Home>Articles>Why Are Time-Delay Fuses Or HVACR-Rated Circuit Breakers Used?

Articles

Why Are Time-Delay Fuses Or HVACR-Rated Circuit Breakers Used?

Modified: January 6, 2024

Discover why time-delay fuses and HVACR-rated circuit breakers are commonly used in articles. Gain insights into their importance and functionality.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

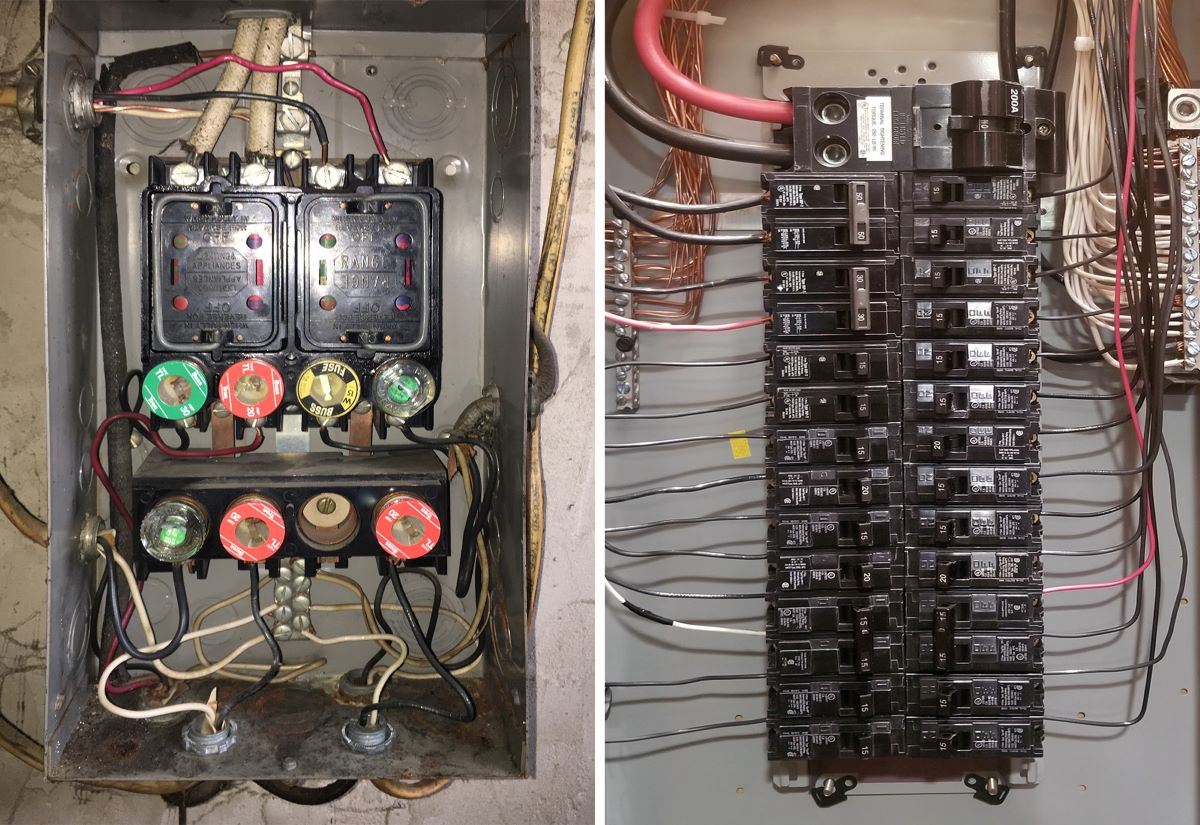

When it comes to the protection of electrical circuits in HVACR (Heating, Ventilation, Air Conditioning, and Refrigeration) systems, the use of time-delay fuses or HVACR-rated circuit breakers is common practice. These components play a crucial role in ensuring the safe and reliable operation of HVACR equipment by safeguarding against overcurrents and short circuits.

Time-delay fuses, also known as slow-blow or time-delayed-action fuses, are specifically designed to withstand temporary surges in current without immediately blowing. This allows for the normal starting currents of motors and compressors without causing an unnecessary interruption in power. On the other hand, HVACR-rated circuit breakers are built to handle the unique requirements and demands of HVACR equipment, providing a reliable and efficient means of circuit protection.

The purpose of this article is to explore why time-delay fuses and HVACR-rated circuit breakers are used in HVACR applications and discuss the benefits they offer. By understanding the importance of proper circuit protection in HVACR systems, we can ensure the longevity and optimal performance of these essential systems.

Throughout the article, we will delve into the functionality, advantages, and safety considerations associated with the use of time-delay fuses and HVACR-rated circuit breakers. So, let’s dive in and explore why these components are an integral part of HVACR systems.

Key Takeaways:

- Time-delay fuses and HVACR-rated circuit breakers protect HVACR systems from motor start-up currents and prevent nuisance tripping, ensuring smooth and uninterrupted operation while promoting equipment longevity and reliability.

- Proper circuit protection in HVACR applications is crucial for system safety and reliability. Time-delay fuses and HVACR-rated circuit breakers offer compatibility, durability, and safety features to ensure efficient and secure operation.

Purpose of Time-Delay Fuses in HVACR Applications

Time-delay fuses serve a critical purpose in HVACR applications by providing reliable electrical circuit protection. These fuses are specifically designed to handle the high starting currents and inrush currents commonly associated with HVACR equipment, such as motors and compressors.

One of the primary reasons for using time-delay fuses in HVACR applications is to protect against motor start-up currents. When a motor is initially switched on, it requires an increased amount of current to overcome the inertia and start rotating. This surge in current is known as the motor’s inrush current. If a standard fuse were used, it would likely blow due to the high inrush current, disrupting the operation of the motor.

However, time-delay fuses are engineered to withstand these temporary overcurrents without immediately blowing. They feature a heat-sensitive element that reacts more slowly to overcurrents, allowing the motor to start and reach its normal operating conditions. This delayed response ensures reliable and uninterrupted operation of the HVACR equipment while providing the necessary protection against sustained overcurrents that could lead to equipment damage or fire hazards.

Moreover, time-delay fuses help prevent nuisance tripping in HVACR systems. Nuisance tripping occurs when a protective device, such as a fuse or circuit breaker, unnecessarily interrupts the power supply due to transient or temporary overcurrents. In HVACR applications, there are instances where the starting current of a motor is higher than its normal running current or when the system experiences momentary electrical surges. A standard fuse may false trip or blow prematurely, disrupting the operation of the HVACR equipment.

Time-delay fuses, with their delayed response to overcurrents, help avoid nuisance tripping and ensure continuous operation of the HVACR system. They provide the necessary protection against sustained overcurrents while allowing for temporary current surges, ensuring stability and reliability in the operation of the equipment.

In summary, the purpose of using time-delay fuses in HVACR applications is to protect against motor start-up currents and prevent nuisance tripping. By allowing for temporary overcurrents and delayed responses, these fuses ensure the safe and optimal functioning of HVACR equipment. In the next section, we will explore the various benefits offered by time-delay fuses in HVACR systems.

Benefits of Using Time-Delay Fuses in HVACR Systems

The use of time-delay fuses in HVACR systems offers several notable benefits that contribute to the reliability, efficiency, and longevity of the equipment. Let’s explore some of these benefits:

1. Protection against Motor Damage: Time-delay fuses protect HVACR equipment motors from sustained overcurrents that could lead to motor damage. By allowing for temporary overcurrents during motor start-up, these fuses ensure smooth and uninterrupted operation without compromising the safety and integrity of the motor.

2. Enhanced Equipment Performance: Time-delay fuses prevent nuisance tripping, ensuring continuous and reliable operation of the HVACR system. This uninterrupted performance allows the equipment to function optimally, leading to improved energy efficiency and overall performance.

3. Reduced Downtime and Maintenance Costs: By avoiding unnecessary interruptions caused by nuisance tripping, time-delay fuses help reduce downtime and minimize maintenance costs. This benefit is particularly significant in critical HVACR applications where interruptions can result in costly repairs, equipment replacement, or a decline in productivity.

4. Longer Lifespan of Equipment: The ability of time-delay fuses to protect against sustained overcurrents contributes to the longevity of HVACR equipment. By preventing damage caused by excessive current flow, these fuses help extend the lifespan of motors, compressors, and other components, reducing the need for frequent replacements and repairs.

5. Compatibility with Motor Control Devices: Time-delay fuses are compatible with various motor control devices commonly used in HVACR systems. They integrate seamlessly with motor starters, contactors, and other control components, ensuring effective protection against overcurrents and promoting the smooth and safe operation of the equipment.

6. Improved Safety: Time-delay fuses provide an added layer of safety by preventing overcurrents that could potentially cause electrical fires or hazards. These fuses offer peace of mind, knowing that the equipment is protected and the risk of electrical accidents or damage is minimized.

Overall, the use of time-delay fuses in HVACR systems brings numerous benefits, including motor protection, enhanced equipment performance, reduced downtime and maintenance costs, extended equipment lifespan, compatibility with motor control devices, and improved safety. These advantages make time-delay fuses an essential component for ensuring the efficient and reliable operation of HVACR equipment.

Protection against Motor Start-Up Currents

One of the primary reasons for using time-delay fuses in HVACR systems is to provide protection against motor start-up currents. When an HVACR system’s motor is initially switched on, it requires a higher amount of current to overcome the inertia and start rotating. This surge in current is known as the motor’s inrush current.

If a standard fuse were used in this scenario, it would likely blow due to the high inrush current, disrupting the operation of the motor and potentially causing damage to the equipment. However, time-delay fuses are specifically designed to withstand these temporary overcurrents without immediately blowing.

Time-delay fuses feature a heat-sensitive element, often a resistor or a special alloy, that reacts more slowly to overcurrents compared to standard fuses. This delayed response allows the motor to start and reach its normal operating conditions without experiencing any unnecessary interruptions in power.

By allowing for temporary overcurrents during motor start-up, time-delay fuses ensure the safe and reliable operation of the HVACR system. They provide the necessary protection against sustained overcurrents that could lead to motor damage or even safety hazards.

Moreover, time-delay fuses not only protect the motor from damage, but they also safeguard other vital components in the system. For example, in HVACR applications that utilize motor starters or contactors, the time-delay fuse prevents excessive current flow that could potentially damage these control devices.

It is important to note that the delay time of these fuses is carefully calculated and selected to ensure optimal protection without compromising the efficiency and performance of the HVACR system. The delay allows for the necessary current surge during motor start-up but responds swiftly in case of sustained or excessive overcurrents beyond the motor’s normal operating conditions.

Overall, time-delay fuses are crucial in protecting HVACR system motors from the high inrush currents experienced during start-up. By allowing for temporary overcurrents and providing an appropriate response time, these fuses ensure the safe and uninterrupted operation of the motor, preventing damage to the equipment and promoting the longevity of the system.

Preventing Nuisance Tripping in HVACR Systems

Nuisance tripping is a common issue in HVACR systems, where the protective devices, such as fuses or circuit breakers, unnecessarily interrupt the power supply due to transient or temporary overcurrents. This can be disruptive to the operation of the system and may lead to unnecessary downtime and maintenance. Time-delay fuses play a crucial role in preventing nuisance tripping in HVACR systems.

One of the main causes of nuisance tripping in HVACR systems is the high starting current of motors and compressors. When these devices are initially switched on, they require a surge of current to overcome the inertia and start running. This inrush current can momentarily exceed the normal operating current and may trigger standard fuses or circuit breakers to trip.

However, time-delay fuses are designed to tolerate these brief periods of overcurrent without immediately blowing. The delayed response of time-delay fuses allows for the temporary current surge during motor start-up, preventing unnecessary interruptions to the power supply.

This delayed response is achieved through the use of a heat-sensitive element within the time-delay fuse. This element reacts more slowly to overcurrents, providing a certain time window for the motor to start properly. During this delay, the fuse ensures that the excessive current is not mistaken for a sustained overcurrent, thus preventing nuisance tripping.

In addition to motor start-up currents, HVACR systems may also experience momentary electrical surges or transients due to factors such as lightning strikes or power fluctuations. Standard fuses or circuit breakers would respond to these temporary surges, causing unnecessary tripping and disruptions to the system.

Time-delay fuses are designed to be more tolerant of these momentary surges, ensuring that they do not mistakenly trip due to transient overcurrents. This ensures the continuous operation of the HVACR system, reducing downtime and preventing unnecessary maintenance calls.

Furthermore, time-delay fuses are especially useful in HVACR systems that have components with varying power requirements. For instance, in systems with multiple motors or compressors, each device may have different starting currents. Time-delay fuses allow for the individual starting characteristics of each component, reducing the chances of nuisance tripping.

In summary, the use of time-delay fuses in HVACR systems helps to prevent nuisance tripping caused by high starting currents, momentary electrical surges, and variations in power requirements. By allowing for temporary overcurrents and implementing a delayed response, these fuses ensure uninterrupted operation and reduce unnecessary downtime and maintenance expenses.

Importance of Proper Circuit Protection in HVACR Applications

Proper circuit protection is of utmost importance in HVACR (Heating, Ventilation, Air Conditioning, and Refrigeration) applications. These systems rely on electrical circuits to power motors, compressors, and other critical components. Without adequate circuit protection, HVACR systems are vulnerable to various risks that can damage the equipment, compromise safety, and lead to costly repairs or downtime.

One of the primary reasons for proper circuit protection in HVACR applications is to ensure the safety of the system and its operators. Electrical systems inherently carry risks, such as electrical shock, fires, and equipment damage. By implementing appropriate protective measures, such as time-delay fuses or HVACR-rated circuit breakers, the risk of electrical accidents and hazards is significantly reduced.

Proper circuit protection also safeguards the HVACR equipment from overcurrents and short circuits. Inadequate or incorrect protection can result in the premature failure of motors, compressors, and other sensitive components. Overcurrents, which occur when the current flow exceeds the designed capacity of the circuit, can cause overheating, insulation breakdown, and even fire hazards. Short circuits, on the other hand, occur when the current bypasses the intended path and takes an unintended path of lower resistance. Short circuits can lead to excessive current flow, circuit damage, and potential electrical fires.

Additionally, proper circuit protection plays a vital role in preventing damage to HVACR equipment due to voltage fluctuations or power surges. Voltage fluctuations, often caused by power grid irregularities or internal electrical disturbances, can lead to unstable operation, impaired performance, and premature aging of the equipment. Power surges, which can occur due to lightning strikes or electrical interferences, can cause catastrophic damage to sensitive electronic components if not adequately protected.

Furthermore, proper circuit protection contributes to the longevity and performance of the HVACR system by minimizing the risk of equipment failures and breakdowns. By ensuring that the electrical circuits are protected against overcurrents, short circuits, and voltage fluctuations, the system can operate reliably and efficiently. This reduces the frequency of costly repairs, extends the lifespan of the equipment, and enhances overall system performance.

Lastly, compliance with electrical codes and regulations is another significant reason for proper circuit protection in HVACR applications. Electrical codes, such as the National Electrical Code (NEC), provide guidelines and requirements for electrical system design, installation, and protection. Adhering to these codes ensures that the HVACR system meets safety standards, reduces legal liabilities, and ensures proper insurance coverage.

In summary, proper circuit protection is essential in HVACR applications to ensure the safety of the system, protect the equipment from overcurrents and short circuits, prevent damage from voltage fluctuations and power surges, prolong the lifespan of the equipment, enhance system performance, and comply with electrical codes. By implementing suitable protective measures, HVACR systems can operate reliably, safely, and efficiently, providing comfort and convenience while minimizing the risk of equipment damage or electrical accidents.

Time-delay fuses or HVACR-rated circuit breakers are used to protect HVAC systems from short-term power surges and overloads, which can occur during start-up or normal operation. This helps to prevent damage to the equipment and ensures reliable performance.

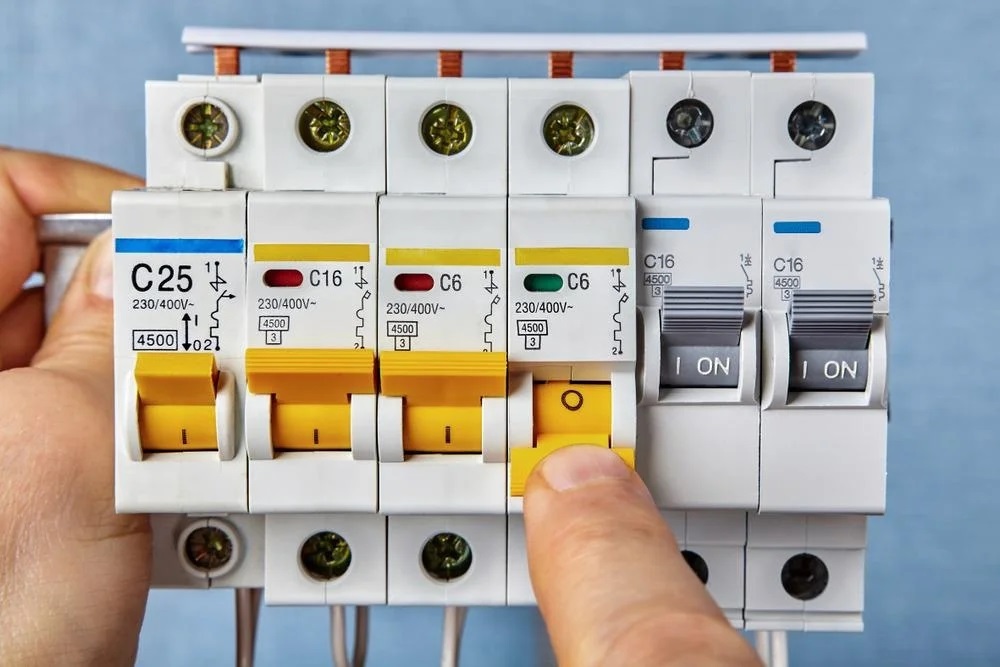

Understanding HVACR-Rated Circuit Breakers

HVACR (Heating, Ventilation, Air Conditioning, and Refrigeration)-rated circuit breakers are specifically designed and engineered to meet the unique requirements and demands of HVACR systems. These circuit breakers play a crucial role in providing reliable and effective circuit protection in HVACR applications.

Unlike general-purpose circuit breakers, which are designed for standard residential or commercial electrical systems, HVACR-rated circuit breakers are built to handle the specific characteristics and challenges of HVACR equipment. They are designed to protect against overcurrents, short circuits, and other electrical abnormalities commonly encountered in HVACR systems.

HVACR-rated circuit breakers come in various sizes and current ratings, ensuring compatibility with the specific power requirements of HVACR equipment. They are typically available in single-pole and double-pole configurations, suitable for protecting single-phase and three-phase HVACR systems.

One of the key features of HVACR-rated circuit breakers is their ability to handle high inrush currents. HVACR equipment, such as motors and compressors, often experience a surge in current when they start. These start-up currents, known as inrush currents, can be significantly higher than the normal operating currents. HVACR-rated circuit breakers are designed to withstand and safely interrupt these high inrush currents without tripping or interrupting the power supply unnecessarily. This capability ensures uninterrupted operation and prevents nuisance tripping in HVACR systems.

Another important feature of HVACR-rated circuit breakers is their sensitivity to low-level overcurrents. HVACR systems often have sensitive components that may be damaged by sustained overcurrents. HVACR-rated circuit breakers are designed to detect and interrupt these overcurrents quickly to prevent equipment damage and potential hazards. This sensitivity helps protect the motors, compressors, control circuits, and other components in the HVACR system, ensuring their longevity and reliability.

Furthermore, HVACR-rated circuit breakers may have additional features to enhance performance and safety. For example, some circuit breakers incorporate thermal-magnetic tripping mechanisms, which provide a combination of thermal protection against sustained overcurrents and magnetic protection against short circuits. This dual mechanism allows for effective and reliable circuit protection across a wide range of fault conditions.

When selecting an HVACR-rated circuit breaker, it is important to consider the specific requirements of the HVACR system, including the voltage, current rating, and fault current capacity. Choosing the right circuit breaker ensures optimal protection and compatibility with the HVACR equipment.

In summary, HVACR-rated circuit breakers are specially designed to provide effective circuit protection in HVACR systems. Their ability to handle high inrush currents, sensitivity to low-level overcurrents, and additional safety features make them crucial components in ensuring the reliable and safe operation of HVACR equipment. By selecting and installing the appropriate HVACR-rated circuit breakers, the system can be effectively protected against overcurrents, short circuits, and electrical abnormalities, minimizing equipment damage and promoting the longevity of the HVACR system.

Features and Advantages of HVACR-Rated Circuit Breakers

HVACR (Heating, Ventilation, Air Conditioning, and Refrigeration)-rated circuit breakers offer a range of features and advantages that make them essential components in HVACR systems. These circuit breakers are specifically designed to meet the unique requirements and challenges of HVACR applications, providing reliable and efficient circuit protection. Let’s explore some of their notable features and advantages:

1. High Inrush Current Tolerance: One of the key features of HVACR-rated circuit breakers is their ability to handle high inrush currents without unnecessary tripping. HVACR equipment, such as motors and compressors, often experience temporary surges in current during start-up. HVACR-rated circuit breakers are designed to tolerate these high inrush currents, ensuring uninterrupted operation and preventing nuisance tripping.

2. Fast Response Time: HVACR-rated circuit breakers have a fast response time, allowing them to quickly detect and interrupt overcurrents. This swift response ensures timely protection of the system and its components, minimizing the risk of equipment damage or hazards.

3. Low-Level Overcurrent Sensitivity: HVACR systems can be sensitive to low-level overcurrents that may damage the equipment or compromise performance. HVACR-rated circuit breakers are designed to detect and interrupt these low-level overcurrents promptly, protecting the motors, compressors, control circuits, and other components from sustained overcurrents.

4. Thermal-Magnetic Tripping Mechanism: Many HVACR-rated circuit breakers incorporate a thermal-magnetic tripping mechanism. This mechanism combines thermal protection against sustained overcurrents and magnetic protection against short circuits. The thermal element provides protection based on the temperature rise caused by current flow, while the magnetic element responds to sudden high current caused by short circuits. This dual mechanism ensures comprehensive and reliable circuit protection.

5. Compatibility with HVACR Equipment: HVACR-rated circuit breakers are specifically designed to be compatible with the power requirements of HVACR equipment. They come in various sizes and current ratings to accommodate different system configurations, ensuring optimal protection and performance.

6. Durable Construction: HVACR-rated circuit breakers are built with robust and durable materials to withstand the demanding conditions often encountered in HVACR applications. They are designed to operate reliably under high temperatures, humidity, and other environmental factors, making them suitable for use in HVACR systems.

7. Multiple Pole Configurations: HVACR-rated circuit breakers are available in both single-pole and double-pole configurations. Single-pole circuit breakers are typically used in single-phase HVACR systems, while double-pole circuit breakers are used in three-phase systems. This flexibility allows for proper protection and compatibility with different HVACR system configurations.

8. Compliance with Standards: HVACR-rated circuit breakers are designed and manufactured according to established electrical standards and regulations. They meet the safety and performance requirements set by organizations such as Underwriters Laboratories (UL) and IEC, ensuring that they are reliable and safe for use in HVACR applications.

Overall, HVACR-rated circuit breakers offer features and advantages that are tailored to the specific needs of HVACR systems. Their ability to handle high inrush currents, sensitivity to low-level overcurrents, thermal-magnetic tripping mechanism, compatibility with HVACR equipment, durable construction, and compliance with standards make them essential components for reliable and effective circuit protection in HVACR applications.

Compatibility with HVACR Equipment

One of the key advantages of HVACR (Heating, Ventilation, Air Conditioning, and Refrigeration)-rated circuit breakers is their compatibility with various types of HVACR equipment. These circuit breakers are specifically designed to meet the unique power requirements and electrical characteristics of HVACR systems, ensuring optimal performance and reliable circuit protection. Let’s explore the compatibility of HVACR-rated circuit breakers with different types of HVACR equipment:

1. Motors: HVACR systems rely on motors for various applications, such as driving fans, compressors, and pumps. HVACR-rated circuit breakers are designed to handle the high starting currents and inrush currents associated with motor-driven equipment. They provide the necessary protection against overcurrents, preventing damage to the motors and ensuring their safe and reliable operation.

2. Compressors: Compressors play a crucial role in HVACR systems, responsible for compressing refrigerant gases in A/C and refrigeration applications. HVACR-rated circuit breakers are compatible with the power requirements of compressors, ensuring effective protection against overcurrents and electrical abnormalities. This compatibility ensures smooth and safe operation, minimizing the risk of equipment failure or downtime.

3. Fans and Blowers: HVACR systems utilize fans and blowers to facilitate airflow, ventilation, and heat dissipation. The motors driving these fans often require high starting currents. HVACR-rated circuit breakers are designed to handle these starting currents without unnecessarily tripping. This compatibility ensures uninterrupted airflow and ventilation, promoting efficient performance and comfort.

4. Pumps: In HVACR systems that incorporate pumps for water circulation or coolant circulation, the motors driving these pumps may require substantial starting currents. HVACR-rated circuit breakers are built to handle these high inrush currents, ensuring reliable operation and preventing nuisance tripping. This compatibility allows for proper protection of the pump motors, extending their lifespan and minimizing the risk of pump failure.

5. Control Devices: HVACR-rated circuit breakers are compatible with various control devices commonly used in HVACR systems, such as motor starters, contactors, and relays. These circuit breakers can integrate seamlessly with these control devices, providing effective circuit protection and ensuring the safe and efficient operation of the HVACR system.

6. Refrigeration Equipment: Refrigeration systems, such as walk-in coolers, freezers, and refrigerated display cases, require reliable circuit protection to ensure the integrity and safety of the refrigeration equipment. HVACR-rated circuit breakers are designed to handle the specific power demands and starting currents associated with refrigeration equipment, providing the necessary protection against overcurrents and electrical faults.

7. Air Conditioning Systems: HVACR-rated circuit breakers are compatible with a wide range of air conditioning systems, including both residential and commercial units. They can handle the power requirements of air conditioning compressors, fans, and control devices, ensuring reliable and safe operation. This compatibility allows for effective circuit protection, promoting energy-efficient cooling and optimal comfort.

8. Heat Pumps: Heat pump systems rely on both heating and cooling functions to provide year-round climate control. HVACR-rated circuit breakers are compatible with heat pumps, offering the necessary protection for the motors and compressors used in these systems. This compatibility ensures efficient operation and reliable heat transfer, both in heating and cooling modes.

In summary, HVACR-rated circuit breakers are designed to be compatible with a wide range of HVACR equipment. Their compatibility with motors, compressors, fans, blowers, pumps, control devices, refrigeration equipment, air conditioning systems, and heat pumps ensures reliable and effective circuit protection. By selecting the appropriate HVACR-rated circuit breakers for specific equipment, HVACR systems can operate safely, efficiently, and with enhanced longevity.

Read more: Why Breakers Trip

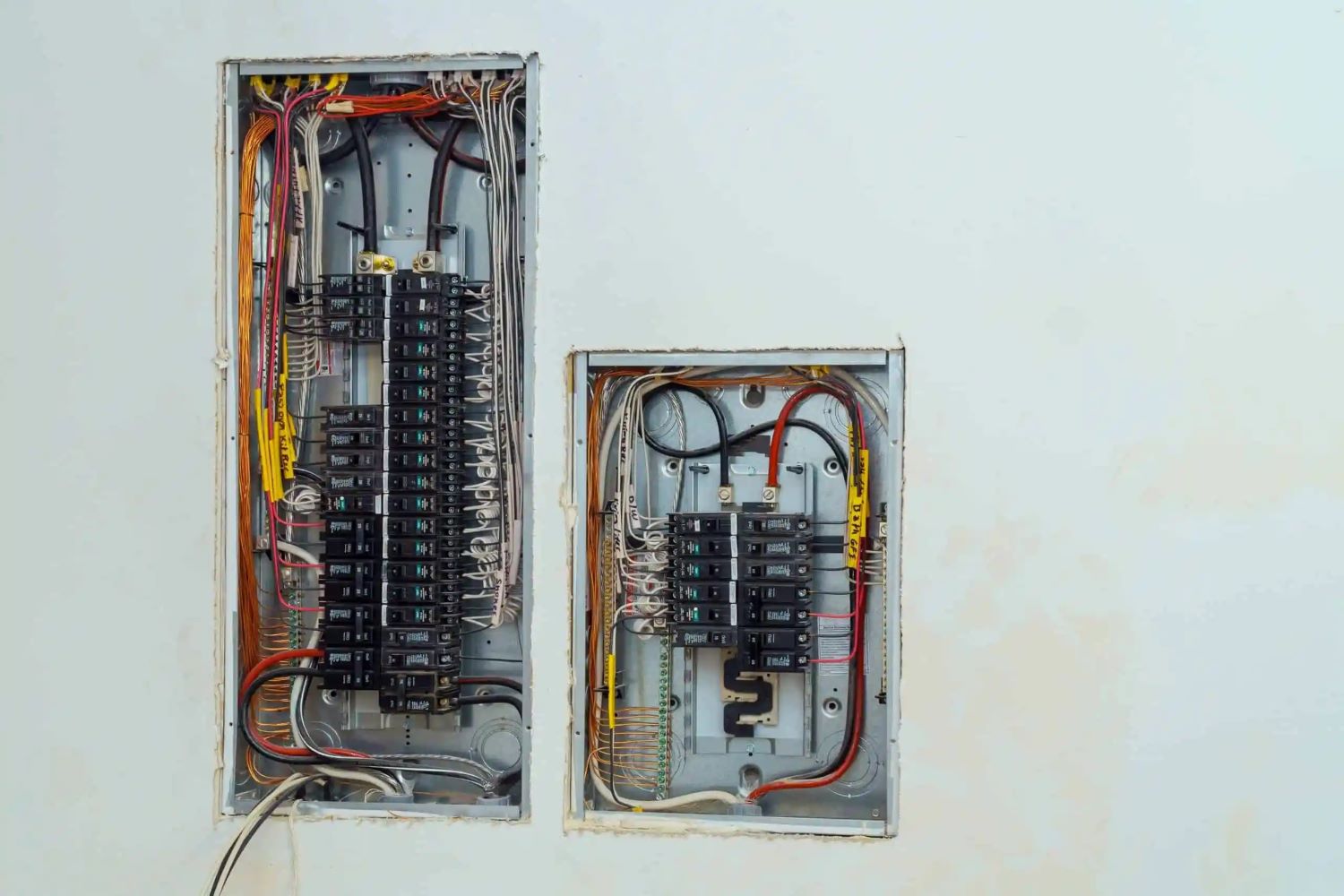

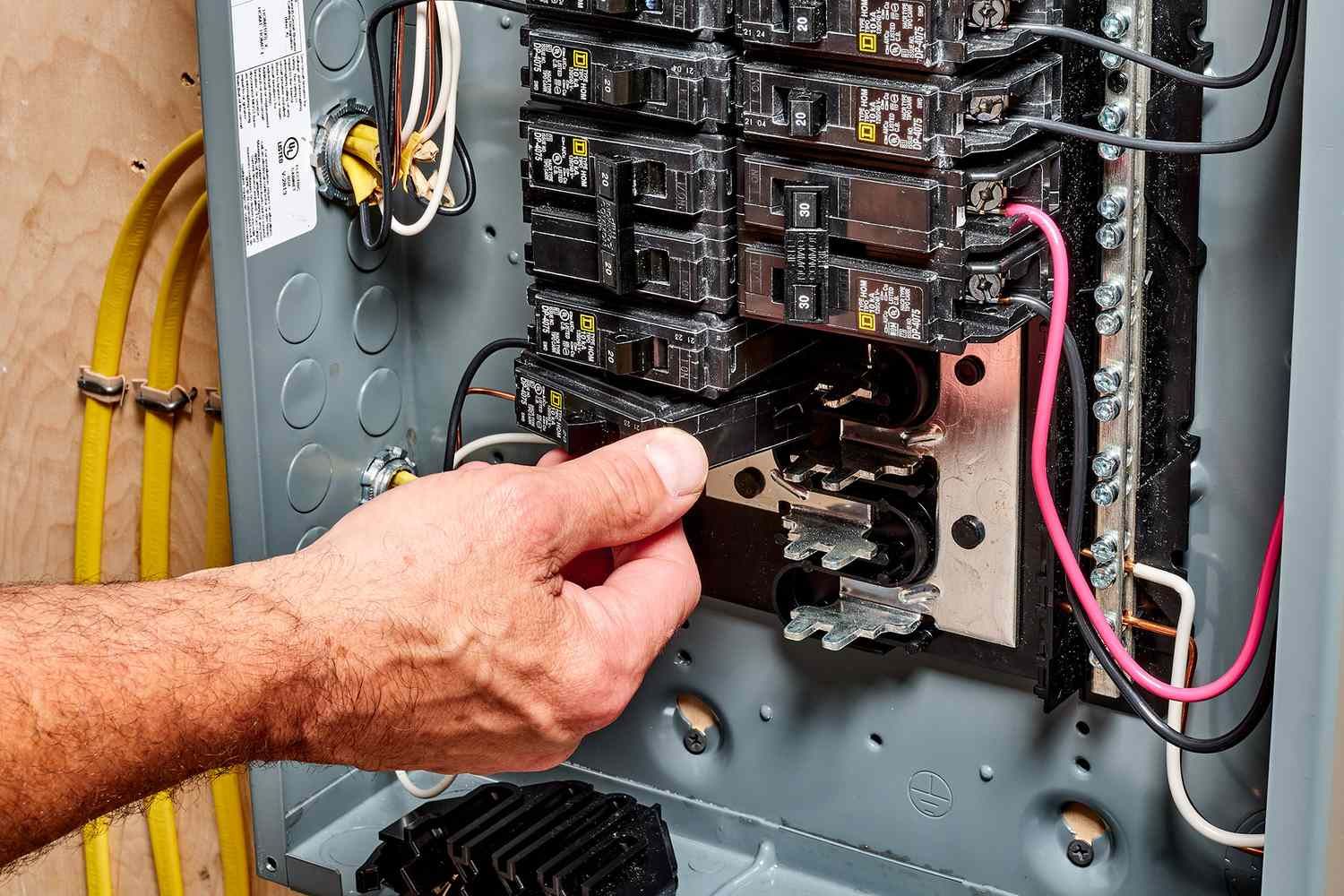

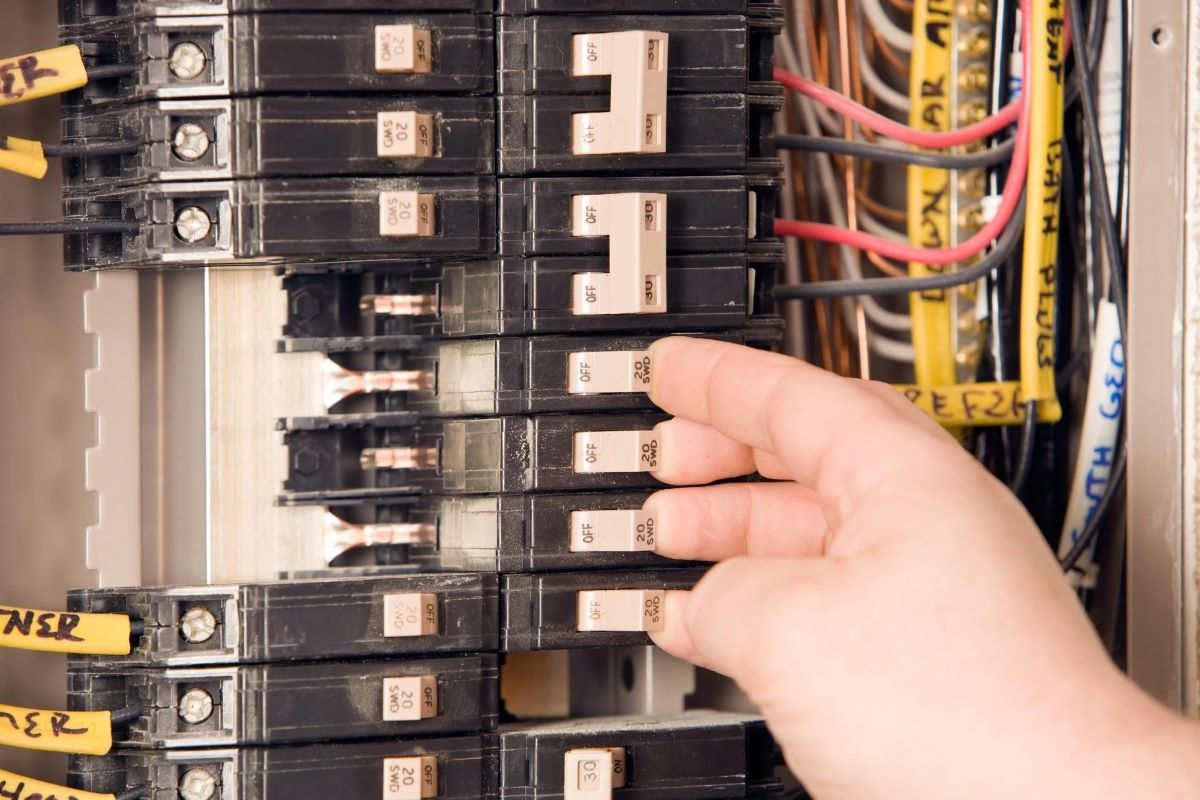

Safety Considerations When Using Time-Delay Fuses or HVACR-Rated Circuit Breakers

While time-delay fuses and HVACR-rated circuit breakers provide reliable circuit protection in HVACR (Heating, Ventilation, Air Conditioning, and Refrigeration) systems, it is essential to consider certain safety aspects when working with these components. Implementing proper safety measures helps ensure the safe installation, operation, and maintenance of the electrical system. Let’s explore some key safety considerations when using time-delay fuses or HVACR-rated circuit breakers:

1. Proper Selection: Selecting the correct rating and size of time-delay fuses or HVACR-rated circuit breakers is crucial for safe operation. Consult the equipment specifications, electrical codes, and manufacturer guidelines to ensure compatibility and compliance. Incorrectly sized protection devices may lead to inadequate protection or potential damage to the equipment.

2. Understanding Overcurrent Conditions: It is essential to understand the potential overcurrent conditions that the HVACR system may experience. This includes considering the starting currents and inrush currents of motors and compressors. Adequate protection must be chosen based on these anticipated overcurrents to prevent equipment damage or safety hazards.

3. Proper Installation: Installation should be performed by a qualified professional following the manufacturer’s instructions and electrical codes. Improper installation may result in loose connections, poor grounding, or other electrical hazards. Ensure that all electrical connections are secure, and wiring is correctly routed to avoid potential short circuits or accidental contact with other components.

4. Regular Inspections and Maintenance: Routine inspections and maintenance of the electrical system are crucial for identifying any signs of wear, damage, or deterioration. Periodically check the condition of time-delay fuses or HVACR-rated circuit breakers, including the condition of their contacts, insulation, and housing. Replace any components that show signs of damage or degradation promptly. It is also important to follow the recommended maintenance schedule provided by the manufacturer.

5. Labeling and Identification: Proper labeling and identification of time-delay fuses or HVACR-rated circuit breakers ensure clear and accurate identification in case of maintenance or troubleshooting. Clearly label each device to indicate its purpose, location, and the corresponding HVACR equipment it protects. This helps in quickly identifying the correct circuit breaker or fuse during inspections or emergency situations.

6. Awareness of Surrounding Environment: Consider the environment in which the HVACR system operates. Ensure that the area around the circuit breakers or fuses is clear of any flammable materials, moisture, or excessive dust. Adequate ventilation should be provided to prevent overheating. Additionally, consider the location of the electrical panel to allow for safe and easy access for maintenance and troubleshooting.

7. Lockout/Tagout: Proper lockout/tagout procedures should be followed when working on the electrical system. This involves de-energizing and securing the electrical supply to prevent accidental re-energization during maintenance. Clearly label and lockout/tagout the circuit breakers or fuses to indicate that work is being performed on the system.

8. Fire Safety Measures: Time-delay fuses or HVACR-rated circuit breakers are crucial components in preventing electrical fires. However, in the event of a fire, it is essential to have appropriate fire safety measures in place, such as fire extinguishers and smoke detectors. Regularly check the functionality of these safety devices to ensure their effectiveness.

Remember that all safety considerations should be in compliance with local electrical codes and regulations. It is always recommended to consult with a qualified electrician or electrical engineer for guidance and assistance in ensuring the safe operation of the electrical system.

In summary, ensuring safety when using time-delay fuses or HVACR-rated circuit breakers involves proper selection, installation, inspection, maintenance, labeling, awareness of the environment, lockout/tagout procedures, and adherence to fire safety measures. By following these safety considerations, HVACR systems can operate safely, preventing equipment damage, electrical hazards, and ensuring the well-being of those working with or around the system.

Conclusion

In conclusion, time-delay fuses and HVACR-rated circuit breakers play a crucial role in providing reliable circuit protection in HVACR (Heating, Ventilation, Air Conditioning, and Refrigeration) systems. These components are specifically designed to meet the unique requirements and challenges of HVACR equipment, ensuring safe and efficient operation.

Time-delay fuses protect against motor start-up currents and prevent nuisance tripping in HVACR systems. By allowing for temporary overcurrents during motor start-up, time-delay fuses ensure the smooth and uninterrupted operation of motors and prevent unnecessary interruptions in power supply. Additionally, they prevent nuisance tripping caused by transient overcurrents, enhancing the reliability and efficiency of the HVACR system.

HVACR-rated circuit breakers offer a range of features and advantages that make them essential components in HVACR systems. These circuit breakers are designed to tolerate high inrush currents, providing effective protection against motor starting currents. They have fast response times and sensitivity to low-level overcurrents, ensuring quick and precise circuit interruption to safeguard HVACR equipment. Moreover, their compatibility with various HVACR equipment, durable construction, and compliance with safety standards contribute to their reliable performance and longevity.

Proper circuit protection in HVACR applications is of utmost importance for the safety and reliability of the system. It protects against overcurrents, short circuits, voltage fluctuations, and power surges that could lead to equipment damage or safety hazards. By selecting the appropriate time-delay fuses or HVACR-rated circuit breakers, the system can operate safely, efficiently, and with enhanced longevity.

When using time-delay fuses or HVACR-rated circuit breakers, it is essential to consider safety considerations such as proper selection, installation, regular inspections and maintenance, labeling, awareness of the surrounding environment, lockout/tagout procedures, and adherence to fire safety measures. Implementing these safety measures ensures the safe installation, operation, and maintenance of the electrical system, minimizing the risk of equipment damage, electrical accidents, and hazards.

In conclusion, incorporating time-delay fuses and HVACR-rated circuit breakers in HVACR systems provides reliable circuit protection, enhances performance, and ensures the safety of both the system and its operators. By understanding their functionality, benefits, and safety considerations, HVACR professionals can effectively utilize these components to maximize the longevity and efficiency of HVACR systems while maintaining a safe operating environment.

Frequently Asked Questions about Why Are Time-Delay Fuses Or HVACR-Rated Circuit Breakers Used?

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “Why Are Time-Delay Fuses Or HVACR-Rated Circuit Breakers Used?”