Home>Garden Essentials>What Is An Infill Speed

Garden Essentials

What Is An Infill Speed

Modified: August 20, 2024

Discover what an infill speed is and how it can enhance your garden. Learn how to maximize your garden's potential with this useful technique.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of 3D printing! As you delve into the realm of additive manufacturing, you will come across various technical terms and settings that play a crucial role in achieving the desired print quality. One such term that you may encounter is “infill speed.”

Infill speed refers to the speed at which the interior structure, or infill, of a 3D printed object is created. It determines the rate at which the printer deposits material within the empty spaces of the model, providing structural support while conserving material and reducing print time. Understanding and optimizing infill speed is essential for achieving the perfect balance between strength, speed, and material usage.

In this article, we will delve deeper into the concept of infill speed, its significance in different applications, and strategies to optimize it.

Key Takeaways:

- Infill speed is the rate at which a 3D printer creates the internal structure of an object. It affects strength, print time, and quality, and can be optimized by considering factors like model complexity and material type.

- Adjusting infill speed is crucial for different applications, from prototyping to artistic prints. By experimenting with settings and monitoring print quality, 3D printing enthusiasts can achieve efficient and strong prints.

Read more: What Is A Good Infill Speed In Cura

Definition of Infill Speed

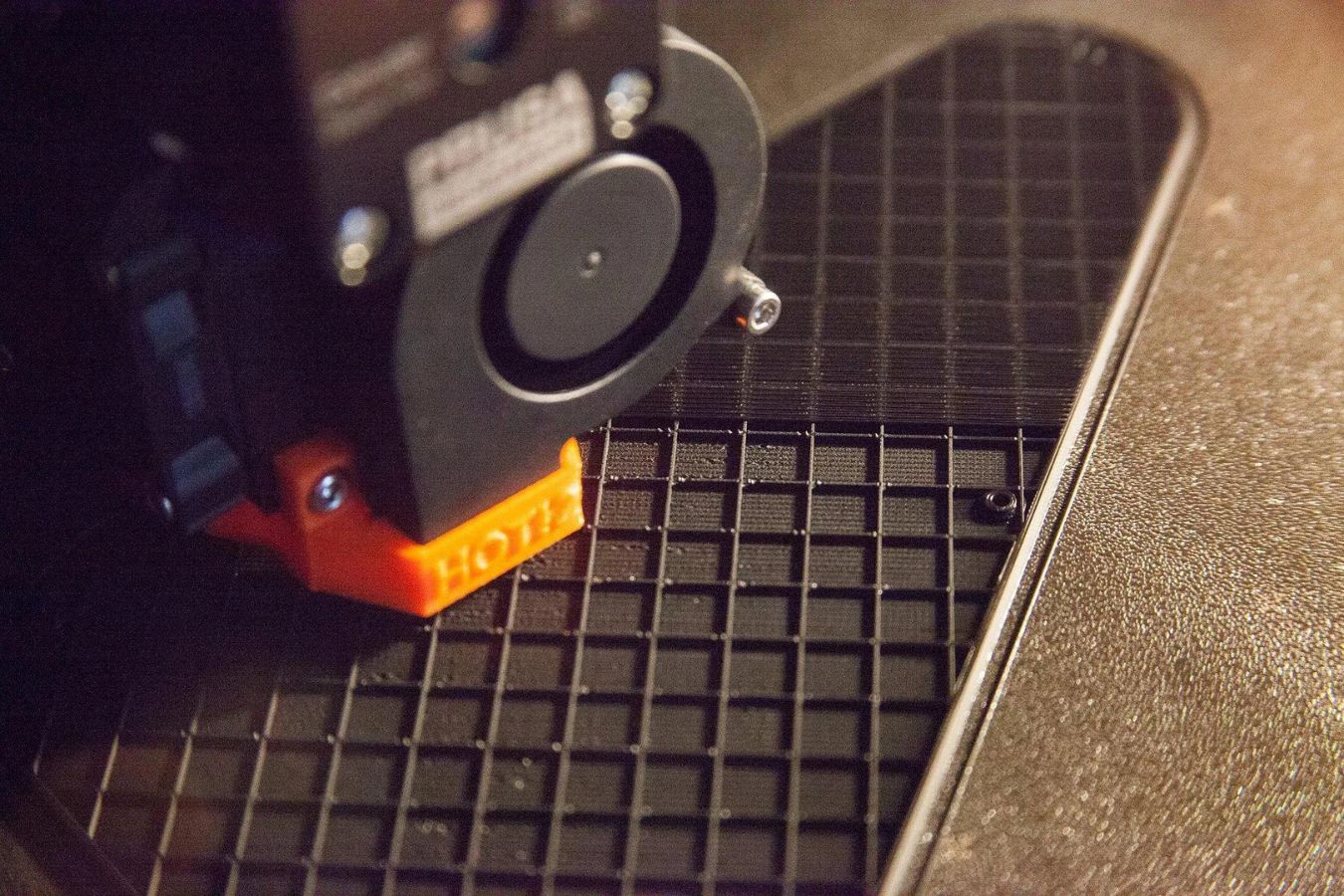

Infill speed refers to the rate or speed at which the 3D printer nozzle moves while depositing material in the infill regions of a 3D printed object. It is an important parameter that determines the speed at which the interior structure of the model is built.

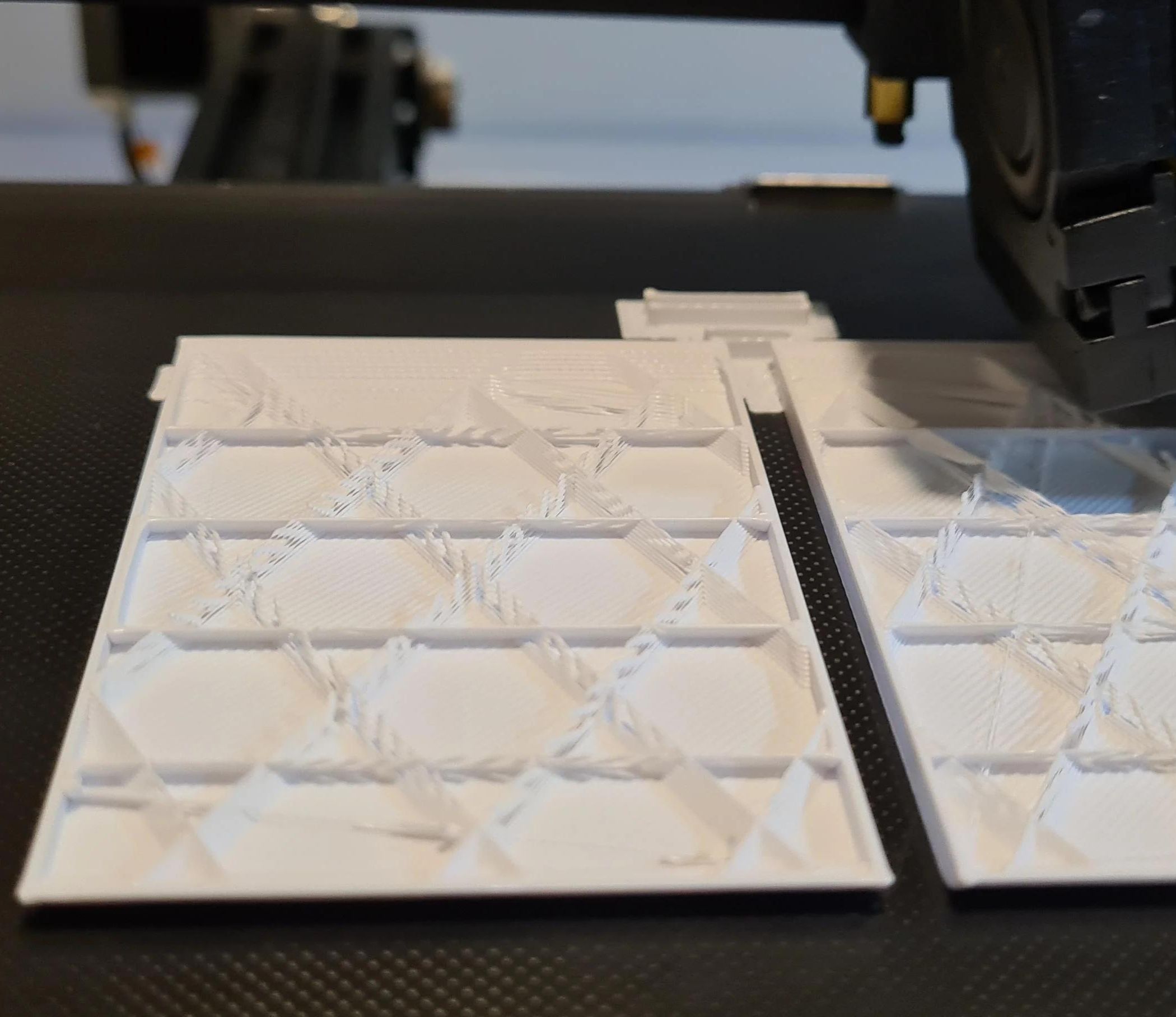

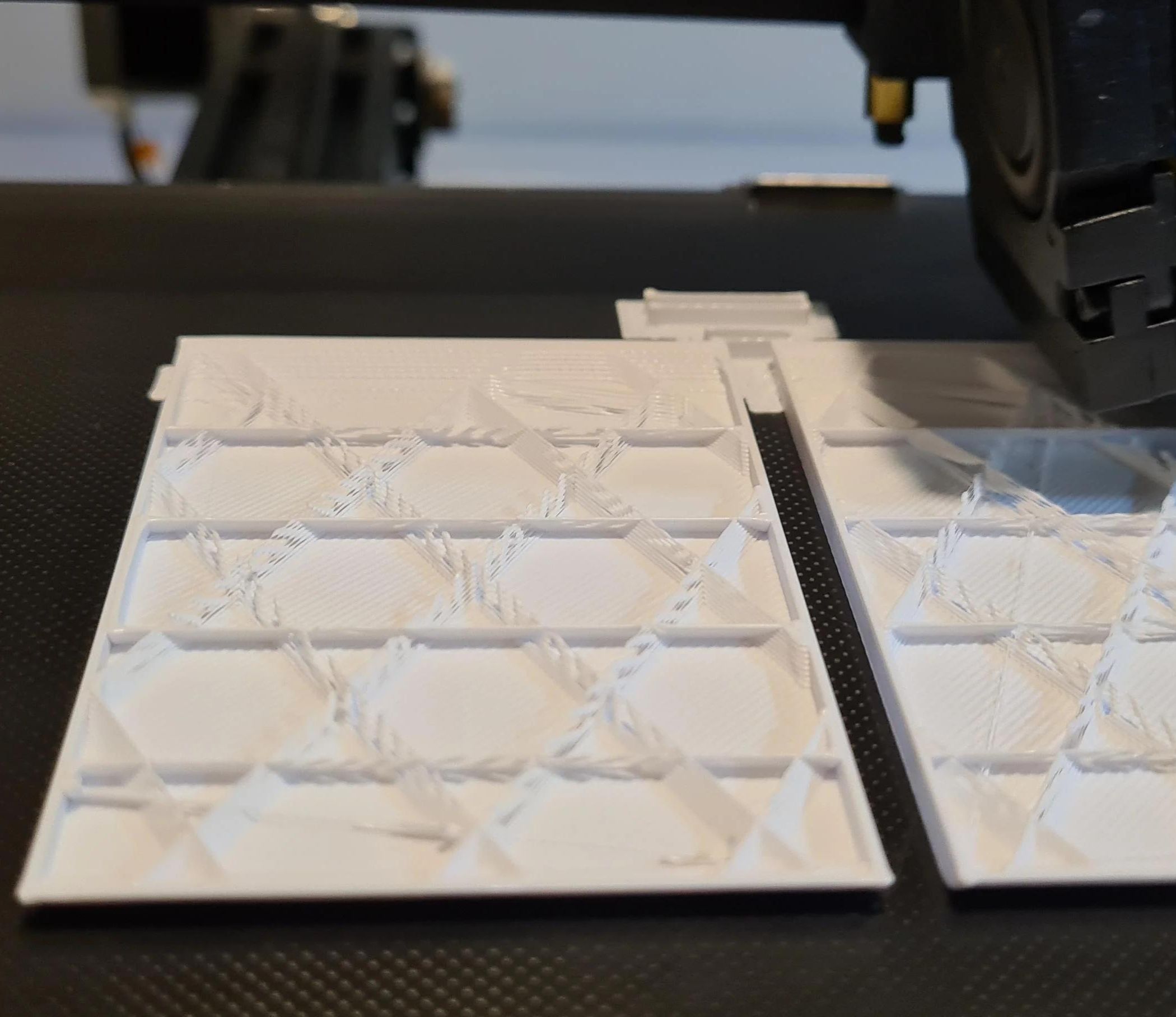

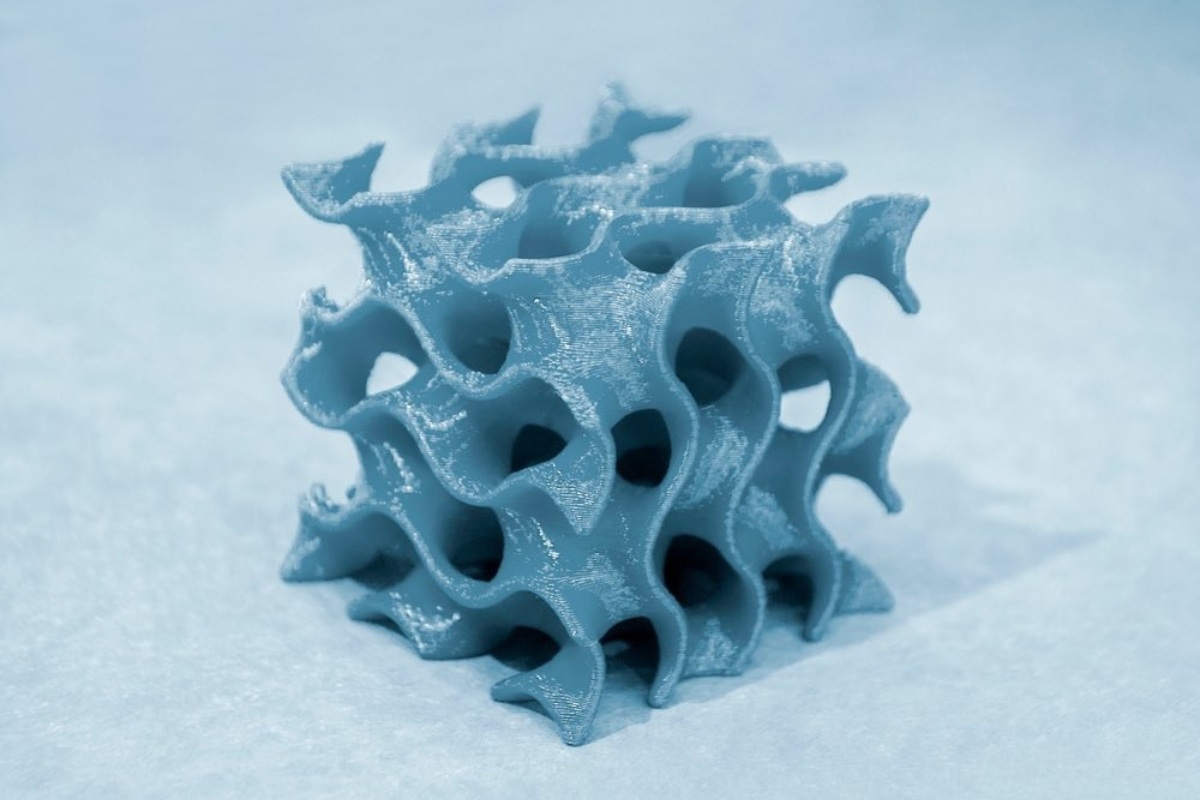

During the 3D printing process, the printer head moves layer by layer, depositing material to create the solid outer shell of the object as well as the internal infill structure. The infill is the internal lattice or honeycomb-like structure that provides support and stability to the printed object. The infill speed determines how quickly this structure is constructed.

The infill speed is usually defined as a percentage of the print speed or the speed at which the outer walls of the object are printed. For example, if the print speed is set to 60 mm/s and the infill speed is set to 50%, the infill will be printed at a speed of 30 mm/s.

The infill speed setting can usually be adjusted in the slicing software used to prepare the 3D model for printing. Most slicing software allows for customization of infill speed to optimize the printing process based on factors such as the complexity of the model, desired strength, and material usage.

Factors Affecting Infill Speed

When determining the appropriate infill speed for a 3D printing project, several factors need to be taken into consideration. This includes the complexity of the model, the desired strength of the printed object, the type of material being used, the capabilities of the 3D printer, and the overall print speed.

1. Model Complexity: The complexity of the model plays a significant role in determining the ideal infill speed. Objects with intricate internal structures or fine details may require slower infill speeds to ensure precision and accuracy.

2. Desired Strength: The strength requirements of the printed object will also influence the infill speed. Objects that require high structural integrity, such as load-bearing components or functional prototypes, may benefit from slower infill speeds to ensure better bonding between layers and increased strength.

3. Material Type: Different types of 3D printing materials have varying characteristics and printing parameters. For example, PLA (polylactic acid) is a commonly used filament that prints well at higher speeds, while materials like ABS (acrylonitrile butadiene styrene) may require lower infill speeds to mitigate issues like warping or poor layer adhesion.

4. Printer Capability: The capabilities of the 3D printer itself, including the maximum achievable print speed and the precision of movement, will also impact the infill speed. Some printers may have limited speeds for infill printing, while others may offer more flexibility.

5. Overall Print Speed: The overall speed at which the 3D printer operates will influence the infill speed. Higher overall print speeds may require faster infill speeds to maintain consistency throughout the print, while slower print speeds may allow for more controlled and precise infill deposition.

It is essential to experiment and find the optimal infill speed for each specific project by considering these factors and making adjustments accordingly. Fine-tuning the infill speed can result in improved print quality, reduced print time, and increased strength of the final printed object.

Importance of Infill Speed in Various Applications

The infill speed setting plays a critical role in 3D printing, as it directly affects the strength, print time, and overall quality of the printed object. The importance of infill speed can vary depending on the specific application and desired outcome. Here are some examples of how infill speed impacts different applications:

1. Prototyping: Infill speed is crucial when it comes to prototyping functional parts. Adjusting the infill speed allows for the creation of rapid prototypes with varying levels of strength and support. For parts that will undergo mechanical stress during testing, a slower infill speed may be necessary to achieve optimal strength and durability.

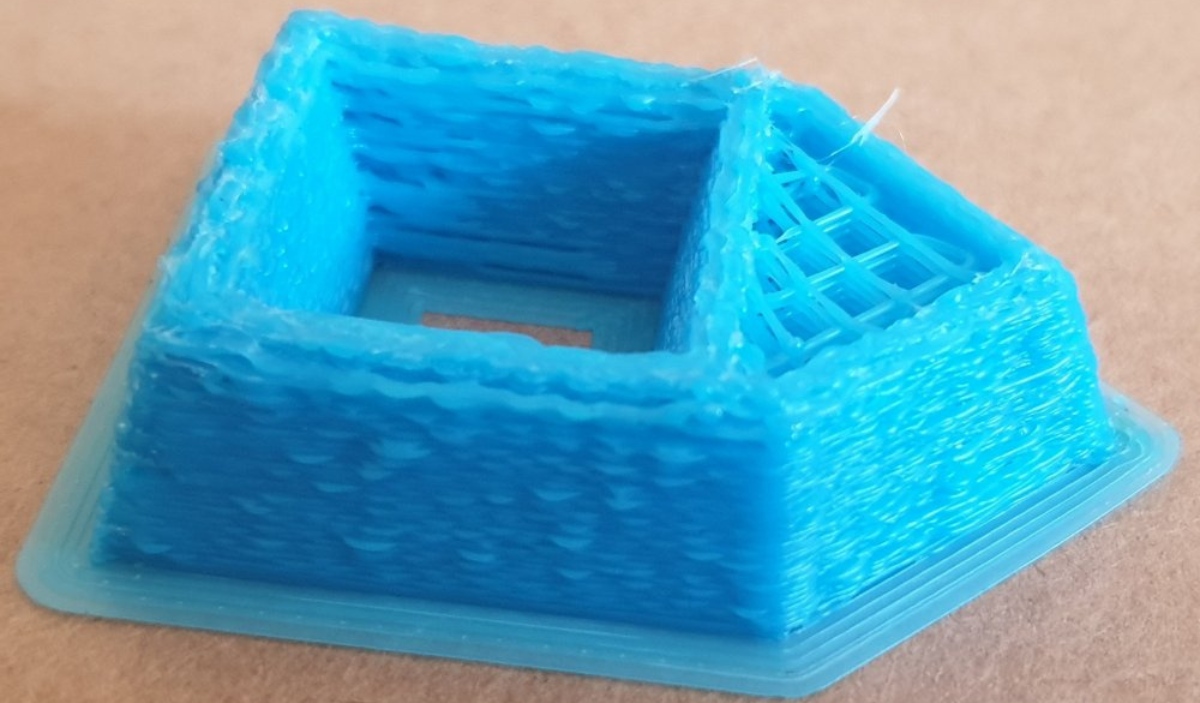

2. Cosmetic Prints: In situations where the aesthetics of the printed object take precedence, such as with art pieces or display models, infill speed can be adjusted to minimize visible layer lines and enhance surface quality. The infill pattern and speed can be fine-tuned to achieve a smoother appearance while still maintaining structural integrity.

3. Engineering Components: Infill speed is particularly important when printing engineering components that require a balance between strength and material usage. By optimizing the infill speed, it is possible to reduce material costs while ensuring that the printed object has sufficient structural support to withstand mechanical stresses and loads.

4. Artistic and Sculptural Prints: In the realm of artistic and sculptural prints, infill speed can be manipulated to create intricate and detailed internal structures. By adjusting the infill speed, artists can create unique patterns and designs within their sculptures that enhance aesthetics and add visual interest.

5. Medical and Dental Applications: Infill speed is critical in medical and dental applications, where precision and accuracy are paramount. Whether it is creating anatomical models for surgical planning or fabricating dental aligners, optimizing infill speed ensures that the 3D printed objects meet the stringent requirements of these fields.

By understanding the importance of infill speed and its application-specific implications, 3D printing enthusiasts can leverage this parameter to achieve the desired results in terms of strength, aesthetics, and functionality. It is essential to experiment and fine-tune the infill speed setting to cater to the specific requirements of each application and maximize the potential of 3D printing technology.

When adjusting infill speed in 3D printing, consider the balance between speed and quality. Increasing infill speed can save time but may compromise strength and surface finish. Experiment with different speeds to find the best balance for your specific project.

Choosing the Right Infill Speed for 3D Printing

When it comes to selecting the ideal infill speed for 3D printing, there are a few considerations that can help guide your decision-making process. The goal is to strike a balance between print speed, strength, and material usage. Here are some strategies to help you choose the right infill speed:

1. Start with Manufacturer Recommendations: Check the manufacturer’s guidelines or product specifications for your specific 3D printer and filament. They often provide recommended infill speed ranges that can serve as a starting point for your prints. These recommendations are based on the printer’s capabilities and the material’s properties, ensuring a good starting point for reliable prints.

2. Consider Material Characteristics: Different materials have varying printing characteristics, so take the material into account when choosing the infill speed. For example, rigid materials like PLA tend to perform well at higher speeds, while more flexible materials like TPU may require slower infill speeds to maintain accuracy and prevent deformation.

3. Assess Print Complexity: Evaluate the complexity of your model. If it has intricate details or fine features, slower infill speeds may be necessary to ensure precision and accuracy. On the other hand, if the model has simpler geometry, you may be able to increase the infill speed without sacrificing print quality.

4. Consider Strength Requirements: Assess the strength requirements of your printed object. If you need a part with high structural integrity, it may be beneficial to choose a slower infill speed to enhance bonding between layers and increase overall strength. For less demanding applications, a faster infill speed may be acceptable.

5. Find the Right Balance: Experiment with different infill speeds to find the sweet spot for your specific project. Start with the manufacturer’s recommendations, and gradually adjust the infill speed up or down to achieve the desired balance between speed, strength, and material usage.

6. Iterate and Optimize: Don’t be afraid to iterate and optimize your infill speed settings. Fine-tuning the infill speed can greatly impact the quality of your prints, reducing print time, minimizing material usage, and improving overall structural integrity. Keep a record of your settings and outcomes to help you refine your future prints.

Remember, finding the optimal infill speed is a process of trial and error. It requires experimentation and iteration to get the best results for your specific 3D printing project. By considering the material properties, print complexity, strength requirements, and striking the right balance, you can choose the infill speed that meets your needs and achieves high-quality prints.

Read more: What Are Speed Cushions

Strategies to Optimize Infill Speed

Optimizing the infill speed in 3D printing can lead to significant improvements in print quality, efficiency, and overall performance. Here are some strategies to help you optimize your infill speed:

1. Gradual Speed Adjustments: Start with a conservative infill speed setting, and gradually increase or decrease it based on the performance and quality of your prints. This iterative approach allows you to find the ideal speed that achieves the right balance between strength and print time.

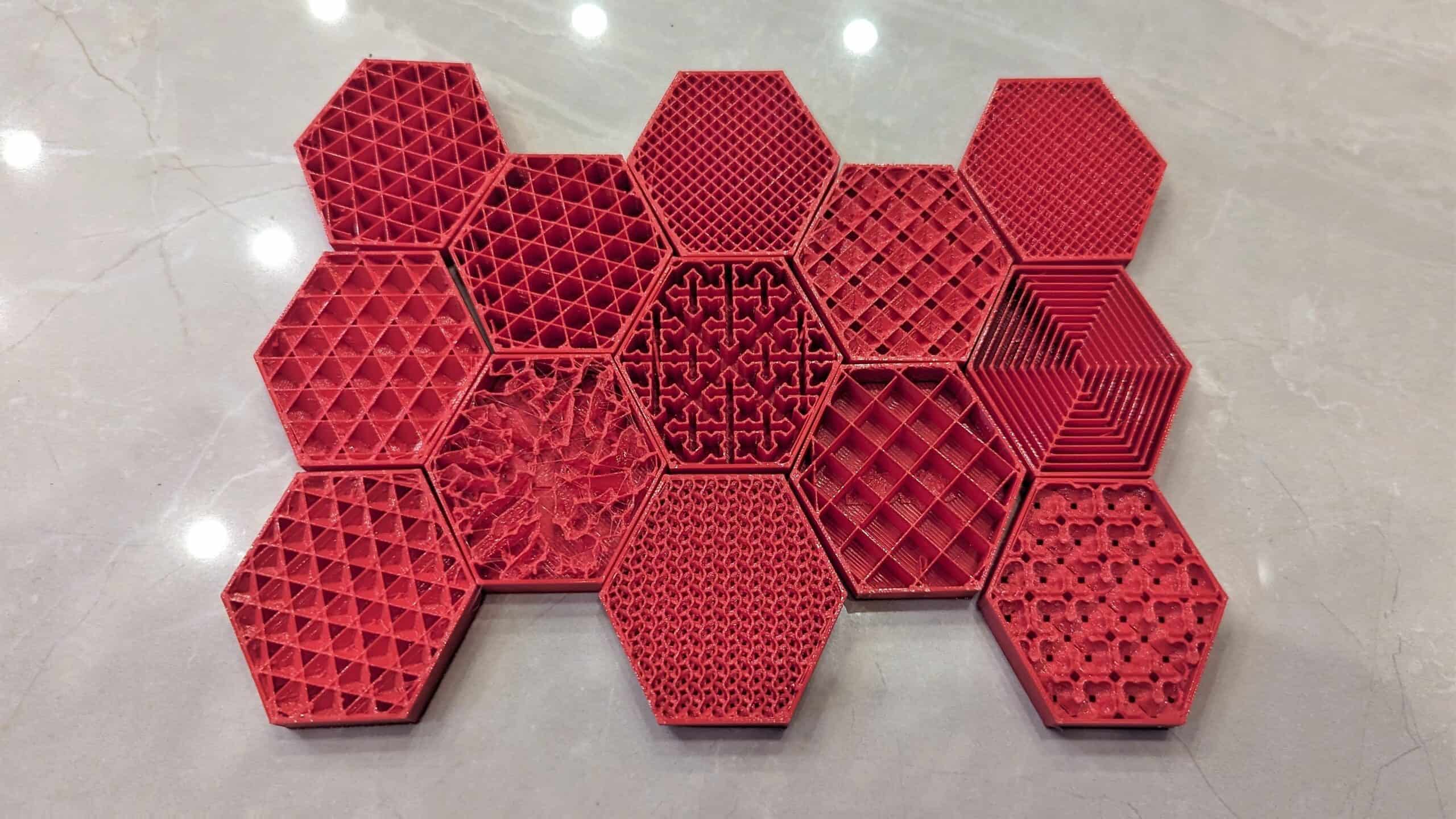

2. Customize Infill Patterns: Experiment with different infill patterns to optimize the infill speed. Some patterns, such as rectilinear or grid, may allow for faster printing speeds, while more complex patterns like gyroid or honeycomb may require slower speeds to maintain accuracy. Explore your slicing software’s options for infill patterns and choose the one that suits your needs best.

3. Layer Height Optimization: Adjusting the layer height can have a direct impact on the infill speed. Thicker layers may allow for faster infill speeds, while thinner layers require slower speeds to ensure proper material deposition and bonding. Strike a balance between layer height, print speed, and desired print quality to maximize your infill speed optimization.

4. Consider Infill Percentage: Lower infill percentages allow for faster infill speeds as less material is being deposited. However, keep in mind that reducing the infill percentage can affect the overall strength and stability of the printed object. Find the right balance between infill percentage and infill speed to achieve the desired results.

5. Optimize Print Cooling: Proper cooling can help maintain print quality at higher infill speeds. Ensure that your printer’s fan settings are optimized for effective cooling during the printing process. This can minimize issues like overheating and improve the quality of the infill.

6. Experiment with Printing Speed: Adjusting the overall print speed can indirectly impact the infill speed. Increasing the print speed will lead to faster infill speeds, while slowing it down can allow for more precise infill deposition. Strike a balance between print speed and infill speed based on your specific requirements.

7. Monitor Print Quality: Keep a close eye on the print quality as you adjust the infill speed. Look for signs of underextrusion, poor adhesion between layers, or other imperfections. Use these observations as indicators to fine-tune your infill speed settings and achieve optimal results.

Remember, the goal of optimizing the infill speed is to achieve the right balance between speed, strength, and print quality. It requires a combination of experimentation, observation, and adjustment to find the optimal settings for each specific print. Keep track of your results and iterate on your settings to continuously improve your infill speed optimization.

Conclusion

Understanding and optimizing infill speed is a crucial aspect of 3D printing. It directly affects the strength, print time, and overall quality of your printed objects. By choosing the right infill speed and implementing strategies to optimize it, you can achieve significant improvements in your prints.

When selecting the infill speed, consider factors such as the complexity of the model, desired strength, material characteristics, printer capabilities, and overall print speed. These factors will help you determine the optimal infill speed for your specific project.

Experimentation is key to finding the sweet spot for your infill speed. Make gradual adjustments, customize infill patterns, optimize layer height, consider infill percentage, and monitor print quality to refine your infill speed settings. By fine-tuning this parameter, you can strike the right balance between speed and quality, achieving efficient and strong prints.

Remember, infill speed optimization is an ongoing process of trial and error. It requires patience, observation, and continuous improvement. Keep track of your settings and outcomes to learn from each print and enhance your future prints.

As you delve into the world of 3D printing, mastering the art of infill speed optimization will not only result in high-quality prints but also unlock new possibilities in various applications. So, embrace the realm of infill speed and enjoy the benefits it brings to your 3D printing journey.

Frequently Asked Questions about What Is An Infill Speed

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is An Infill Speed”