Home>Furniture & Design>Interior Design Trends>How To Tell If Glass Is Tempered

Interior Design Trends

How To Tell If Glass Is Tempered

Modified: October 19, 2024

Learn how to determine if glass is tempered and stay updated on the latest interior design trends. Discover the best ways to identify tempered glass and explore the current trends in interior design.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When it comes to glass, safety is paramount. Whether you're selecting glass for a new construction project or assessing the existing glass in your home, it's crucial to determine if the glass is tempered. Tempered glass is designed to withstand higher levels of stress and impact compared to regular glass, making it a preferred choice for applications where safety is a concern.

In this comprehensive guide, we will explore various methods to determine if glass is tempered. From visual inspections to specialized tests, we'll delve into the techniques used by professionals to identify tempered glass accurately. By understanding these methods, you'll be equipped with the knowledge to make informed decisions about the glass in your surroundings.

Let's embark on this journey to unravel the mystery of tempered glass and empower ourselves with the ability to discern its presence through practical and insightful means.

Key Takeaways:

- Look for smooth, rounded edges, surface distortions, unique fragmentation patterns, and etched markings to identify tempered glass through visual inspection. It’s like solving a mystery by examining clues on the glass itself!

- Use polarized light to reveal mesmerizing interference patterns, and subject glass to extreme temperature differentials to test its resilience. These methods help ensure the safety and durability of tempered glass in various applications.

What is tempered glass?

Tempered glass, also known as toughened glass, is a type of safety glass that is processed through controlled thermal or chemical treatments. The fundamental characteristic of tempered glass lies in its enhanced strength and durability, making it highly resistant to impact and thermal stress. This is achieved through a process of rapid heating and cooling, which results in a glass that is approximately four times stronger than regular glass of the same thickness.

The production of tempered glass involves heating the glass to a high temperature, typically around 620 degrees Celsius (1,148 degrees Fahrenheit), and then rapidly cooling it using high-pressure air. This rapid cooling process induces significant internal stress within the glass, leading to its increased strength and resilience. As a result, tempered glass is less likely to break under impact and, if it does, it fractures into small, relatively harmless pieces rather than sharp, jagged shards.

One of the key properties of tempered glass is its ability to withstand thermal stress differentials. This means that it can endure rapid temperature changes without cracking or shattering, making it suitable for a wide range of applications, including shower enclosures, glass doors, table tops, and automobile windows. The safety aspect of tempered glass is particularly crucial in environments where human interaction is prevalent, as it minimizes the risk of serious injury in the event of breakage.

In addition to its strength and safety benefits, tempered glass also exhibits resistance to scratches and surface damage, contributing to its longevity and aesthetic appeal. These qualities have made tempered glass a popular choice in modern architecture and interior design, where both safety and visual elegance are essential considerations.

In summary, tempered glass is a specialized type of glass that undergoes a controlled thermal or chemical treatment process to enhance its strength, durability, and safety features. Its ability to withstand impact, thermal stress, and surface damage makes it a preferred option for a wide array of applications, offering both practical and aesthetic advantages in various settings.

Visual inspection

Visual inspection is one of the primary methods used to determine if glass is tempered. While it may not provide conclusive evidence on its own, a thorough visual examination can reveal certain characteristics that are indicative of tempered glass.

When conducting a visual inspection, there are several key factors to consider:

-

Edges: The edges of tempered glass are a crucial indicator of its type. Unlike regular glass, which typically has sharp edges, tempered glass often exhibits a different edge profile. Tempered glass is known for its characteristic smooth, rounded edges resulting from the tempering process. These edges are a result of the rapid cooling process, which strengthens the glass and alters its physical properties. By carefully examining the edges of the glass, one can often discern whether they possess the distinctive smoothness associated with tempered glass.

-

Surface Distortion: Another visual cue to look for is surface distortion. Tempered glass may exhibit slight surface distortions, commonly referred to as "roller wave" or "quench marks." These faint irregularities are a byproduct of the tempering process and can be observed when light reflects off the glass at certain angles. While not always present or easily noticeable, surface distortions can provide valuable clues when inspecting glass for tempering.

-

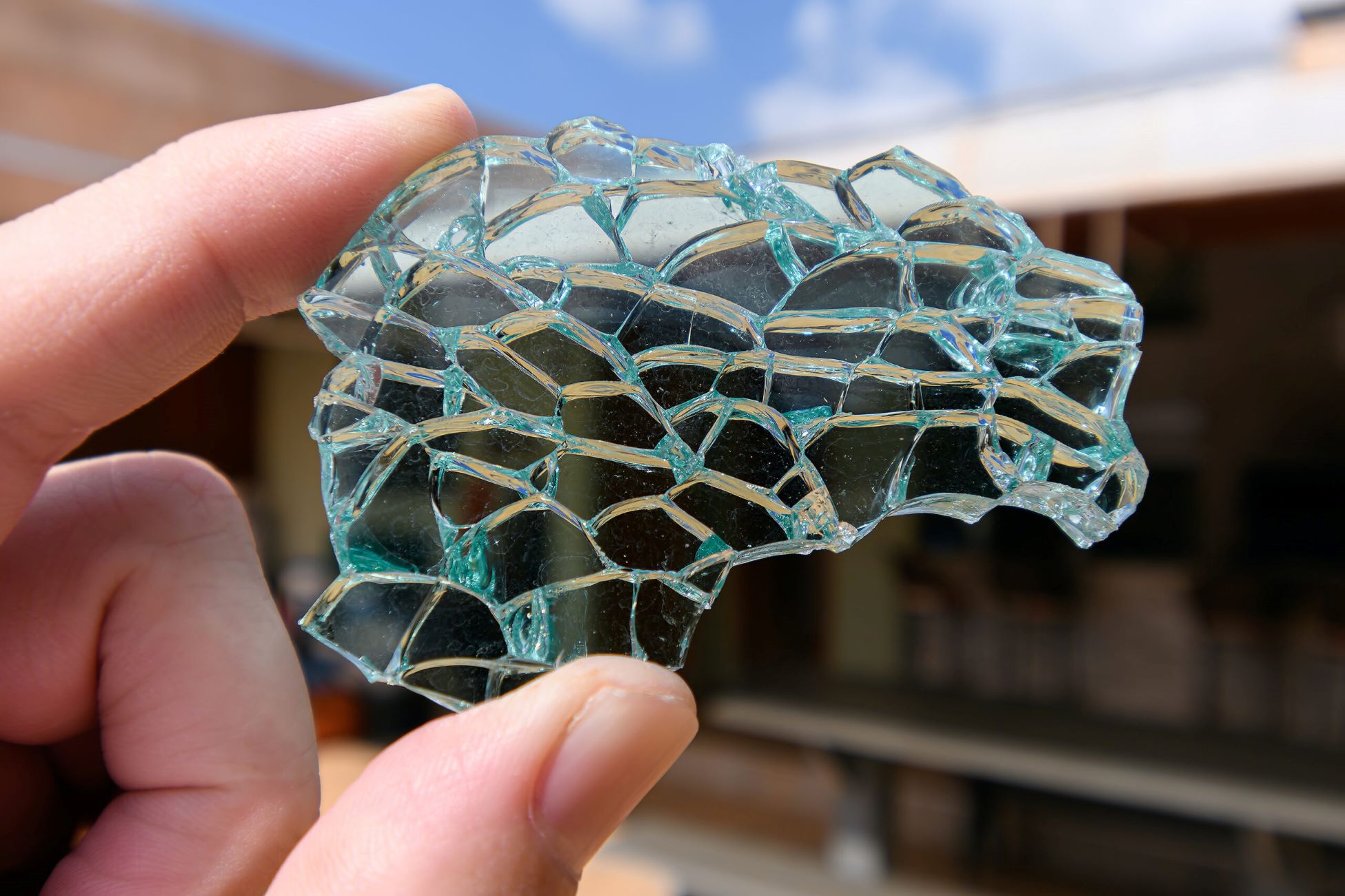

Fragmentation Pattern: In the event of breakage, tempered glass demonstrates a unique fragmentation pattern. Instead of shattering into large, sharp pieces like regular glass, tempered glass fractures into small, relatively harmless granular chunks. This distinctive behavior is a critical safety feature of tempered glass and can be observed when examining broken glass pieces.

-

Etched Markings: In some cases, tempered glass may bear etched markings or labels indicating its tempered nature. These markings are typically placed by the manufacturer and serve as a clear identifier of the glass's tempered status. Look for imprints or labels containing phrases such as "tempered," "safety glass," or a small "TPG" (tempered glass) insignia.

By carefully assessing these visual indicators, one can gain valuable insights into the nature of the glass in question. While visual inspection alone may not always provide a definitive confirmation of tempered glass, it serves as an essential initial step in the process of identification.

In summary, visual inspection involves closely examining the edges, surface characteristics, fragmentation pattern, and any potential markings on the glass to assess its likelihood of being tempered. This method, when combined with other testing techniques, forms a comprehensive approach to determining the tempered status of glass in various applications.

Look for a small “bug” etched into the glass, or check for distortion in the reflection. Tempered glass will also shatter into small, dull pieces when broken.

Polarized light test

The polarized light test is a specialized method employed to discern the tempered nature of glass through the interaction of polarized light waves with the glass surface. This technique leverages the unique optical properties of tempered glass to reveal distinct patterns and characteristics that are not readily observable under normal lighting conditions.

To conduct the polarized light test, a pair of polarizing filters is utilized in conjunction with a light source. When polarized light passes through tempered glass, it undergoes specific alterations in its polarization state, resulting in the manifestation of intricate patterns known as interference patterns. These patterns, often referred to as "quench marks," are a direct consequence of the tempering process and are indicative of the glass's tempered status.

When the polarized light is transmitted through the tempered glass, the interference patterns become visible, displaying a mesmerizing array of colors and shapes. These patterns are a result of the internal stresses within the tempered glass, which interact with the polarized light to produce the distinctive visual effects. By carefully observing these patterns, one can discern the tempered nature of the glass, as regular annealed glass does not exhibit the same intricate interference patterns under polarized light.

The polarized light test offers a non-destructive and visually captivating means of identifying tempered glass, making it a valuable tool for professionals in the glass industry and individuals seeking to ascertain the safety features of glass installations. This method provides a direct visual representation of the internal stress patterns within tempered glass, offering a compelling insight into its structural composition and safety characteristics.

In summary, the polarized light test is a fascinating and effective technique that harnesses the unique optical properties of tempered glass to reveal intricate interference patterns when illuminated with polarized light. This method serves as a compelling visual indicator of the tempered status of glass, contributing to a comprehensive approach to determining the safety and durability of glass installations in diverse environments.

Thermal stress test

The thermal stress test is a rigorous method employed to evaluate the tempered nature of glass by subjecting it to extreme temperature differentials. This test capitalizes on the unique thermal properties of tempered glass, which enable it to withstand rapid and substantial changes in temperature without succumbing to breakage or structural failure.

To conduct the thermal stress test, the glass specimen is carefully heated and subsequently cooled in a controlled manner. This process induces significant temperature differentials across the surface of the glass, simulating real-world scenarios where abrupt temperature changes may occur. The objective is to observe how the glass responds to these thermal differentials and whether it exhibits the characteristic behavior of tempered glass.

During the heating phase of the test, the glass is subjected to elevated temperatures, typically ranging from 500 to 600 degrees Celsius (932 to 1112 degrees Fahrenheit), depending on the specific testing standards and requirements. The glass is uniformly heated to the specified temperature, ensuring that the thermal stress is evenly distributed across its surface.

Following the heating phase, the glass is rapidly cooled using a carefully controlled process. This rapid cooling induces internal stresses within the glass, simulating the quenching process used during the tempering of glass. The rapid cooling process is critical in determining the glass's ability to withstand thermal differentials, a key characteristic of tempered glass.

Throughout the test, the glass is closely monitored for any signs of stress, distortion, or structural compromise. Tempered glass is expected to withstand the thermal stress test without exhibiting any visible signs of failure, such as cracking or shattering. Its ability to endure the extreme temperature differentials and rapid cooling process reaffirms its tempered nature and its suitability for applications where thermal resilience is essential.

The thermal stress test serves as a robust and practical method for assessing the tempered status of glass, providing valuable insights into its ability to withstand thermal shocks and environmental variations. By subjecting glass to extreme temperature differentials, this test offers a comprehensive evaluation of its safety and durability, contributing to informed decision-making in architectural, automotive, and industrial settings.

In summary, the thermal stress test is a vital component of the comprehensive approach to determining the tempered nature of glass. By subjecting glass to extreme temperature differentials and closely monitoring its response, this test offers a practical and insightful means of evaluating the safety and resilience of tempered glass in diverse applications.

Read more: What Is Tempered Glass

Conclusion

In conclusion, the identification of tempered glass is a critical aspect of ensuring safety and durability in various glass applications. Through visual inspection, the polarized light test, and the thermal stress test, professionals and individuals can effectively discern the tempered nature of glass, enabling informed decision-making and risk mitigation.

Visual inspection serves as an initial step in the process, allowing for the observation of key indicators such as edge characteristics, surface distortions, fragmentation patterns, and potential markings. While visual inspection alone may not always provide definitive confirmation, it lays the groundwork for further testing and assessment.

The polarized light test offers a captivating and non-destructive method of identifying tempered glass, leveraging the unique optical properties of tempered glass to reveal intricate interference patterns when illuminated with polarized light. This visually compelling technique provides a direct representation of the internal stress patterns within tempered glass, offering valuable insights into its structural composition and safety features.

The thermal stress test, on the other hand, provides a rigorous evaluation of the glass's ability to withstand extreme temperature differentials. By subjecting the glass to controlled heating and rapid cooling, this test simulates real-world thermal stress scenarios, reaffirming the tempered glass's resilience and suitability for applications where thermal resistance is paramount.

By integrating these testing methods, individuals and professionals can confidently ascertain the tempered status of glass, ensuring that it meets the necessary safety standards and performance requirements. Whether in architectural designs, automotive installations, or industrial settings, the ability to identify tempered glass is instrumental in promoting safety, longevity, and peace of mind.

In essence, the comprehensive approach to determining tempered glass encompasses a blend of visual assessment, optical analysis, and practical testing, culminating in a thorough understanding of the glass's safety and durability characteristics. This knowledge empowers individuals to make informed choices regarding glass installations, fostering environments that prioritize both aesthetic appeal and uncompromising safety standards.

Frequently Asked Questions about How To Tell If Glass Is Tempered

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Tell If Glass Is Tempered”