Articles

How To Test Condenser Fan Motor

Modified: May 6, 2024

Learn how to test condenser fan motor with these informative articles. Ensure your fan motor is functioning properly for optimal cooling performance.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to our step-by-step guide on how to test a condenser fan motor. The condenser fan motor plays a crucial role in the functioning of your air conditioning system, as it helps to dissipate heat from the condenser coils. Over time, the motor may experience issues such as overheating, malfunctioning, or a decrease in performance. Testing the motor is essential to diagnose any problems and ensure that it is operating correctly.

In this article, we will walk you through the process of testing a condenser fan motor to determine its functionality. We will provide you with the necessary steps to follow and highlight the precautions you need to take to ensure your safety during the testing process. By following these instructions, you can save time and money by identifying any potential issues with your condenser fan motor and taking the appropriate action.

Before we proceed with the testing process, it is important to note that if you are not confident in performing these tasks, it is always recommended to seek the assistance of a professional HVAC technician. Safety should be your top priority, and if you are unsure or uncomfortable working with electrical components, it is best to leave the job to the experts.

Now, let’s dive into the step-by-step process of testing a condenser fan motor and ensure the optimal functioning of your air conditioning system.

Key Takeaways:

- Ensure safety first by following proper precautions when testing the condenser fan motor, including disconnecting the power supply, using PPE, and seeking professional help if needed.

- Regular testing and maintenance of the condenser fan motor can enhance the performance of your air conditioning system, prevent breakdowns, and save on costly repairs.

Read more: How To Test Fan Motor

Safety Precautions

Before you begin testing the condenser fan motor, it is crucial to prioritize your safety. Working with electrical components can be hazardous if not done correctly. Here are some essential safety precautions to follow:

- Disconnect the power supply: Before starting any work, ensure that the power supply to the air conditioning unit is completely disconnected. This can be done by turning off the circuit breaker or disconnecting the unit from the power source. This step is vital to prevent any electrical shock or accidents.

- Use Personal Protective Equipment (PPE): Wear appropriate safety gear such as insulated gloves, safety goggles, and non-conductive footwear to protect yourself from potential electrical hazards.

- Allow the system to cool down: Before accessing the condenser fan motor, ensure that the unit has been turned off for a sufficient amount of time to allow the components to cool down. A hot motor can cause burns or voltage irregularities.

- Be cautious of sharp edges: When inspecting or accessing the condenser fan motor, be mindful of any sharp edges or protruding components. Use caution and protective measures to avoid any cuts or injuries.

- Avoid contact with moving parts: Do not attempt to touch the fan blades or any other moving parts of the motor while it is in operation or immediately after turning it off. Wait for the motor to completely stop before engaging with any components.

- Follow manufacturer guidelines: Refer to the manufacturer’s instructions and guidelines specific to your condenser fan motor. Different models may have variations in testing procedures, so it is essential to follow the recommended steps provided by the manufacturer.

- Seek professional help if needed: If you are uncertain about any step of the testing process or if you encounter any difficulties, it is advisable to contact a qualified HVAC technician for assistance. They have the expertise and experience to handle these tasks safely and effectively.

By adhering to these safety precautions, you can minimize the risk of accidents and ensure a safe testing process for your condenser fan motor. Remember, your safety should always be your top priority when working with electrical components.

Step 1: Gather necessary tools and equipment

Before you start testing the condenser fan motor, it is important to gather the necessary tools and equipment to carry out the process smoothly. Here is a list of items you will need:

- Insulated gloves: Wear insulated gloves to protect yourself from any potential electrical shocks during the testing process.

- Safety goggles: Protect your eyes from any debris or particles that may be released while inspecting or working with the motor.

- Multimeter: This is an essential tool that will be used to measure voltage and check for continuity in the motor windings.

- Allen wrench or screwdriver: Depending on your specific condenser fan motor, you may need an Allen wrench or screwdriver to access and inspect the motor.

- Lubricant: If necessary, you may need a suitable lubricant to ensure the smooth operation of the motor’s moving parts.

- Electrical tape: Use electrical tape to secure and insulate any loose wires or connections.

- Owner’s manual: Keep the owner’s manual of your air conditioning unit handy. It contains specific information about the condenser fan motor, including diagrams and troubleshooting tips.

By ensuring you have these tools and equipment readily available, you can proceed with testing the condenser fan motor efficiently and effectively.

Step 2: Disconnect the power supply

Before you begin testing the condenser fan motor, it is crucial to disconnect the power supply to ensure your safety. Here’s how you can do it:

- Locate the circuit breaker panel: Identify where the circuit breaker panel is located in your home or building. It is usually found in the basement, garage, or utility room.

- Identify the correct breaker: Look for the breaker that corresponds to the air conditioning unit or HVAC system. The breakers are typically labeled, so you should easily be able to identify the correct one. If not, refer to the owner’s manual of your unit for guidance.

- Switch off the breaker: Once you have identified the correct breaker, switch it off. This will cut off the power supply to the air conditioning unit, including the condenser fan motor.

- Double-check the power supply: To ensure that the power supply is completely disconnected, test the unit by turning on your air conditioner. If it does not turn on or produce any air, it means that the power supply has been successfully disconnected.

It is important to be extra cautious when working with electrical components. By disconnecting the power supply, you minimize the risk of electric shock or injury during the testing process.

Remember that safety should always be your top priority. If you are unsure about handling electrical components, it is recommended to seek the assistance of a professional HVAC technician.

Step 3: Locate the condenser fan motor

Now that you have disconnected the power supply, you can proceed with locating the condenser fan motor. The motor is typically located within the outdoor unit of your air conditioning system, known as the condenser unit. Here’s how you can find it:

- Identify the outdoor unit: Go outside to where your air conditioning unit is installed. The condenser unit is usually situated next to your home or on the rooftop. It is a large metal box that houses the condenser coil, compressor, and the condenser fan motor.

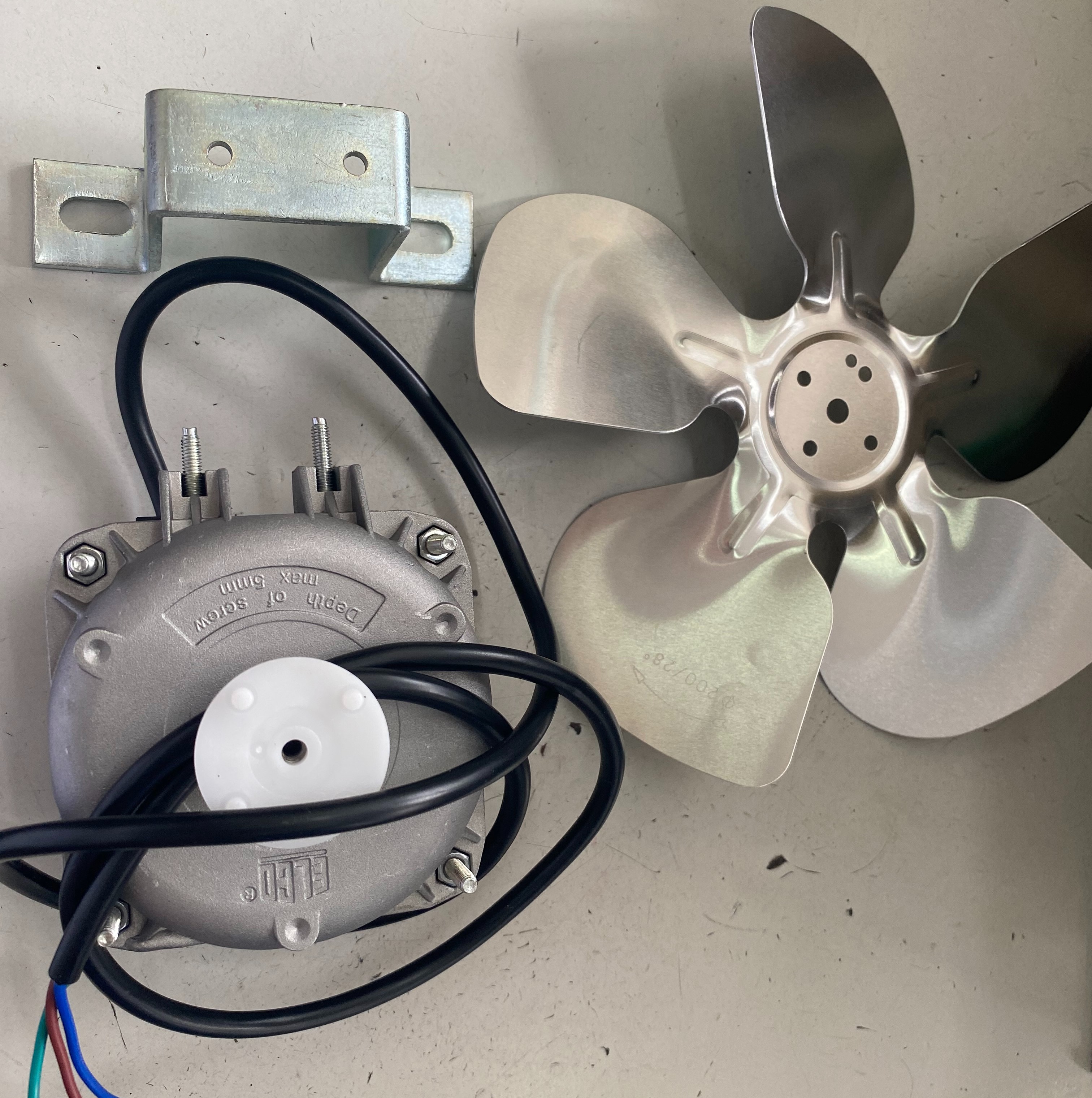

- Inspect the unit: Once you have located the outdoor unit, visually inspect it to find the condenser fan motor. Look for a cylindrical component with fan blades attached to it. The fan blades are responsible for drawing air through the condenser coil to dissipate heat.

- Observe the wiring: Take note of the wiring connected to the motor. This will help you later in the testing process when you need to check for loose connections.

Keep in mind that the exact location of the condenser fan motor may vary depending on the make and model of your air conditioning unit. If you are having trouble finding it, refer to the owner’s manual or consult a professional technician for assistance.

Once you have located the condenser fan motor, you are ready to proceed with inspecting and testing it.

Step 4: Inspect the motor visually

With the condenser fan motor located, it is time to visually inspect it for any visible signs of damage or wear. A thorough visual inspection can provide insights into the overall condition of the motor. Here’s what to look for:

- Check for physical damage: Examine the motor for any visible physical damage such as cracks, dents, or corrosion. These can indicate potential issues that may affect the motor’s performance.

- Inspect the fan blades: Take a close look at the fan blades attached to the motor. Ensure that they are intact, free from damage, and securely fastened. Any loose or damaged fan blades can impact the motor’s efficiency and cause imbalance.

- Look for excessive dirt or debris: Dust, debris, and dirt can accumulate on the motor over time and affect its performance. Inspect the motor’s surface and clean it if necessary. Be careful not to disturb any components or wiring while cleaning.

- Check for signs of overheating: Look for discoloration or burn marks on the motor or its surroundings, as these can indicate overheating. If you notice any signs of overheating, it may be a sign of a deeper problem that needs further attention.

- Inspect the wiring: Carefully examine the wiring connected to the motor. Check for any loose or frayed wires and ensure that all connections are secure. Loose connections can cause the motor to malfunction or not operate at all.

A visual inspection allows you to identify any obvious issues with the condenser fan motor. If you notice any significant damage or abnormalities during this inspection, it is recommended to contact a professional technician for further evaluation and repair.

If the motor appears to be in good condition, you can proceed with the next steps to perform additional tests and ensure its proper functioning.

Step 5: Check for any loose connections

Now that you have visually inspected the condenser fan motor, it’s time to check for any loose connections. Loose connections can lead to poor performance or even complete motor failure. Follow these steps to ensure that all connections are secure:

- Turn off the power supply: Before working on any electrical components, make sure to turn off the power supply to the condenser unit. This will prevent any risk of electrical shock.

- Inspect the wiring: Take a close look at the wiring connected to the condenser fan motor. Locate the terminals where the wires are connected and ensure they are tightly secured.

- Tighten any loose connections: If you find any loose connections, use a screwdriver or an appropriate tool to tighten them. Make sure to handle the connections with care, as excessive force or improper handling can cause damage.

- Check for frayed or damaged wires: While inspecting the connections, also look for any frayed or damaged wires. These can be a potential hazard and should be replaced immediately. If you notice any damaged wires, it is best to consult a professional technician to handle the rewiring.

- Secure the connections: After tightening any loose connections and replacing any damaged wires, ensure that all connections are secure. Double-check each terminal and make sure they are snugly attached.

By checking for any loose connections and ensuring a secure electrical connection for the condenser fan motor, you can help prevent issues such as motor malfunction or erratic performance. Loose connections can also cause overheating or electrical shorts, so it is crucial to address them promptly.

If you are unsure about the proper handling of electrical connections or if you notice any significant issues during the inspection, it is best to seek the assistance of a professional HVAC technician to avoid any further complications or potential hazards.

When testing a condenser fan motor, start by checking for power at the motor using a multimeter. If there is power, but the motor is not running, it may be faulty and in need of replacement.

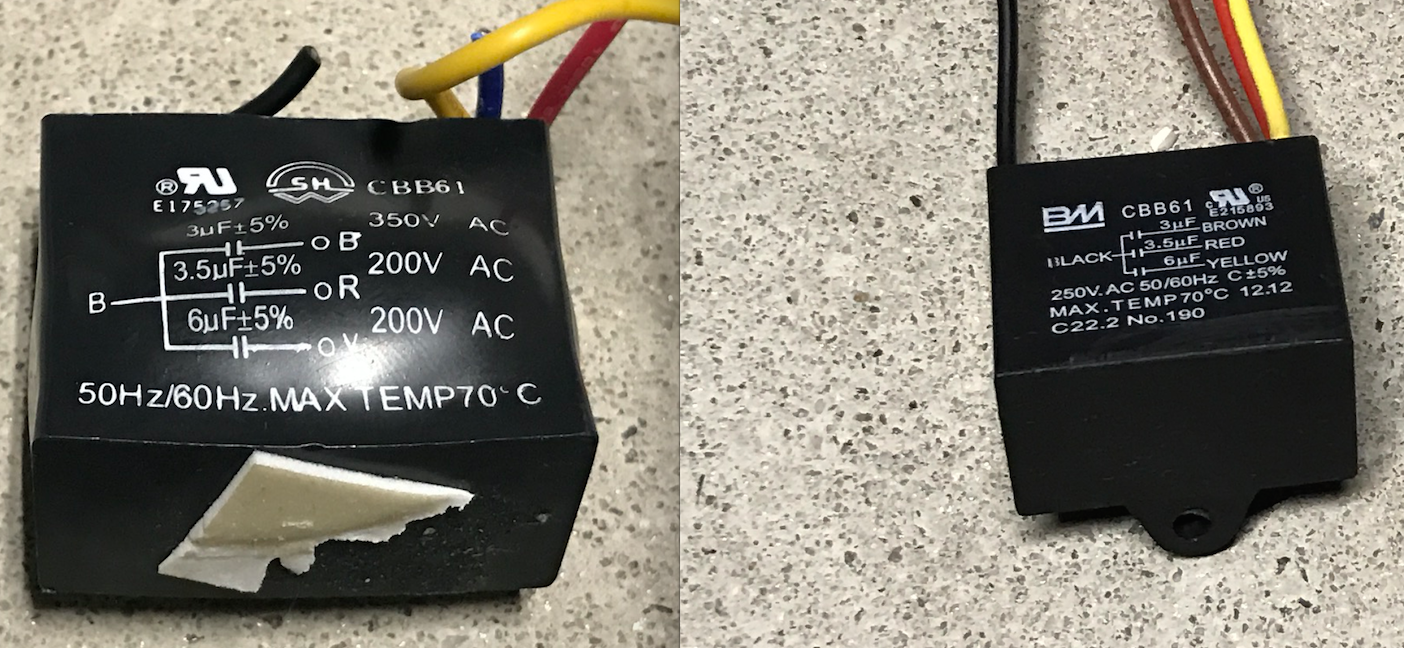

Step 6: Test the motor windings for continuity

Continuity testing is an important step in checking the health of the condenser fan motor’s windings. The windings are responsible for generating the electromagnetic field that powers the motor. Here’s how you can perform a continuity test:

- Ensure the power supply is turned off: Before conducting any tests, make sure that the power supply to the condenser unit is turned off to prevent any electrical accidents or damage.

- Locate the motor winding terminals: Identify the terminals where the motor windings are connected. The specific location can vary depending on the motor and manufacturer. Refer to the owner’s manual or consult a professional technician if you are uncertain.

- Set the multimeter: Set your multimeter to the continuity or resistance mode. This mode allows you to measure the flow of electrical current through the windings.

- Test between windings: Touch the multimeter probes to each set of motor winding terminals one at a time. If the multimeter displays a reading of close to zero or beeps, it indicates that there is continuity between the windings. This means the motor windings are in good condition.

- Test between each winding and motor casing: Next, touch one probe of the multimeter to each motor winding terminal and the other probe to the motor casing. If there is no continuity or the multimeter reads “infinite” resistance, it indicates that there is no electrical connection between the winding and the motor casing, which is the expected result.

By testing the motor windings for continuity, you can determine if there are any issues with the windings that may affect the motor’s efficiency or performance. If you find any significant deviations or problems during this test, it is recommended to consult a professional technician for further evaluation and repair.

Continuity testing helps to ensure that the motor windings are in good working condition and can help diagnose any potential underlying problems with the condenser fan motor.

Step 7: Check the motor for proper voltage

Checking the motor for proper voltage is an important step in the testing process to ensure that it is receiving the correct amount of power. Here’s how to check the motor for proper voltage:

- Turn off the power supply: Before conducting any tests, make sure the power supply to the condenser unit is turned off to avoid any electrical accidents or damage.

- Locate the motor power supply wires: Identify the wires connected to the motor for power supply. These wires are usually marked as “L1” and “L2” or may be color-coded.

- Set the multimeter: Set the multimeter to the AC voltage mode, selecting the appropriate voltage range for your electrical system.

- Test the power supply: Touch one probe of the multimeter to one power supply wire and the other probe to the other wire. Ensure that the probes make good contact with the wires. Turn on the power supply to the condenser unit.

- Read the multimeter: The multimeter should display a reading close to the rated voltage of your electrical system. Common voltages for residential systems include 120V or 240V.

If the multimeter reading does not match the expected voltage, it may indicate a problem with the power supply or electrical connections. In such cases, it is recommended to consult a professional technician to diagnose and address the issue.

Checking the motor for proper voltage ensures that it is receiving the correct electrical supply, which is essential for its optimal performance. If the motor is not receiving the adequate voltage, it may not function properly or may experience performance issues.

Remember to exercise caution and follow safety procedures while testing electrical components. If you are uncertain about the process or encounter any difficulties, it’s best to seek the assistance of a qualified HVAC technician.

Read also: 10 Amazing AC Condenser Fan Motor for 2024

Step 8: Inspect the motor fan blades

Inspecting the motor fan blades is an important step in testing the condenser fan motor. The fan blades play a crucial role in drawing air through the condenser coil to dissipate heat effectively. Here’s how you can inspect the motor fan blades:

- Ensure the power supply is turned off: Before conducting any inspections, make sure to turn off the power supply to the condenser unit to prevent any accidents or injuries.

- Visually inspect the fan blades: Take a close look at the fan blades for any visible damage or wear. Look for signs of bending, cracks, chips, or excessive dirt buildup.

- Check for balance: Spin the fan blades gently and observe if they rotate smoothly without any wobbling or imbalance. Imbalanced blades can cause excessive vibration and strain on the motor, leading to performance issues or premature wear.

- Clean the fan blades: If you notice any dirt or debris on the fan blades, clean them gently using a soft brush or cloth. Accumulated debris can obstruct airflow and decrease the fan’s effectiveness.

During the inspection, if you notice significant damage to the fan blades or any other issues, it is advised to consult a professional technician for further evaluation and possible replacement.

Properly functioning and well-maintained fan blades are vital for the efficient performance of the condenser fan motor. By inspecting and cleaning the fan blades, you can help maintain optimal airflow and prevent potential problems.

Remember to exercise caution during the inspection process and avoid touching the fan blades while they are in motion or right after turning off the power supply. Safety should always be a top priority when working with any mechanical components.

Step 9: Lubricate the motor if necessary

Lubricating the condenser fan motor is an important maintenance task that can help ensure smooth operation and extend the motor’s lifespan. Here’s how to lubricate the motor if necessary:

- Check manufacturer’s guidelines: Refer to the manufacturer’s guidelines or the owner’s manual for specific instructions on lubrication. Different motors may have different lubrication requirements, so it’s important to follow the recommended guidelines.

- Identify lubrication points: Locate the lubrication points on the motor. These points are often marked with small caps or oiling ports. They are usually found near the motor shaft or bearings.

- Choose the right lubricant: Select the appropriate lubricant recommended by the manufacturer. Use a high-quality lubricating oil or grease that is specifically designed for HVAC motors. Avoid using WD-40 or other general-purpose lubricants as they may not be suitable for this application.

- Apply the lubricant: Carefully apply a small amount of lubricant to each lubrication point. Use a syringe or a small oil can with a needle applicator for precise application. Ensure that you don’t over-lubricate, as excess lubricant can attract dust and debris, leading to motor inefficiency.

- Rotate the motor shaft: After applying the lubricant, manually rotate the motor shaft a few times to help distribute the lubricant evenly. This ensures that the lubricant reaches all the necessary areas, providing effective lubrication.

It’s important to note that not all condenser fan motors require lubrication. Some newer models have permanently sealed bearings that do not need lubrication. Therefore, it’s crucial to check the manufacturer’s guidelines to determine if lubrication is necessary and the recommended lubrication frequency.

Regular lubrication helps reduce friction, prevent premature wear, and maintain the motor’s efficiency. It is a maintenance task that should be performed periodically as part of your HVAC system care routine.

If you are unsure about how to lubricate the motor or if you notice any issues during the process, it’s best to consult a professional HVAC technician for guidance and assistance.

Step 10: Reconnect the power supply

After completing the necessary tests and maintenance, it’s time to reconnect the power supply to the condenser fan motor. Follow these steps to ensure a safe and successful reconnection:

- Ensure all components are in place: Before connecting the power supply, make sure that all components, including the motor, fan blades, and wiring, are properly aligned and secured.

- Double-check your work: Take a moment to review the steps you have performed during the testing and maintenance process. Make sure that all connections are secure, the motor is in good condition, and any lubrication or cleaning tasks have been completed.

- Turn off the power supply: If you had temporarily turned off the power supply during the testing process, now is the time to turn it back on.

- Restore power to the condenser unit: Locate the circuit breaker panel and switch on the breaker that controls the power supply to the condenser unit. Alternatively, reconnect the unit to its power source if it was disconnected.

- Test the motor: Turn on your air conditioning system and monitor the operation of the condenser fan motor. Ensure that the motor starts up smoothly, the fan blades are rotating properly, and there are no unusual sounds or vibrations.

- Observe for optimal performance: Keep an eye on the performance of the condenser fan motor in the following hours and days. Check for any signs of abnormal operation such as overheating, excessive noise, or inadequate airflow. If you notice any issues, it may indicate the need for further inspection or professional assistance.

By reconnecting the power supply in a careful and systematic manner, you can ensure the safe and efficient operation of the condenser fan motor.

Remember to always prioritize safety and consult a professional technician if you are uncertain about any steps or encounter any difficulties during the reconnection process.

With the power supply reconnected, your condenser fan motor should be ready to operate effectively, providing cool air and maintaining the optimal performance of your air conditioning system.

Conclusion

Testing the condenser fan motor is an essential task to ensure the smooth and efficient operation of your air conditioning system. By following the step-by-step guide outlined in this article, you can identify any potential issues with the motor and take the necessary measures to rectify them.

Throughout the testing process, it is crucial to prioritize safety. Disconnecting the power supply and wearing appropriate personal protective equipment will help prevent accidents and injuries. If you are unsure about any step or encounter difficulties, it is best to seek the assistance of a professional HVAC technician.

Starting with gathering the necessary tools and equipment, you can proceed to inspect the motor visually for any visible damage or wear. Checking for loose connections and testing the motor windings for continuity provide insights into the motor’s electrical functioning. Verifying the motor’s voltage and inspecting the fan blades help ensure proper operation and airflow.

If necessary, lubricating the motor can contribute to its smooth functioning and longevity. Finally, reconnecting the power supply in a safe and careful manner completes the testing process.

Regular testing and maintenance of the condenser fan motor not only enhance the performance of your air conditioning system but also help prevent potential breakdowns and costly repairs.

Remember, if you are unsure about any aspect of testing the condenser fan motor, it is always wise to consult a professional HVAC technician. They have the expertise and knowledge to guide you through the process and address any issues that may arise.

By taking the time to test and maintain your condenser fan motor, you can enjoy reliable cooling and ensure the longevity of your air conditioning system for years to come.

Now that you're equipped with the skills to test a condenser fan motor, why stop there? If you've ever wondered about the location of the condenser fan in your refrigerator, our next article is perfect for you. Delve into understanding not just where but why the placement is crucial for your appliance's efficiency. Keeping cool and maintaining your fridge's performance has never been easier with our handy guides.

Frequently Asked Questions about How To Test Condenser Fan Motor

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Test Condenser Fan Motor”