Home>Renovation & DIY>Tools & Equipment>What Grit Sandpaper For Rims

Tools & Equipment

What Grit Sandpaper For Rims

Modified: January 4, 2024

Choose the right grit sandpaper for rims with our comprehensive guide. Find the best tools and equipment for a seamless rim restoration.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of automotive detailing, where every inch of your vehicle’s surface deserves meticulous care and attention. When it comes to rims, their shiny appearance can enhance the overall aesthetics of your car or motorcycle. But over time, rims can accumulate dirt, grime, and scratches, detracting from their original beauty.

One effective way to restore the luster of your rims is by sanding them with the appropriate grit sandpaper. However, understanding the different types of sandpaper and knowing which grit to use can be a bit overwhelming, especially for beginners. That’s why in this article, we will guide you through the process of selecting the right grit sandpaper for your rims, ensuring a successful and satisfying detailing experience.

Before delving into the specifics of grit sandpaper for rims, it is important to have a fundamental understanding of what grit sandpaper actually is and how it works.

Key Takeaways:

- Choose finer grit sandpaper for aluminum or alloy rims to avoid damaging the softer material, and opt for coarser grits for durable steel rims with deeper scratches.

- Start with medium grit sandpaper for light surface scratches, then progress to finer grits for precision finishing, ensuring a smooth and polished rim appearance.

Read more: What Grit Sandpaper For Stairs

Understanding Grit Sandpaper

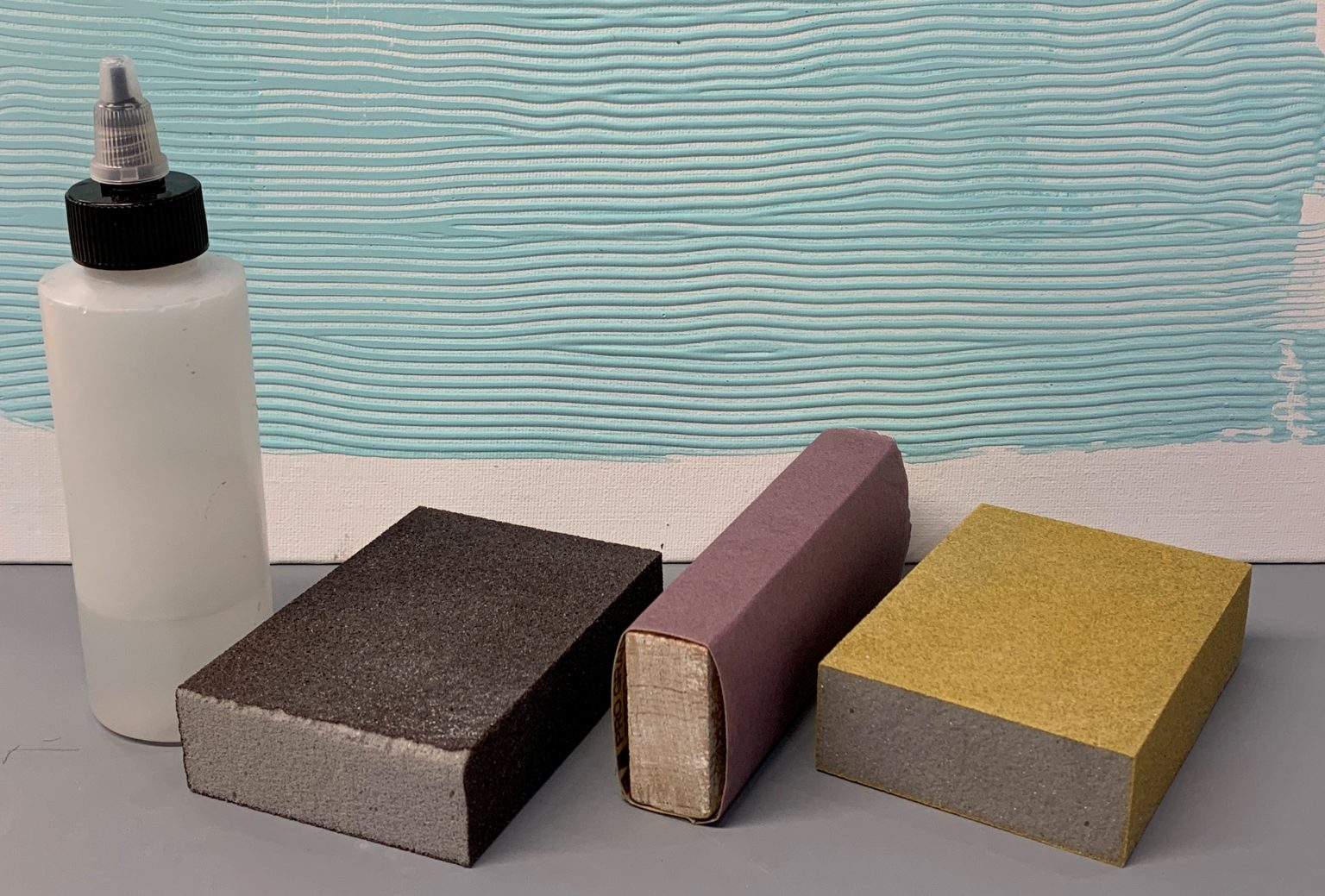

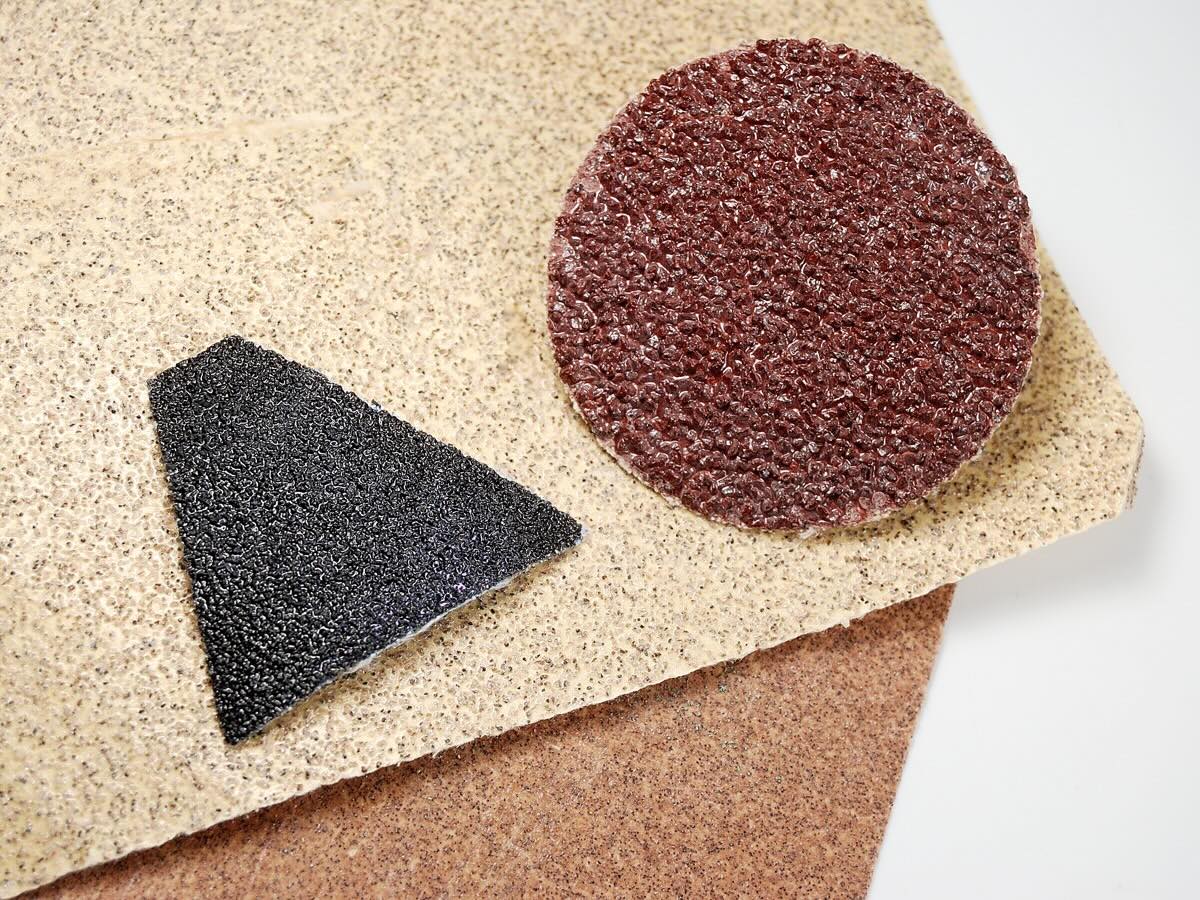

Grit sandpaper is a versatile abrasive material used for smoothing, shaping, and finishing various surfaces. It consists of a backing material, such as paper or cloth, which is coated with abrasive particles. These abrasive particles, known as grit, come in different sizes and shapes, and they determine the sandpaper’s level of coarseness.

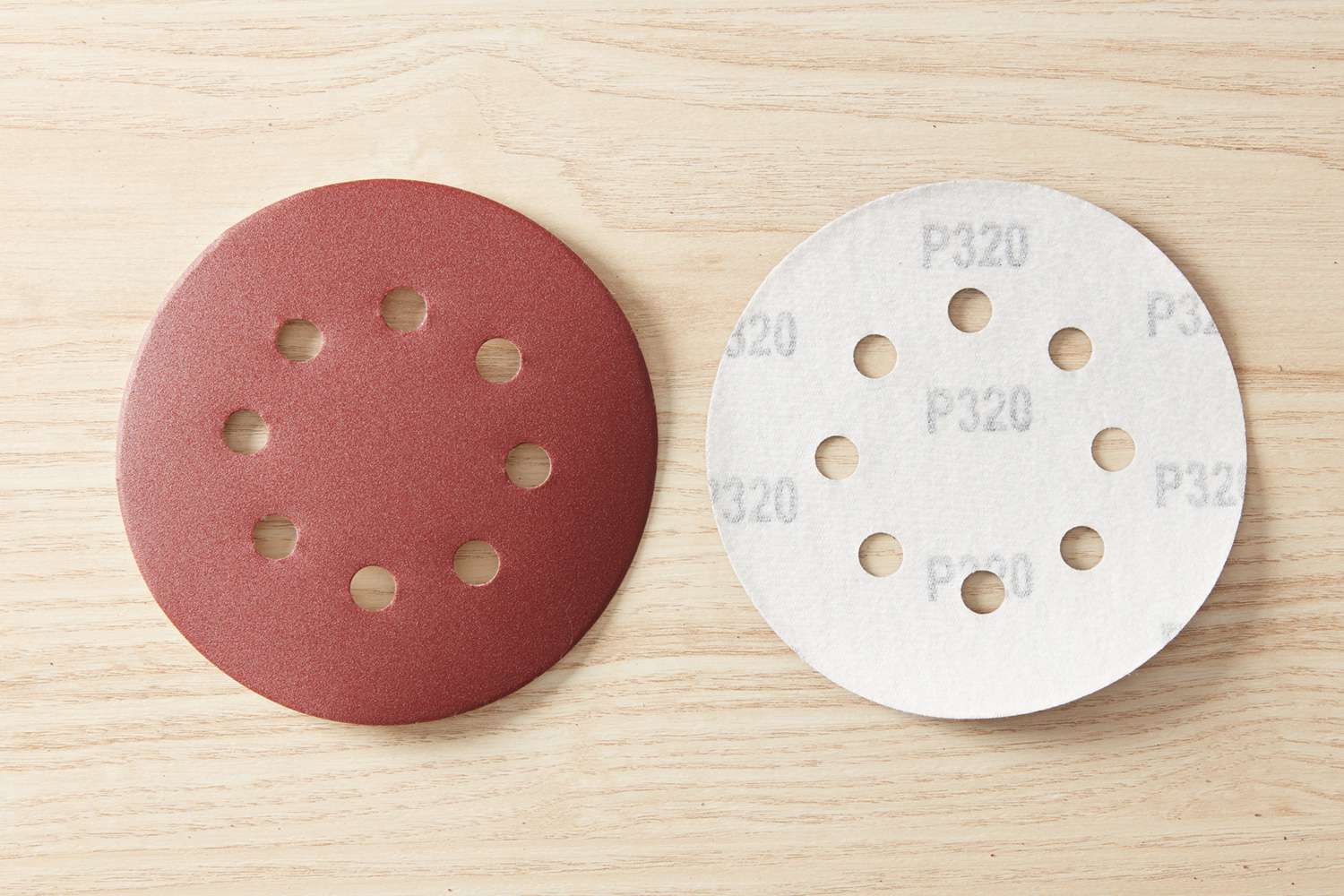

The grit size of sandpaper refers to the number of abrasive particles per square inch. The higher the number, the finer the grit. For instance, sandpaper with a grit size of 80 has coarser particles compared to sandpaper with a grit size of 400.

Each grit size serves a specific purpose in the sanding process. Coarser grits are typically used for aggressive material removal, such as stripping paint or removing deep scratches. Finer grits, on the other hand, are used for achieving a smooth and polished surface.

There are different types of grit sandpaper available, including garnet, aluminum oxide, silicon carbide, and ceramic. The type of sandpaper you choose depends on the material you’re working with and the desired outcome.

Garnet sandpaper is best suited for wood sanding as it provides a fine and smooth finish. Aluminum oxide sandpaper is commonly used for general purpose sanding, including metal, wood, and fiberglass. Silicon carbide sandpaper is known for its versatility and is often used for wet or dry sanding on materials like stone, plastic, or glass. Ceramic sandpaper is a premium option, offering long-lasting performance and high cutting efficiency.

Factors to Consider for Rim Sanding

Before diving into the process of rim sanding, there are a few important factors to consider. These factors will help you determine the right approach and ensure a successful sanding job:

- Material and Finish: Rims come in various materials, such as aluminum, steel, or alloy. It’s crucial to identify the material of your rims as different materials require different sanding techniques. Additionally, consider the existing finish on your rims. Some rims may have a clear coat or paint that needs to be taken into account during the sanding process.

- Extent of Damage: Assess the condition of your rims to determine the level of sanding required. If your rims have minor surface scratches, a finer grit sandpaper may be sufficient. However, if there are deep scratches or imperfections, you may need to start with a coarser grit to remove them before moving on to finer grit sandpaper.

- Time and Patience: Rim sanding is a meticulous process that requires time and patience. Depending on the extent of damage and the size of your rims, sanding them thoroughly may take several hours or even days. Be prepared to invest the necessary time to achieve the desired results.

- Protective Measures: It’s important to take measures to protect other parts of your vehicle from accidental damage during the sanding process. Consider using masking tape or plastic sheeting to cover nearby areas and prevent them from being scratched or damaged by flying debris.

- Safety Precautions: Sanding produces fine particles and dust that can be harmful if inhaled. Ensure you wear protective gear such as a dust mask, safety goggles, and gloves to protect yourself during the sanding process.

By considering these factors, you can plan your rim sanding process effectively and achieve the best possible results. Now let”s move on to understanding how to determine the appropriate grit sandpaper for rim sanding.

Use 400-600 grit sandpaper for rims to remove light scratches and prepare the surface for painting or clear coating. Sand in a circular motion for even results.

Determine the Grit for Rim Sanding

Choosing the right grit sandpaper for rim sanding is crucial to achieve the desired outcome. The grit you select will depend on the extent of damage, the material of your rims, and the desired finish. Here are some guidelines to help you determine the appropriate grit for rim sanding:

- Assess the Level of Damage: Start by examining the condition of your rims. If they have light surface scratches or minor imperfections, you can begin with a medium to fine grit sandpaper. However, if the rims have deep scratches, pitting, or stubborn stains, you may need to start with a coarser grit sandpaper to remove the damage.

- Consider the Rim Material: Different rim materials require different sanding approaches. For aluminum or alloy rims, it’s best to start with a finer grit sandpaper as these materials are relatively soft and can be easily damaged. On the other hand, steel rims can tolerate coarser grits due to their durability.

- Decide on the Desired Finish: Determine the level of smoothness and shine you want to achieve for your rims. If you’re aiming for a mirror-like finish, you will need to progress through multiple grits starting from a coarser grit and gradually moving to finer grits. For a more general clean-up and removal of light scratches, a single medium to fine grit may be sufficient.

- Experiment on a Small Area: To ensure you have chosen the correct grit, it’s a good idea to test it on a small inconspicuous area of the rim first. This will help you determine if the grit is too aggressive or too fine for your specific rim and situation.

- Invest in a Variety of Grits: It’s recommended to have a range of grit sandpapers on hand to accommodate different levels of damage and desired finishes. Having options such as 80, 120, 220, and 400 grits will allow you to customize your sanding approach based on the specific needs of your rims.

Remember, every rim is unique, and the required grit may vary. It’s always better to start with a less aggressive grit and gradually progress to coarser grits if necessary. This will help you avoid unintentional damage to your rims.

Now that you understand how to determine the appropriate grit for rim sanding, let’s move on to discussing the recommended grit sandpaper for different types of rims.

Recommended Grit Sandpaper for Rims

Choosing the right grit sandpaper for rim sanding is crucial to achieve the best results. The following recommendations can serve as a starting point, but keep in mind that the specific needs of your rims may vary:

- Light Surface Scratches: If your rims have light surface scratches or require minimal touch-ups, start with a medium grit sandpaper such as 220 or 320. This will help to smooth out minor imperfections and restore the luster of your rims.

- Deep Scratches and Blemishes: For rims with deep scratches, pitting, or stubborn stains, you may need to begin with a coarser grit sandpaper such as 80 or 120. This will effectively remove the damage and prepare the surface for further sanding and polishing.

- Precision Finishing: To achieve a smooth, polished finish with no visible scratches, gradually progress through finer grit sandpapers. Start with a medium grit like 220, then move to a finer grit such as 400 or even 600. This will refine the surface and bring out a mirror-like shine on your rims.

- Aluminum or Alloy Rims: For rims made of aluminum or alloy, it’s important to use a finer grit sandpaper to avoid damaging the relatively softer material. Start with a medium or fine grit, such as 220 or 320, and ensure gentle and controlled sanding motions to preserve the integrity of the rims.

- Steel Rims: Steel rims are more durable and can tolerate coarser grits. If you have steel rims with deeper scratches or rough surfaces, you can start with a coarser grit sandpaper such as 80 or 120. Gradually progress to finer grits like 220 and 320 for a smoother finish.

Remember to always follow the manufacturer’s recommendations for both the sandpaper and rim material. Additionally, take your time and be thorough in your sanding process to achieve the best results.

After the sanding process, it is important to thoroughly clean and inspect your rims before applying any protective coatings or finishes. This will ensure that any debris or fine particles are removed, leaving the rims ready for the next steps in the detailing process.

By using the recommended grit sandpaper and following the proper technique, you can effectively restore the beauty and shine of your rims, enhancing the overall appearance of your vehicle.

Read more: What Grit Sandpaper For Marble

Conclusion

When it comes to rim sanding, choosing the right grit sandpaper is essential for achieving the desired results. By understanding the different types of sandpaper, considering various factors, and determining the appropriate grit, you can effectively restore the appearance of your rims.

Take into account the material and finish of your rims, as well as the extent of damage, to determine the correct sanding approach. Consider the desired outcome and invest in a variety of grit sandpapers to accommodate different needs.

Remember to take the necessary safety precautions, protect other parts of your vehicle, and allocate sufficient time and patience for the sanding process. This will ensure a successful rim sanding job without causing unintentional damage.

Following the recommended grit sandpaper guidelines, start with a medium grit for light surface scratches and progress to coarser grits for deeper scratches and blemishes. For precision finishing, gradually move through finer grits to achieve a smooth and polished finish.

Always be mindful of the specific material of your rims. Aluminum or alloy rims require gentler sanding with finer grits, while steel rims can tolerate coarser grits.

After rim sanding, be sure to clean and inspect your rims thoroughly before applying any protective coatings or finishes. This will ensure that the rims are free from debris and ready to shine.

By following these recommendations and techniques, you can revitalize the appearance of your rims and elevate the overall aesthetics of your vehicle. So, grab your sandpaper and embark on the journey to restore the luster of your rims!

Frequently Asked Questions about What Grit Sandpaper For Rims

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Grit Sandpaper For Rims”