Home>diy>Building & Construction>What Is MDF Construction Material

Building & Construction

What Is MDF Construction Material

Modified: January 3, 2024

Learn about MDF, a popular building construction material. Find out what MDF is, how it's made, and its advantages in construction projects.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of construction, where materials play a vital role in determining the strength, durability, and aesthetics of buildings. One such material that has gained significant popularity in recent years is Medium Density Fiberboard (MDF).

MDF is a versatile and cost-effective construction material that has revolutionized the way we build and design structures. In this article, we will explore the ins and outs of MDF, from its definition and manufacturing process to its advantages and disadvantages in construction projects. We will also delve into its various applications, maintenance requirements, and its environmental impact.

So, whether you are a builder, architect, or simply someone interested in the construction industry, buckle up and join us on this journey to discover the wonders of MDF construction material.

Key Takeaways:

- MDF, a medium density fiberboard, offers stability, durability, and versatility in construction. Its uniform surface, easy finishing, and environmental sustainability make it a popular choice for interior applications.

- While MDF has advantages such as cost-effectiveness and design flexibility, it requires careful maintenance due to its moisture sensitivity. Understanding its properties and limitations is crucial for informed material selection in construction projects.

Read more: What Does MDF Stand For In Construction

Definition of MDF Construction Material

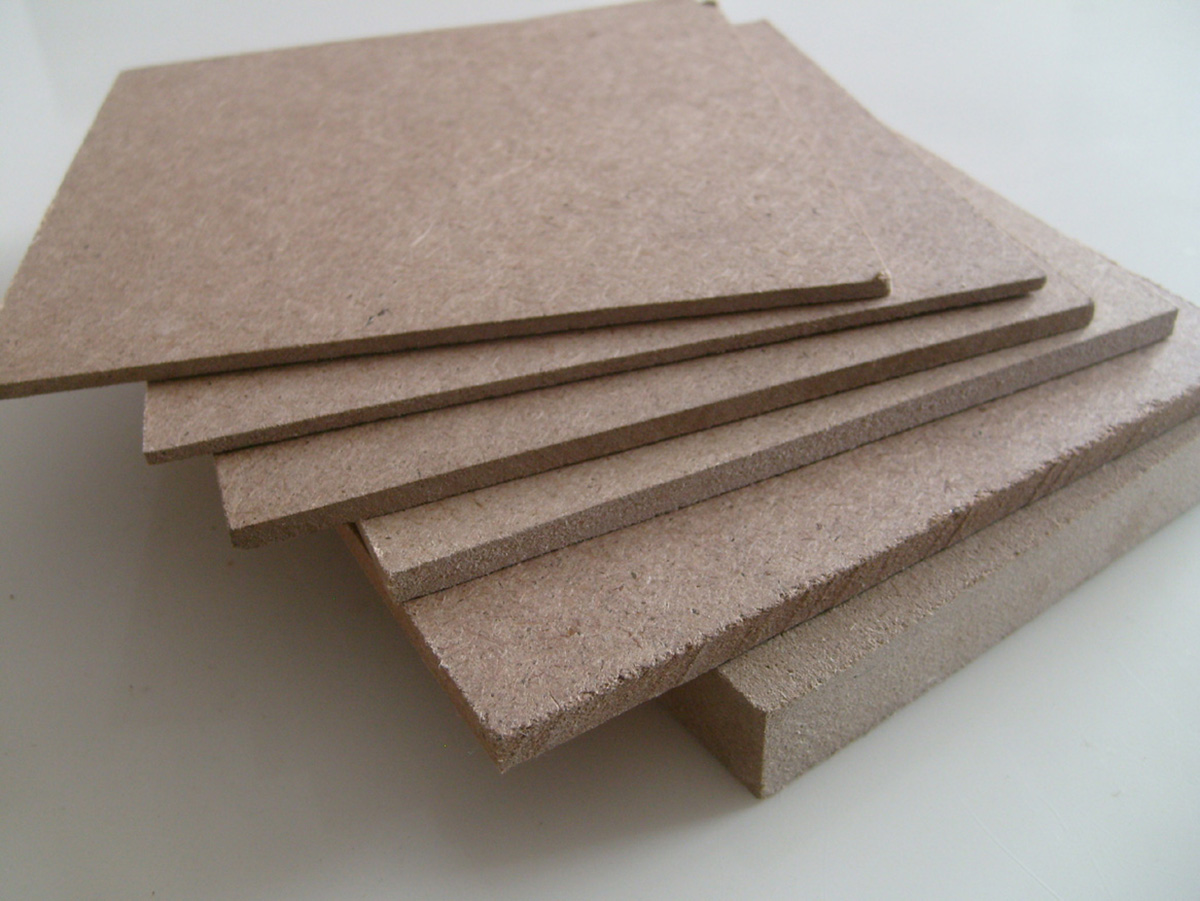

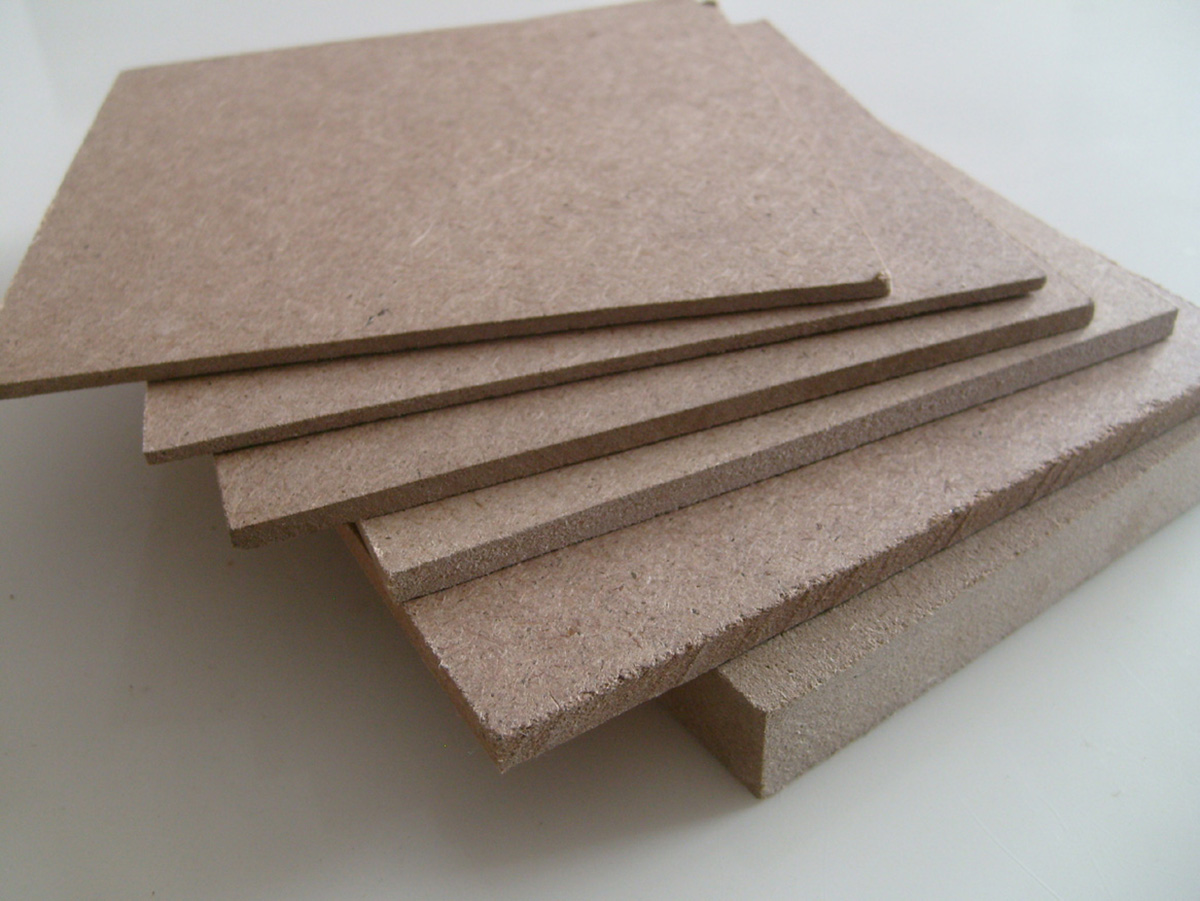

Medium Density Fiberboard (MDF) is an engineered wood product made from compressed wood fibers. It is composed of small wood particles and adhesive resin that are bonded together under high pressure and heat. The result is a dense, uniform panel that is free from defects commonly found in natural wood, such as knots or grain inconsistencies.

MDF is known for its excellent strength and stability, making it an ideal choice for construction applications. Unlike solid wood, which can shrink, expand, or warp due to changes in temperature and humidity, MDF remains dimensionally stable, ensuring that structures and furniture made from it maintain their shape over time.

One of the defining characteristics of MDF is its medium density. It falls between the lower density of particleboard and the higher density of solid wood. The density of MDF ranges from 600-800 kg/m³, which contributes to its strength while still allowing for easy cutting, shaping, and finishing.

In terms of appearance, MDF has a smooth and uniform surface, making it an ideal substrate for finishes such as paint, laminate, or veneer. It can also be easily machined, allowing for intricate designs and detailing.

It is important to note that MDF is not suitable for outdoor use or areas with high moisture content, as it is susceptible to swelling and eventual damage. However, with proper treatment and usage, MDF can excel in a wide range of indoor construction applications.

Now that we have established the definition and basic characteristics of MDF, let’s delve deeper into its manufacturing process to understand how this versatile material is produced.

Manufacturing Process of MDF

The manufacturing process of Medium Density Fiberboard (MDF) involves several key steps to transform wood fibers into a sturdy and versatile construction material. The process typically includes the following stages:

- Raw Material Preparation: The first step involves the collection and preparation of raw materials. Wood chips or residuals from sawmills and manufacturing operations are commonly used. The wood is debarked, and any contaminants, such as dirt or metal, are removed.

- Fiber Production: The debarked wood is then fed into a chipper, which breaks it down into small chips. These chips are further reduced in size using a grinder or hammer mill. The resulting fibers are then screened to remove oversized particles.

- Blending: The wood fibers are mixed with resin, typically a synthetic adhesive such as urea-formaldehyde or phenol-formaldehyde. This adhesive helps bind the fibers together during the pressing process.

- Forming: The wood fiber-resin mixture is spread onto a forming line, where it is evenly distributed and compacted. The addition of wax or other additives may occur during this stage to enhance moisture resistance or improve the final properties of the MDF.

- Hot Pressing: The formed fiber mat is then transferred to a hot press. The press applies heat and pressure to the mat, causing the resin to cure and the fibers to bond together. The press time and temperature are carefully controlled to ensure proper consolidation and curing of the MDF.

- Finishing: Once the pressing process is complete, the MDF panels are trimmed to the desired sizes and thicknesses. The edges may be profiled or machined as per the specific requirements. The surface of the MDF is typically sanded to achieve a smooth finish.

- Testing and Quality Control: Before the MDF panels are packaged and transported, quality control tests are performed to ensure they meet the required standards. These tests may include checks for thickness, density, moisture content, and dimensional stability.

The entire manufacturing process of MDF is conducted in a controlled environment to ensure consistent quality and performance. It is important to note that different manufacturers may have variations in their specific techniques and additives used, resulting in variations in the final product.

Now that we have explored the manufacturing process of MDF, let’s move on to discuss the properties and characteristics of this construction material.

Properties and Characteristics of MDF

Medium Density Fiberboard (MDF) possesses a range of properties and characteristics that make it a desirable construction material. Understanding these properties can help builders, designers, and architects make informed decisions about its usage in various projects. Here are some key properties and characteristics of MDF:

- Density: As the name suggests, MDF has a medium density, typically ranging from 600-800 kg/m³. This density contributes to its strength and stability, making it suitable for a variety of applications.

- Strength: MDF offers excellent strength and durability, thanks to the bonding of wood fibers with adhesive resin during the manufacturing process. It has good load-carrying capacity, making it suitable for load-bearing applications such as cabinets, shelves, and furniture.

- Dimensional Stability: Unlike solid wood, which can expand or contract with changes in temperature and humidity, MDF remains dimensionally stable. This stability ensures that structures and furniture made from MDF maintain their shape and size over time, reducing the risk of warping or distortion.

- Machinability: MDF is easy to cut, shape, and machine due to its uniform composition. It can be drilled, routed, and carved into intricate designs and profiles. However, it is important to note that MDF produces fine dust when cut or machined, so appropriate safety measures should be taken to avoid inhalation.

- Finishing Capabilities: MDF has a smooth and consistent surface, making it an ideal substrate for various finishes. It accepts paint, laminate, veneer, and other coatings with ease, allowing for customization and a wide range of design possibilities.

- Sound and Thermal Insulation: MDF has inherent acoustic and thermal insulation properties. Its composition helps absorb sound waves, reducing noise transmission between rooms. Additionally, MDF acts as a thermal insulator, helping to maintain comfortable indoor temperatures.

- Affordability: MDF is generally more affordable than solid wood, making it a cost-effective choice for construction projects. It offers a balance between quality, performance, and price, making it accessible for various budgets.

It is important to note that while MDF offers many advantages, it also has some limitations and considerations that should be taken into account. In the next section, we will discuss the advantages and disadvantages of MDF in construction.

Advantages of MDF in Construction

Medium Density Fiberboard (MDF) is a highly versatile construction material that offers numerous advantages for builders, designers, and architects. Let’s explore some of the key advantages of using MDF in construction projects:

- Stability and Durability: One of the greatest advantages of MDF is its outstanding stability and durability. Unlike solid wood, MDF is less prone to warping, shrinking, or swelling when exposed to changes in temperature and humidity. This ensures that structures and furniture made from MDF maintain their integrity over time.

- Consistency: MDF has a uniform composition, free from knots, grains, or other natural defects found in solid wood. This consistency allows for precise cutting, shaping, and machining, making it easier to achieve the desired design and aesthetics.

- Easy Finishing: The smooth and consistent surface of MDF allows for effortless finishing. It readily accepts paints, laminates, veneers, and other coatings, offering endless design possibilities. Finishes can be applied evenly, resulting in a professional and polished appearance.

- Cost-Effective: MDF is generally more affordable than solid wood, making it a cost-effective choice for construction projects. Its availability, consistent quality, and competitive pricing make it accessible for a wide range of budgets.

- Design Flexibility: MDF’s machinability and uniform composition make it ideal for intricate designs and detailing. It can be easily routered, carved, and shaped to create customized elements and unique architectural features.

- Environmental Considerations: MDF is considered an environmentally friendly alternative to solid wood. It is made from recycled wood fibers and does not contribute to deforestation. Additionally, the manufacturing process of MDF utilizes wood residuals that would otherwise go to waste.

- Sound and Thermal Insulation: Due to its dense composition, MDF offers excellent sound and thermal insulation properties. It helps absorb sound waves, reducing noise transmission between rooms. Additionally, it acts as a thermal insulator, contributing to energy efficiency and maintaining comfortable indoor temperatures.

These advantages make MDF a popular choice in various construction applications, including cabinetry, furniture, shelving, interior trim, and architectural detailing. However, it is important to weigh the advantages against any potential disadvantages, which we will explore in the next section.

Read more: How To Seal Mdf For Outdoor Use

Disadvantages of MDF in Construction

While Medium Density Fiberboard (MDF) offers several advantages, it is essential to consider its potential disadvantages when using it in construction projects. Here are some key factors to keep in mind:

- Moisture Sensitivity: MDF is highly susceptible to moisture and water damage. It can swell, warp, and deteriorate when exposed to high levels of humidity or direct water contact. Therefore, using MDF in areas prone to moisture, such as kitchens, bathrooms, or outdoor applications, is not recommended without appropriate sealing or protection.

- Strength Limitations: While MDF is known for its good load-carrying capacity, it is not as structurally strong as solid wood. It may not be suitable for heavy-load applications or areas where extreme strength is required.

- Environmental Concerns: MDF is manufactured using adhesive resins that may contain formaldehyde, a volatile organic compound (VOC). These emissions can contribute to indoor air pollution. It is important to choose MDF products with low formaldehyde content or opt for alternative materials for sensitive environments.

- Fire Hazard: MDF is highly combustible and can contribute to the spread of fires. It releases toxic gases and smoke when burned. Therefore, proper fire safety measures should be taken when using MDF in construction, such as applying fire-resistant coatings or using fire-retardant additives.

- Handling and Dust Safety: MDF produces fine dust particles when cut or machined. These particles can be harmful when inhaled, causing respiratory issues. It is crucial to take appropriate safety measures, such as wearing protective masks and using dust collection systems, to minimize the risk of dust-related health hazards.

- Limited Outdoor Use: Due to its moisture sensitivity and lack of natural resistance to weather elements, MDF is not recommended for outdoor applications. Exposure to sunlight, rain, and temperature fluctuations can cause significant damage to MDF structures or furniture.

By considering and addressing these potential disadvantages, builders and designers can make informed decisions about the appropriate usage of MDF in construction projects. It is important to assess the specific requirements, environmental conditions, and desired performance of the material before incorporating MDF into any construction project.

Now that we have discussed the advantages and disadvantages of MDF, let’s explore the common applications of this versatile construction material.

When working with MDF (medium-density fiberboard) construction material, it’s important to wear a mask and work in a well-ventilated area to avoid inhaling harmful dust particles. Additionally, use proper cutting and sanding techniques to prevent splintering and create a smooth finish.

Common Applications of MDF in Construction

Medium Density Fiberboard (MDF) is widely utilized in the construction industry due to its versatility and range of applications. Let’s explore some of the common uses of MDF:

- Cabinetry and Furniture: MDF is a popular choice for cabinetry and furniture construction. It can be easily shaped, routed, and finished to create custom designs and intricate details. MDF panels are used for cabinet doors, shelves, table tops, and various furniture components.

- Interior Wall Paneling: MDF panels are widely used for interior wall paneling due to their smooth surface and ability to take a variety of finishes. They provide a cost-effective alternative to solid wood paneling and add a sleek and contemporary look to interior spaces.

- Architectural Millwork: MDF is often used in architectural millwork applications such as baseboards, crown moldings, and window casings. Its consistency and ease of machining make it ideal for creating uniform and detailed profiles.

- Doors and Door Frames: MDF is commonly used for interior doors and door frames. It provides a smooth and stable surface that can be painted or veneered to match any interior design style. MDF door frames offer a cost-effective alternative to solid wood frames.

- Shelving and Storage Units: MDF is widely used for constructing shelves and storage units due to its strength and stability. It provides a reliable and long-lasting solution for organizing spaces, whether in residential or commercial settings.

- Store Fixtures and Displays: MDF is a popular material for store fixtures and displays in retail environments. It can be easily customized to create eye-catching designs and provide a durable solution for showcasing merchandise.

- Exhibition Stands: MDF is frequently used in exhibition stands and trade show displays. Its machinability allows for the creation of complex structures and unique designs, while its smooth surface provides an excellent canvas for branding and graphics.

- DIY and Craft Projects: MDF is a favored material for DIY enthusiasts and crafters due to its affordability and ease of use. It can be cut, painted, and decorated to create various decorative items, storage solutions, or personalized gifts.

These are just a few examples of the wide range of applications of MDF in the construction industry. Its versatility, cost-effectiveness, and ability to take finishes make it a popular choice for numerous projects. However, it is essential to consider the specific requirements and limitations of MDF for each application.

Now that we have explored the common applications of MDF, let’s move on to discuss the maintenance and care required for this construction material.

Maintenance and Care for MDF

Maintaining and caring for Medium Density Fiberboard (MDF) is crucial to ensure its longevity and appearance over time. While MDF is a durable material, it requires proper maintenance and consideration of certain factors. Here are some guidelines for maintaining and caring for MDF:

- Protection from Moisture: As mentioned earlier, MDF is highly sensitive to moisture. It is essential to protect MDF surfaces from direct water contact or high humidity levels. Avoid using MDF in areas prone to moisture, such as bathrooms or kitchens. If MDF comes into contact with water, dry it promptly to prevent swelling or warping.

- Sealing and Coating: To enhance the moisture resistance of MDF, it is recommended to seal or coat its surfaces. Apply a suitable primer or sealant to the edges and surfaces before applying paint or other finishes. This helps reduce the absorption of moisture and increases the lifespan of MDF.

- Preventing Scratches and Dents: While MDF has a smooth and uniform surface, it is still susceptible to scratches and dents. Avoid dragging or sliding heavy objects across MDF surfaces, as this can leave permanent marks. Place protective pads or coasters under furniture legs to minimize the risk of damage.

- Regular Cleaning: Keep MDF surfaces clean and free from dust and dirt. Use a soft, damp cloth or a mild cleaning solution to wipe the surfaces gently. Avoid using abrasive materials or harsh chemicals that can damage the finish or penetrate the MDF surface.

- Avoiding Extreme Temperatures: MDF should be kept in an environment with stable temperature and humidity levels. Avoid exposing MDF surfaces to direct sunlight, excessive heat, or extreme cold, as these conditions can cause the material to expand or contract, leading to damage.

- Handling with Care: When working with MDF, handle it with care to avoid chipping or breaking. Use appropriate lifting techniques and tools to prevent accidents. Ensure that sharp edges and corners are adequately protected during transportation and installation.

- Repairing Minor Damage: In the event of minor damage, such as scratches or dents, these can be repaired using wood fillers or appropriate touch-up paints. Follow the manufacturer’s instructions and match the color and finish as closely as possible.

By following these maintenance guidelines, you can prolong the life of MDF and keep it looking its best. It is important to note that specific care instructions may vary depending on the specific finish or coating applied to the MDF surface. Always refer to the manufacturer’s recommendations for the best care practices.

Now that we have discussed the maintenance and care for MDF, let’s move on to compare MDF with other construction materials.

Comparisons between MDF and Other Construction Materials

When it comes to construction materials, Medium Density Fiberboard (MDF) offers unique characteristics and advantages compared to other commonly used materials. Let’s compare MDF with some popular construction materials:

- Solid Wood: While solid wood is renowned for its beauty and natural appeal, it can be expensive and prone to warping or shrinking when exposed to changes in humidity. MDF, on the other hand, is more affordable, dimensionally stable, and provides a consistent surface without knots or imperfections.

- Plywood: Plywood is composed of thin veneer layers bonded together, creating a strong and versatile panel. MDF, on the other hand, is made of wood fibers and adhesive resin. While plywood offers better strength and may be more suitable for structural applications, MDF excels in terms of stability, consistency, and ability to take finishes.

- Particleboard: Particleboard is made from small wood particles bonded together with resin. It is generally less expensive than MDF but has lower density and may lack the strength and stability of MDF. MDF offers better screw-holding capability, machinability, and overall durability.

- High-Density Fiberboard (HDF): HDF is similar to MDF but has a higher density and strength. It is often used for applications where increased durability and load-bearing capacity are required, such as door skins or heavy-duty furniture. MDF, being medium density, offers a balance of strength and ease of handling.

- Gypsum Board (Drywall): Gypsum board is a widely used interior wall material due to its fire-resistance and ease of installation. However, MDF is often preferred for applications that require customization, such as wall paneling or architectural millwork. MDF offers a smoother surface for finishes and better dimensional stability.

Each material has its own set of advantages and disadvantages, and the choice ultimately depends on the specific needs and requirements of the construction project. MDF excels in terms of consistency, machinability, and finishing capabilities, making it a popular choice for interior applications where aesthetics and customization are crucial.

However, it is important to consider factors such as budget, environmental impact, moisture resistance, and load-bearing requirements when making a material selection. Consulting with professionals and considering the specific project needs will help determine the most suitable material for the job.

Having explored the comparisons between MDF and other construction materials, let’s move on to discuss the environmental impact and sustainability of MDF.

Read more: What Is TPO Roof

Environmental Impact and Sustainability of MDF

As environmental concerns continue to grow, it is essential to consider the impact of construction materials on sustainability and the environment. Medium Density Fiberboard (MDF) has both positive and negative aspects in terms of its environmental impact. Let’s delve into the sustainability considerations of MDF:

Use of Recycled Materials: MDF is often made using wood residuals from sawmills and manufacturing operations. These residuals would otherwise be discarded as waste. By utilizing these by-products, MDF reduces the amount of wood waste sent to landfills, making it a more sustainable option compared to using virgin wood for construction purposes.

Reduced Deforestation: Unlike solid wood, which requires cutting down trees, MDF can be produced without further contributing to deforestation. By using recycled wood fibers and residues, MDF helps minimize the demand for new timber resources, helping to preserve forest ecosystems.

Energy Consumption: The manufacturing process of MDF involves the use of high pressure and heat, which requires energy. However, advancements in technology have helped reduce energy consumption in the production of MDF. Manufacturers are implementing energy-efficient practices and utilizing renewable energy sources to minimize their carbon footprint.

Formaldehyde Emissions: One environmental concern associated with MDF is the potential release of formaldehyde. Formaldehyde is a volatile organic compound (VOC) that can contribute to indoor air pollution and have health effects. However, many manufacturers have taken steps to reduce formaldehyde emissions by using low-emitting adhesives or implementing formaldehyde emission standards.

Recyclability and Biodegradability: MDF, although durable, is not biodegradable. However, it can be recycled and used in the production of other wood-based products. Proper management of waste MDF ensures that it does not end up in landfills and can be repurposed or recycled.

It is important to note that while MDF has positive sustainability aspects, care must be taken to address its limitations. Proper disposal and recycling of waste MDF, as well as the use of low-emitting adhesives, can further enhance its environmental performance.

Builders, architects, and consumers can contribute to the sustainability of MDF by choosing products from manufacturers committed to eco-friendly practices, such as using recycled materials, reducing emissions, and implementing responsible sourcing of wood fibers.

Now that we have discussed the environmental impact and sustainability considerations of MDF, let’s conclude our exploration of this versatile construction material.

Conclusion

Medium Density Fiberboard (MDF) has significantly impacted the construction industry, offering a versatile and cost-effective alternative to traditional materials. Throughout this article, we have explored the definition, manufacturing process, properties, advantages, and disadvantages of MDF in construction.

MDF’s medium density, stability, and uniform surface make it ideal for a wide range of applications, including cabinetry, furniture, wall paneling, and architectural millwork. Its machinability and excellent finishing capabilities allow for intricate designs and customization, enhancing the aesthetics of any project.

While MDF offers numerous advantages, it does come with some considerations. Its sensitivity to moisture, potential for formaldehyde emissions, and limited strength for certain applications are important factors to keep in mind when choosing to use MDF.

Proper maintenance and care, such as protecting MDF from moisture, using appropriate coatings, and handling it with care, can help maximize its lifespan and ensure its appearance over time.

In terms of sustainability, MDF demonstrates positive attributes through its use of recycled materials, reduced deforestation, and recyclability. Manufacturers’ efforts to reduce energy consumption and formaldehyde emissions contribute to its overall environmental impact.

As with any construction material, it is crucial to weigh the advantages and disadvantages of MDF based on the specific requirements, environmental factors, and budget of a project. Consultation with professionals and adherence to sustainable practices can help make informed decisions and contribute to a more eco-friendly construction industry.

In conclusion, Medium Density Fiberboard (MDF) has revolutionized construction through its versatility, stability, and cost-effectiveness. As the demand for sustainable and customizable materials continues to grow, MDF offers a valuable solution for builders, designers, and architects in creating functional and visually appealing spaces.

Frequently Asked Questions about What Is MDF Construction Material

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is MDF Construction Material”