Home>diy>Building & Construction>Why Is Asbestos Used In Construction

Building & Construction

Why Is Asbestos Used In Construction

Modified: January 8, 2024

Learn why asbestos is commonly used in building construction and the potential risks associated with its use. Find out how to safely handle and manage asbestos in construction projects.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the fascinating world of construction, where the fusion of innovation and tradition shapes our built environment. In the realm of construction materials, one substance has played a significant role for decades: asbestos. This naturally occurring mineral has been a cornerstone of construction, revered for its remarkable properties and versatility. However, the use of asbestos has been a subject of intense scrutiny due to its potential health risks. In this article, we will delve into the history, properties, benefits, health risks, and regulations surrounding the use of asbestos in construction. Additionally, we will explore alternative materials that have emerged as safer substitutes in modern construction practices.

As we embark on this exploration, we will unravel the enigmatic allure of asbestos and gain insight into its profound impact on the construction industry. While shedding light on its advantages, we will also confront the sobering reality of its associated health hazards. By the end of this journey, you will have a comprehensive understanding of why asbestos has been both revered and reviled in the realm of construction. Let's embark on this enlightening expedition to uncover the mysteries and complexities of asbestos in construction.

Key Takeaways:

- Asbestos, once a popular construction material, offers fire resistance, insulation, and durability. However, its health risks have led to the development of safer alternatives in the construction industry.

- The construction industry is transitioning away from asbestos towards safer alternatives like mineral wool, fiberglass, and cellulose fiber for insulation and fire-resistant materials. This shift prioritizes safety and sustainability in building practices.

Read more: When Did Construction Stop Using Asbestos

History of Asbestos Use in Construction

The use of asbestos in construction can be traced back thousands of years, with its origins rooted in ancient civilizations. The word “asbestos” itself is derived from the ancient Greek term meaning “unquenchable” or “inextinguishable,” a testament to its exceptional fire-resistant properties. Its remarkable durability and resistance to heat made it an invaluable material for various construction applications throughout history.

One of the earliest documented uses of asbestos dates back to ancient Greece and Rome, where it was utilized in the construction of fabrics, pottery, and even ceremonial wicks for eternal flames. The ancient Egyptians also recognized its insulating properties and employed it in embalming processes and the construction of burial cloths.

As civilization progressed, the use of asbestos expanded, with its incorporation into a myriad of construction materials. During the industrial revolution, asbestos experienced a surge in popularity, becoming a staple in the construction of buildings, ships, and industrial facilities. Its widespread application in insulation, roofing materials, cement, and fireproofing products cemented its status as a go-to construction material.

By the mid-20th century, asbestos had permeated nearly every facet of the construction industry, with its presence felt in residential, commercial, and industrial construction projects worldwide. Its popularity soared due to its affordability, abundance, and unparalleled fire-retardant and insulating properties.

However, the euphoria surrounding asbestos was short-lived as mounting evidence began to surface regarding its detrimental health effects. The subsequent shift in public perception and stringent regulations marked a turning point in the history of asbestos use in construction. The once-revered “miracle mineral” now stood at the center of a contentious debate, sparking a reevaluation of its role in the construction industry.

As we reflect on the historical trajectory of asbestos in construction, we gain a profound appreciation for its enduring legacy and the pivotal role it has played in shaping the built environment. Its journey from revered construction staple to vilified health hazard underscores the complex interplay between innovation, tradition, and the evolving understanding of material safety.

Properties of Asbestos

Asbestos possesses a remarkable array of properties that have made it a coveted material in the construction industry. Its intrinsic characteristics have rendered it invaluable for a diverse range of applications, contributing to its widespread use in construction materials.

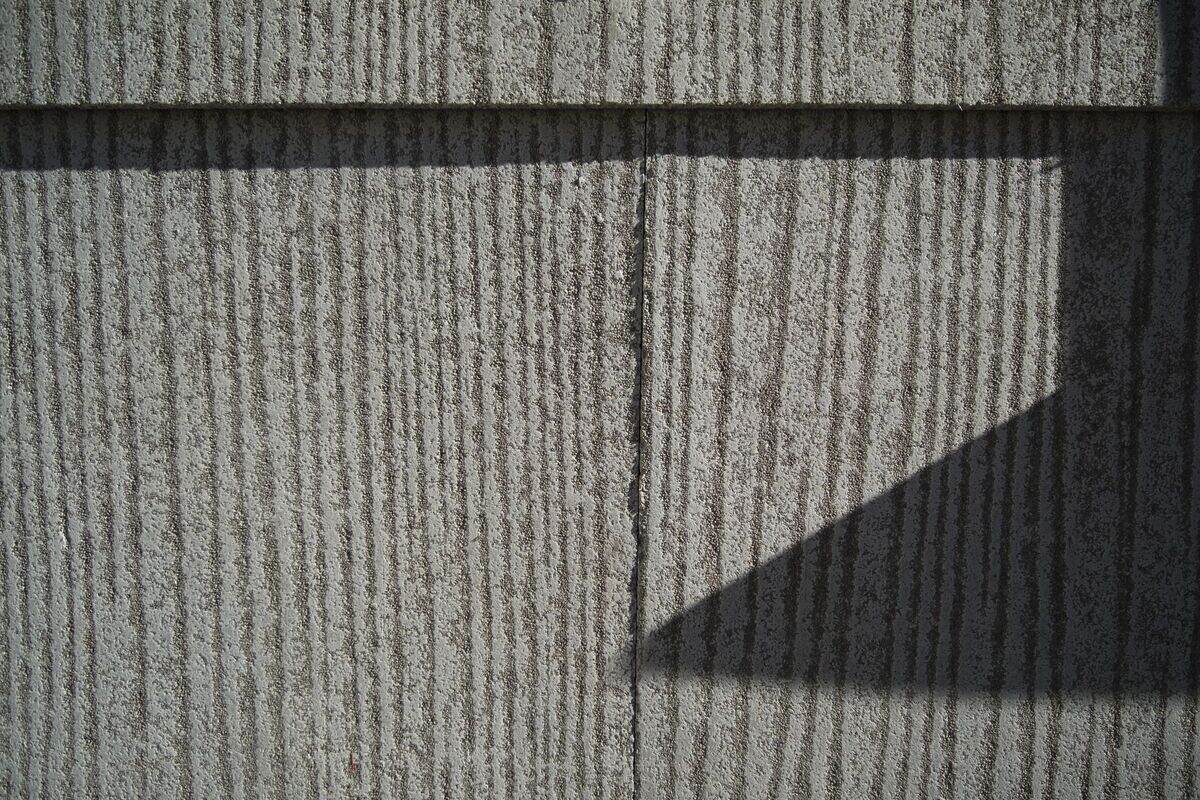

- Fire Resistance: One of the most renowned properties of asbestos is its exceptional resistance to heat and flames. This attribute has made it a preferred choice for fireproofing materials in buildings, ships, and industrial facilities. Its ability to withstand high temperatures without igniting or conducting heat has been instrumental in enhancing the fire safety of various structures.

- Insulation: Asbestos exhibits outstanding insulating properties, effectively preventing the transfer of heat and electricity. Its insulative capabilities have been harnessed in the production of thermal insulation materials for pipes, boilers, and electrical wiring, contributing to energy efficiency and safety in buildings and industrial settings.

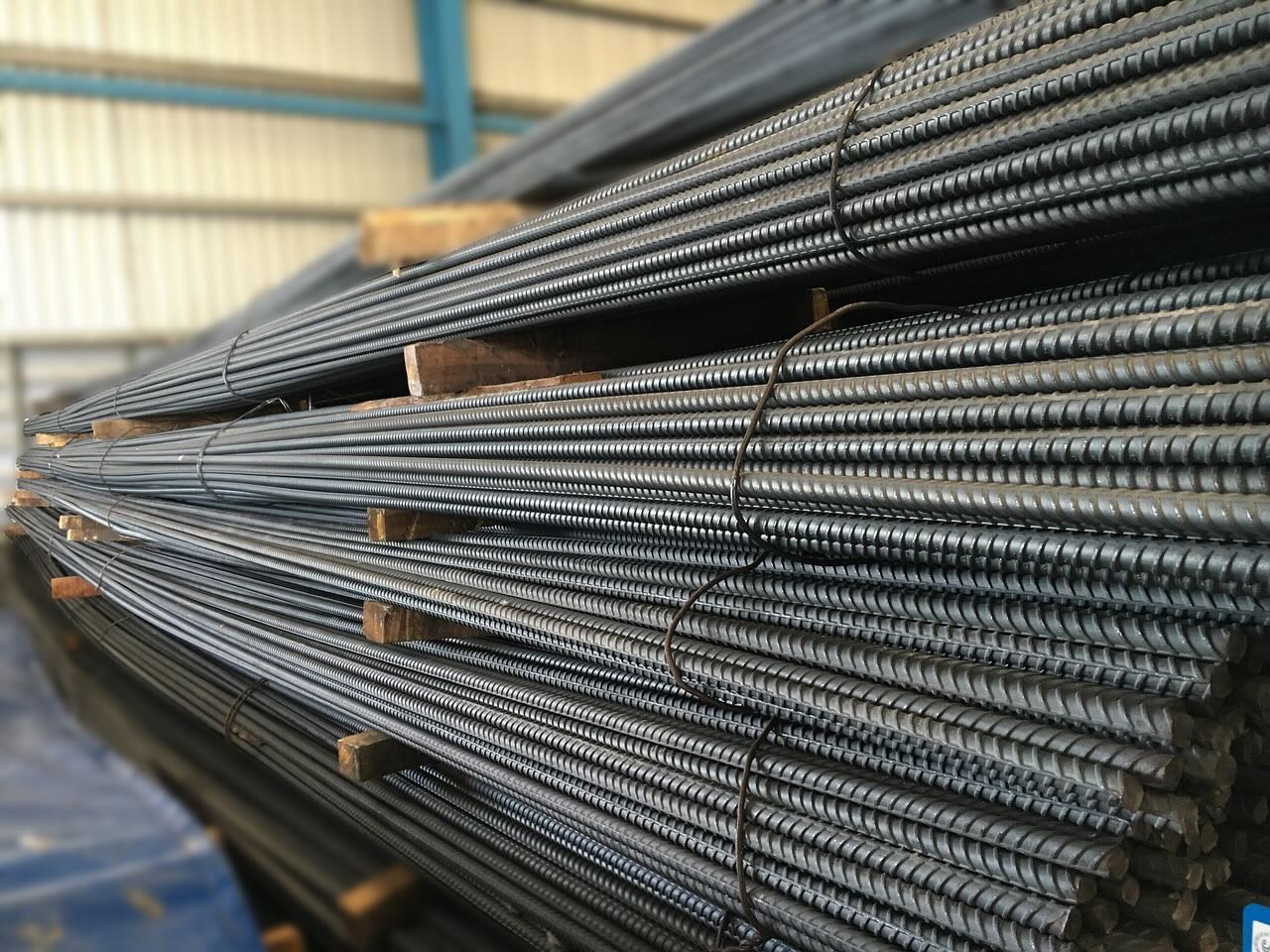

- Strength and Durability: Asbestos fibers are renowned for their tensile strength and durability, making them an ideal reinforcement component in cement, plastics, and other composite materials. The incorporation of asbestos has bolstered the structural integrity of construction products, enhancing their resistance to wear, corrosion, and mechanical stress.

- Chemical Inertness: Asbestos exhibits resistance to chemical degradation, making it suitable for applications in corrosive environments. Its inert nature has rendered it a valuable component in chemical-resistant coatings, gaskets, and friction materials, contributing to the longevity and reliability of construction materials exposed to harsh chemical conditions.

- Sound Absorption: Asbestos possesses sound-absorbing properties, dampening noise and vibration within architectural spaces. Its acoustic insulation capabilities have been leveraged in the construction of soundproofing materials for walls, ceilings, and floors, enhancing the acoustic comfort and privacy of buildings.

These inherent properties have positioned asbestos as a versatile and indispensable material in construction, offering a unique combination of fire resistance, insulation, strength, and chemical resilience. Its multifaceted utility has left an indelible imprint on the built environment, shaping the design, safety, and performance of structures across the globe.

Benefits of Using Asbestos in Construction

The utilization of asbestos in construction has historically conferred a multitude of advantages, contributing to its widespread incorporation in building materials and infrastructure. The unique properties of asbestos have engendered several benefits that have significantly impacted the construction industry.

- Fire Safety: Asbestos’s exceptional resistance to heat and flames has been pivotal in enhancing the fire safety of buildings, particularly in high-risk environments such as industrial facilities and commercial structures. Its incorporation in fireproofing materials has mitigated the spread of fires, providing critical time for evacuation and reducing the structural damage caused by conflagrations.

- Insulation Efficiency: Asbestos’s superior insulating properties have bolstered the energy efficiency of buildings by minimizing heat transfer and reducing thermal losses. This has led to lower energy consumption for heating and cooling, contributing to environmental sustainability and cost savings for building owners and occupants.

- Durability and Longevity: The addition of asbestos fibers to construction materials has imparted exceptional strength and durability, extending the lifespan of various building components. Asbestos-reinforced products have exhibited heightened resistance to wear, weathering, and mechanical stress, resulting in reduced maintenance requirements and prolonged structural integrity.

- Cost-Effectiveness: Asbestos’s abundance and affordability have historically made it an economically viable choice for construction materials. Its widespread availability and favorable cost-to-performance ratio have facilitated the production of durable and high-performing building products at competitive prices, contributing to the accessibility of quality construction materials.

- Acoustic Comfort: Asbestos’s sound-absorbing properties have been instrumental in creating acoustically optimized environments, reducing noise transmission and enhancing the auditory comfort of occupants. Its incorporation in soundproofing materials has facilitated the creation of quieter and more peaceful indoor spaces, particularly in residential and commercial settings.

These benefits have underscored the pivotal role of asbestos in construction, shaping the safety, efficiency, and longevity of built structures. While its advantages have been instrumental in advancing construction practices, the evolving understanding of its health risks has prompted a reevaluation of its place in modern construction, leading to the exploration of safer alternatives.

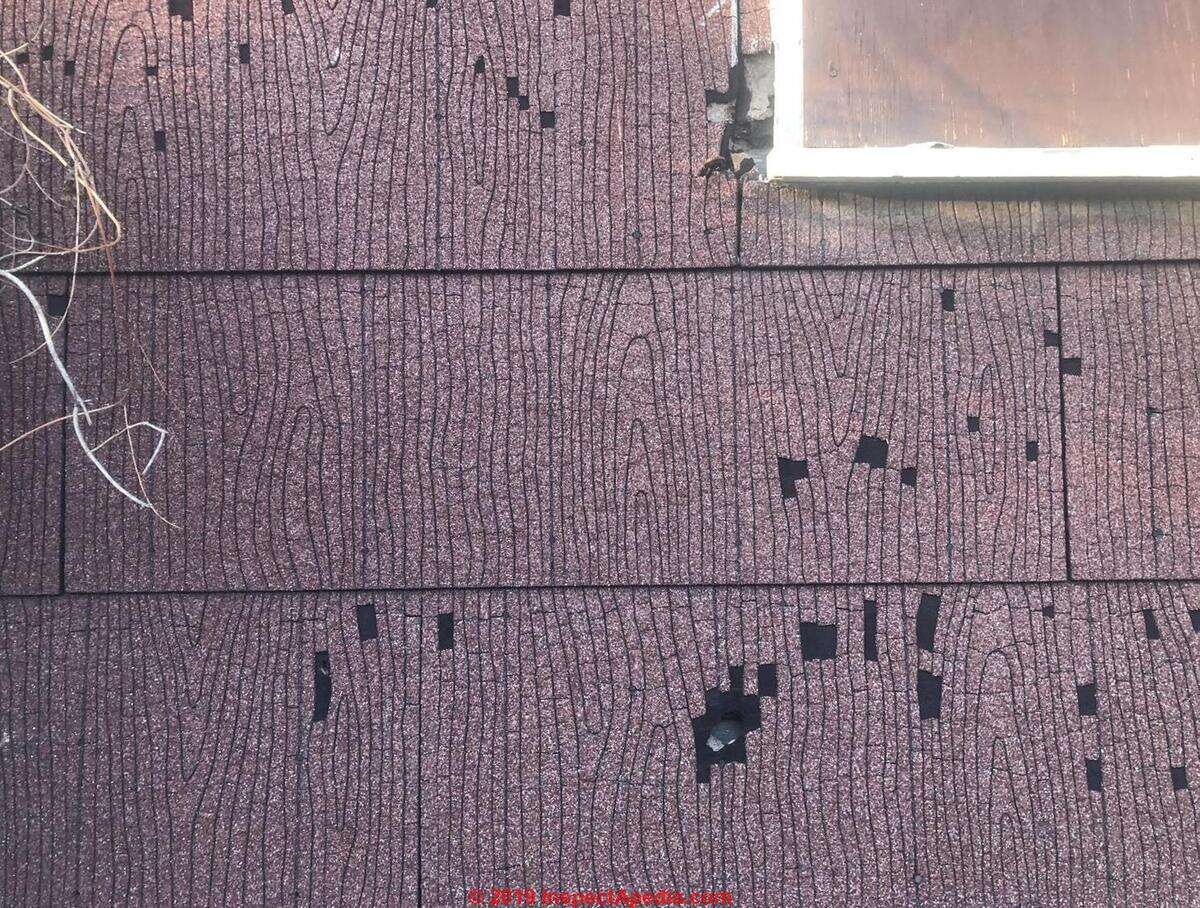

Asbestos was used in construction for its heat resistance and durability. However, it is now known to cause serious health issues. When working with older buildings, always check for asbestos and take proper precautions.

Health Risks and Regulations

Despite its remarkable properties, the use of asbestos in construction has been overshadowed by profound health risks associated with exposure to its fibers. Prolonged inhalation or ingestion of asbestos particles can lead to severe health complications, including respiratory diseases and various forms of cancer. As a result, stringent regulations and guidelines have been implemented to mitigate the health hazards posed by asbestos in the construction industry.

Health Risks: The inhalation of asbestos fibers can result in debilitating respiratory conditions such as asbestosis, a progressive scarring of the lung tissue that impairs breathing. Additionally, exposure to asbestos has been linked to the development of mesothelioma, a rare and aggressive form of cancer affecting the lining of the lungs, abdomen, or heart. Furthermore, prolonged asbestos exposure increases the risk of lung cancer and other respiratory ailments, posing a significant threat to the well-being of individuals working with or inhabiting structures containing asbestos materials.

Regulations and Guidelines: In response to the escalating health concerns, regulatory bodies and governmental agencies have enacted stringent measures to control the use, handling, and disposal of asbestos in construction. These regulations encompass the monitoring of asbestos exposure levels, the implementation of safe handling practices, and the proper encapsulation or removal of asbestos-containing materials in existing structures. Additionally, building codes and occupational safety standards mandate the disclosure of asbestos presence in buildings, ensuring that occupants and workers are informed about potential asbestos hazards.

The enforcement of regulations pertaining to asbestos abatement, encapsulation, and disposal has been instrumental in safeguarding the health and well-being of individuals involved in construction activities. Moreover, public awareness campaigns and educational initiatives have been pivotal in disseminating information about the risks of asbestos exposure and promoting adherence to safety protocols in construction practices.

While the stringent regulations have significantly reduced the prevalence of asbestos in new construction projects, the management of existing asbestos-containing structures remains a critical concern. The safe removal and disposal of asbestos materials in older buildings necessitate specialized expertise and adherence to rigorous safety protocols to prevent the release of hazardous fibers into the environment.

As we navigate the complex landscape of asbestos regulations and health risks, it becomes evident that the conscientious management of asbestos in construction is imperative to safeguarding the health of construction workers, occupants, and the broader community.

Alternatives to Asbestos in Construction

The evolving understanding of the health risks associated with asbestos has spurred the development and adoption of safer alternatives in the construction industry. These alternatives aim to replicate the beneficial properties of asbestos while mitigating the potential health hazards posed by its use. The pursuit of asbestos-free construction materials has led to the emergence of innovative substitutes that offer comparable performance and enhanced safety.

- Mineral Wool: Mineral wool, derived from natural minerals such as basalt or diabase, serves as an effective alternative to asbestos for thermal and acoustic insulation. Its fire-resistant properties and high thermal performance make it a popular choice for insulating buildings, HVAC systems, and industrial equipment.

- Fiberglass: Fiberglass insulation, composed of fine glass fibers, provides a non-toxic and non-combustible alternative to asbestos insulation. Its versatility and thermal efficiency make it a preferred option for residential and commercial insulation applications, offering a safe and sustainable solution for temperature regulation.

- Cellulose Fiber: Cellulose fiber insulation, made from recycled paper or plant-based fibers, offers an environmentally friendly alternative to asbestos for thermal and acoustic insulation. Its low environmental impact and fire-retardant properties make it a compelling choice for sustainable construction practices.

- Calcium Silicate Boards: Calcium silicate boards, featuring a mineral composition, provide a non-toxic and fire-resistant substitute for asbestos-containing building materials. These boards are utilized in applications requiring high-temperature resistance, such as fire-rated wall partitions, ceiling panels, and structural fire protection systems.

- Polymer Composites: Polymer-based composites, reinforced with synthetic fibers or additives, offer a durable and non-toxic alternative to asbestos for enhancing the strength and resilience of construction materials. These composites are employed in various structural and architectural applications, providing a safe and versatile solution for reinforcing building components.

The advent of these alternatives has heralded a new era of construction practices, prioritizing safety, sustainability, and performance. The ongoing research and development of innovative materials continue to expand the repertoire of asbestos-free solutions, empowering construction professionals to build structures that are resilient, environmentally conscious, and devoid of hazardous materials.

By embracing these alternatives, the construction industry is poised to transcend the legacy of asbestos and forge a future defined by safe, sustainable, and innovative building practices.

Conclusion

The saga of asbestos in construction is a tale of triumphs and tribulations, encapsulating the paradoxical nature of a material that has both revolutionized building practices and engendered profound health concerns. Its remarkable properties have shaped the safety, durability, and functionality of structures, leaving an indelible imprint on the built environment. However, the shadow of health risks has cast a sobering light on the pervasive use of asbestos, prompting a reevaluation of its role in modern construction.

As we navigate the complex terrain of asbestos in construction, it is imperative to acknowledge the dual narrative that defines its legacy. The historical significance of asbestos as a fire-resistant, insulating, and durable material cannot be understated, as it has safeguarded structures and facilitated advancements in construction technology. Yet, the imperative to prioritize the health and well-being of individuals necessitates a conscientious transition toward safer alternatives.

The emergence of innovative substitutes and the stringent enforcement of regulations signal a pivotal shift in construction practices, heralding an era of asbestos-free building materials that offer comparable performance without compromising safety. The ongoing pursuit of sustainable, non-toxic, and resilient alternatives embodies the ethos of progress and responsibility that defines the contemporary construction industry.

As we bid farewell to the era of asbestos dominance, we embrace a future defined by ingenuity, sustainability, and a steadfast commitment to creating structures that prioritize the health and safety of occupants and builders. The journey toward asbestos-free construction is a testament to the resilience and adaptability of the construction industry, showcasing its capacity to evolve in response to emerging challenges and ethical imperatives.

In this transformative paradigm, the legacy of asbestos serves as a poignant reminder of the enduring interplay between tradition, innovation, and ethical stewardship. As we forge ahead, we honor the lessons of the past while charting a course toward a future where construction materials harmonize with human and environmental well-being, embodying the ethos of progress and responsibility that defines the contemporary construction industry.

Frequently Asked Questions about Why Is Asbestos Used In Construction

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “Why Is Asbestos Used In Construction”