Home>diy>Building & Construction>What Is Scaffolding Construction

Building & Construction

What Is Scaffolding Construction

Modified: December 7, 2023

Learn about the importance of scaffolding in building construction, including its functions, types, and safety considerations. Discover how scaffolding ensures a secure and efficient construction process.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

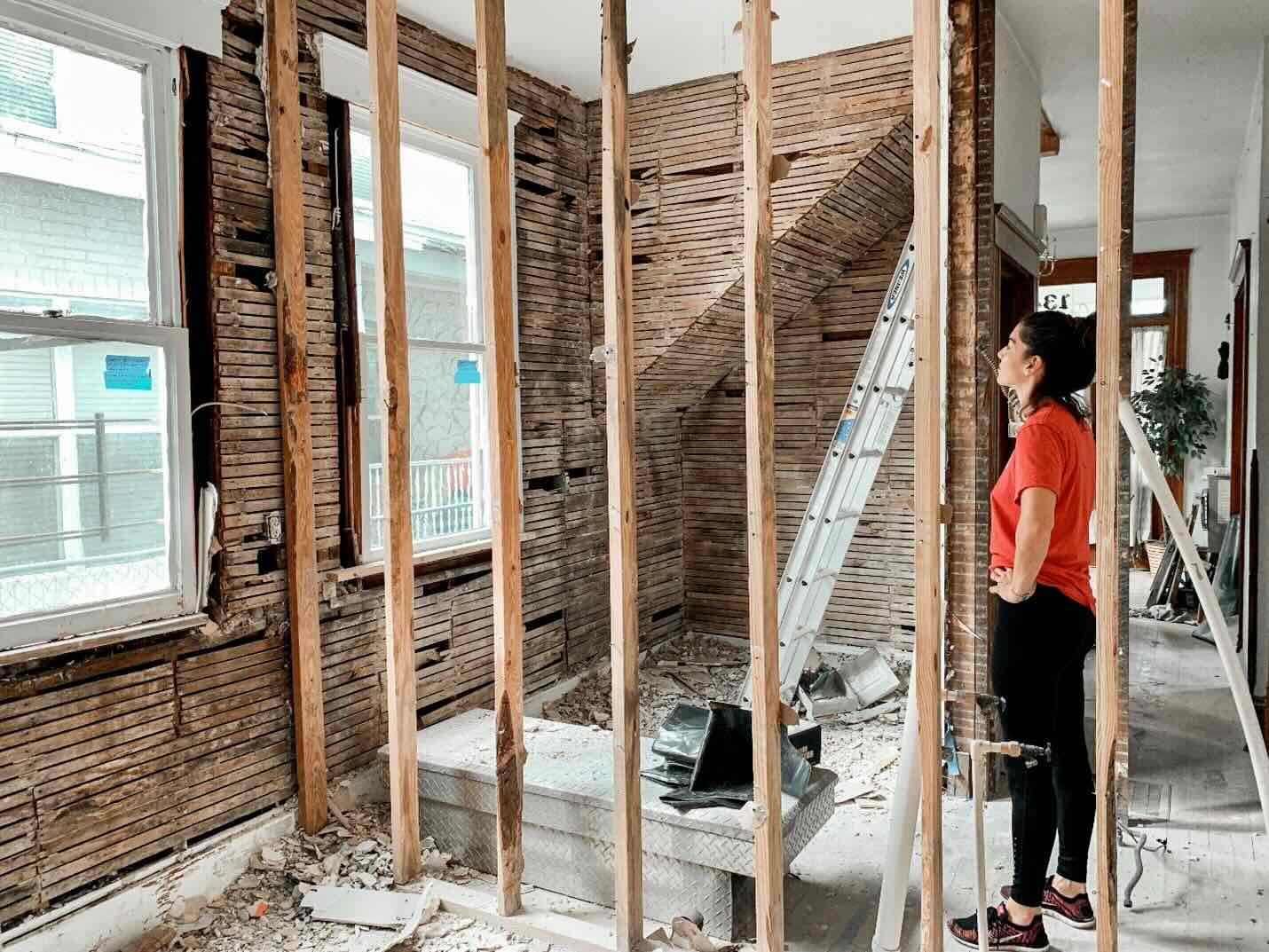

Scaffolding construction is an essential aspect of the building industry and plays a crucial role in ensuring the safe and efficient completion of construction projects. It involves the temporary structure and support system erected around buildings to provide a stable working platform for workers and materials during construction, repair, or maintenance activities. Scaffolding serves as a vital tool for workers to access elevated areas that are otherwise difficult or impossible to reach.

In the world of construction, safety is paramount, and scaffolding provides the necessary support and stability for workers to perform their tasks with confidence. It not only ensures the safety of workers but also enhances productivity by facilitating easy access to different parts of a building. Scaffolding construction requires a deep understanding of building structures, safety regulations, and the proper use of tools and equipment.

In this article, we will explore the definition of scaffolding construction, the various types of scaffolding, the components involved, the tools and equipment used, the construction process, safety measures, common issues and challenges faced, as well as the regulations and standards that govern this important aspect of the building industry.

Whether you are a construction professional, an aspiring builder, or simply curious about the world of construction, this article will provide you with valuable insights into the fascinating process of scaffolding construction.

So, let’s delve into the world of scaffolding construction and discover the key concepts and practices that make it an integral part of the building process.

Key Takeaways:

- Scaffolding construction is crucial for worker safety and efficient building projects, requiring proper planning, adherence to safety measures, and compliance with industry standards to ensure stability and reliability.

- Understanding the various types of scaffolding, key components, and safety measures is essential for successful scaffolding construction, contributing to a safe working environment and the completion of construction projects.

Read more: What Is A Ladder Jack Scaffold

Definition of Scaffolding Construction

Scaffolding construction refers to the process of erecting temporary platforms, frameworks, or structures around buildings to provide support and a safe working platform for workers during construction, renovation, or maintenance tasks. It is an essential component of the construction industry, enabling workers to access and work on elevated areas that are out of reach or difficult to reach using conventional means.

The primary purpose of scaffolding construction is to ensure the safety of workers and facilitate efficient completion of construction projects. Scaffolding structures are designed to be strong, stable, and durable, capable of supporting the weight of workers, tools, and materials. These structures are typically made of steel or aluminum and consist of various components, such as pipes, tubes, clamps, and platforms.

Scaffolding construction involves careful planning, design, and implementation to ensure that the scaffold meets the specific requirements of the project. Factors such as the height and shape of the building, the nature of the work to be carried out, and local regulations need to be considered during the construction process.

The main objectives of scaffolding construction are:

- Providing a stable working platform: Scaffolding structures offer a secure and stable platform for workers to perform their tasks at various heights and positions.

- Facilitating safe access: Scaffolding provides safe and easy access to different levels of a building, eliminating the need for dangerous alternatives such as ladders or unstable makeshift arrangements.

- Supporting materials and equipment: Scaffolding systems enable workers to transport and store materials and tools at elevated positions, enhancing productivity and efficiency.

- Ensuring worker safety: Properly constructed scaffolding reduces the risk of falls, accidents, and injuries, as it provides a stable and secure working environment.

- Promoting efficient workflow: Scaffolding construction allows workers to move freely and access different areas of a building, enabling them to complete tasks more quickly and effectively.

Overall, scaffolding construction is a critical component of the building industry, ensuring worker safety, enhancing productivity, and enabling smooth construction operations. With proper planning, design, and implementation, scaffolding structures become reliable and indispensable tools in the construction process.

Types of Scaffolding

Scaffolding construction utilizes various types of scaffolding, each designed for specific purposes and tailored to meet the requirements of different construction projects. These scaffolding types differ in their structure, material, and configuration. Let’s explore some of the most common types of scaffolding:

- Supported Scaffolding: Supported scaffolding is the most commonly used type of scaffolding. It consists of a series of vertical and horizontal members supported by rigid supports, such as poles or frames. The horizontal members, known as ledgers and transoms, provide a platform for workers to stand on and support the weight of the structure.

- Suspended Scaffolding: Suspended scaffolding, as the name suggests, is suspended from an overhead structure, such as a roof or building facade, using ropes or chains. This type of scaffolding is often used for tasks like window washing or exterior painting. Workers can lower or raise the scaffolding to access different levels of a building. Suspended scaffolding offers flexibility and adaptability to different building heights and configurations.

- Mobile Scaffolding: Mobile scaffolding, also known as rolling scaffolding or tower scaffolding, is a versatile option that features wheels or casters at the base. It allows for easy movement from one location to another, providing flexibility in terms of access and mobility on construction sites. Mobile scaffolding is commonly used for tasks that require frequent relocation, such as interior finishing or maintenance work.

- Cantilever Scaffolding: Cantilever scaffolding is designed to provide access to hard-to-reach areas or structures, such as bridges or tall buildings. It consists of a horizontal platform that is supported at one end by needles or beams extending from the building or structure. The other end of the platform remains unsupported, relying on counterweights and anchors for stability.

- System Scaffolding: System scaffolding, also known as modular scaffolding, is a versatile and customizable scaffolding system that utilizes pre-engineered components. These components, such as frames, braces, and connectors, can be quickly assembled and disassembled, offering efficiency and ease of use. System scaffolding is commonly used for large-scale construction projects or in situations where flexibility and speed are crucial.

- Tube and Coupler Scaffolding: Tube and coupler scaffolding is a traditional and widely used type of scaffolding construction. It consists of steel tubes that are connected using couplers or clamps to create a sturdy framework. This type of scaffolding offers versatility and strength, making it suitable for various construction tasks, including building maintenance, renovation, and repair.

Each type of scaffolding offers unique advantages and is suitable for specific construction scenarios. The choice of scaffolding type depends on factors such as the nature of the project, building height, access requirements, and safety considerations. Proper understanding and selection of the appropriate scaffolding type are crucial to ensure the safety and efficiency of construction operations.

Components of Scaffolding

Scaffolding construction involves the assembly and integration of various components to create a stable and secure working platform for workers. Each component has a specific role and contributes to the overall strength and functionality of the scaffolding structure. Let’s explore some of the key components commonly used in scaffolding construction:

- Standards: Standards, also known as uprights or verticals, are vertical tubes or poles that form the vertical framework of the scaffolding structure. They are responsible for providing overall stability and support to the scaffolding system.

- Ledgers: Ledgers, also known as horizontal tubes or transoms, are horizontal members that connect the standards together. They provide additional support and stability to the scaffolding structure. Ledgers are placed horizontally at right angles to the standards.

- Braces: Braces are diagonal members that connect the standards and ledgers. They enhance the rigidity and strength of the scaffolding structure by providing lateral support and preventing swaying or collapsing. Braces are placed diagonally between the standards and ledgers.

- Platforms: Platforms, also known as scaffold boards or walkboards, are flat surfaces that provide a safe working area for workers. They are made of wood, metal, or composite materials and are placed horizontally across the ledgers to form the working platform.

- Base Plates: Base plates are flat plates that provide stability and prevent the scaffolding structure from sinking into the ground. They are placed under the standards and act as a solid foundation for the scaffolding system.

- Couplers: Couplers, also known as clamps or fittings, are devices used to connect and secure the different components of the scaffolding structure. They ensure the stability and integrity of the scaffolding by providing a strong and reliable connection between the tubes or poles.

- Guardrails: Guardrails are horizontal bars or rails installed along the edges of the scaffolding platform to prevent workers from accidentally falling off. They provide an additional layer of safety and support, reducing the risk of accidents and injuries.

- Toeboards: Toeboards are horizontal barriers that are attached to the edge of the platform, below the guardrails. They prevent tools, materials, or debris from falling off the scaffolding and potentially causing harm to workers or bystanders.

- Access: Access components include ladders or stairs that allow workers to safely and easily climb up and down the scaffolding structure. They are designed to provide convenient and secure access to different levels of the scaffolding system.

These are just some of the fundamental components used in scaffolding construction. The specific configuration and arrangement of these components may vary depending on the type of scaffolding being used and the requirements of the project. It is important to ensure that all components are properly assembled, secured, and inspected to maintain a safe and functional scaffolding structure.

Tools and Equipment Used in Scaffolding Construction

Scaffolding construction requires the use of various specialized tools and equipment to ensure the proper assembly, installation, and disassembly of scaffolding structures. These tools and equipment are designed to enhance efficiency, safety, and accuracy during the construction process. Let’s explore some of the key tools and equipment commonly used in scaffolding construction:

- Scaffold Spanners: Scaffold spanners, also known as scaffold wrenches, are essential tools used to tighten and loosen couplers, fittings, and clamps in the scaffolding system. They ensure secure connections between components and help maintain the stability and integrity of the scaffolding structure.

- Scaffold Levels: Scaffold levels are devices used to check the horizontal and vertical alignment of the scaffolding structure. They ensure that the structure is level and plumb, preventing any leaning or instability that could compromise the safety and functionality of the scaffolding.

- Scaffold Ratchets and Belts: Scaffold ratchets and belts are used to secure platforms, materials, and tools to the scaffolding structure. They provide added safety by preventing accidental falls or objects from dislodging and causing potential hazards.

- Scaffold Tubes: Scaffold tubes, typically made of steel or aluminum, are integral components of scaffolding construction. They are used to create the vertical standards, horizontal ledgers, and diagonal braces that form the scaffolding framework. Scaffold tubes are available in various lengths and diameters to accommodate different scaffolding configurations.

- Scaffold Boards: Scaffold boards, also known as scaffold planks, are sturdy platforms that provide a safe working surface for workers. They are made of strong, durable materials, such as wood or aluminum, and are placed horizontally across the ledgers to create a stable and secure platform.

- Ladders: Ladders are indispensable tools in scaffolding construction as they enable workers to access different levels of the scaffolding system. Extension ladders are commonly used to reach higher sections, while step ladders are suitable for lower levels. Ladders should be properly secured and placed on stable ground or secured to the scaffolding structure to ensure safe and reliable climbing.

- Safety Harnesses and Lanyards: Safety harnesses and lanyards are personal protective equipment (PPE) used to prevent falls from elevated heights. They are worn by workers and attached to secure anchor points on the scaffolding structure, providing a lifeline in case of accidents. Safety harnesses and lanyards are essential for ensuring the safety of workers working at heights.

- Scaffold Ties: Scaffold ties are used to secure the scaffolding structure to the building or structure being worked on. They provide additional stability and prevent the scaffolding from swaying or collapsing. Scaffold ties should be properly designed, installed, and inspected to ensure the structural integrity of the scaffolding.

These are just a few examples of the tools and equipment used in scaffolding construction. Other equipment, such as hoists, pulleys, and lifting devices, may be required for specific scaffolding tasks, such as material handling or transporting heavy loads. It is important to use appropriate tools and equipment, follow safety guidelines, and receive proper training to ensure the efficient and safe construction of scaffolding structures.

When working with scaffolding, always ensure that it is properly erected, inspected, and maintained to prevent accidents and ensure safety for workers and the public.

Read more: How To Store Scaffolding

Scaffolding Construction Process

The scaffolding construction process involves several key steps to ensure the safe and efficient erection, use, and dismantling of scaffolding structures. These steps include planning, site preparation, assembly, inspection, and dismantling. Let’s explore each step in detail:

- Planning: The first step in scaffolding construction is meticulous planning. This involves assessing the requirements of the project, understanding the building’s structure and height, determining the type of scaffolding needed, and considering any specific safety or environmental concerns. Proper planning ensures that the scaffolding structure meets the needs of the project and adheres to relevant regulations.

- Site Preparation: Once the planning phase is complete, the construction site needs to be prepared for scaffolding installation. This involves clearing the area of any debris or obstacles that could hinder the scaffolding construction process. It may also involve leveling the ground or addressing any site-specific challenges.

- Assembly: The assembly phase involves erecting the scaffolding structure according to the predetermined plan. This typically starts with laying the base plates or leveling the ground surface to create a stable foundation. The vertical standards are then positioned and secured, followed by the horizontal ledgers. Braces, platforms, and other components are gradually added to complete the scaffolding structure. It is crucial to follow proper assembly techniques and secure each component tightly to ensure stability and safety.

- Inspection: After the scaffolding structure is fully assembled, it must be inspected to confirm its structural integrity and compliance with safety standards. A thorough inspection checks for proper assembly, secure connections, stability, and adequate bracing. This step ensures that the scaffolding is safe for use and will support the expected loads. Qualified personnel should conduct these inspections to identify any issues or hazards that need to be addressed before workers can access the scaffolding.

- Use and Maintenance: Once the scaffolding structure passes inspection, it is ready for use. Workers can now access elevated areas safely and efficiently to carry out their construction tasks. Regular maintenance, including inspecting for any signs of damage, monitoring weather conditions, and addressing any immediate safety concerns, is essential throughout the construction process. This ensures that the scaffolding remains safe and functional during the project’s duration.

- Dismantling: Finally, when the construction project is completed or the need for scaffolding no longer exists, the dismantling process begins. It involves systematically removing each component of the scaffolding structure in the reverse order of the assembly process. Care must be taken to ensure the safe disassembly of the scaffolding to prevent accidents or damage. Proper storage and maintenance of dismantled scaffolding components are also important for future reuse or disposal.

The scaffolding construction process requires careful planning, adherence to safety regulations, and proper installation techniques. By following these steps and regularly inspecting and maintaining the scaffolding structure, construction projects can proceed smoothly and safely, ensuring the well-being of workers and the successful completion of the project.

Safety Measures in Scaffolding Construction

Safety is of utmost importance in scaffolding construction to protect workers from potential hazards and ensure a secure working environment. Implementing appropriate safety measures is crucial to prevent accidents, reduce the risk of injuries, and maintain a safe construction site. Here are some essential safety measures to consider during scaffolding construction:

- Proper Training and Certification: All workers involved in scaffolding construction should receive adequate training on the safe assembly, use, and dismantling of scaffolding structures. They should be familiar with industry best practices, safety guidelines, and relevant regulations. Certification programs, such as the Scaffolding User and Inspector Training, can further enhance knowledge and competency in scaffolding safety.

- Site Evaluation and Planning: Before starting any scaffolding construction, conduct a thorough site evaluation to identify potential hazards and plan accordingly. Consider factors such as ground stability, overhead obstacles, nearby power lines, and weather conditions. Adequate planning ensures that the scaffolding structure is appropriately designed, erected, and used in a safe manner.

- Use of Proper Equipment: Ensure that appropriate tools, equipment, and materials are used throughout the scaffolding construction process. This includes reliable scaffold components, sturdy platform boards, secure anchoring systems, and personal protective equipment (PPE) such as safety harnesses, hard hats, and non-slip footwear.

- Regular Inspections: Regular inspections of the scaffolding structure are crucial to identify any defects or hazards that may compromise safety. Inspections should be conducted by competent personnel and should encompass all aspects of the scaffolding, including connections, platforms, guardrails, and tie-ins. Inspections should be carried out before initial use, after any modifications, and at regular intervals during prolonged use.

- Secure Assembly and Stability: Ensure that the scaffolding structure is securely assembled, with all components properly connected and tightened. Use appropriate bracing and ties to maintain stability, especially in tall or complex scaffolding arrangements. Regularly check for signs of movement, shifting, or instability and take immediate corrective action to rectify any issues.

- Fall Protection: Implement effective fall protection measures to prevent workers from falling from elevated heights. This includes the use of guardrails, toeboards, and safety nets to provide a secure working platform. Workers should also be equipped with and properly use personal fall protection systems, such as safety harnesses and lanyards, and be trained on their proper usage.

- Clear Communication: Maintain clear communication among workers involved in scaffolding construction. Ensure that everyone is aware of their roles and responsibilities, as well as any safety protocols or emergency procedures. Promote open dialogue and encourage reporting of any safety concerns or near-miss incidents.

- Adherence to Regulations and Standards: Familiarize yourself with and follow the relevant safety regulations, guidelines, and standards specific to scaffolding construction in your region. This includes standards such as OSHA (Occupational Safety and Health Administration) in the United States or NASC (National Access & Scaffolding Confederation) in the UK. Staying updated with the latest industry best practices helps ensure compliance and the highest level of safety.

By implementing these safety measures and maintaining a strong safety culture, the risks associated with scaffolding construction can be minimized. Regular training, thorough inspections, proper planning, and clear communication contribute to a safe working environment, protecting the well-being of workers and promoting successful scaffolding construction projects.

Common Issues and Challenges in Scaffolding Construction

Scaffolding construction, like any other construction activity, comes with its own set of challenges and potential issues. Being aware of these challenges and taking proactive measures to address them is crucial to ensure the smooth progress of the project and the safety of workers involved. Here are some common issues and challenges that can arise in scaffolding construction:

- Instability and Collapse: One of the primary concerns in scaffolding construction is ensuring the stability of the structure. Incorrect assembly, improper bracing, or inadequate anchoring can lead to scaffold collapse or instability. This can cause serious accidents and injuries. Regular inspections and adherence to proper assembly techniques are crucial in preventing such incidents.

- Falls and Falling Objects: Falls from heights and falling objects pose significant risks in scaffolding construction. Workers must be equipped with and trained to use personal fall protection equipment, such as safety harnesses and lanyards, to prevent falls. Proper barricades, guardrails, and toeboards should also be in place to protect workers below from falling objects.

- Inadequate Training and Competency: Lack of proper training and competency among workers involved in scaffolding construction can lead to safety hazards. It is essential to provide comprehensive training on scaffold assembly, inspection, and safe work practices to all workers involved. Regular refresher courses and ongoing supervision can further enhance competence and safety awareness.

- Poor Communication: Ineffective communication among team members can lead to misunderstandings, delays, and unsafe practices. Clear communication channels and protocols should be established to ensure that instructions, safety updates, and coordination among workers are effectively communicated.

- Weather Challenges: Adverse weather conditions, such as high winds, rain, or ice, can significantly impact scaffolding construction. It is important to monitor weather forecasts and take appropriate precautions, such as reinforcing the structure, suspending work during severe conditions, or implementing additional safety measures to counter weather-related challenges.

- Inadequate Planning: Insufficient planning and inadequate understanding of project requirements can lead to errors and delays in scaffolding construction. A comprehensive plan should consider factors such as the layout of the building, access requirements, and intended use to ensure the proper selection and assembly of the scaffolding structure.

- Material Quality and Inspections: The quality of scaffold components and regular inspections are vital in ensuring the reliability and safety of the structure. Poor-quality materials can compromise the strength and stability of the scaffold, while inadequate inspections can lead to undetected defects or wear and tear. Regular inspections and adherence to quality standards are crucial to identify and address any issues promptly.

- Obstacles and Restricted Access: In some construction sites, obstacles such as trees, power lines, or nearby buildings may restrict access or interfere with scaffold assembly. These challenges need to be carefully assessed and addressed through proper planning and coordination with relevant authorities or stakeholders.

By being aware of these common issues and challenges, stakeholders involved in scaffolding construction can take proactive measures to minimize risks and ensure a safe working environment. Proper planning, thorough inspections, adequate training, and effective communication are key in addressing these challenges and fostering successful scaffolding construction projects.

Regulations and Standards for Scaffolding Construction

Scaffolding construction is subject to various regulations and industry standards to ensure the safety of workers and the proper installation and use of scaffolding structures. These regulations and standards outline the requirements and best practices that must be followed during scaffolding construction. Understanding and complying with these regulations is crucial for contractors, workers, and anyone involved in scaffolding construction. Let’s explore some of the key regulations and standards:

- Occupational Safety and Health Administration (OSHA): In the United States, the Occupational Safety and Health Administration (OSHA) sets the regulations that govern scaffolding construction. The OSHA standards address various aspects of scaffolding safety, including scaffold design, assembly, use, inspections, and worker training. Compliance with OSHA standards is mandatory for construction companies and contractors to ensure a safe working environment.

- National Access & Scaffolding Confederation (NASC): The UK’s scaffolding industry is regulated by the National Access & Scaffolding Confederation (NASC). NASC provides guidance, training, and sets industry standards that scaffold companies must adhere to. Their code of practice covers all aspects of scaffolding, including design, installation, inspection, and dismantling.

- International Organization for Standardization (ISO): The International Organization for Standardization (ISO) develops and publishes international standards that provide guidance on scaffold safety, components, testing, and inspection. ISO standards serve as a benchmark for quality and safety in scaffolding construction and are recognized worldwide.

- Health and Safety Executive (HSE): In the United Kingdom, the Health and Safety Executive (HSE) is responsible for enforcing health and safety regulations, including those related to scaffolding construction. HSE provides guidelines and resources to ensure compliance with health and safety laws, including scaffolding-specific regulations.

- Local Building Codes: Local building codes and regulations vary depending on the country, state, or region. These codes outline the specific requirements for scaffolding construction, including design, materials, load capacities, and safety measures. Contractors and construction professionals must familiarize themselves with the local building codes applicable to their specific project.

In addition to these specific regulations and standards, it is important to note that compliance with general construction safety guidelines and best practices is crucial for scaffolding construction. This includes providing adequate training to workers, conducting regular inspections, implementing proper fall protection measures, and ensuring the overall stability and integrity of the scaffolding structure.

Failure to comply with the relevant regulations and standards can result in legal consequences, delays, accidents, and injuries. Therefore, contractors, workers, and other stakeholders involved in scaffolding construction must consistently follow the established regulations and standards to ensure the safety and well-being of all individuals on the construction site.

Read also: 8 Unbelievable Masonry Scaffolding For 2024

Conclusion

Scaffolding construction is an integral part of the building industry, providing a safe and stable working platform for workers during construction, renovation, and maintenance projects. It plays a crucial role in ensuring worker safety, enhancing productivity, and facilitating efficient construction operations. With proper planning, adherence to safety regulations, and the use of appropriate tools and equipment, scaffolding structures can be erected and used with confidence.

Throughout this article, we explored the definition of scaffolding construction and the various types of scaffolding commonly used. We learned about the key components and essential tools and equipment involved in scaffolding construction. The scaffolding construction process, including planning, assembly, inspection, and dismantling, was discussed in detail.

Safety measures, such as proper training, regular inspections, and the use of personal protective equipment, were highlighted as crucial aspects of scaffolding construction. We also identified common issues and challenges that may arise, such as instability, falls, inadequate planning, and communication issues. Finally, we emphasized the importance of adhering to regulations and industry standards specific to scaffolding construction.

In conclusion, scaffolding construction requires a comprehensive understanding of safety protocols, proper assembly techniques, and compliance with relevant regulations. By implementing the recommended practices and maintaining a strong safety culture, workers can perform their tasks confidently, and projects can progress smoothly, meeting deadlines and ensuring the well-being of everyone involved.

As the building industry continues to evolve, scaffolding construction will remain a vital aspect of construction projects. By staying updated with the latest advancements, regulations, and best practices, construction professionals can contribute to safer and more efficient scaffolding construction, further enhancing the success of the overall building process.

Frequently Asked Questions about What Is Scaffolding Construction

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is Scaffolding Construction”