Tableware

What Vinyl To Use On Charger Plates

Modified: February 24, 2024

Looking for the perfect vinyl for your charger plates? Discover durable and stylish options for your tableware collection.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of tableware, where every detail matters, including even the smallest elements like charger plates. These decorative plates, often placed beneath dinner plates or bowls, add elegance and flair to any tabletop setting. With a wide variety of charger plates available in the market, it is essential to choose the right vinyl to personalize and customize them according to your preference.

In this article, we will explore the different types of vinyl that can be used on charger plates, discuss the differences between heat transfer vinyl (HTV) and adhesive vinyl, and provide recommendations for the best vinyl brands. Additionally, we will delve into the application process and share some helpful tips and tricks to achieve professional-looking results.

Whether you are a DIY enthusiast or a tableware business owner, this article will equip you with the knowledge and insights to make informed decisions when it comes to selecting and applying vinyl on charger plates.

Key Takeaways:

- Choose the right vinyl for your charger plates based on their intended use and durability. Consider factors such as material compatibility, design options, and ease of application to achieve professional and long-lasting results.

- Explore reputable vinyl brands like Siser, Oracal, and Cricut for high-quality options to customize your charger plates. Follow the application process and valuable tips to create stunning and personalized tableware for any occasion.

Read more: What Are Charger Plates Used For?

Types of Vinyl

When it comes to vinyl for charger plates, there are two main types that are commonly used: heat transfer vinyl (HTV) and adhesive vinyl. Each type has its own unique characteristics and applications, so let’s take a closer look at both.

1. Heat Transfer Vinyl (HTV): HTV, also known as iron-on vinyl, is a type of vinyl that requires heat and pressure to adhere to a surface. It comes with a carrier sheet that protects the vinyl until it is ready to be applied. HTV is typically used on fabric, but it can also be used on hard surfaces like charger plates. It is available in a wide range of colors, finishes, and textures, allowing for endless creativity and personalization.

2. Adhesive Vinyl: Adhesive vinyl, also known as permanent vinyl, is a self-adhesive material that can be applied to various surfaces, including charger plates. Unlike HTV, adhesive vinyl does not require heat for application. It comes in sheets or rolls and can be cut into different designs using a cutting machine or scissors. Adhesive vinyl is available in a multitude of colors, finishes, and patterns, making it versatile for a wide range of creative projects.

Both HTV and adhesive vinyl offer their own advantages and are suitable for different applications. HTV works well on charger plates that will be used for decorative purposes and are not intended to come into direct contact with food or liquids. On the other hand, adhesive vinyl is a great option for charger plates that will be used for serving food, as it can withstand light washing and handling.

When choosing between HTV and adhesive vinyl for your charger plates, consider the intended use, durability, and your personal preferences in terms of design options and application methods.

Heat Transfer Vinyl (HTV) vs. Adhesive Vinyl

When it comes to choosing vinyl for your charger plates, it’s important to understand the differences between heat transfer vinyl (HTV) and adhesive vinyl. Let’s compare the two types to help you make an informed decision.

Application Method: HTV requires heat and pressure to adhere to the surface. This is done by using a heat press or a household iron. Adhesive vinyl, on the other hand, has a self-adhesive backing that can be easily applied by hand or with the help of transfer tape.

Material Compatibility: HTV is primarily designed for use on fabrics, but it can also be used on hard surfaces like charger plates. It is important to note that not all HTV types are suitable for heat-sensitive materials. Adhesive vinyl, on the other hand, can be used on various surfaces, including charger plates, without any compatibility concerns.

Durability: HTV is generally more durable than adhesive vinyl as it is made to withstand repeated washing and handling without peeling or fading. This makes it an excellent choice for charger plates that may come into contact with heat, moisture, or friction. Adhesive vinyl is less durable and may start to peel or fade over time, especially when exposed to harsh conditions.

Design Options: Both HTV and adhesive vinyl offer a wide range of colors, finishes, and textures to choose from. However, HTV tends to have a more vibrant and textured appearance, making it ideal for creating intricate and detailed designs. Adhesive vinyl provides a smoother and flatter finish, perfect for simpler and sleek designs.

Removability: HTV is not easily removable once applied, and it may leave residue on the surface if attempt to remove it. Adhesive vinyl, on the other hand, can usually be peeled off without leaving any residue, making it easier to change designs or replace the vinyl if desired.

Usage: HTV is recommended for charger plates that will be used for decorative purposes or as gifts, as the heat transfer process adds a professional and permanent finish. Adhesive vinyl is suitable for charger plates that will be used for serving food, as it is easier to clean and can withstand light washing and handling.

Ultimately, the choice between HTV and adhesive vinyl comes down to your specific needs and preferences. Consider factors such as application method, material compatibility, durability, design options, removability, and usage to make the best choice for your charger plate project.

Factors to Consider when Choosing Vinyl for Charger Plates

When selecting vinyl for charger plates, there are several important factors to consider. These factors will help ensure that you choose the right vinyl type and brand to achieve the desired results. Here are some key considerations:

1. Intended Use: Determine how you plan to use the charger plates. Will they be used for decorative purposes, or will they come into direct contact with food? This will help determine whether heat transfer vinyl (HTV) or adhesive vinyl is more suitable.

2. Material Compatibility: Check the compatibility of the vinyl with the charger plate material. Some vinyl types may not adhere well to certain surfaces or may not be suitable for heat-sensitive materials. Ensure that the vinyl is compatible and will adhere properly.

3. Durability: Consider the durability requirements of the vinyl. If the charger plates will be frequently handled, washed, or exposed to heat, it’s important to choose a vinyl that is durable and can withstand such conditions without peeling or fading.

4. Design and Finish: Evaluate the design options and finishes available in the vinyl. Look for a wide variety of colors, textures, and finishes to match your desired aesthetic. Additionally, consider whether you prefer a glossy, matte, or metallic finish.

5. Temperature and Food Safety: If the charger plates will come into contact with food, ensure that the vinyl is food-safe and suitable for use with food. Some vinyl types may not be food-safe and could potentially contaminate the food if they come into direct contact with it.

6. Ease of Application: Consider the application method and tools required for the vinyl. Some vinyl types may require a heat press or special equipment for application. Choose a vinyl that is easy to apply, whether by hand or with basic tools such as a household iron or transfer tape.

7. Removal and Reusability: Determine whether the vinyl can be easily removed and replaced if needed. Adhesive vinyl generally allows for easier removal without leaving residue, while HTV is more permanent. Consider if you may want to change the design or reuse the charger plates in the future.

8. Budget: Lastly, consider your budget. Vinyl prices may vary depending on the type, brand, and quantity. Determine your budget and choose a vinyl that meets your requirements without exceeding your allocated budget.

By considering these factors, you can make an informed decision when choosing the right vinyl for your charger plates. Take your time to evaluate your needs and preferences to ensure the best results for your tableware customization project.

Recommended Vinyl Brands for Charger Plates

When it comes to choosing vinyl for your charger plates, selecting a reputable brand can make a significant difference in the quality and longevity of your design. Here are some highly recommended vinyl brands that offer excellent options for charger plate customization:

1. Siser: Siser is a well-known and respected brand in the vinyl industry, offering a wide range of heat transfer vinyl (HTV) options. Their products are known for their durability, vibrant colors, and ease of use. Siser offers various HTV lines, including EasyWeed and Glitter, which are popular choices for charger plate customization.

2. Oracal: Oracal is a trusted brand that specializes in adhesive vinyl. They offer a diverse range of vinyl options, including solid colors, patterned designs, and specialty finishes such as metallic and holographic. Oracal vinyl is known for its high-quality adhesion and durability, making it an excellent choice for charger plate projects.

3. Cricut: Cricut is a well-known brand among crafters and DIY enthusiasts. They offer both heat transfer vinyl and adhesive vinyl, compatible with their popular cutting machines. Cricut vinyl comes in a wide range of colors and finishes, allowing for versatile charger plate customization options.

4. Silhouette America: Silhouette America is another reputable brand that provides a range of vinyl options suitable for charger plate customization. Their vinyl products are known for their quality and versatility. Silhouette heat transfer vinyl and adhesive vinyl come in various colors and finishes, ensuring you can find the perfect vinyl for your charger plate project.

5. Specialty Vinyl Companies: In addition to the aforementioned brands, there are several specialty vinyl companies that offer unique options for charger plate customization. Companies like Expressions Vinyl, StyleTech, and StarCraft HD offer an extensive range of vinyl choices, including specialty finishes like glitter, holographic, and metallic, allowing for stunning and unique designs on charger plates.

When choosing a vinyl brand for your charger plates, consider factors such as product availability, range of colors and finishes, ease of use, and customer reviews. It’s also beneficial to explore each brand’s website or visit local craft stores to get a hands-on feel for the vinyl options available.

Keep in mind that personal preference plays a significant role in choosing the right vinyl brand. It’s always a good idea to try out different brands and vinyl types to see which ones work best for your specific charger plate customization projects.

By selecting vinyl from reputable brands, you can ensure the highest quality and longevity of your designs on charger plates, allowing you to create stunning and personalized tableware for any occasion.

When choosing vinyl for charger plates, opt for permanent adhesive vinyl to ensure it stays in place and withstands regular handling and cleaning.

Read more: How To Use Charger Plates

Application Process for Vinyl on Charger Plates

Applying vinyl to charger plates may seem daunting at first, but with the right process and tools, it can be a straightforward and enjoyable experience. Here is a step-by-step guide to help you achieve professional-looking results:

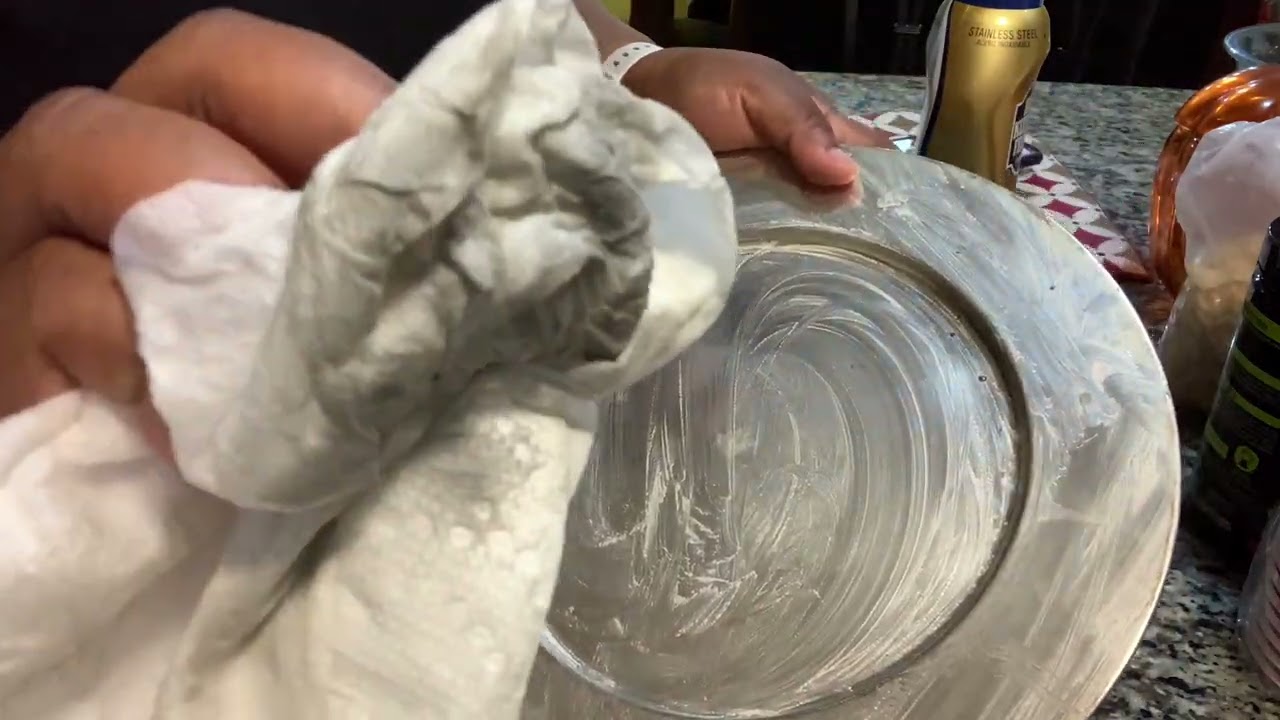

1. Clean the Charger Plates: Before applying vinyl, make sure the charger plates are clean and free from dust, grease, or any other debris. Use mild soap and water to wash them, and dry them thoroughly with a soft cloth.

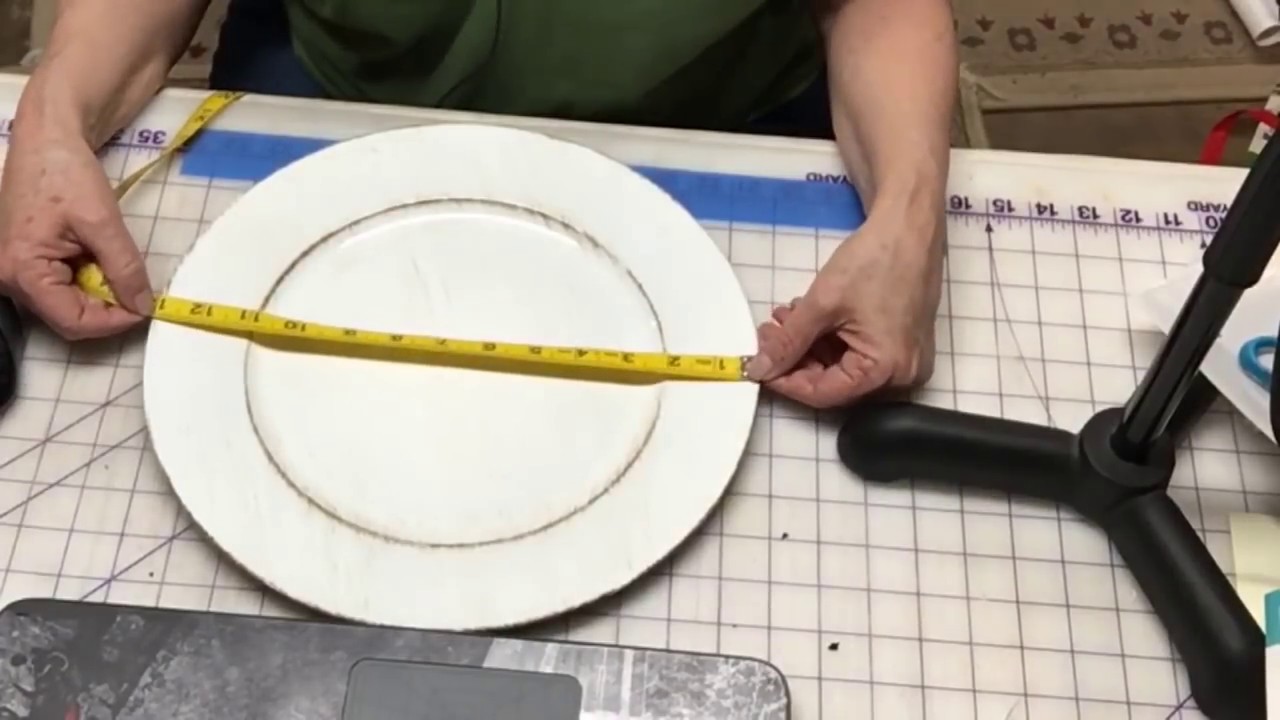

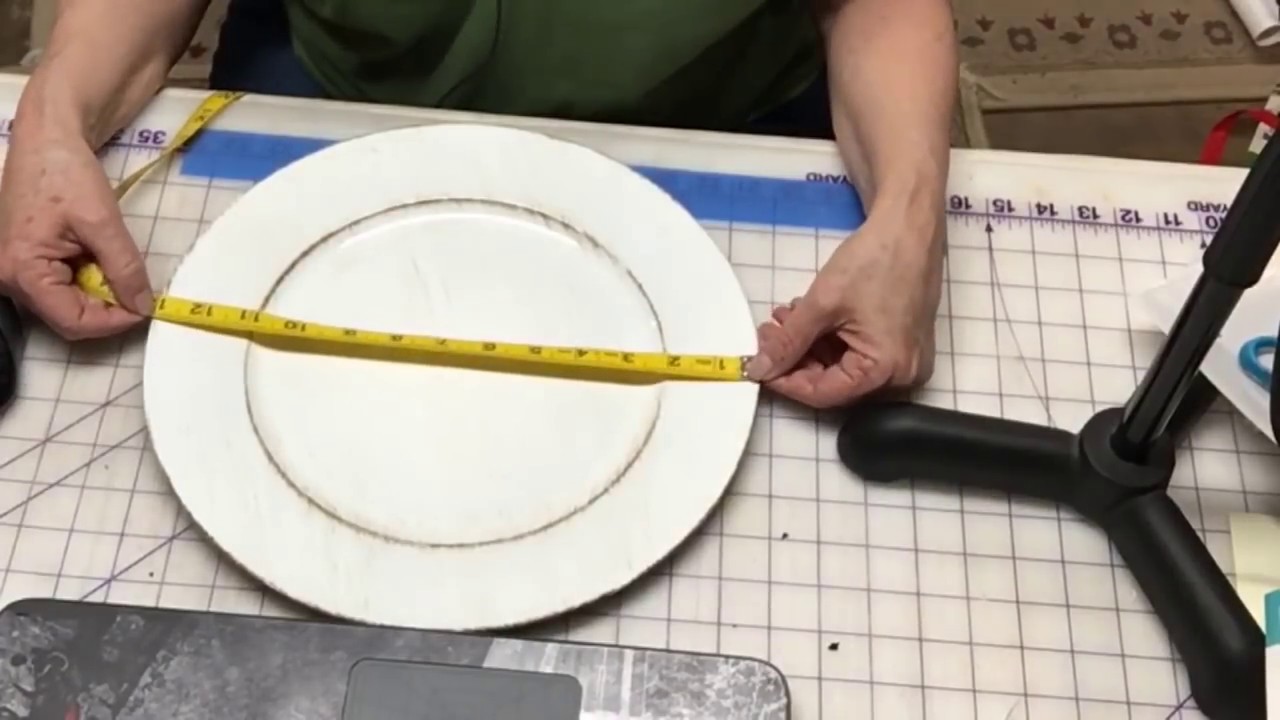

2. Measure and Cut the Vinyl: Measure the diameter of the charger plate, and cut the vinyl accordingly, allowing for a slight overlap if desired. Use a cutting machine or sharp scissors for precise and clean cuts. If using adhesive vinyl, consider using transfer tape to help transfer the design onto the charger plate.

3. Prepare the Vinyl: If using heat transfer vinyl (HTV), make sure to mirror or reverse the design before cutting. This is necessary as the design will be flipped when applied to the charger plate. Weed any excess vinyl or unwanted parts of the design carefully.

4. Apply the Vinyl: If using adhesive vinyl, peel off the backing and carefully place the vinyl onto the charger plate. Smooth out any wrinkles or bubbles using a vinyl squeegee or your fingers. If using HTV, position the design onto the charger plate, making sure it is centered and aligned. Use a heat press or household iron, following the specific instructions provided by the vinyl manufacturer, to apply heat and pressure to adhere the HTV to the charger plate.

5. Remove Transfer Tape (if applicable): If you used transfer tape with adhesive vinyl, gently peel off the transfer tape, starting from one corner and pulling it back at a 45-degree angle. This will ensure that the vinyl remains adhered to the charger plate while the transfer tape is removed.

6. Apply Heat (if applicable): If using HTV, it is recommended to apply heat once again after removing the carrier sheet. This will ensure a strong bond between the HTV and the charger plate. Follow the heat and time instructions provided by the vinyl manufacturer to prevent any excessive heat exposure.

7. Allow to Cure (if applicable): Depending on the type of vinyl used, it may require a curing period to fully adhere to the charger plate. Follow the specific instructions provided by the vinyl manufacturer regarding curing time and temperature. This step will ensure the longevity of the vinyl design.

8. Finishing Touches: Once the vinyl is applied and cured, inspect the charger plate for any imperfections or bubbles. Use a pin or needle to puncture any trapped air bubbles and smooth them out. This will create a seamless and professional finish.

Following these steps will help you achieve a successful vinyl application on your charger plates. Remember to take your time, be patient, and refer to the specific instructions provided by the vinyl manufacturer for the best results. With practice and experience, you will master the application process and create beautifully customized charger plates to elevate your table settings.

Tips and Tricks for Vinyl Application on Charger Plates

Applying vinyl to charger plates requires precision and careful attention to detail. To help you achieve the best results, here are some valuable tips and tricks:

1. Prepare the Surface: Before applying vinyl, ensure that the charger plates are clean and free from any residue or oils. This will help the vinyl adhere properly to the surface. Use a mild soap and water solution to clean the plates, and dry them thoroughly with a soft cloth.

2. Use Transfer Tape: If you’re working with adhesive vinyl, using transfer tape can make the application process more manageable. Place the cut vinyl on the transfer tape and gently press it down. This will help you position the design accurately and prevent any stretching or distortion during the application.

3. Apply Even Pressure: When applying vinyl, whether it’s adhesive vinyl or heat transfer vinyl (HTV), ensure you apply even pressure across the entire surface. This will help eliminate any air bubbles and ensure a smooth and clean application. Use a vinyl squeegee or your fingers to gently press down and smooth out the vinyl.

4. Use a Heat Transfer Pillow (for HTV): When using HTV on curved or uneven surfaces like charger plates, placing a heat transfer pillow inside the plate can help create an even and consistent heat distribution. This will prevent any unwanted wrinkles or distortions in the vinyl design.

5. Heat and Wash Tests (for Adhesive Vinyl): Before applying adhesive vinyl to charger plates intended for frequent use and washing, perform a heat and wash test on a sample piece. Apply the vinyl to a spare plate and subject it to the same conditions it will encounter during regular use and cleaning. This will ensure that the adhesive vinyl can withstand those circumstances without peeling or fading.

6. Seal the Edges: To enhance the longevity of your vinyl designs on charger plates, consider sealing the edges with a clear sealant. This will help protect the edges of the vinyl from peeling and prolong the lifespan of the design. Use a food-safe sealant if the charger plates will come in contact with food.

7. Practice on Spare Plates: If you’re new to working with vinyl, or if you’re trying out new techniques or designs, it’s always a good idea to practice on spare or inexpensive charger plates. This will allow you to familiarize yourself with the application process and test different methods before working on your final project.

8. Remove Air Bubbles: If you notice any air bubbles forming under the vinyl, use a pin or needle to gently puncture the bubbles. Then, smooth out the vinyl with your fingers or a vinyl squeegee to ensure a bubble-free finish. Take care not to puncture the vinyl itself, but rather release the trapped air.

9. Follow Vinyl Manufacturer Instructions: Each vinyl brand may have specific instructions for application, heat settings, and durability. Always refer to the manufacturer’s guidelines and recommendations for the best results. This will ensure that you are using the vinyl correctly and adhering to any specific requirements for your charger plates.

10. Allow Proper Curing Time: After applying vinyl, it is crucial to allow sufficient curing time before using or washing the charger plates. Follow the specific instructions provided by the vinyl manufacturer to ensure the vinyl has properly adhered and will withstand regular use and cleaning.

By utilizing these tips and tricks, you will be well-equipped to achieve professional-looking vinyl applications on your charger plates. Experiment with different techniques, practice your skills, and enjoy the process of customizing your tableware with beautiful and personalized designs.

Frequently Asked Questions (FAQs)

Here are answers to some of the frequently asked questions about applying vinyl on charger plates:

Q: Can I use any type of vinyl on charger plates?

A: It is essential to choose a vinyl type that is suitable for charger plates. Heat transfer vinyl (HTV) and adhesive vinyl are the most common types used. HTV is recommended for decorative purposes, while adhesive vinyl is more suitable for charger plates that will be used for serving food.

Q: Can I wash charger plates with vinyl designs?

A: If your charger plates have adhesive vinyl designs, they can withstand light washing. However, hand washing is recommended to maintain the longevity of the vinyl. HTV designs on charger plates should be washed with caution, ensuring proper heat and wash tests have been conducted beforehand.

Q: Can I use vinyl on charger plates that will be in contact with food?

A: While adhesive vinyl is generally considered food-safe, it is recommended to avoid placing food directly on the vinyl surface to prevent any potential contamination. HTV is not recommended for charger plates that will come into contact with food.

Q: How long will vinyl designs last on charger plates?

A: The longevity of vinyl designs on charger plates depends on various factors, such as the type of vinyl, usage, washing methods, and maintenance. With proper care, adhesive vinyl designs can last for months, and HTV designs can last even longer.

Q: Can I remove vinyl from charger plates?

A: Adhesive vinyl can typically be removed from charger plates, but it may leave some residue. HTV is more permanent and not easily removable. Ensure that the charger plates are suitable for vinyl removal and that any residue is cleaned carefully afterwards.

Q: Can I reuse charger plates with vinyl designs?

A: It is possible to reuse charger plates with adhesive vinyl designs. However, HTV designs are generally more challenging to remove, making them less suitable for reuse. If reusing charger plates, consider changing the vinyl design or using a vinyl brand that allows for easier removal.

Q: Can I apply vinyl on charger plates with curved surfaces?

A: Applying vinyl on charger plates with curved surfaces can be a bit more challenging. It is recommended to use a heat transfer pillow (for HTV) or find a vinyl brand that is designed to conform to curved surfaces better. Applying heat evenly and using proper technique can help ensure successful application.

Q: Can I personalize charger plates with multiple vinyl colors?

A: Yes, you can create personalized designs on charger plates using multiple vinyl colors. Adhesive vinyl and HTV can be layered to achieve intricate and multicolored designs. Ensure that each layer of vinyl is properly aligned and adhered to create a cohesive and professional-looking design.

Q: Do I need special equipment to apply vinyl on charger plates?

A: Special equipment is not always necessary for applying vinyl on charger plates. Basic tools like a cutting machine or scissors, a squeegee, and a household iron or heat press (for HTV) can be used. However, investing in a cutting machine and a heat press can make the process more efficient and yield better results.

If you have any other questions about applying vinyl on charger plates, always refer to the instructions provided by the vinyl manufacturer and seek advice from experienced crafters or professionals. Enjoy the process of customizing your charger plates and creating unique tableware that adds a personal touch to any occasion!

Conclusion

Customizing charger plates with vinyl is a fantastic way to add a personal touch and elevate the look of your tableware. Whether you’re a DIY enthusiast or a tableware business owner, choosing the right vinyl and applying it correctly is key to achieving stunning results.

In this article, we explored the different types of vinyl, including heat transfer vinyl (HTV) and adhesive vinyl, and discussed the factors to consider when choosing vinyl for charger plates. We also recommended some reputable vinyl brands known for their quality and versatility in charger plate customization.

We provided a step-by-step application process, along with tips and tricks to help you achieve professional-looking results. From preparing the charger plates to applying the vinyl and troubleshooting common issues, these guidelines will assist you in creating beautiful designs on your charger plates.

Remember to consider the intended use, material compatibility, durability, design options, and ease of application when selecting vinyl for your charger plates. Follow the instructions provided by the vinyl manufacturer, conduct heat and wash tests when necessary, and allow for proper curing time to ensure a long-lasting and visually appealing vinyl design.

By utilizing the tips and tricks shared in this article, you can confidently embark on your vinyl customization journey. Experiment with different techniques, explore various vinyl brands, and unleash your creativity to create stunning and personalized charger plates that will impress your guests or customers.

Whether it’s for weddings, special events, or everyday table settings, vinyl customization on charger plates adds a touch of elegance and uniqueness. Enjoy the process, showcase your creativity, and make your tableware truly stand out with personalized vinyl designs on charger plates!

Frequently Asked Questions about What Vinyl To Use On Charger Plates

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Vinyl To Use On Charger Plates”