Home>Furniture & Design>Interior Design Trends>What Kind Of Glue To Use On Glass

Interior Design Trends

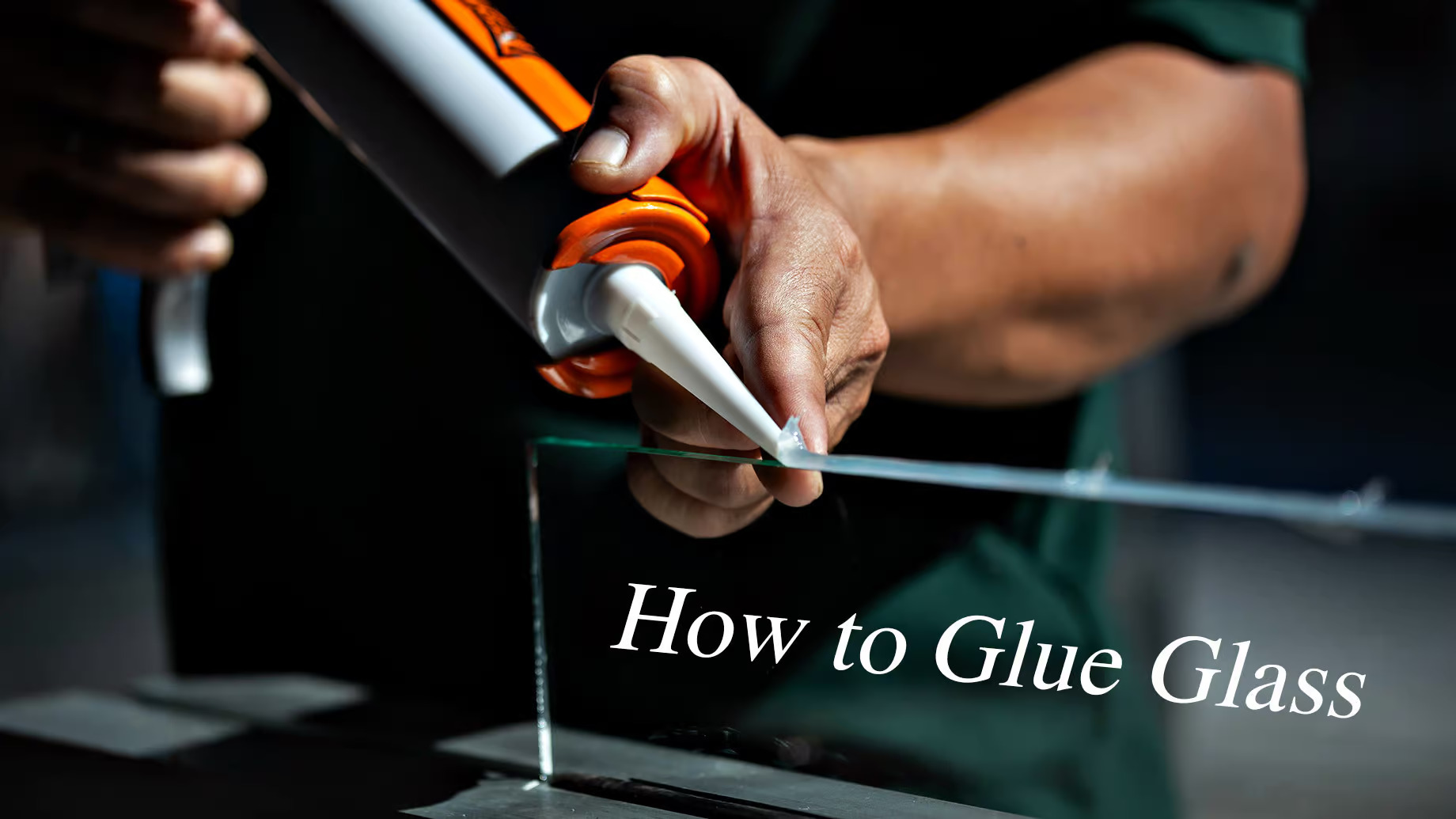

What Kind Of Glue To Use On Glass

Published: February 3, 2024

Discover the best glue for glass in interior design trends. Find out which adhesive is perfect for your glass projects. Explore tips and recommendations for successful glass bonding.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When it comes to crafting, repairing, or creating art, glass is a versatile material that offers a unique set of challenges. Whether you're mending a broken vase, creating a stunning mosaic, or embarking on a DIY project, choosing the right glue for glass is crucial for achieving a strong and lasting bond. With a myriad of adhesive options available, it's essential to understand the different types of glue suitable for glass, the factors to consider when making a selection, and the best practices for ensuring successful adhesion.

Glass, known for its transparency, fragility, and smooth surface, requires a specialized approach when it comes to bonding. Unlike other materials, such as wood or metal, glass presents a unique challenge due to its non-porous nature and susceptibility to cracking under pressure. Therefore, selecting the appropriate adhesive is paramount to achieving a secure and durable bond.

In this comprehensive guide, we will delve into the various types of glue specifically designed for glass, explore the factors to consider when choosing the right adhesive, and provide best practices for using glue on glass. By the end of this article, you will have a clear understanding of the options available and the knowledge needed to make an informed decision when working with glass and adhesive. Let's embark on this journey to discover the art and science of bonding glass with the perfect glue.

Key Takeaways:

- Choose the right glue for glass based on transparency, strength, application method, curing time, environmental resistance, flexibility, and chemical compatibility to ensure a strong and lasting bond for your project.

- Follow best practices such as thorough surface preparation, precision application, proper clamping, adherence to curing conditions, safety precautions, post-bonding inspection, and ongoing maintenance when using glue on glass to achieve reliable and aesthetically pleasing bonds.

Read more: What Glue To Use For Glass

Types of Glue for Glass

When it comes to bonding glass, selecting the right type of glue is crucial for achieving a strong and lasting bond. There are several types of adhesives specifically formulated for glass, each with its own unique properties and applications. Understanding the characteristics of these glues can help you make an informed decision based on your specific project requirements. Here are some common types of glue suitable for glass:

-

Cyanoacrylate Glue (Super Glue): This fast-acting adhesive is known for its quick bonding properties. It forms a strong and durable bond on glass surfaces, making it ideal for small repairs and bonding glass to non-porous materials. However, it may not be suitable for load-bearing applications or areas exposed to moisture.

-

UV-curing Glue: This specialized adhesive cures when exposed to ultraviolet light, creating a strong and transparent bond on glass surfaces. It is commonly used in glass art and jewelry making due to its ability to bond intricate glass pieces without leaving visible residue.

-

Epoxy Resin: Epoxy resin is a versatile adhesive that forms a durable and waterproof bond on glass. It consists of a resin and hardener that, when mixed, create a strong adhesive suitable for a wide range of glass bonding applications, including mosaics, jewelry, and glassware repair.

-

Silicone Adhesive: Silicone adhesive is known for its flexibility and resistance to temperature and moisture. It is commonly used for bonding glass in aquariums, terrariums, and outdoor glass fixtures due to its ability to withstand environmental stressors.

-

Polyurethane Adhesive: This adhesive is valued for its strong and flexible bond on glass surfaces. It is suitable for both indoor and outdoor applications, making it ideal for bonding glass to various substrates in construction and DIY projects.

-

Glass Adhesive Tape: This innovative adhesive solution offers a convenient and mess-free alternative for bonding glass. It is commonly used in the assembly of glass panels and displays, providing a clean and efficient bonding method.

Each type of glue for glass offers unique advantages and considerations, and the choice of adhesive depends on the specific requirements of your project. By understanding the properties and applications of these adhesives, you can confidently select the most suitable glue for achieving optimal results when working with glass.

Remember, the key to successful glass bonding lies in choosing the right adhesive and following best practices to ensure a secure and durable bond. With the knowledge of different types of glue for glass, you are better equipped to embark on your glass-related projects with confidence and precision.

Factors to Consider When Choosing Glue

When selecting the appropriate glue for bonding glass, several crucial factors should be taken into account to ensure the success and longevity of the bond. Understanding these factors will help you make an informed decision and choose the most suitable adhesive for your specific glass-related project.

-

Transparency and Aesthetics: Consider the transparency of the glue and its impact on the overall aesthetics of the project. For applications where the bond line should be nearly invisible, opt for adhesives specifically designed to dry clear, such as UV-curing glue or certain types of epoxy resin.

-

Strength and Durability: Assess the strength and durability requirements of the bond based on the intended use of the glass. For load-bearing applications or repairs that require high impact resistance, choose adhesives known for their strong and durable bonds, such as epoxy resin or polyurethane adhesive.

-

Application Method: Evaluate the application method that best suits your project. Some adhesives come in liquid form and require mixing, while others are available in gel or tape form for easier application. Consider the accessibility of the bonding area and the precision required for the application when choosing the adhesive type.

-

Curing Time: Take into consideration the curing time of the adhesive and how it aligns with your project timeline. Some adhesives offer rapid curing, making them suitable for quick repairs, while others require longer curing periods for optimal bond strength. Understanding the curing time will help you plan and execute your project effectively.

-

Resistance to Environmental Factors: Assess the environmental conditions to which the bonded glass will be exposed. Consider factors such as temperature fluctuations, moisture, and UV exposure. Choose adhesives with appropriate resistance to these environmental stressors to ensure the longevity of the bond.

-

Flexibility and Expansion: For applications where the bonded glass may experience slight movement or expansion, such as in outdoor fixtures or glass assemblies, consider adhesives that offer flexibility and can accommodate such movements without compromising the bond integrity.

-

Chemical Compatibility: If the bonded glass will come into contact with chemicals or cleaning agents, ensure that the chosen adhesive is chemically compatible with the anticipated substances to prevent degradation or weakening of the bond over time.

By carefully considering these factors, you can make a well-informed decision when choosing the right glue for glass bonding. Each factor plays a crucial role in determining the suitability of the adhesive for your specific project requirements, ultimately contributing to the success and durability of the bond.

When gluing glass, use a clear, waterproof adhesive like silicone or epoxy. Make sure the surfaces are clean and roughened for better adhesion. Allow the glue to cure for the recommended time before handling the glass.

Best Practices for Using Glue on Glass

When working with glass and adhesive, following best practices is essential to ensure a successful and enduring bond. By adhering to these guidelines, you can maximize the effectiveness of the chosen glue and achieve optimal results in your glass-related projects.

-

Surface Preparation: Before applying the adhesive, it is crucial to prepare the glass surface to ensure proper adhesion. Thoroughly clean the glass to remove any dust, dirt, or residues that may hinder the bonding process. Use a gentle glass cleaner and ensure that the surface is completely dry before applying the glue.

-

Precision Application: Apply the adhesive with precision, ensuring that it is distributed evenly and covers the bonding area thoroughly. Depending on the type of adhesive, use a small brush, syringe, or precision applicator to control the application and minimize excess glue that could affect the aesthetics of the bond.

-

Clamping or Support: For certain bonding applications, especially those involving larger or heavier glass pieces, using clamps or providing external support during the curing process can help achieve a stronger and more secure bond. Follow the manufacturer's recommendations regarding clamping pressure and duration to ensure optimal bonding conditions.

-

Curing Conditions: Pay attention to the recommended curing conditions specified by the adhesive manufacturer. Factors such as temperature, humidity, and exposure to light can significantly impact the curing process and the ultimate strength of the bond. Create an environment that aligns with the optimal curing conditions for the chosen adhesive.

-

Safety Precautions: When working with adhesives, prioritize safety by following the recommended safety precautions provided by the adhesive manufacturer. Use protective gloves and ensure adequate ventilation in the workspace, especially when working with adhesives that emit fumes during the curing process.

-

Post-Bonding Inspection: After the adhesive has cured, inspect the bonded area to ensure that the bond is secure and free from any visible defects. Check for uniformity, clarity, and strength of the bond to confirm that the adhesive has effectively bonded the glass surfaces.

-

Maintenance and Care: Once the adhesive has fully cured, follow any specific maintenance and care instructions provided by the adhesive manufacturer to preserve the integrity of the bond. This may include recommendations for cleaning, handling, and protecting the bonded glass surfaces.

By incorporating these best practices into your glass bonding process, you can enhance the effectiveness of the chosen adhesive and achieve reliable and aesthetically pleasing bonds. Whether you are repairing a cherished glass item or engaging in a creative glass art project, following these guidelines will contribute to the success and longevity of the bonded glass surfaces.

Conclusion

In conclusion, the art of bonding glass with the perfect glue involves a thoughtful consideration of adhesive types, essential factors, and best practices. The diverse range of glues designed for glass offers unique properties and applications, catering to various project requirements. Whether it's the rapid bonding of cyanoacrylate glue, the transparent allure of UV-curing glue, or the durable versatility of epoxy resin, each adhesive type serves as a valuable tool in the hands of crafters, artisans, and DIY enthusiasts.

When choosing the right glue for glass, factors such as transparency, strength, application method, curing time, environmental resistance, flexibility, and chemical compatibility play pivotal roles in determining the suitability of the adhesive for a specific project. By carefully evaluating these factors, individuals can make informed decisions, ensuring that the chosen adhesive aligns with the intended use and environmental conditions.

Moreover, adhering to best practices when using glue on glass is essential for achieving reliable and aesthetically pleasing bonds. From meticulous surface preparation to precision application, proper clamping, adherence to curing conditions, safety precautions, post-bonding inspection, and ongoing maintenance, each step contributes to the overall success and longevity of the bond.

By embracing the knowledge of different adhesive types, understanding the critical factors to consider, and implementing best practices, individuals can embark on glass-related projects with confidence and precision. Whether it's repairing a cherished glass item, creating intricate glass art, or engaging in innovative DIY endeavors, the right adhesive, coupled with informed decision-making and meticulous application, paves the way for remarkable outcomes.

In the realm of glass bonding, the synergy between creativity and precision is paramount. The ability to fuse artistry with technical expertise, while harnessing the right adhesive, empowers individuals to bring their glass-related visions to life. As the art and science of bonding glass continue to evolve, the knowledge shared in this guide serves as a valuable compass, guiding enthusiasts and professionals alike toward successful and enduring glass bonding endeavors.

In essence, the journey of bonding glass with the perfect glue is a testament to the harmonious blend of creativity, craftsmanship, and technical acumen. With the right adhesive as a trusted ally, the possibilities for creating, repairing, and innovating with glass are as boundless as the imagination itself.

Frequently Asked Questions about What Kind Of Glue To Use On Glass

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Kind Of Glue To Use On Glass”