systems in residential, commercial, and institutional buildings. These systems are responsible for regulating indoor temperature, providing comfort to occupants. Condensers with fans help remove heat from the refrigerant, allowing for efficient cooling or heating.

- Industrial Cooling: Various industrial processes require cooling for machinery, equipment, and production lines. Condensers with fans are employed in applications such as power generation, manufacturing, chemical processing, and metal fabrication. They provide reliable and efficient heat dissipation, ensuring smooth operation and longevity of industrial equipment.

- Transportation Refrigeration: Condensers with fans are utilized in refrigerated trucks, trailers, and containers for transporting temperature-sensitive goods. These condensers maintain the desired temperature within the transport units, keeping perishable items fresh and preventing spoilage.

- Renewable Energy Systems: Condensers with fans have applications in renewable energy systems, such as geothermal heat pumps and solar thermal power plants. They facilitate the heat transfer process, ensuring efficient energy conversion and utilization.

These are just a few examples of the broad range of applications where condensers with fans are utilized. The versatility and effectiveness of these condensers make them an integral part of cooling systems across various industries and sectors.

Conclusively, condensers with fans provide reliable and efficient cooling solutions for diverse applications, from residential air conditioning to large-scale industrial processes. Their ability to utilize ambient air for heat dissipation makes them a cost-effective and environmentally friendly choice in the cooling industry.

Conclusion

Condensers with fans are an integral part of cooling systems, providing efficient heat transfer and effective cooling in various industries and applications. The use of fans to push air across the condenser coils enhances heat dissipation and enables the condensation process, allowing for the continuous operation of refrigeration, air conditioning, and heat pump systems.

We have explored the different types of condensers, with a specific focus on air-cooled condensers that utilize fans for airflow. These condenser types offer several benefits, including cost-effectiveness, ease of installation, independence from water sources, and flexibility in system design. However, they also come with certain drawbacks, such as reduced heat rejection capacity and potential noise concerns.

Air-cooled condensers with fans find wide-ranging applications in air conditioning, refrigeration, heat pumps, data centers, industrial cooling, and transportation refrigeration, among others. They play a crucial role in maintaining optimal temperatures, preserving perishable goods, and ensuring the reliable operation of equipment and systems.

While condensers with fans are a practical and efficient cooling solution, their performance is influenced by factors such as ambient temperature, airflow conditions, and regular maintenance. Proper maintenance, including the cleaning of condenser coils and ensuring adequate airflow, is essential for optimal performance and energy efficiency.

In conclusion, condensers with fans offer a cost-effective and reliable cooling solution for a wide range of applications. Their ability to utilize ambient air for heat dissipation, flexibility in installation, and independence from water sources make them a preferred choice in many industries. Advancements in fan technology and design continue to improve their efficiency and performance.

As cooling requirements continue to evolve in an energy-conscious world, the development of more efficient and sustainable cooling technologies remains a focus. Condensers with fans will continue to play a significant role in meeting these demands, providing effective cooling solutions while minimizing environmental impact.

Frequently Asked Questions about Which Type Of Condenser Uses A Fan To Push Air Across The Condenser?

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “Which Type Of Condenser Uses A Fan To Push Air Across The Condenser?”