Home>Construction & Tools>Building Materials>What Is A Fire Brick

Building Materials

What Is A Fire Brick

Modified: April 22, 2024

Learn about fire bricks, a durable and heat-resistant building material ideal for constructing fireplaces, furnaces, and kilns. Understand their composition, uses, and benefits.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When it comes to constructing or renovating a building, the choice of materials is paramount. Among the many components that contribute to the structural integrity and safety of a building, fire bricks play a crucial role. These specialized bricks are designed to withstand high temperatures and are commonly used in applications where conventional bricks would fail.

Fire bricks, also known as refractory bricks, are engineered to endure extreme heat without deforming, cracking, or disintegrating. This remarkable heat resistance makes them indispensable in a variety of industrial and domestic settings.

In the following sections, we will delve into the composition, types, uses, advantages, and considerations when choosing fire bricks. Whether you are a homeowner embarking on a fireplace renovation or a professional in the construction industry, understanding the intricacies of fire bricks is essential for making informed decisions and ensuring the safety and longevity of your projects. Let's explore the fascinating world of fire bricks and uncover the myriad ways in which they contribute to the durability and resilience of structures.

Key Takeaways:

- Fire bricks are specialized building materials designed to withstand high temperatures, making them essential for fireplaces, industrial furnaces, and other applications where conventional bricks would fail.

- With exceptional heat resistance, thermal insulation properties, and resistance to chemical corrosion, fire bricks play a crucial role in ensuring the safety, efficiency, and longevity of structures and equipment exposed to high temperatures and harsh operating environments.

Read more: What Kind Of Bricks For Fire Pit

Composition of Fire Bricks

Fire bricks are crafted from various heat-resistant materials, each carefully selected for its ability to withstand high temperatures. The primary components of fire bricks include:

- Fireclay: This clay is renowned for its exceptional heat resistance and is a fundamental ingredient in fire brick production. Its high alumina content enables it to endure intense heat without deforming, making it an indispensable component in the manufacturing of fire bricks.

- Chamotte: Also known as grog, chamotte is a type of calcined clay that has been specially processed to enhance its refractory properties. It is added to the fire brick mixture to improve its thermal shock resistance and prevent cracking under rapid temperature changes.

- Silica: Silica, in the form of sand or quartz, is incorporated into fire bricks to enhance their resistance to thermal stress. It also contributes to the bricks’ ability to withstand chemical corrosion, making them suitable for applications involving acids and alkalis.

- Alumina: Alumina, derived from bauxite or aluminum oxide, is a key component in high-temperature ceramics. It enhances the fire bricks’ refractoriness, ensuring they retain their structural integrity even at elevated temperatures.

- Other Additives: Various additives, such as sawdust or other organic materials, may be included in the fire brick mixture to facilitate the formation of pores during firing. These pores improve the bricks’ insulating properties, making them more effective at retaining heat.

The precise combination of these materials, along with the manufacturing process, determines the thermal conductivity, mechanical strength, and chemical stability of the resulting fire bricks. By carefully selecting and proportioning these components, manufacturers can produce fire bricks tailored to specific temperature ranges and environmental conditions, ensuring optimal performance in diverse applications.

Understanding the composition of fire bricks provides insight into their remarkable ability to withstand extreme heat and harsh operating conditions, making them a cornerstone of countless industrial and domestic installations.

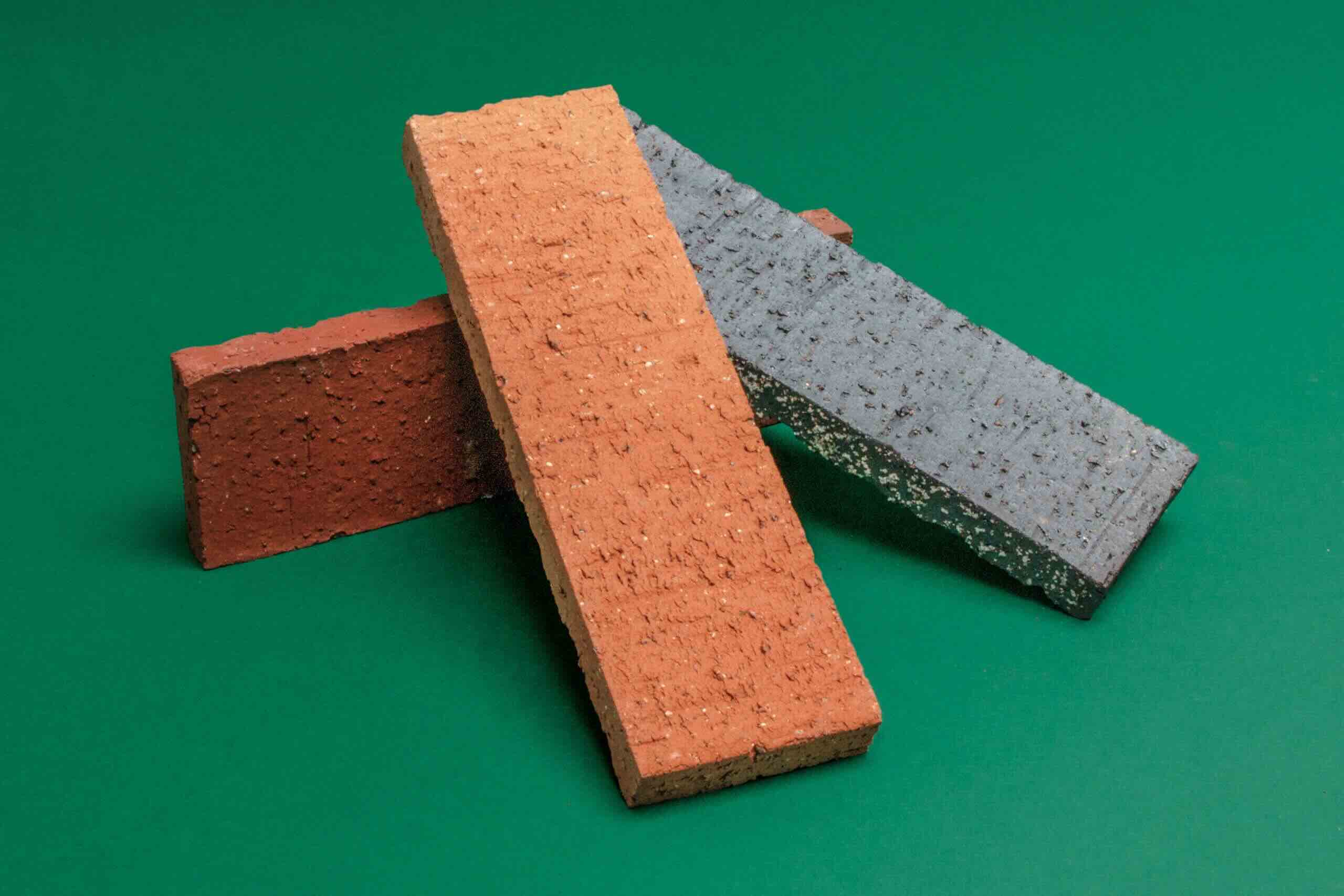

Types of Fire Bricks

Fire bricks are available in a variety of types, each designed to meet specific thermal and structural requirements. The classification of fire bricks is based on their composition, density, porosity, and refractoriness. Here are some common types of fire bricks:

- Standard Fire Bricks: These are the most common type of fire bricks and are suitable for general-purpose applications. They offer good thermal conductivity and are often used in fireplaces, wood-fired ovens, and other moderate-temperature environments.

- High-Alumina Fire Bricks: With a higher alumina content than standard fire bricks, high-alumina fire bricks exhibit superior refractoriness and resistance to thermal shock. They are well-suited for applications involving high temperatures, such as industrial furnaces and kilns.

- Insulating Fire Bricks: Also known as lightweight fire bricks, insulating fire bricks are characterized by their low thermal conductivity and high porosity. These properties make them ideal for insulating industrial furnaces, kilns, and other high-temperature equipment, helping to conserve energy and improve thermal efficiency.

- Silica Fire Bricks: Silica fire bricks are made from silica, quartz, and other siliceous materials. They offer excellent resistance to acid slag and are commonly used in the construction of glass tanks, coke ovens, and other applications where high silica content is beneficial.

- Chrome Fire Bricks: Chrome fire bricks, containing chromium oxide as a key component, are highly resistant to corrosion and erosion by molten metals and slags. They are essential in the construction of metallurgical and chemical industry furnaces where harsh operating conditions prevail.

Each type of fire brick is engineered to excel in specific thermal environments, ensuring optimal performance and longevity in diverse applications. By understanding the unique characteristics of each type, builders and engineers can select the most suitable fire bricks for their projects, thereby enhancing safety and operational efficiency.

Now that we have explored the various types of fire bricks, let’s delve into their wide-ranging uses and the indispensable role they play in numerous industries and construction projects.

Uses of Fire Bricks

Fire bricks are indispensable in a wide array of industrial, commercial, and domestic applications, owing to their exceptional heat resistance and durability. Some common uses of fire bricks include:

- Fireplaces and Wood-Fired Ovens: Fire bricks are essential components in the construction of fireplaces and wood-fired ovens. Their ability to withstand high temperatures makes them ideal for lining the interiors of these heating appliances, providing insulation and protecting the surrounding structures from heat damage.

- Industrial Furnaces and Kilns: In industrial settings, fire bricks are utilized to construct the linings of furnaces, kilns, and incinerators. Their high refractoriness and thermal shock resistance enable them to endure the extreme heat generated in these processes, facilitating the production of metals, ceramics, glass, and other materials.

- Boilers and Incinerators: Fire bricks play a crucial role in the construction of boilers and waste incinerators, where they form the inner lining to contain and withstand the intense heat produced during combustion. Their ability to maintain structural integrity at high temperatures ensures the efficient and safe operation of these critical systems.

- Metallurgical and Chemical Industry Applications: In the metallurgical and chemical industries, fire bricks are utilized in the construction of smelting furnaces, reactors, and vessels that handle molten metals and corrosive chemicals. Their resistance to chemical erosion and thermal shock makes them essential for maintaining the integrity of these high-temperature processes.

- Glass Tanks and Coke Ovens: Fire bricks are employed in the construction of glass tanks, coke ovens, and other facilities involved in glass production and coke manufacturing. Their ability to withstand the harsh conditions of these operations ensures the longevity and reliability of these industrial installations.

These are just a few examples of the diverse uses of fire bricks across different industries and applications. Their ability to withstand extreme heat, thermal shock, and chemical corrosion makes them indispensable in environments where conventional building materials would fail, underscoring their crucial role in ensuring the safety, efficiency, and longevity of various structures and industrial processes.

Now that we’ve explored the multifaceted uses of fire bricks, let’s delve into the numerous advantages they offer, further highlighting their significance in construction and industrial settings.

When using fire bricks, make sure to choose the right type for your project. Insulating fire bricks are lightweight and ideal for high-temperature applications, while dense fire bricks are better for lower temperature uses.

Advantages of Fire Bricks

Fire bricks offer a multitude of advantages that make them indispensable in numerous industrial, commercial, and domestic applications. Some key advantages of fire bricks include:

- Exceptional Heat Resistance: Fire bricks are engineered to withstand extremely high temperatures, making them ideal for applications involving intense heat, such as industrial furnaces, kilns, and fireplaces.

- Thermal Insulation: Their low thermal conductivity and high porosity make insulating fire bricks particularly effective at conserving heat and improving energy efficiency in industrial furnaces and kilns, thereby reducing operational costs.

- Chemical Resistance: Certain types of fire bricks, such as silica and chrome fire bricks, exhibit excellent resistance to chemical corrosion, making them essential in environments where exposure to acids, alkalis, and molten metals is prevalent.

- Structural Integrity: Fire bricks maintain their structural stability and resist deformation, cracking, and disintegration even when subjected to rapid temperature changes and thermal shock, ensuring the longevity and reliability of the structures they line.

- Versatility: With a range of specialized types available, fire bricks can be tailored to specific applications, from standard fireplaces to high-temperature industrial processes, providing a versatile solution for diverse construction and industrial needs.

- Longevity: The durability and resilience of fire bricks contribute to the longevity of the structures in which they are employed, reducing maintenance requirements and enhancing the overall safety and efficiency of the installations.

These advantages underscore the critical role that fire bricks play in safeguarding structures, optimizing industrial processes, and ensuring the safety and operational efficiency of various applications. Their remarkable properties make them an indispensable component in the construction and maintenance of structures exposed to high temperatures and harsh operating conditions.

As we continue to explore the significance of fire bricks, it’s essential to consider key considerations when selecting and utilizing these specialized building materials to maximize their effectiveness and performance in diverse applications.

Read more: What Type Of Brick For Fire Pit

Considerations When Choosing Fire Bricks

When selecting fire bricks for a specific application, several crucial considerations come into play to ensure optimal performance and longevity. These considerations include:

- Operating Temperature: It is essential to choose fire bricks with a refractoriness that matches or exceeds the anticipated operating temperature of the application. Different types of fire bricks are designed to withstand specific temperature ranges, and selecting the appropriate grade is critical to prevent premature failure.

- Thermal Conductivity: The thermal conductivity of fire bricks determines their insulating properties and heat retention capabilities. For applications requiring thermal insulation, such as industrial furnaces and kilns, selecting fire bricks with low thermal conductivity is essential to conserve energy and optimize operational efficiency.

- Chemical Exposure: Consider the chemical environment in which the fire bricks will be deployed. Certain types of fire bricks, such as silica and chrome fire bricks, offer superior resistance to chemical erosion and are well-suited for applications involving acids, alkalis, and molten metals.

- Physical Dimensions and Shapes: The physical dimensions and shapes of fire bricks should align with the specific requirements of the installation. Custom shapes and sizes may be necessary to ensure a precise fit and optimal coverage within the structure.

- Load-Bearing Capacity: In applications where fire bricks are subjected to mechanical loads or pressure, their load-bearing capacity and compressive strength are critical factors to consider. Choosing fire bricks with the appropriate mechanical properties ensures the structural integrity of the installation.

- Installation Method and Environment: The installation method and environmental conditions, such as exposure to vibration, abrasion, or rapid temperature changes, should be taken into account when selecting fire bricks to ensure compatibility and longevity in the given setting.

By carefully evaluating these considerations and selecting fire bricks that align with the specific demands of the application, builders, engineers, and industrial professionals can optimize the performance, safety, and durability of the structures and equipment in which these specialized bricks are employed.

With an understanding of the critical considerations when choosing fire bricks, we have gained valuable insights into the factors that influence their effectiveness and suitability for diverse applications. As we conclude our exploration of fire bricks, it is evident that these exceptional building materials are essential components in numerous industrial, commercial, and domestic settings, contributing to the resilience and longevity of structures and equipment exposed to high temperatures and harsh operating conditions.

Conclusion

Fire bricks, with their exceptional heat resistance, thermal insulation properties, and resistance to chemical corrosion, are indispensable components in a myriad of industrial, commercial, and domestic applications. From lining the interiors of fireplaces and wood-fired ovens to withstanding the extreme conditions of industrial furnaces, kilns, and chemical reactors, fire bricks play a crucial role in ensuring the safety, efficiency, and longevity of structures and equipment exposed to high temperatures and harsh operating environments.

The composition, types, and advantages of fire bricks, coupled with the critical considerations when choosing these specialized building materials, underscore their significance in diverse construction and industrial settings. The careful selection of fire bricks tailored to specific temperature ranges, thermal insulation requirements, chemical exposure, and mechanical loads is essential to optimize their performance and longevity in various applications.

As we have journeyed through the world of fire bricks, we have gained a profound appreciation for their remarkable properties and the pivotal role they play in safeguarding structures, enhancing energy efficiency, and facilitating industrial processes. Whether in the construction of residential fireplaces, the operation of industrial furnaces, or the manufacturing of glass and metals, fire bricks stand as a testament to human ingenuity and engineering excellence, enabling the realization of structures and processes that endure the rigors of high-temperature environments.

Ultimately, the enduring legacy of fire bricks lies in their ability to withstand the heat of industrial processes, the warmth of household hearths, and the demands of diverse applications, exemplifying their indispensable nature in the tapestry of construction and industrial engineering. As we continue to innovate and adapt to ever-evolving challenges, fire bricks remain steadfast in their role as guardians of resilience, durability, and safety in the face of intense heat and demanding conditions.

In conclusion, the remarkable properties and multifaceted uses of fire bricks position them as indispensable allies in the pursuit of structural integrity, operational efficiency, and safety across a spectrum of applications, embodying the enduring spirit of resilience in the built environment.

Frequently Asked Questions about What Is A Fire Brick

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is A Fire Brick”