Home>Home Maintenance>What Is A Capacitor On An Air Conditioner

Home Maintenance

What Is A Capacitor On An Air Conditioner

Modified: August 27, 2024

Learn about the role of a capacitor in an air conditioner and its importance for home maintenance. Discover how this component helps to start the unit and regulate performance.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to our comprehensive guide on capacitors and their role in air conditioners. Whether you’re a homeowner or a professional in the home maintenance industry, understanding the function and importance of capacitors is crucial for properly maintaining and troubleshooting air conditioning systems. In this article, we will delve into the definition of a capacitor, its function in an air conditioner, the types of capacitors commonly used, how to detect capacitor failure, and the steps to replace a faulty capacitor.

Have you ever wondered how an air conditioner works to cool down your home during those scorching summer months? Well, one of the key components responsible for this cooling process is the capacitor. So, let’s begin by exploring what a capacitor is and why it is an essential part of your air conditioning system.

Key Takeaways:

- Capacitors are like energy storage units for air conditioners, providing the initial boost needed to start the motors and ensuring smooth operation. Recognizing signs of capacitor failure can help maintain a cool and comfortable home.

- Safety is crucial when dealing with capacitors. If you suspect an issue, it’s best to seek help from a professional technician to test and replace the faulty capacitor, ensuring a safe and efficient air conditioning system.

Definition of a Capacitor

A capacitor, in its simplest form, is an electrical component that stores and releases electrical energy. It consists of two conductive plates separated by an insulating material known as a dielectric. When a voltage is applied to a capacitor, it charges up by storing electric charge on its plates. This stored charge can then be released when needed.

The capacitance of a capacitor, measured in farads (F), determines its ability to store charge. Capacitors used in air conditioners typically have capacitance values ranging from microfarads (µF) to farads (F). These values may seem small, but they are sufficient for the specific requirements of air conditioning systems.

Capacitors come in various shapes, sizes, and materials. They can be cylindrical, rectangular, or even chip-like in appearance. Regardless of their physical form, capacitors play a vital role in the operation of air conditioners by providing the necessary electrical energy for different components to function efficiently.

Now that we have a basic understanding of what a capacitor is, let’s explore its crucial function in air conditioning systems.

Function of a Capacitor on an Air Conditioner

The primary function of a capacitor in an air conditioner is to provide a jolt of electrical energy to start the system’s electric motor. The compressor, blower motor, and fan motor in an air conditioner require a significant amount of energy to start running. However, they don’t need that much power to keep them running once they are in motion. It is the capacitor’s job to deliver that initial burst of energy.

When you turn on your air conditioner, the capacitor stores electrical energy from the power supply. As the compressor motor and fan motor startup, they require a higher amount of energy than what is provided by the power supply alone. This is where the stored energy in the capacitor becomes crucial. The capacitor discharges this energy, giving the motors the extra boost they need to initiate their movement.

Once the motors are running, the capacitor continues to aid in their operation by providing a steady flow of electricity. It helps ensure consistent performance, efficient operation, and smooth running of the compressor and fan motors. Without a functioning capacitor, the motors may struggle to start, may not run at their optimal speed, or may fail to run altogether.

In addition to starting the motors, capacitors also help maintain a stable voltage supply to different components in the air conditioning system. They act as voltage stabilizers, preventing voltage fluctuations and ensuring the proper operation of various electrical equipment.

Now that we understand the essential function of a capacitor in an air conditioner, let’s explore the different types of capacitors commonly used in these systems.

Types of Capacitors Used in Air Conditioners

There are several types of capacitors used in air conditioning systems, each designed to suit specific applications and requirements. Let’s take a look at the most commonly used types:

- Start Capacitor: As the name suggests, the start capacitor is responsible for providing the initial boost of energy needed to start the compressor motor. It has a higher capacitance value compared to other capacitors and is only active during the startup process.

- Run Capacitor: The run capacitor helps maintain the motor’s performance and efficiency once it is running. It provides a continuous flow of energy to the motor, ensuring smooth operation and reducing power fluctuations. Run capacitors have lower capacitance values compared to start capacitors.

- Dual Run Capacitor: Some air conditioning systems utilize a dual run capacitor, which combines the functions of both the start and run capacitors into a single component. This simplifies the design and reduces the number of components in the system.

- Oil-Filled Capacitor: Oil-filled capacitors are designed to withstand high temperatures and provide stability and reliability in challenging environments. They are commonly used in outdoor air conditioning units where exposure to extreme weather conditions is a concern.

- Electrolytic Capacitor: Electrolytic capacitors are commonly used in the electronic control boards of air conditioning systems. They have higher capacitance values and are polarized, meaning they have a positive and negative terminal. These capacitors are known for their high energy storage capabilities.

When it comes to choosing the right capacitor for your air conditioning system, it’s essential to consider factors such as voltage rating, capacitance value, and physical dimensions. Checking the manufacturer’s specifications and consulting a professional technician will help ensure you select the appropriate capacitor for your specific system.

Now that we understand the different types of capacitors used in air conditioners, let’s move on to discussing the common symptoms of capacitor failure.

Regularly check and clean the capacitor in your air conditioner to ensure it is functioning properly. This can help prevent potential breakdowns and extend the lifespan of your unit.

Capacitor Failure and Common Symptoms

Capacitor failure is not uncommon in air conditioning systems, and it can significantly impact the performance and functionality of the unit. It’s important to be aware of the common symptoms of a failing capacitor so that you can address the issue promptly. Here are some signs to watch out for:

- Difficulty Starting: One of the primary indicators of a faulty capacitor is difficulty in starting the air conditioner. You may notice that the system takes longer than usual to start, or it may not start at all. This is because a failing capacitor cannot provide the necessary electrical boost to the motor.

- Excessive Humming or Buzzing: If you hear unusual humming or buzzing sounds coming from your air conditioner, it may be a sign of a failing capacitor. This noise is caused by the struggling motor trying to start or maintain operation due to insufficient electrical energy.

- Inconsistent Cooling: A faulty capacitor can lead to inconsistent cooling performance. You may notice that the air conditioner does not cool the room as effectively as it used to. This inconsistency can be attributed to the motor not running at its optimal speed or struggling to maintain a stable operation.

- Frequent System Tripping: Capacitor failure can cause the air conditioner to trip frequently, leading to the system shutting down unexpectedly. This occurs as a safety mechanism to protect the motors from damage due to insufficient electrical power.

- Hot or Swollen Capacitor: In some cases, a failing capacitor may become hot or swollen. This physical change indicates that the capacitor is overheating or experiencing internal damage.

If you notice any of these symptoms, it’s recommended to have a professional HVAC technician inspect your system. They will be able to diagnose the issue accurately and determine if a faulty capacitor is the culprit.

Next, let’s explore how to test a capacitor on an air conditioner to confirm if it is indeed faulty.

Read more: How To Check Air Conditioner Capacitor

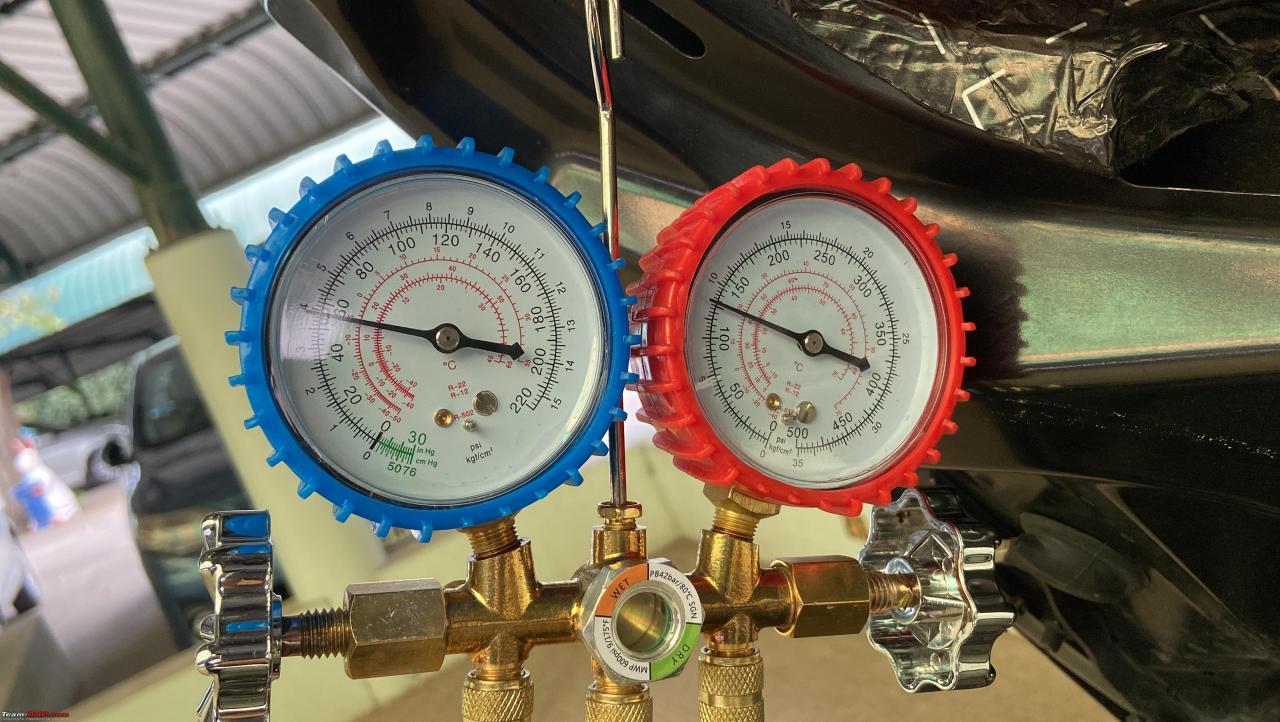

How to Test a Capacitor on an Air Conditioner

If you suspect that a capacitor is faulty in your air conditioning system, you can perform a simple test to confirm its condition. However, it’s essential to note that working with electrical components can be dangerous, so it’s recommended to leave this task to a qualified professional. Here’s a general overview of the testing process:

- Safety First: Ensure that the power to the air conditioner is completely turned off. This step is vital to prevent any electrical shocks or accidents during the testing process.

- Discharge the Capacitor: Capacitors store an electrical charge, so it’s necessary to discharge them before testing. Using an insulated screwdriver with a rubber handle, carefully bridge the terminals of the capacitor to discharge any stored energy. Be cautious not to touch the metal part of the screwdriver to avoid shocks.

- Use a Capacitor Tester: A capacitor tester, also known as a multimeter, is a handy tool for testing capacitors. Set the multimeter to the capacitance function and connect the test leads to the terminals of the capacitor. The multimeter will display the capacitance value. If the reading is significantly lower than the capacitor’s specified rating or if it shows zero capacitance, it indicates a faulty capacitor that needs to be replaced.

- Additional Testing: Sometimes, a capacitor may have internal damage that affects its functionality, but its capacitance value may still appear normal. In such cases, additional testing may be required, such as checking for resistance or conducting a leakage current test. These tests require specialized equipment and expertise, so it’s best to consult a professional technician.

Again, it’s crucial to exercise caution when working with electrical components. If you’re unsure or uncomfortable performing these tests yourself, it’s always best to seek professional assistance. A qualified technician will have the necessary knowledge and experience to accurately diagnose and test capacitors in your air conditioning system.

Now that we’ve covered how to test a capacitor, let’s move on to discussing the steps involved in replacing a faulty capacitor.

Steps to Replace a Faulty Capacitor

If you have determined that a capacitor in your air conditioning system is faulty and needs replacement, follow these steps to ensure a safe and successful capacitor replacement:

- Ensure Safety: Before starting any work, disconnect the power supply to the air conditioning unit. This step is crucial to prevent any electrical accidents or shocks.

- Identify the Capacitor: Locate the faulty capacitor in your air conditioning system. Capacitors are typically cylindrical in shape and can be found near the condenser unit or on the control board depending on the specific system design.

- Note Wiring Connections: Take a picture or make a note of the capacitor’s wiring connections. This will help you ensure the correct reconnection of wires during the replacement process.

- Discharge the Capacitor: To discharge the capacitor, use an insulated screwdriver with a rubber handle to bridge the terminals, as we mentioned in the testing section. This step is crucial to eliminate any residual electrical charge.

- Remove the Faulty Capacitor: Use the appropriate tools, such as pliers or a screwdriver, to disconnect the wires attached to the faulty capacitor. Then, use a wrench to remove any retaining bolts or clamps that hold the capacitor in place. Gently remove the capacitor from its mounting location.

- Install the New Capacitor: Take the new capacitor and position it in the same location where the faulty capacitor was removed. Ensure that the mounting position and orientation match the original capacitor. Secure the new capacitor with the retaining bolts or clamps.

- Reconnect the Wires: Refer to the picture or notes you made earlier to reconnect the wires to the correct terminals of the new capacitor. Double-check the connections to ensure they are secure.

- Reconnect Power Supply and Test: Once the new capacitor is installed and wired correctly, restore the power supply to the air conditioning system. Turn on the unit and observe its operation. Confirm that the system starts smoothly and functions properly.

It’s important to note that while these steps provide a general overview, the exact process may vary depending on your specific air conditioning system. If you’re unsure or uncomfortable with any step of the process, it’s best to seek assistance from a qualified HVAC technician to ensure a safe and proper replacement.

Now that we’ve covered the steps to replace a faulty capacitor, let’s wrap up our article.

Conclusion

In conclusion, capacitors play a vital role in the functioning of air conditioning systems. They store and deliver electrical energy to start the motors and ensure their smooth operation. Understanding capacitors and their significance in air conditioners is essential for homeowners and professionals in the home maintenance industry.

We have learned that capacitors come in various types, such as start capacitors, run capacitors, dual run capacitors, oil-filled capacitors, and electrolytic capacitors. Each type serves a specific purpose and is chosen based on the system’s requirements.

Additionally, recognizing the symptoms of capacitor failure, such as difficulty starting, excessive humming or buzzing, inconsistent cooling, frequent system tripping, and physical changes in the capacitor, can help identify and resolve problems promptly.

When it comes to testing a capacitor, it’s crucial to prioritize safety. Utilizing a capacitor tester allows you to measure capacitance and determine if a replacement is necessary. However, it’s recommended to seek assistance from a qualified technician for accurate diagnosis and testing.

If a faulty capacitor is identified, following the proper steps to replace it is crucial. Discharging the capacitor, disconnecting the wiring, removing the old capacitor, installing and wiring the new one, and testing the system’s operation are essential to ensure a successful replacement.

Remember, working with electrical components can be dangerous, and it’s important to exercise caution. If you’re unsure or uncomfortable with any step of the process, consulting a professional HVAC technician is the best course of action.

By understanding capacitors and their role in air conditioners, you can effectively maintain and troubleshoot your system, ensuring optimal performance and cool comfort in your home. Regular maintenance, including inspecting and testing capacitors, can help prolong the lifespan of your air conditioning system and prevent costly repairs.

We hope this comprehensive guide has provided valuable insights into capacitors and their significance in air conditioning systems. Stay informed, stay safe, and enjoy the benefits of a well-functioning and efficient air conditioner!

Frequently Asked Questions about What Is A Capacitor On An Air Conditioner

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.