Articles

Why Is Electrical Conduit So Expensive

Modified: October 20, 2024

Discover why electrical conduit is often considered expensive and learn about the factors that contribute to its higher cost. Explore articles that provide insights into the pricing and potential alternatives.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

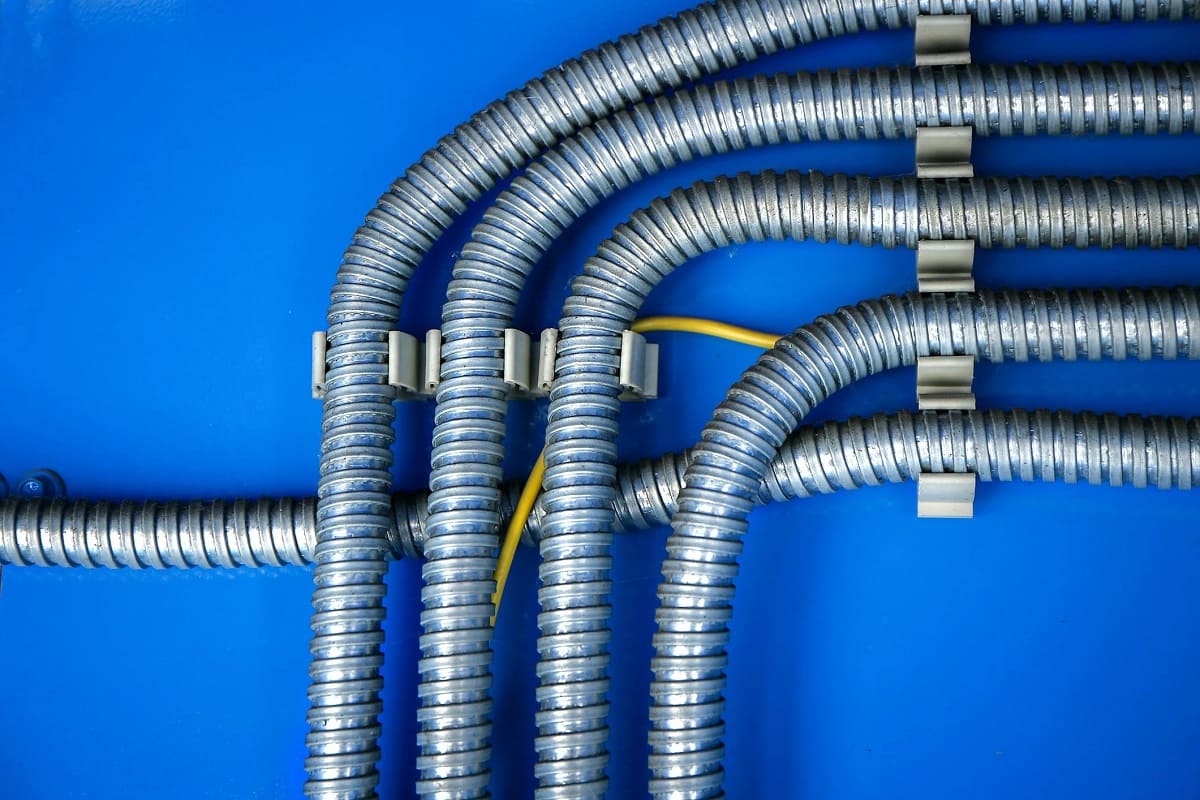

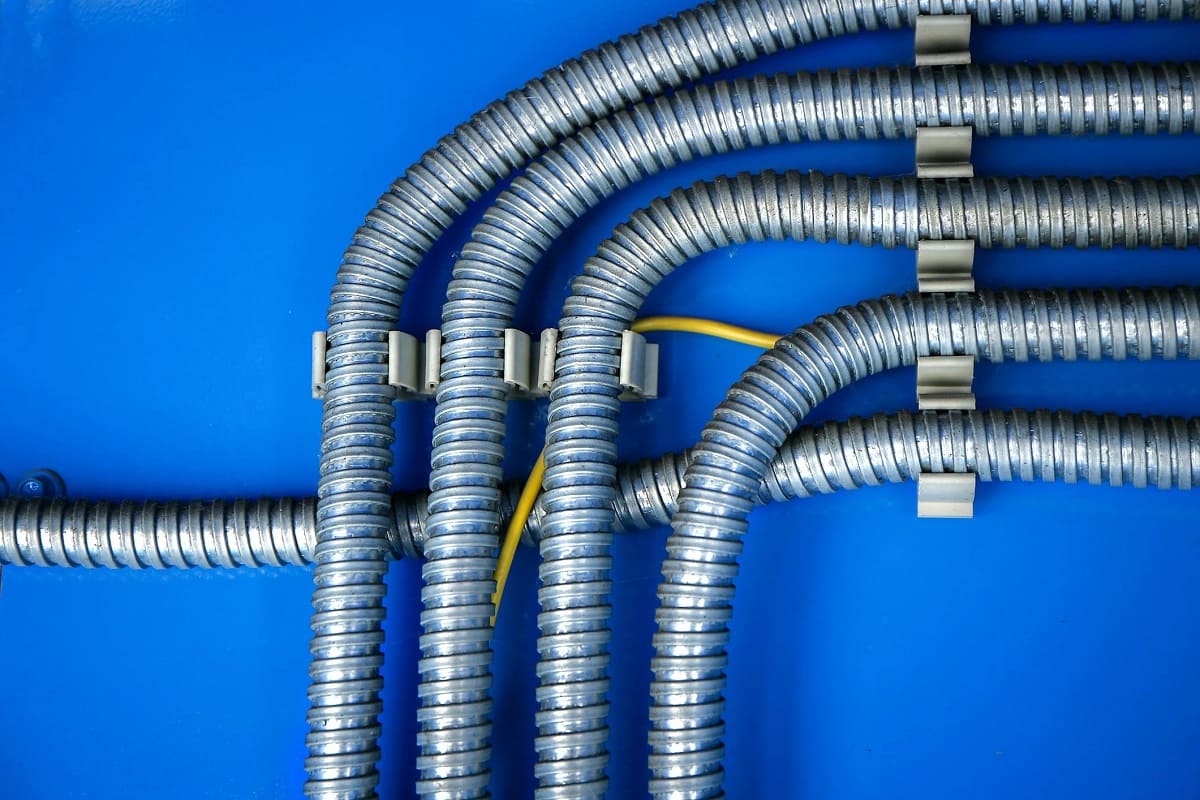

Electrical conduit is an essential component of any electrical system, serving as a protective enclosure for electrical wiring. It plays a crucial role in ensuring the safe and efficient distribution of electricity in residential, commercial, and industrial buildings. However, one common question that arises is why electrical conduit can be so expensive. In this article, we will explore the factors that contribute to the high cost of electrical conduit and provide insights into the various aspects that impact its pricing.

Before delving into the reasons for the expense of electrical conduit, it is important to understand what electrical conduit actually is. Electrical conduit is a conduit system consisting of pipes or tubes made of metal or plastic that are used to protect and route electrical wiring. These conduits provide a secure pathway for electrical wires, shielding them from damage caused by moisture, heat, or physical impact. They also help in organizing and managing the electrical wiring, making it easier to troubleshoot and perform maintenance tasks.

Key Takeaways:

- Electrical conduit’s cost is influenced by material, manufacturing, installation, regulations, and market dynamics. Understanding these factors helps make informed decisions when selecting and purchasing conduit for electrical projects.

- Alternative options to traditional electrical conduit, such as cable trays, raceway systems, wire ducts, flexible conduit, and wireless solutions, offer different benefits and cost-effective solutions for specific applications. It’s essential to evaluate their suitability for specific electrical requirements and compliance with local regulations.

Read more: Why Is HVAC So Expensive

What is electrical conduit?

Electrical conduit comes in various types, including rigid metal conduit (RMC), intermediate metal conduit (IMC), electrical metallic tubing (EMT), and PVC conduit. RMC is made of steel and provides the highest level of protection, while IMC is a lighter-weight steel conduit. EMT is a thin-walled metal tubing that is more flexible and easier to handle compared to RMC and IMC. PVC conduit, on the other hand, is made of plastic and is a more affordable and versatile option.

Now that we have a basic understanding of electrical conduit, let’s explore the factors that contribute to its expense.

Key Takeaways:

- Electrical conduit’s cost is influenced by material, manufacturing, installation, regulations, and market dynamics. Understanding these factors helps make informed decisions when selecting and purchasing conduit for electrical projects.

- Alternative options to traditional electrical conduit, such as cable trays, raceway systems, wire ducts, flexible conduit, and wireless solutions, offer different benefits and cost-effective solutions for specific applications. It’s essential to evaluate their suitability for specific electrical requirements and compliance with local regulations.

Read more: Why Is HVAC So Expensive

What is electrical conduit?

Electrical conduit is a system of pipes or tubes that is used to protect and route electrical wiring. It provides a secure pathway for electrical wires, shielding them from damage caused by moisture, heat, or physical impact. By enclosing the electrical wiring, conduit ensures the safety and proper functioning of the electrical system.

There are several types of electrical conduit available, each with its own unique characteristics and applications:

- Rigid Metal Conduit (RMC): RMC is made of steel and is the most durable and protective type of electrical conduit. It is often used in industrial and commercial installations where the wiring needs maximum protection.

- Intermediate Metal Conduit (IMC): IMC is a lighter-weight steel conduit that offers a similar level of protection as RMC. It is commonly used in areas where the wiring needs moderate protection.

- Electrical Metallic Tubing (EMT): EMT is a thin-walled metal tubing that is more flexible and easier to handle compared to RMC and IMC. It is often used in residential and commercial applications where moderate protection is sufficient.

- PVC Conduit: PVC conduit is made of plastic and is a more affordable and versatile option. It is lightweight, corrosion-resistant, and easy to install, making it an ideal choice for various electrical applications.

Electrical conduit is available in various sizes, ranging from small diameters for residential applications to large diameters for industrial and commercial installations. It is typically sold in lengths and can be easily cut and joined using connectors or couplings.

The main purpose of electrical conduit is to protect the electrical wiring from physical damage and environmental factors. It also helps in organizing and managing the wiring, making it easier to troubleshoot and perform maintenance tasks. Additionally, conduit ensures compliance with electrical codes and regulations established by governmental and safety organizations.

Overall, electrical conduit serves as a critical component in electrical systems, providing a safe and reliable means of routing and protecting electrical wiring. It offers flexibility, durability, and protection, making it an essential element in residential, commercial, and industrial buildings.

Factors that contribute to the expense of electrical conduit

Electrical conduit can be relatively expensive, and there are several factors that contribute to its cost. Understanding these factors can help shed light on why electrical conduit is priced the way it is. Here are some key factors that contribute to the expense of electrical conduit:

- Material costs: The type of material used to manufacture the electrical conduit greatly affects its cost. Conduits made of high-quality metals, such as steel or aluminum, tend to be more expensive than those made of plastic, such as PVC. The cost of raw materials, as well as the production and processing costs, impact the overall price of the conduit.

- Manufacturing processes: The manufacturing processes involved in producing electrical conduit can be complex and require specialized equipment. The costs associated with the machinery, labor, and quality control measures all contribute to the final price of the conduit.

- Installation requirements: Installing electrical conduit requires skilled labor and expertise. The cost of installation includes factors such as labor charges, the complexity of the installation, and any additional materials needed, such as fittings and connectors. The time and effort required for proper installation contribute to the overall expense of electrical conduit.

- Government regulations and certifications: Electrical conduit must comply with strict safety regulations and industry standards. Meeting these requirements often involves additional testing, certifications, and quality control processes, which can increase the cost of the conduit.

- Market demand and supply: The principles of supply and demand play a significant role in pricing electrical conduit. Higher demand for conduit can lead to increased prices, especially during periods of high construction activity. Additionally, fluctuations in the availability and cost of raw materials can impact the price of electrical conduit.

- Specialized features and customization: Certain types of electrical conduit may offer specialized features or customization options. For example, conduit with enhanced fire resistance or corrosion resistance may be more expensive due to the additional materials and manufacturing processes involved.

- Brand reputation: The reputation and brand recognition of a conduit manufacturer can also influence the pricing. Well-established brands often command higher prices due to their perceived quality and reliability.

It is important to note that while electrical conduit may seem expensive, its cost is justified by the benefits it provides. The protective nature of conduit ensures the safety and longevity of electrical wiring, reducing the risk of electrical hazards and potential damage to the electrical system.

Understanding the factors that contribute to the expense of electrical conduit can help individuals and businesses make informed decisions when it comes to selecting the right conduit for their specific needs. It is essential to consider the quality, durability, and compliance with safety standards when evaluating the cost-effectiveness of electrical conduit.

The cost of materials used in electrical conduit

The cost of materials is one of the primary factors that contribute to the overall expense of electrical conduit. The type of material used in the construction of the conduit significantly affects its price. Here, we will explore the different materials commonly used in electrical conduit and understand how they contribute to the overall cost.

Metal Conduit: Metal conduit, such as rigid metal conduit (RMC) and intermediate metal conduit (IMC), is typically made of steel. Steel is a durable and sturdy material that provides excellent protection for electrical wiring. However, the cost of steel can vary depending on factors such as raw material prices, availability, and market demand. Steel conduit can be more expensive than other materials, but it offers superior strength and durability, making it suitable for applications that require maximum protection.

Electrical Metallic Tubing (EMT): EMT is a thin-walled metal tubing commonly used in residential and commercial applications. It is often made of galvanized steel or aluminum, which are less expensive than conventional steel. EMT is a cost-effective option that provides moderate protection for electrical wiring and is easier to handle and install compared to rigid metal conduit.

PVC Conduit: PVC conduit is made of a type of plastic called polyvinyl chloride. PVC is a lightweight, affordable, and versatile material that is widely used in electrical conduit applications. It is less expensive than metal conduit and provides good protection against moisture and corrosion. PVC conduit is easy to work with, making it a popular choice for both residential and commercial installations.

Other Materials: In addition to steel and PVC, there are other materials used in specialized electrical conduit. For example, aluminum conduit is lightweight and corrosion-resistant, making it suitable for outdoor applications. Fiberglass conduit offers excellent corrosion resistance and is an ideal choice for environments with high levels of moisture or chemical exposure. However, these specialized materials can be more expensive due to their unique properties and manufacturing processes.

The cost of materials used in electrical conduit is influenced by several factors, including raw material prices, availability, and manufacturing processes. Fluctuations in these factors can impact the overall price of conduit in the market. Additionally, the type and quality of the materials used can also affect the price. Higher-quality materials and specialized features, such as fire resistance or UV resistance, can increase the cost of the conduit.

It’s worth noting that the cost of materials is just one aspect of the overall cost of electrical conduit. Other factors, such as manufacturing processes, labor charges, and market demand, also contribute to the price. When selecting electrical conduit, it’s essential to consider the specific requirements of the installation while weighing the cost-effectiveness of different materials.

Read more: Why Are Rugs So Expensive

The cost of manufacturing electrical conduit

The cost of manufacturing electrical conduit is a significant factor that contributes to its overall expense. The manufacturing processes involved in producing conduit can be complex and require specialized equipment, skilled labor, and quality control measures. Here, we will explore the various aspects that impact the cost of manufacturing electrical conduit.

Raw materials: The cost of raw materials is an essential component of manufacturing electrical conduit. The type of material used, such as steel, aluminum, or plastic, directly affects the cost. The prices of these raw materials can fluctuate due to factors like demand, supply, and market conditions. Manufacturers need to consider the cost of procurement and storage of raw materials, which influences the overall manufacturing cost.

Manufacturing equipment: Specialized machinery and equipment are required to manufacture electrical conduit. The cost of acquiring, maintaining, and operating this equipment adds to the manufacturing expense. Additionally, technology advancements and automation in production processes can increase the initial investment but also lead to more efficient and cost-effective manufacturing in the long run.

Production processes: The manufacturing processes involved in producing electrical conduit can vary depending on the material and type of conduit being produced. Processes such as extrusion, bending, cutting, welding, coating, and packaging are carried out to shape and assemble the conduit. These processes require skilled labor and detailed quality control measures to ensure that the conduit meets the required standards and specifications. The complexity and time involved in these manufacturing processes contribute to the overall manufacturing cost.

Quality control measures: Electrical conduit must adhere to stringent quality control measures to ensure its durability, safety, and compliance with industry standards. Manufacturers implement quality control processes such as testing the raw materials, inspecting the manufacturing process, and conducting final inspections on finished products. These measures help identify any defects or deviations from the required specifications and ensure that only high-quality conduit reaches the market. The cost of quality control measures is accounted for in the manufacturing expenses.

Research and development: Manufacturers continually invest in research and development to improve the performance, efficiency, and safety of electrical conduit. Developing new materials, manufacturing techniques, and product designs require resources and funding. The cost of research and development activities is a part of the manufacturing cost and is reflected in the pricing of the conduit.

Economies of scale: The scale of production also impacts the manufacturing cost of electrical conduit. Large-scale manufacturers often benefit from economies of scale, allowing them to produce conduit at a lower cost per unit. Conversely, smaller manufacturers may have higher production costs due to the lack of scale. The cost-effectiveness of manufacturing electrical conduit can be influenced by the volume of production.

It is important to consider that manufacturing costs can vary among different types and brands of electrical conduit. Higher-quality materials, advanced manufacturing processes, and stricter quality control measures can increase the manufacturing expenses and consequently the price of the conduit in the market.

Understanding the cost of manufacturing electrical conduit provides insight into why it may be relatively expensive. Manufacturers need to recover their expenses, and the quality and reliability of the conduit justify its price. When evaluating the cost-effectiveness of conduit, it is crucial to consider factors such as material quality, manufacturing methods, and adherence to industry standards.

Consider using PVC conduit as an alternative to metal conduit, as it is generally more affordable while still providing adequate protection for electrical wiring. Additionally, shop around and compare prices from different suppliers to find the best deal.

The cost of installation and labor

The cost of installation and labor is an important aspect to consider when determining the overall expense of electrical conduit. Proper installation of conduit requires skilled labor and expertise. Here, we will explore the factors that contribute to the cost of installation and labor for electrical conduit.

Skilled labor: Installing electrical conduit requires technicians who are knowledgeable and experienced in electrical systems and conduit installation. These skilled workers must be trained to handle the various types of conduit and understand the specific requirements of different installations. The labor cost associated with skilled workers is a significant factor in determining the overall cost of conduit installation.

Complexity of the installation: The complexity of the electrical system and the installation process can greatly impact the labor cost. Installing conduit in a straightforward residential application may be relatively simple, whereas a large-scale commercial or industrial installation with multiple bends, junction boxes, and connections can require more time and effort. The more complex the installation, the higher the labor cost will be.

Additional materials and tools: Conduit installation often requires additional materials such as connectors, fittings, and fasteners. These materials are necessary to securely connect and fasten the conduit and electrical wires. The cost of these additional materials adds to the overall expense of the installation. Additionally, the tools required for conduit installation, such as conduit benders, cutters, and measuring instruments, need to be factored into the labor cost.

Time and effort: Installing conduit is a labor-intensive process that requires careful planning, measuring, cutting, and securing. The time and effort required for proper installation contribute to the labor cost. The complexity of the electrical system, the length and number of conduits, and any special configurations or requirements can extend the installation time and increase the labor cost.

Local labor rates: Labor rates can vary based on geographical location and local market conditions. Factors such as labor supply and demand, cost of living, and prevailing wage rates can influence the labor cost of conduit installation. Contractors and technicians must consider these factors when determining their rates, which ultimately impact the overall cost of installation.

Permits and inspections: Depending on local regulations, obtaining permits and undergoing inspections for conduit installation may be required. The cost of permits and any associated fees add to the overall cost of installation. Inspections ensure that the installation meets necessary safety codes and standards, further contributing to the labor cost.

It is essential to hire a qualified and licensed electrical contractor or technician for conduit installation to ensure a professional and compliant installation. When budgeting for electrical conduit, it is important to consider not only the cost of the conduit materials but also the labor cost associated with installation. Obtaining multiple quotes from reputable contractors and carefully considering the complexity of the installation can help in estimating the installation and labor cost accurately.

By understanding the factors involved in the cost of installation and labor for electrical conduit, individuals and businesses can make informed decisions and budget effectively for their electrical projects.

Government regulations and certifications

Government regulations and certifications play a crucial role in the cost of electrical conduit. Electrical conduit must comply with various safety standards and regulations established by governmental and safety organizations. These regulations aim to ensure the safety, quality, and reliability of electrical systems. Here, we will explore how government regulations and certifications impact the cost of electrical conduit.

Safety standards and codes: Electrical conduit must meet specific safety standards and codes to ensure the protection of electrical systems and individuals. These standards outline requirements for factors such as material composition, construction, installation methods, fire resistance, corrosive environments, and mechanical impact resistance. Adhering to these standards requires additional testing, compliance with specific specifications, and certifications, which can increase the manufacturing and testing costs of conduit.

Certification bodies: There are several certification bodies that assess and certify electrical conduit in accordance with safety standards and regulations. These organizations, such as Underwriters Laboratories (UL), Intertek Testing Services (ETL), and Canadian Standards Association (CSA), evaluate products for compliance with specific standards. Manufacturers must obtain certifications from these bodies, which involve rigorous testing and assessment processes. The cost of certification and maintaining compliance adds to the overall expense of producing electrical conduit.

Product labeling and marking: In order to demonstrate compliance with safety standards, electrical conduit often requires specific labeling and marking. This includes important information such as the manufacturer’s name, product specifications, applicable standards, and certification marks. The cost of labeling and marking equipment, materials, and processes is factored into the overall price of the conduit.

Third-party inspections: Government regulations may require third-party inspections to ensure that the electrical conduit meets the required safety standards. These inspections can involve on-site visits by accredited inspectors who assess the manufacturing processes, quality control measures, and compliance with applicable regulations. The cost of third-party inspections is typically borne by the manufacturer, enhancing the overall expenses associated with electrical conduit production.

Warranty and liability: Meeting government regulations and obtaining certifications give manufacturers confidence in the quality and safety of their electrical conduit. Manufacturers often provide warranties to their customers, ensuring that the product will perform as intended. These warranties and liabilities, which cover any defects or failures with the conduit, contribute to the overall cost of the product.

While compliance with government regulations and certifications adds to the expense of electrical conduit, it is important to recognize the importance of these factors in ensuring the safety and reliability of electrical systems. Government regulations help protect individuals and properties from electrical hazards and ensure that electrical products meet consistent performance standards.

Understanding the impact of government regulations and certifications on the cost of electrical conduit allows individuals and businesses to make informed decisions when purchasing and installing conduit. It is important to consider the compliance and certification requirements of the local regulatory authorities to ensure the safe and reliable operation of electrical systems.

Market demand and supply

The principles of market demand and supply play a significant role in determining the cost of electrical conduit. The dynamics between supply and demand directly impact the pricing of conduit in the market. Here, we will explore how market demand and supply influence the expense of electrical conduit.

Construction activity: The demand for electrical conduit is closely linked to construction activity. During periods of high construction activity, there is a greater need for electrical conduit as new buildings, residential complexes, commercial spaces, and industrial facilities are being constructed. Increased demand can lead to higher prices due to the competition for conduit among contractors, electricians, and developers. Conversely, during periods of low construction activity, the demand for electrical conduit may decrease, which can result in lower prices as manufacturers and suppliers aim to attract customers.

Product availability: The availability of electrical conduit in the market can also impact its pricing. If the supply of conduit is limited due to factors such as production capacity constraints or shortages of raw materials, it can lead to an increase in prices. Conversely, when the supply of conduit exceeds demand, manufacturers may lower prices to stimulate sales. Manufacturers and suppliers closely monitor market conditions to adjust production levels and pricing accordingly.

Raw material costs: Fluctuations in the costs of raw materials used in electrical conduit, such as steel, aluminum, and plastic, can influence the pricing of conduit products. The prices of these raw materials can be influenced by factors such as supply chain disruptions, changes in global economic conditions, and market speculation. Increases in raw material costs can lead to higher prices for conduit products, while decreases in raw material costs may result in lower prices, assuming other factors remain constant.

Competition among manufacturers: The level of competition among manufacturers can also impact the pricing of electrical conduit. When there are multiple manufacturers or suppliers offering similar conduit products, a competitive environment is created. In such a scenario, manufacturers may adjust their pricing strategies to attract customers and gain a larger market share. This competition can lead to more competitive pricing, benefitting consumers. Conversely, in situations where a few manufacturers dominate the market or face limited competition, higher prices may prevail.

Product differentiation: Differentiation among electrical conduit offerings can also influence pricing. Manufacturers may introduce unique features or qualities in their conduit products, such as enhanced fire resistance, increased durability, or specialized applications. These differentiated products may command higher prices due to the perceived added value they offer. Consumers who prioritize specific features or requirements may be inclined to pay a premium for these specialized conduit products.

Understanding the interplay of market demand and supply is crucial when considering the cost of electrical conduit. Although the pricing of conduit is influenced by market dynamics, it is also important to carefully evaluate the quality, suitability, and compliance of the conduit with safety standards and regulations.

By staying informed about market conditions, being aware of the demand and supply dynamics, and considering various conduit options, consumers can make informed choices that balance their budget considerations with their specific needs for electrical conduit.

Read more: Why Are Curtains So Expensive

Alternatives to traditional electrical conduit

While traditional electrical conduit has been widely used for many years, there are several alternative options available for routing and protecting electrical wiring. These alternatives offer different benefits and may be more cost-effective or suitable for specific applications. Here, we will explore some of the alternatives to traditional electrical conduit.

Cable Tray Systems: Cable tray systems are a popular alternative to conduit for organizing and supporting electrical cables. They consist of a series of open, ladder-like structures made of metal or plastic, designed to hold and route cables. Cable trays provide easier access to cables, allowing for easier maintenance and troubleshooting. They are commonly used in industrial and commercial applications where cable runs are extensive and require flexibility.

Raceway Systems: Raceway systems, also known as surface raceway or wire mold systems, provide a versatile alternative to traditional conduit. They are typically made of PVC or metal and are designed to be mounted on walls or ceilings. Raceway systems offer the advantage of flexibility, allowing additional wires to be added or removed easily. They are commonly used in residential and commercial buildings where surface-mounted electrical solutions are preferred.

Wire Ducts: Wire ducts, also known as wire troughs or wire channels, are another alternative for protecting and organizing electrical wiring. They are typically made of PVC or metal and can be mounted directly on walls or within cabinets. Wire ducts provide a neat and organized solution for grouping and separating wires, making it easier to identify and manage specific circuits.

Flexible Conduit: Flexible conduit, also referred to as liquidtight conduit or flex conduit, offers a more pliable and adaptable alternative to rigid conduit. It is typically made of PVC or metal and is designed to provide protection in areas where bending or maneuvering the conduit is necessary. Flexible conduit is commonly used in situations where traditional conduit would be challenging to install, such as in tight spaces or around machinery.

Wireless Solutions: Advancements in wireless technology have led to the development of wireless solutions for transmitting and controlling electrical signals. Wireless alternatives eliminate the need for physical conduit altogether, as they rely on wireless communication protocols to transmit data and control electrical devices. Wireless solutions are commonly used in smart home systems and for remote control applications.

Note that while these alternatives provide viable options in certain situations, it is essential to evaluate their suitability for the specific electrical requirements and compliance with local electrical codes and regulations.

When considering alternatives to traditional electrical conduit, factors such as aesthetics, installation flexibility, accessibility, and cost-effectiveness should be taken into account. It is advisable to consult with an electrical professional or contractor to determine the best solution for a particular electrical project.

As technology continues to advance, new alternative options may emerge, offering further choices for routing and protecting electrical wiring. Staying informed about these developments can help individuals and businesses make informed decisions when it comes to electrical system installations.

Conclusion

Electrical conduit plays a crucial role in safely and efficiently routing and protecting electrical wiring in residential, commercial, and industrial buildings. However, the cost of electrical conduit can sometimes be perceived as expensive. Understanding the factors that contribute to the expense of electrical conduit can shed light on why it is priced the way it is.

Factors such as the cost of materials, manufacturing processes, installation and labor, government regulations, market demand and supply, and alternative options all play a role in determining the cost of electrical conduit. The type and quality of materials used in the manufacturing process, including metals like steel and aluminum or plastics like PVC, can influence the pricing of conduit. The cost of manufacturing, which includes specialized equipment, production processes, quality control measures, and certifications, is also reflected in the final price of conduit.

The cost of installation and labor is another significant factor contributing to the overall expense of electrical conduit. Skilled labor, complexity of the installation, additional materials, and the time and effort required all impact the labor cost. Government regulations and certifications ensure the safety and quality of electrical conduit but add to the manufacturing and testing expenses. Market demand and supply dynamics, including construction activity, product availability, raw material costs, competition, and product differentiation, also influence conduit pricing.

Additionally, there are alternative options to traditional electrical conduit, such as cable tray systems, raceway systems, wire ducts, flexible conduit, and wireless solutions. These alternatives offer different benefits and may be more suitable or cost-effective for specific applications.

In conclusion, the cost of electrical conduit is determined by a combination of factors, including materials, manufacturing processes, installation and labor, government regulations, market demand and supply, and alternative options. By understanding these factors, individuals and businesses can make informed decisions when selecting and purchasing electrical conduit, balancing their specific needs with cost considerations. Ultimately, the expense of electrical conduit is justified by the benefits it provides in terms of protecting electrical wiring, ensuring safety, and complying with industry standards.

Frequently Asked Questions about Why Is Electrical Conduit So Expensive

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “Why Is Electrical Conduit So Expensive”