Home>diy>Building & Construction>What Is Jha In Construction

Building & Construction

What Is Jha In Construction

Modified: January 23, 2024

Learn more about JHA in construction and its importance in building construction. Gain insights on how JHA contributes to safety and risk management in construction projects.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Construction projects involve complex and hazardous tasks that require careful planning and management to ensure the safety of workers and the successful execution of the project. One crucial aspect of ensuring safety in construction is conducting a Job Hazard Analysis (JHA), also known as Job Safety Analysis (JSA).

A JHA is a systematic process that identifies potential hazards and analyzes the risks associated with specific job tasks. It aims to assess the possible dangers and develop appropriate safety measures to mitigate those risks. By conducting a JHA, construction companies can proactively address potential hazards, prevent accidents, and promote a culture of safety on worksites.

The primary goal of a JHA in construction is to reduce the likelihood of accidents and injuries by identifying and controlling hazards. It acts as a roadmap for workers and supervisors, providing guidance on how to execute tasks safely while minimizing the potential for incidents. Additionally, JHAs enable construction companies to comply with occupational health and safety regulations and demonstrate their commitment to creating a safe work environment for employees.

Throughout this article, we will explore the purpose, components, importance, and steps involved in conducting a JHA in construction projects. We will also discuss the challenges faced in implementing JHAs and highlight the benefits of incorporating this analysis into construction site practices. By the end, you will have a comprehensive understanding of JHAs and their significance in the construction industry.

Key Takeaways:

- JHA in construction is a proactive process that identifies and controls potential hazards, ensuring worker safety, regulatory compliance, cost reduction, and a positive safety culture within construction companies.

- Successful JHA implementation in construction projects, from iconic bridges to high-rise buildings, demonstrates its efficacy in safeguarding workers, improving project efficiency, and minimizing accidents and health risks.

Read more: What Is A JHA In Construction

Definition of JHA in Construction

A Job Hazard Analysis (JHA) in construction is a systematic method used to identify and evaluate potential hazards associated with specific job tasks. It involves breaking down each task into individual steps and assessing the associated risks to prevent accidents and injuries.

JHAs are typically conducted before starting a new construction project, when introducing new tasks or equipment, or when there are changes in the work environment. By analyzing the hazards and implementing appropriate control measures, construction companies can mitigate risks and ensure the safety of their workers.

The process of conducting a JHA involves gathering information about the job tasks and the work environment, identifying potential hazards, assessing the risks, and implementing control measures to eliminate or reduce those risks. It requires collaboration between workers, supervisors, and safety professionals to accurately identify and address hazards.

The JHA process aims to ensure that workers have the necessary knowledge, skills, and protective measures to perform their tasks safely. It helps in identifying potential hazards such as falls, electrical hazards, exposure to harmful substances, equipment malfunctions, and many others that are commonly found in construction sites.

It is important to note that JHAs are not a one-time activity. They should be regularly reviewed and updated as job tasks change or new risks are identified. By continuously reassessing and improving the JHAs, construction companies can ensure the ongoing safety of their workers.

In summary, a JHA in construction is a systematic approach used to identify, assess, and control hazards associated with specific job tasks. It plays a vital role in preventing accidents, promoting a safe work environment, and ensuring the overall success of construction projects.

Purpose of JHA in Construction Projects

The primary purpose of conducting a Job Hazard Analysis (JHA) in construction projects is to identify potential hazards, assess their risks, and develop strategies to control and mitigate those risks. By doing so, construction companies can achieve several significant objectives:

- Protecting Workers’ Safety: The safety and well-being of construction workers are paramount. JHAs help identify and eliminate or minimize potential hazards, reducing the likelihood of accidents, injuries, and even fatalities. By proactively addressing job hazards, companies can create a safer work environment for their employees.

- Promoting Compliance with Regulations: Construction projects are subject to various occupational health and safety regulations. Conducting JHAs ensures that companies comply with these regulations, thereby avoiding legal penalties and maintaining a positive reputation in the industry.

- Enhancing Project Efficiency: By identifying potential hazards and implementing appropriate control measures, JHAs can improve the efficiency of construction projects. By minimizing risks, companies can reduce the chances of work delays, disruptions, and rework caused by accidents or injuries.

- Reducing Costs: Workplace accidents not only harm workers but also result in financial losses for construction companies. Medical expenses, legal fees, worker compensation claims, and project delays can all have a significant impact on profitability. JHAs help minimize the risks associated with accidents, reducing costs and preserving the financial health of construction projects.

- Creating a Safety Culture: Conducting JHAs demonstrates a commitment to safety and establishes a strong safety culture within construction companies. When workers see that their employers prioritize their well-being and actively identify and address job hazards, it fosters a sense of trust and engagement, promoting a positive work environment.

Overall, the purpose of conducting JHAs in construction projects is to safeguard workers, ensure compliance with regulations, improve project efficiency, reduce costs, and foster a safety-conscious culture. By systematically assessing and controlling job hazards, construction companies can create a safer, more productive, and successful work environment.

Components of JHA in Construction

Job Hazard Analysis (JHA) in construction consists of several key components that help ensure the thorough identification and assessment of potential hazards. These components work together to create a comprehensive analysis of the risks associated with specific job tasks. The main components of a JHA in construction include:

- Task Identification: The first step in conducting a JHA is to identify the specific job tasks that will be analyzed. This involves breaking down the project or work area into individual tasks, ensuring that each task is analyzed separately to uncover potential hazards.

- Hazard Identification: Once the tasks are identified, the JHA process involves identifying potential hazards associated with each task. This can include physical hazards (such as noise, falls, or electrical hazards), chemical hazards (such as exposure to harmful substances), and biological hazards (such as exposure to mold or bacteria).

- Risk Assessment: After identifying the hazards, the next step is to assess the risks associated with each hazard. This involves determining the severity of potential injuries or damage and the likelihood of those hazards occurring. Risk assessment helps prioritize the hazards and determine which control measures are necessary.

- Control Measures: Control measures are strategies and actions implemented to eliminate or reduce the risks identified in the JHA. This can include engineering controls (such as installing guardrails or safety barriers), administrative controls (such as implementing safety protocols or training), or personal protective equipment (PPE) requirements.

- Documentation: It is crucial to document the findings of the JHA process. This includes recording the identified hazards, the associated risks, and the control measures implemented. Having well-documented JHAs helps with future reference and allows for easy communication and dissemination of safety information to workers.

- Review and Revision: JHAs should be periodically reviewed and revised to ensure they remain relevant and effective. As construction projects progress, new hazards may emerge or tasks may change, requiring an update of the JHA. Regular review and revision help maintain the accuracy and usefulness of the analysis.

These components work together to create a comprehensive and systematic assessment of job hazards in construction. By following this structured process, construction companies can effectively identify, assess, and control potential hazards, enhancing the safety of their workers and minimizing the risks associated with construction projects.

Importance of JHA in the Construction Industry

Job Hazard Analysis (JHA) is of utmost importance in the construction industry due to the inherent risks and hazards involved in construction projects. Implementing JHA processes and procedures brings several key benefits, including:

- Accident Prevention: The construction industry is known for its high rate of accidents and injuries. By conducting JHAs, construction companies can identify potential hazards and take proactive measures to prevent accidents from occurring. This ensures the safety and well-being of workers, reducing the occurrence of workplace incidents.

- Compliance with Safety Regulations: The construction industry is heavily regulated to ensure worker safety. JHA helps construction companies comply with these regulations by assessing and controlling hazards in accordance with applicable laws and guidelines. Compliance not only protects workers but also prevents legal liabilities and penalties.

- Increased Productivity: Implementing JHA in construction projects leads to increased productivity. By identifying potential hazards and implementing control measures, interruptions, accidents, and unforeseen incidents are minimized. This enables workers to focus on their tasks, leading to improved project efficiency and timely completion.

- Cost Savings: Workplace accidents and injuries pose significant financial burdens on construction companies. Medical expenses, legal fees, workers’ compensation claims, and project delays can all contribute to escalated costs. JHA helps reduce these costs by preventing accidents and injuries, preserving financial resources, and maintaining the profitability of construction projects.

- Enhanced Risk Management: JHA plays a critical role in risk management within the construction industry. By systematically identifying and addressing job hazards, construction companies can effectively manage risks and minimize potential threats to project success. This, in turn, helps mitigate unexpected disruptions or incidents that could result in project delays or increased expenses.

- Fostering a Safety Culture: Incorporating JHA into construction practices fosters a culture of safety within the organization. It showcases a commitment to worker well-being and encourages employees to prioritize safety in their daily tasks. A safety-conscious workforce contributes to a positive work environment, higher morale, and improved employee retention.

Overall, the importance of JHA in the construction industry cannot be overstated. It ensures worker safety, promotes regulatory compliance, increases productivity, reduces costs, enhances risk management, and fosters a culture of safety. By implementing JHA processes, construction companies can create safer work environments, protect their workers, and ultimately achieve successful project outcomes.

Jha in construction stands for Job Hazard Analysis. It is a process used to identify and address potential hazards associated with a specific job or task. It helps to ensure the safety of workers and minimize the risk of accidents on the construction site.

Read more: What Is Pre-Construction In Construction

Steps to Conduct a JHA in Construction

Conducting a Job Hazard Analysis (JHA) in construction involves a systematic process that helps identify potential hazards, assess risks, and implement control measures. While the exact steps may vary depending on the specific project and company, the following are common steps to conduct a JHA:

- Select the Job or Task: Choose the job or task that will be analyzed. It is essential to break down the task into smaller components for a more accurate assessment.

- Break Down the Task Into Steps: Identify and list the individual steps involved in completing the selected job or task. This provides a clear framework for evaluating hazards associated with each step.

- Identify Potential Hazards: For each step, identify and document potential hazards that can pose a risk to worker safety. Consider physical, chemical, and biological hazards that may be present during the task and its surroundings.

- Analyze the Risks: Assess the risks associated with each identified hazard. Determine the severity of potential injuries or damages and the likelihood of occurrence. This analysis helps prioritize hazards for effective control measures.

- Implement Control Measures: Develop and implement control measures to eliminate or minimize the identified hazards. This can include engineering controls, administrative controls, and personal protective equipment (PPE) requirements. Ensure that control measures are feasible and effective in reducing risks.

- Communicate and Train: Proper communication and training are vital to ensure that workers understand the hazards and control measures identified in the JHA. Provide comprehensive training on safe work practices, use of equipment, and emergency procedures.

- Monitor and Review: Regularly monitor the effectiveness of implemented control measures and review the JHA. Make necessary revisions and improvements based on new information, changes in the job or task, or feedback from workers. Continuous monitoring and reviews help maintain a safe working environment.

- Document and Maintain Records: Document the findings of the JHA, including the identified hazards, risk assessments, control measures, and training records. Maintain these records for future reference, audits, and communication with workers and regulatory authorities.

It is important to involve workers, supervisors, and safety professionals in each step of the JHA process to ensure a comprehensive analysis and effective hazard control. By following these steps and integrating JHA into construction project planning, companies can significantly reduce the risks associated with tasks and create a safer work environment for their employees.

Challenges Associated with Implementing JHA in Construction Projects

While conducting a Job Hazard Analysis (JHA) in construction projects is essential for ensuring worker safety and project success, several challenges may arise during the implementation process. It is important for construction companies to be aware of these challenges and address them effectively. Some of the common challenges associated with implementing JHA in construction projects include:

- Lack of Awareness and Knowledge: One of the primary challenges is the lack of awareness and knowledge about the importance and process of conducting JHA. Many workers and even some supervisors may not be fully aware of the purpose and benefits of JHA, which can hinder its implementation.

- Time and Resource Constraints: Construction projects often operate under strict deadlines and budget constraints. The time and resources required to conduct a thorough JHA may be seen as an obstacle, as it may be perceived as slowing down project progress or increasing costs.

- Resistance to Change: Resistance to change is another challenge that can impede the implementation of JHA. Some workers and supervisors may resist the introduction of new safety protocols or control measures, as it may disrupt established work routines or require additional training.

- Complexity of Construction Tasks: Construction tasks can be highly complex and involve multiple hazards and risks. Analyzing and identifying all potential hazards associated with each task can be challenging, especially when tasks are intricate or involve constantly changing work environments.

- Communication and Language Barriers: In construction projects with diverse workforces, language barriers can pose a significant challenge in effectively implementing JHA. Communication gaps may hinder the understanding and implementation of control measures, increasing the risk of accidents or misunderstandings.

- Continuous Update and Review: Construction projects are dynamic, with tasks and environments constantly evolving. Keeping JHAs up to date and continuously reviewing them to account for new hazards or changes in procedures can be challenging but is crucial for maintaining an effective JHA process.

- Engaging Worker Participation: Involving workers in the JHA process is essential to its success. However, engaging worker participation can be challenging, especially if workers feel that their input is not valued or if there is a lack of trust between workers and management.

To overcome these challenges, construction companies should prioritize safety and invest in training and awareness programs to educate workers and supervisors about the importance of JHA. Adequate resources and time should be allocated for JHA implementation, and efforts should be made to address language barriers and ensure effective communication. Regular reviews and updates of JHAs, along with engaging worker participation, will help overcome challenges and ensure the successful implementation of JHA in construction projects.

Benefits of Using JHA in Construction Sites

The implementation of Job Hazard Analysis (JHA) in construction sites provides numerous benefits that contribute to improved safety, productivity, and project outcomes. Some key benefits of using JHA in construction sites include:

- Enhanced Worker Safety: JHA systematically identifies potential hazards and assesses the associated risks, leading to the implementation of appropriate control measures. This helps prevent accidents, injuries, and illnesses, ensuring the safety and well-being of workers.

- Improved Project Efficiency: JHA helps streamline construction processes by proactively identifying and addressing potential obstacles and hazards. By spotting and mitigating risks in advance, JHA reduces the likelihood of work delays, disruptions, and rework, resulting in improved project efficiency.

- Regulatory Compliance: Construction projects are subject to various occupational health and safety regulations. JHA ensures compliance with these regulations by identifying and addressing hazards in alignment with legal requirements. Compliance not only protects workers but also safeguards construction companies from potential legal liabilities.

- Cost Savings: Implementing JHA helps reduce costs associated with workplace accidents and injuries. Effective hazard identification and control measures minimize medical expenses, legal fees, and worker compensation claims. Moreover, JHA helps avoid project delays and disruptions, preserving financial resources and maintaining project profitability.

- Risk Management: JHA plays a crucial role in risk management at construction sites. By systematically identifying and assessing hazards, construction companies can mitigate potential risks and prevent unexpected incidents or accidents. This leads to a more controlled and predictable working environment.

- Promotion of a Safety Culture: Incorporating JHA into daily work practices fosters a culture of safety within the construction site. It emphasizes the importance of worker well-being and encourages all employees to prioritize safety. A safety-conscious culture improves morale, increases employee engagement, and reduces the likelihood of safety-related incidents.

- Improved Communication and Collaboration: JHA facilitates communication and collaboration among workers, supervisors, and safety professionals. By involving all stakeholders in the identification and control of hazards, JHA promotes open dialogue and shared responsibility for safety. This leads to better coordination, increased trust, and a more cohesive working environment.

Overall, the implementation of JHA in construction sites yields numerous benefits. It ensures enhanced worker safety, improves project efficiency, promotes regulatory compliance, reduces costs, enhances risk management, fosters a safety culture, and facilitates better communication and collaboration among project stakeholders. By incorporating JHA into construction site practices, companies can create a safer working environment, protect their workers, and achieve successful project outcomes.

Examples of Successful Implementation of JHA in Construction Projects

The successful implementation of Job Hazard Analysis (JHA) in construction projects has been demonstrated in various real-world scenarios. These examples highlight the positive impact of JHA in ensuring worker safety and improving project outcomes. Here are a few notable examples:

- The Golden Gate Bridge Construction: During the construction of the iconic Golden Gate Bridge in San Francisco, JHA played a critical role in maintaining worker safety. JHA helped identify potential hazards, such as working at heights, crane operations, and working on steel structures. The JHA process allowed for the implementation of effective control measures, including fall protection systems, proper rigging procedures, and ongoing safety training. As a result, the project was completed with minimal accidents, ensuring the safety of the workers involved in this complex construction endeavor.

- High-Rise Building Construction: In the construction of high-rise buildings, JHA has proven to be instrumental in mitigating risks associated with working at heights, heavy machinery operations, and material handling. By conducting JHA, construction companies have successfully identified hazards and implemented control measures such as guardrails, safety harnesses, and crane safety protocols. This has significantly reduced the occurrence of falls, crane-related incidents, and other construction site accidents, leading to improved worker safety and smoother construction operations.

- Industrial Plant Construction: In industrial plant construction, JHA has been vital in ensuring worker safety in challenging and potentially hazardous environments. By conducting a thorough JHA, companies have identified and controlled hazards such as chemical exposures, respiratory risks, confined spaces, and machinery-related dangers. The implementation of control measures, such as personal protective equipment, ventilation systems, and lockout/tagout procedures, has resulted in a safer working environment and minimized the risk of accidents and occupational illnesses.

- Road Construction Projects: Road construction projects involve various hazards, including working near traffic, operating heavy equipment, and trenching. JHA has been successfully employed to address these hazards and protect workers. Through JHA, companies have implemented control measures such as traffic management plans, proper equipment operation training, and trenching safety procedures. These measures have significantly reduced the risk of accidents, injuries, and fatalities, ensuring the safety of workers and improving the overall efficiency of road construction projects.

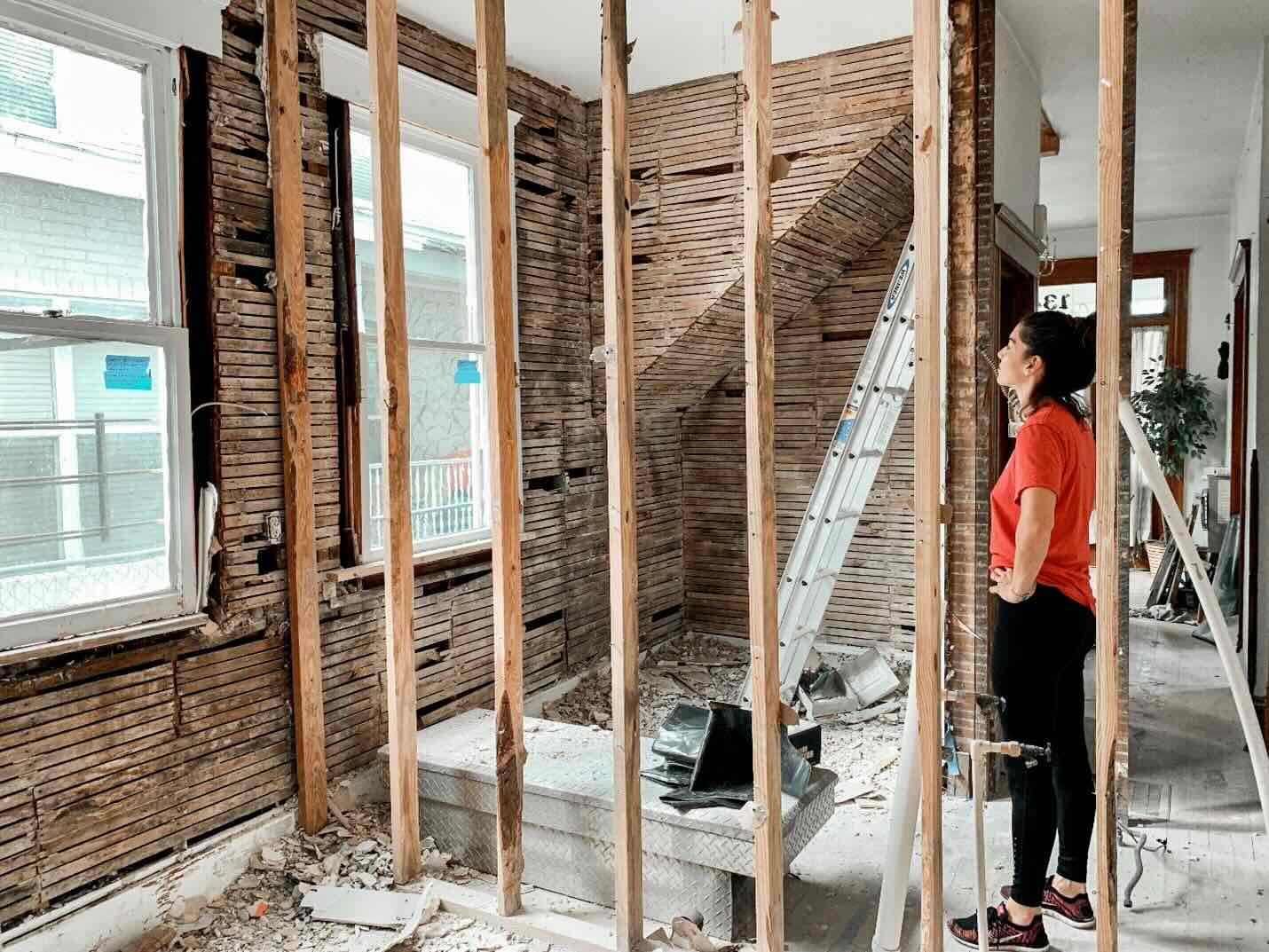

- Demolition and Remodeling Projects: In demolition and remodeling projects, JHA has proven indispensable in ensuring worker safety amid potentially hazardous conditions. JHA helps identify and assess risks associated with structural instability, exposure to hazardous materials, and unsafe working conditions. By implementing control measures such as structural shoring, proper personal protective equipment, and thorough asbestos abatement procedures, companies have successfully conducted these projects while prioritizing worker safety and minimizing health risks.

These examples highlight the successful implementation of JHA in various construction projects. By integrating JHA into construction site practices, companies can effectively identify and control hazards, ensure worker safety, and achieve project success.

Read more: What Is Construction

Conclusion

Job Hazard Analysis (JHA) is a crucial process in the construction industry that plays a vital role in ensuring worker safety, improving project efficiency, and minimizing risks. By proactively identifying and assessing potential hazards, construction companies can implement effective control measures and create a safer work environment.

The benefits of using JHA in construction sites are significant. JHA enhances worker safety by preventing accidents and injuries, promotes compliance with safety regulations, and reduces costs associated with workplace incidents. It also contributes to improved project efficiency, risk management, and the development of a safety-conscious culture within construction companies.

The implementation of JHA in construction projects involves several key components, including task identification, hazard identification, risk assessment, and the implementation of control measures. Regular review and revision are essential to keep JHAs up to date. Overcoming challenges such as lack of awareness, time constraints, and communication barriers is crucial to successfully implementing JHA.

Successful examples of JHA implementation in construction projects demonstrate its efficacy in safeguarding workers and achieving project success. These examples range from iconic bridge constructions to high-rise buildings, industrial plants, road projects, and demolition endeavors. By conducting JHA and implementing appropriate control measures, construction companies have successfully minimized accidents, injuries, and health risks.

In conclusion, the use of JHA in construction is not just a regulatory requirement but a critical practice that prioritizes worker safety, drives project efficiency, and protects construction companies from legal liabilities. By integrating JHA into construction site practices, companies can create a safer work environment, ensure compliance with safety regulations, and achieve successful project outcomes.

Frequently Asked Questions about What Is Jha In Construction

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is Jha In Construction”