Home>Furniture & Design>Interior Design Trends>What Is The Hardness Of Glass

Interior Design Trends

What Is The Hardness Of Glass

Modified: August 18, 2024

Discover the hardness of glass and its impact on interior design trends. Learn how glass can elevate your interior spaces. Explore more with us.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

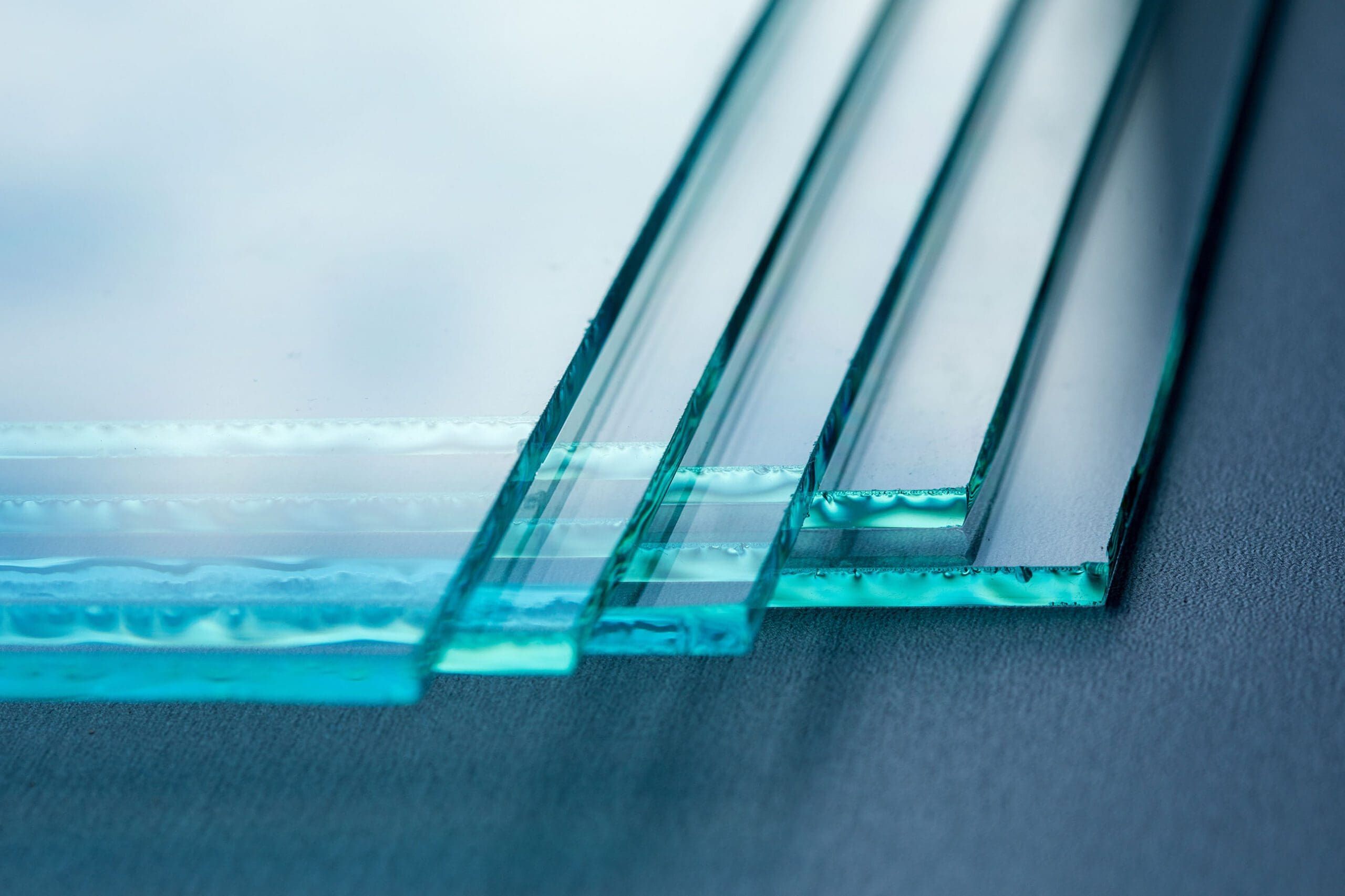

Glass is a ubiquitous material that surrounds us in various forms, from the windows of our homes to the screens of our smartphones. Its versatility and transparency make it an essential component of modern architecture and design. However, have you ever wondered about the hardness of glass? This often-overlooked aspect of glass plays a crucial role in determining its durability and suitability for different applications.

Understanding the hardness of glass involves delving into its composition, structural properties, and the factors that influence its resistance to scratches, abrasion, and impact. By exploring the intricacies of glass hardness, we can gain a deeper appreciation for this remarkable material and its widespread utility in our daily lives.

In this article, we will embark on a fascinating journey into the world of glass hardness, unraveling the science behind its resilience and uncovering the methods used to measure and assess its hardness. We will also explore the practical implications of hardened glass in various industries, shedding light on its diverse applications and the indispensable role it plays in enhancing safety, security, and aesthetic appeal.

Join us as we venture into the captivating realm of glass hardness, where science meets functionality, and discover the remarkable properties that make glass a cornerstone of modern design and innovation.

Key Takeaways:

- Glass hardness is crucial for durability and safety in architecture, automotive, and electronics. It’s influenced by composition, manufacturing, and environmental factors, shaping its impact on modern design and innovation.

- Hardened glass, with enhanced hardness and resilience, is essential in architectural glazing, automotive safety, electronic displays, security, and interior decor. Its versatility and durability drive innovation and elevate modern living experiences.

Read more: How Hard Is Glass

Understanding Glass Hardness

Glass hardness refers to the material's resistance to surface indentation or abrasion. It is a crucial characteristic that determines the durability and longevity of glass in various applications. The hardness of glass is influenced by its molecular structure and the presence of certain elements or compounds within its composition. Unlike metals or minerals, glass does not have a definitive hardness value on the Mohs scale, which is commonly used to measure the hardness of minerals. Instead, the hardness of glass is evaluated using specialized testing methods that assess its resistance to scratching and impact.

The hardness of glass is intrinsically linked to its chemical composition and the process of its formation. Glass is primarily composed of silica, which is a key component responsible for its transparency and structural integrity. However, the addition of other elements such as sodium, calcium, and aluminum oxide can significantly impact the hardness of the glass. For instance, tempered glass, which undergoes a thermal or chemical strengthening process, exhibits enhanced hardness and resistance to breakage compared to untreated glass.

Understanding the hardness of glass also involves recognizing its amorphous nature. Unlike crystalline materials, glass lacks a regular atomic structure, which contributes to its unique mechanical properties. This amorphous structure makes glass inherently brittle, yet its hardness can be modified through various treatments and manufacturing processes. By altering the cooling rate during production or subjecting the glass to tempering or laminating techniques, its hardness can be enhanced to meet specific performance requirements.

Furthermore, the hardness of glass is closely related to its scratch resistance, which is a critical consideration in applications where the material is exposed to wear and friction. Glass with higher hardness values is less prone to surface scratches, maintaining its clarity and visual appeal over time. This property is particularly important in architectural glazing, automotive windshields, and electronic displays, where the durability of the glass directly impacts its functionality and aesthetic quality.

In essence, understanding the hardness of glass entails recognizing its complex interplay of chemical composition, structural properties, and manufacturing processes. By comprehending the factors that influence glass hardness, designers, engineers, and manufacturers can leverage this knowledge to develop innovative solutions that harness the remarkable properties of glass to meet diverse industrial and consumer needs.

Factors Affecting Glass Hardness

The hardness of glass is influenced by a myriad of factors that encompass its chemical composition, manufacturing processes, and structural characteristics. Understanding these influential elements is essential for comprehending the diverse range of glass hardness and its suitability for specific applications.

Chemical Composition:

The chemical composition of glass plays a pivotal role in determining its hardness. While silica is the primary component of most glasses, the addition of various oxides such as sodium, calcium, and aluminum can significantly impact its hardness. For instance, the introduction of aluminum oxide can enhance the hardness of glass, making it more resistant to scratches and abrasion. Additionally, the presence of impurities or uneven distribution of elements within the glass matrix can affect its overall hardness, highlighting the importance of precise composition control during the manufacturing process.

Manufacturing Processes:

The method of glass production and treatment processes directly influence its hardness. Tempered glass, for example, undergoes a specialized thermal or chemical strengthening process that imparts exceptional hardness and resistance to breakage. This is achieved through rapid cooling or chemical treatments, creating a state of compressive stress within the glass, thereby enhancing its overall hardness. Similarly, laminated glass, which consists of multiple layers bonded together, exhibits improved hardness due to the interlayer materials that contribute to its structural integrity and impact resistance.

Read more: What Is Hard Landscaping

Structural Properties:

The structural characteristics of glass, including its amorphous nature and molecular arrangement, also impact its hardness. Unlike crystalline materials, glass lacks a regular atomic structure, contributing to its inherent brittleness. However, the manipulation of the cooling rate during production and the application of tempering or annealing processes can modify the molecular arrangement, resulting in enhanced hardness and durability. Furthermore, the thickness and surface finish of the glass can influence its hardness, with thicker and polished surfaces exhibiting greater resistance to indentation and wear.

Environmental Factors:

Environmental conditions and exposure to external elements can affect the hardness of glass over time. Factors such as temperature fluctuations, humidity, and chemical exposure can impact the surface hardness and structural integrity of glass. Additionally, mechanical stress and impact loads can influence the hardness of glass, making it susceptible to microcracks and reduced resistance to abrasion. Therefore, considering the environmental factors and intended usage conditions is crucial in determining the appropriate hardness of glass for specific applications.

In essence, the hardness of glass is a complex interplay of chemical composition, manufacturing techniques, structural properties, and environmental influences. By understanding the multifaceted factors that affect glass hardness, designers, engineers, and manufacturers can optimize the material's performance and durability to meet the diverse demands of modern applications.

Measuring Glass Hardness

Measuring the hardness of glass is a meticulous process that involves specialized testing methods to evaluate its resistance to scratching, abrasion, and impact. Unlike minerals, which are assigned definitive hardness values on the Mohs scale, glass requires precise and controlled assessments due to its unique structural properties and amorphous nature.

One of the primary techniques used to measure glass hardness is the Mohs hardness test, which involves assessing the material's resistance to scratching by comparing it to standard minerals with known hardness values. While this method provides a qualitative indication of glass hardness, it may not offer precise measurements for engineering and industrial applications due to the variability of glass compositions and the absence of a standardized scale for glass hardness.

Another widely employed method for measuring glass hardness is the Vickers hardness test, which utilizes a pyramidal diamond or sapphire indenter to create controlled impressions on the glass surface. By measuring the size of the indentation, the Vickers hardness number can be calculated, providing a quantitative assessment of the material's resistance to deformation. This method is particularly valuable for evaluating the hardness of tempered and laminated glass, where precise hardness values are essential for ensuring structural integrity and performance.

Furthermore, the Knoop hardness test is utilized to measure the hardness of thin glass samples or areas with limited access, employing a rhombic-based diamond indenter to create microscopic impressions. This method is well-suited for assessing the hardness of delicate glass components and thin substrates, offering valuable insights into the material's resistance to localized deformation and surface wear.

In addition to these standardized testing methods, specialized instruments such as nanoindentation systems are employed to measure the nanomechanical properties of glass, providing detailed information on hardness, elastic modulus, and fracture resistance at the micro and nanoscale levels. These advanced techniques enable precise characterization of glass hardness, facilitating the development of high-performance glass materials for cutting-edge applications in optics, electronics, and advanced engineering.

By employing a combination of traditional and advanced testing methodologies, researchers, engineers, and material scientists can gain comprehensive insights into the hardness of glass, enabling the optimization of material formulations, manufacturing processes, and performance criteria for diverse industrial and technological applications. The precise measurement of glass hardness is essential for ensuring the reliability, safety, and functionality of glass-based products in a wide range of sectors, from architectural glazing to consumer electronics, underscoring the significance of rigorous hardness testing in the realm of glass materials.

Common Uses of Hardened Glass

Hardened glass, renowned for its exceptional strength and durability, finds widespread application across diverse industries, serving as a cornerstone of modern design and engineering. The unique properties of hardened glass, including enhanced hardness, impact resistance, and safety features, make it an indispensable material for a myriad of practical and aesthetic purposes.

Architectural Glazing

In the realm of architecture and construction, hardened glass plays a pivotal role in creating safe, visually striking, and energy-efficient structures. Tempered glass, known for its superior hardness and shatter-resistant properties, is extensively utilized in windows, doors, and curtain walls. Its ability to withstand high wind loads, thermal stress, and impact makes it an ideal choice for enhancing the safety and longevity of architectural glazing systems. Additionally, laminated glass, composed of multiple interlayers for enhanced strength, is employed in skylights, canopies, and balustrades, offering both structural integrity and aesthetic appeal.

Automotive Applications

The automotive industry relies on hardened glass to ensure passenger safety, vehicle performance, and design innovation. Tempered glass is utilized in side windows, rear windshields, and sunroofs, providing exceptional hardness and resistance to breakage. Its ability to fragment into small, dull pieces upon impact reduces the risk of injury in the event of breakage, making it a critical component for automotive safety standards. Furthermore, laminated glass is employed in windshields, offering superior impact resistance and structural support, thereby enhancing driver and passenger safety while contributing to the overall vehicle design.

Electronic Displays

The proliferation of electronic devices and digital interfaces has propelled the demand for hardened glass in the realm of electronic displays. From smartphones and tablets to televisions and touchscreens, tempered glass serves as a protective cover, safeguarding the delicate display panels from scratches, impacts, and environmental stress. Its high hardness and scratch resistance ensure the longevity and visual clarity of electronic screens, enhancing user experience and device durability. Moreover, chemically strengthened glass, renowned for its exceptional hardness and thin profile, is utilized in advanced display technologies, enabling sleek and durable electronic devices with vibrant, high-definition visuals.

Safety and Security

Hardened glass is instrumental in enhancing safety and security across various applications, ranging from public facilities to residential spaces. Bullet-resistant glass, a specialized form of hardened glass, is employed in high-security environments such as banks, government buildings, and VIP vehicles, providing unparalleled protection against ballistic threats. Its exceptional hardness and impact resistance offer peace of mind in high-risk scenarios, underscoring the critical role of hardened glass in safeguarding lives and assets. Additionally, security laminates applied to glass surfaces reinforce intrusion resistance, mitigating the risk of forced entry and vandalism in commercial and residential settings.

Read more: How To Clean Hard Water Off Glass

Furniture and Decor

The integration of hardened glass in furniture and interior decor exemplifies its versatility and aesthetic appeal. Toughened glass tabletops, shelves, and cabinets offer a blend of elegance and durability, enhancing the visual appeal of living spaces while ensuring robustness and safety. The use of laminated glass in decorative applications, such as glass partitions and feature walls, adds a touch of sophistication and design versatility, creating visually stunning interiors with enhanced structural integrity. Furthermore, the utilization of colored and textured hardened glass in artistic installations and architectural features showcases the creative potential of this resilient material in elevating interior design concepts.

In essence, the pervasive presence of hardened glass in architectural, automotive, electronic, safety, and decorative applications underscores its indispensable role in modern design, engineering, and everyday life. The remarkable combination of hardness, resilience, and aesthetic versatility positions hardened glass as a fundamental material that continues to drive innovation and elevate the standards of functionality, safety, and visual appeal across diverse industries and consumer experiences.

Conclusion

In conclusion, the hardness of glass is a multifaceted aspect that encompasses its chemical composition, structural properties, and diverse applications. The intricate interplay of factors influencing glass hardness, from the presence of specific elements to the implementation of advanced manufacturing processes, underscores the remarkable adaptability and resilience of this ubiquitous material.

Understanding the science behind glass hardness unveils its pivotal role in shaping modern architecture, automotive safety, electronic innovation, and aesthetic design. The ability to modify and enhance the hardness of glass through tempering, lamination, and specialized treatments empowers designers, engineers, and manufacturers to create solutions that prioritize safety, durability, and visual appeal.

The precise measurement of glass hardness, facilitated by traditional and advanced testing methodologies, provides invaluable insights into the material's mechanical properties, enabling the development of high-performance glass materials for cutting-edge applications. This rigorous approach to hardness testing ensures the reliability, safety, and functionality of glass-based products across diverse sectors, from structural glazing to consumer electronics.

The widespread use of hardened glass in architectural glazing, automotive applications, electronic displays, safety and security installations, and interior decor underscores its indispensable role in enhancing safety, functionality, and aesthetic appeal. The fusion of exceptional hardness, impact resistance, and design versatility positions hardened glass as a fundamental material that continues to drive innovation and elevate the standards of modern living and industrial practices.

As we navigate the captivating realm of glass hardness, we gain a deeper appreciation for the ingenuity and adaptability of this remarkable material, recognizing its enduring impact on our built environment, technological advancements, and everyday experiences. The pursuit of optimizing glass hardness represents a testament to human creativity and engineering excellence, shaping a future where safety, sustainability, and design converge to redefine the possibilities of glass as a cornerstone of modern innovation.

Frequently Asked Questions about What Is The Hardness Of Glass

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is The Hardness Of Glass”