Home>Renovation & DIY>Tools & Equipment>What Grit Sandpaper Is Equal To 0000 Steel Wool

Tools & Equipment

What Grit Sandpaper Is Equal To 0000 Steel Wool

Published: December 20, 2023

Discover the best abrasive for your project with our comparison of grit sandpaper and 0000 steel wool. Find the right tools and equipment for a flawless finish.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When it comes to woodworking, metalworking, or any DIY project that involves smoothing or finishing surfaces, the right abrasive material can make all the difference. Two popular choices for achieving a smooth, polished finish are grit sandpaper and steel wool. Each material has its own unique properties and applications, and understanding their differences is crucial for achieving the desired results. In this article, we will delve into the world of grit sandpaper and steel wool, exploring their individual characteristics and applications. Furthermore, we will compare grit sandpaper to 0000 steel wool, shedding light on their equivalency and when to use one over the other. So, let's embark on this journey of discovery and gain a deeper understanding of these essential tools for achieving a flawless finish.

Key Takeaways:

- Grit sandpaper is great for precise material removal and surface smoothing, while steel wool, especially the fine #0000 grade, excels in achieving a smooth, lustrous finish on woodwork and metalwork.

- Understanding the unique advantages of grit sandpaper and steel wool helps craftsmen and DIY enthusiasts make informed decisions for flawless finishes in woodworking and metalworking projects.

Understanding Grit Sandpaper

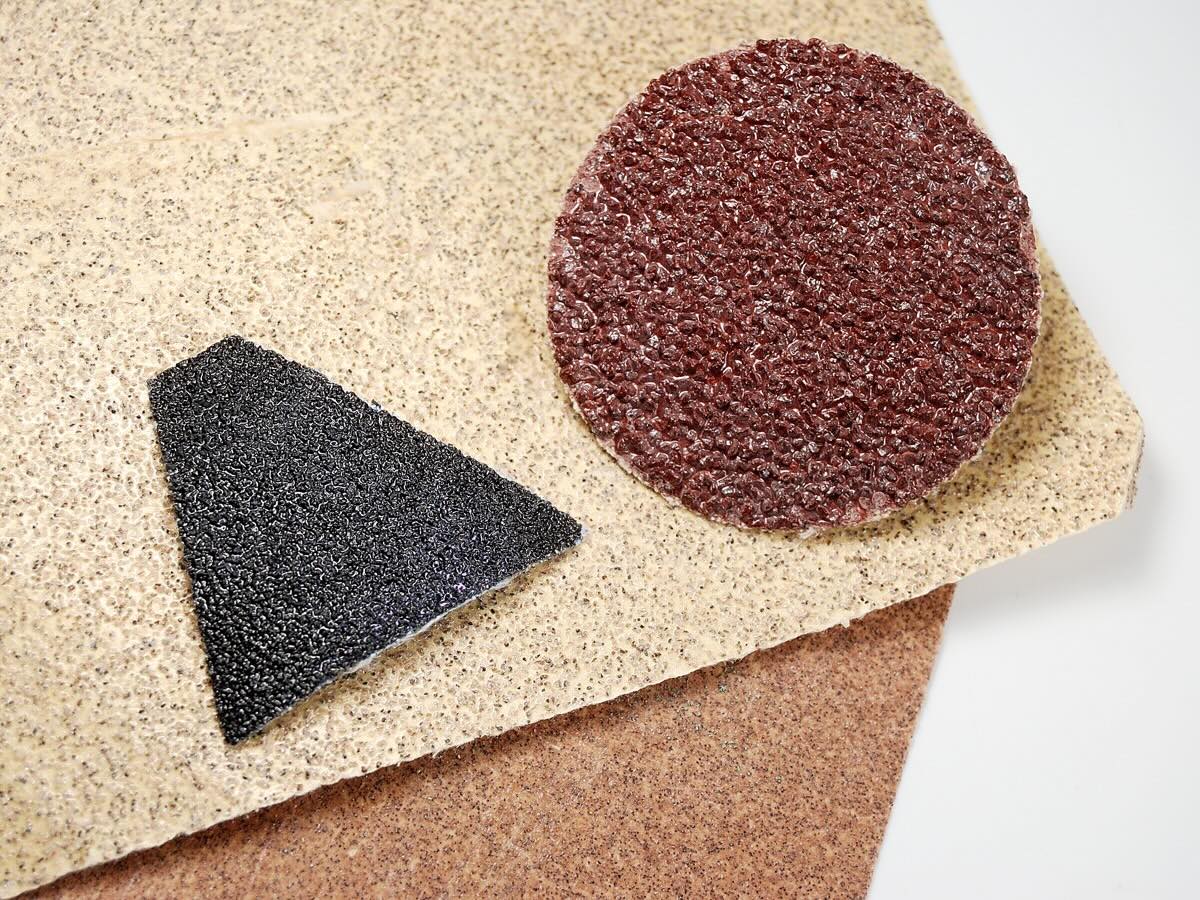

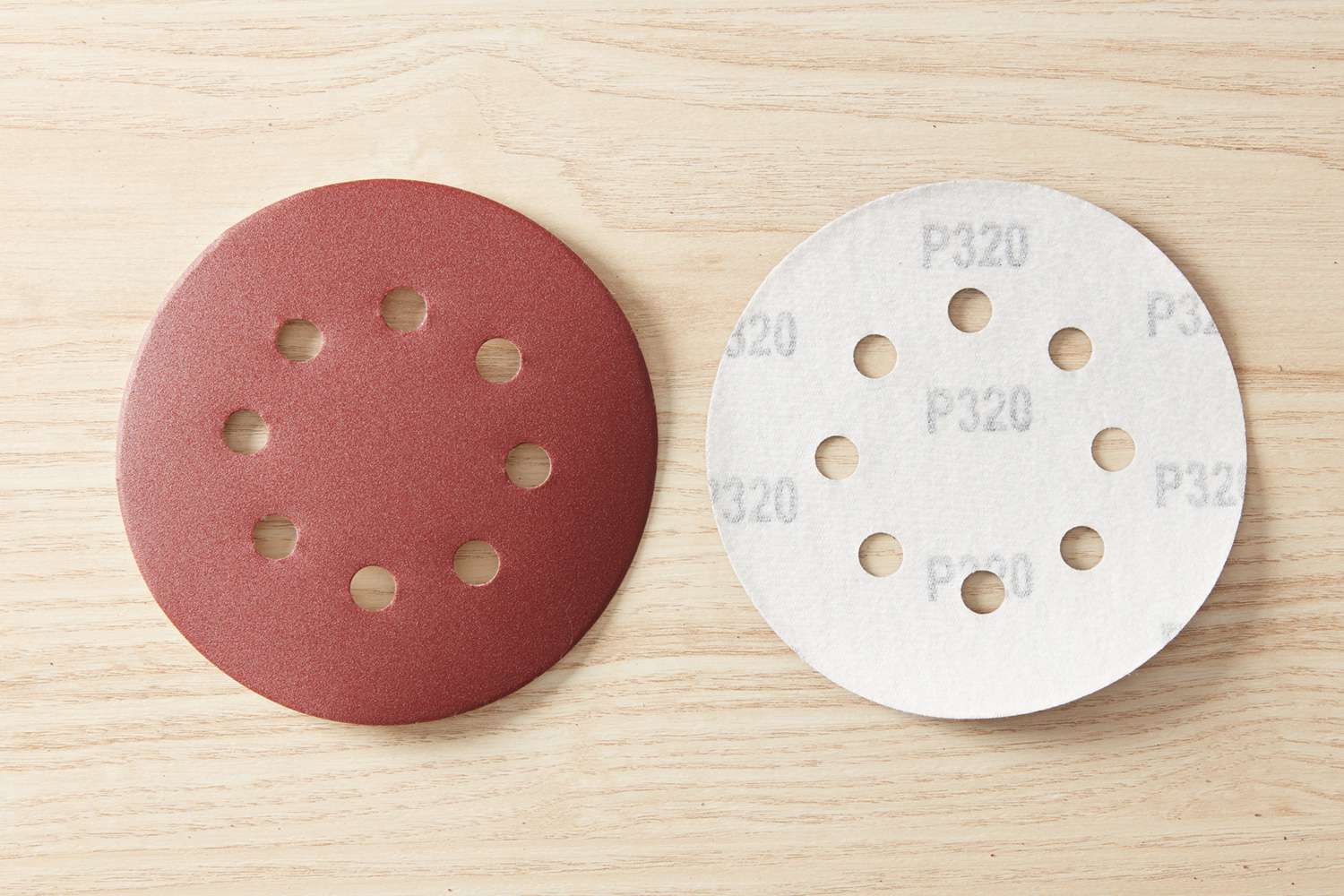

Grit sandpaper is a versatile abrasive material used for smoothing and finishing various surfaces, including wood, metal, and even some plastics. The term “grit” refers to the coarseness or fineness of the abrasive particles bonded to the paper backing. These particles are typically made of aluminum oxide, silicon carbide, or other abrasives, and they come in a range of grit sizes, each serving a specific purpose in the sanding process.

When selecting grit sandpaper, it’s essential to consider the level of coarseness or fineness required to achieve the desired finish. Lower grit numbers, such as 40 or 60, are coarser and ideal for removing heavy material, smoothing rough surfaces, or shaping wood or metal. As the grit number increases, the sandpaper becomes finer, with 100 to 180 grit suitable for intermediate smoothing and 220 to 400 grit ideal for fine sanding and preparing surfaces for finishing touches like staining or painting.

One of the key advantages of grit sandpaper is its ability to provide a consistent and controlled abrasion, allowing for precise material removal and surface refinement. Whether it’s leveling uneven wooden surfaces, removing old finishes, or preparing metal for painting, grit sandpaper offers the versatility and precision needed to achieve professional results.

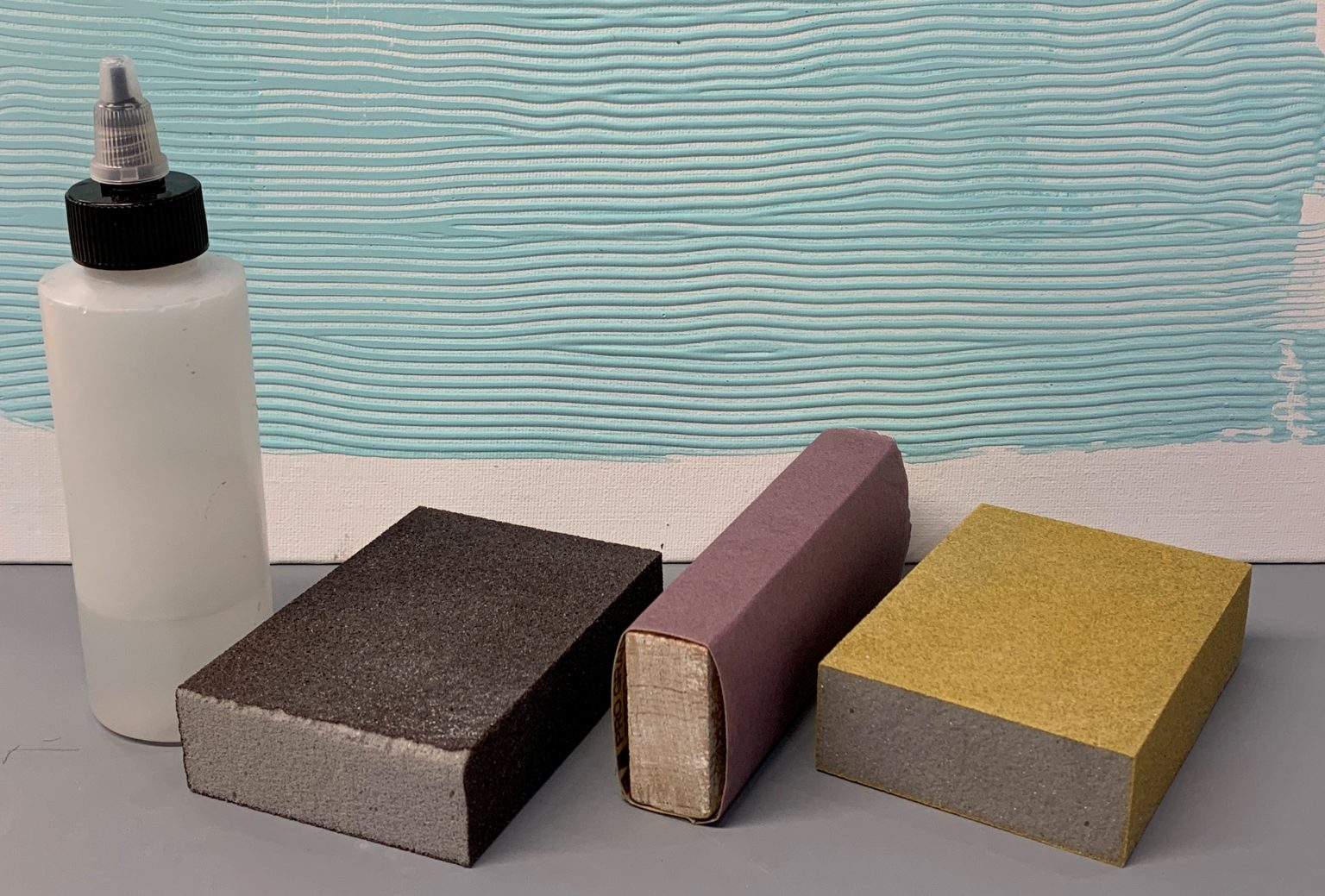

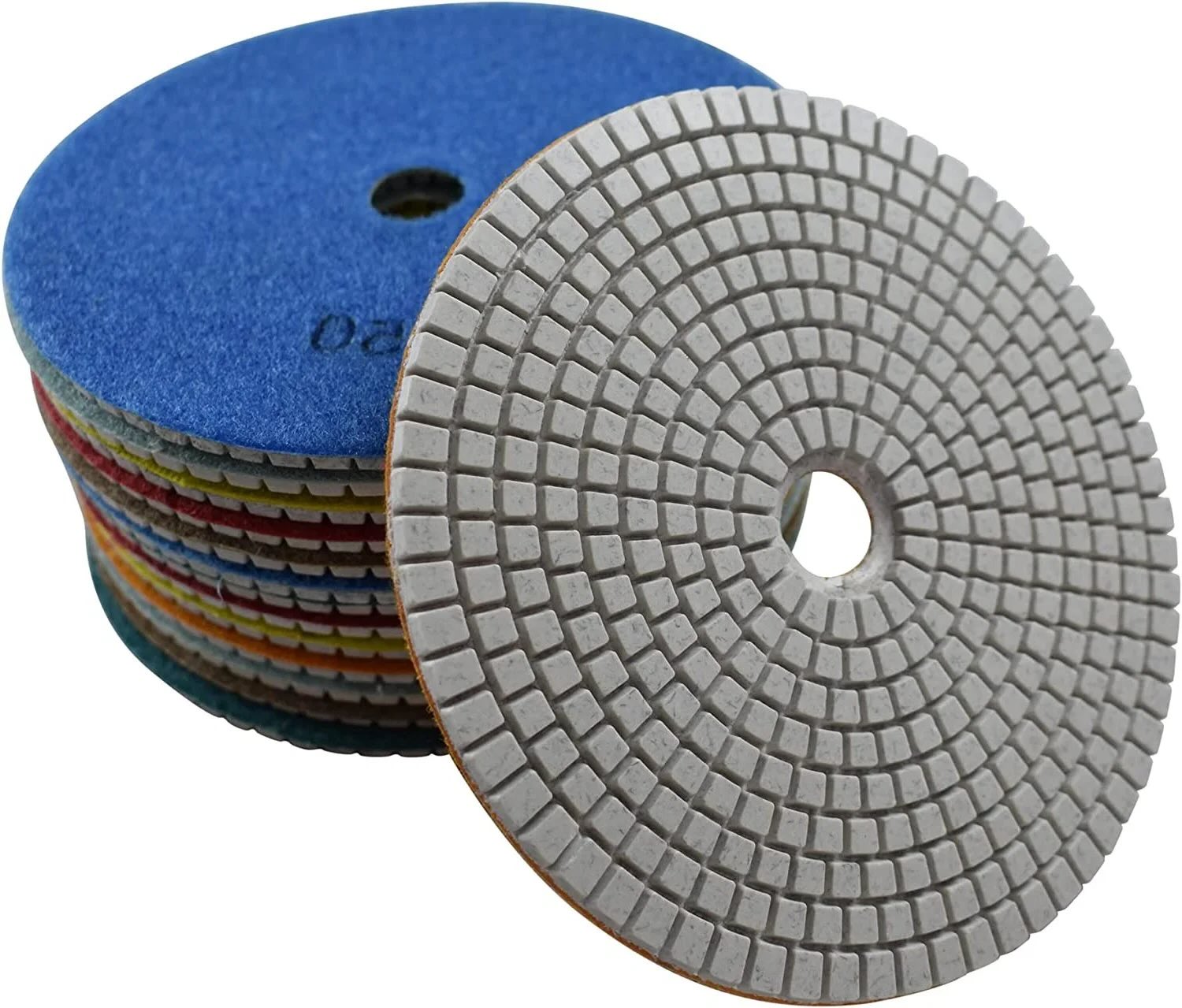

Furthermore, grit sandpaper comes in various forms, including sheets, rolls, discs, and belts, making it adaptable to different tools and applications. Whether hand sanding or using a power sander, there’s a suitable form of grit sandpaper to accommodate the specific requirements of the project at hand.

Understanding the characteristics and applications of grit sandpaper is essential for executing woodworking, metalworking, and refinishing projects with precision and finesse. Now that we’ve gained insight into the world of grit sandpaper, let’s turn our attention to another essential abrasive material: steel wool.

Understanding Steel Wool

Steel wool, a versatile and abrasive material, is widely used in various applications, including woodworking, metalworking, and household tasks. It is composed of thin, flexible strands of steel, often referred to as “wool,” which are intertwined to form a fibrous and resilient pad. Steel wool is available in different grades, ranging from coarse to fine, with the coarseness determined by the thickness and weight of the strands.

One of the primary characteristics of steel wool is its abrasive nature, making it effective for smoothing, cleaning, and polishing various surfaces. The coarser grades of steel wool, such as #3 or #4, are suitable for removing paint, varnish, and rust from metal surfaces, as well as for cleaning and preparing wood for finishing. On the other hand, finer grades, like #0000, are renowned for their polishing and finishing capabilities, leaving surfaces with a smooth, lustrous sheen.

Steel wool is prized for its versatility and effectiveness in tasks such as removing paint or varnish from wood, smoothing raised wood grain, cleaning metal surfaces, and achieving a polished finish on woodwork and metalwork. Its flexibility and ability to conform to various shapes and contours make it a valuable tool for intricate and detailed work.

When using steel wool, it’s important to consider the potential for steel particles to become embedded in the workpiece. This can lead to rust spots, especially on wood surfaces, if the steel particles are not thoroughly removed. Therefore, it’s advisable to use steel wool in conjunction with a vacuum or tack cloth to ensure the complete removal of loose particles after the sanding or polishing process.

Steel wool is available in pads or rolls, providing flexibility and convenience for different applications. Whether it’s preparing wood for a smooth finish, restoring the luster of metal surfaces, or removing stubborn stains, steel wool is a valuable and indispensable abrasive material in the toolkit of craftsmen, artisans, and DIY enthusiasts.

Now that we have explored the properties and applications of steel wool, let’s proceed to compare the characteristics of grit sandpaper and steel wool to understand their respective roles in achieving a flawless finish.

Use 320-400 grit sandpaper to achieve a similar smooth finish as 0000 steel wool. Sand in the direction of the wood grain for best results.

Comparing Grit Sandpaper and Steel Wool

When it comes to achieving a smooth and polished finish on various surfaces, both grit sandpaper and steel wool offer unique advantages and applications. Understanding the differences between these two abrasive materials is essential for selecting the most suitable option for a specific project.

- Material Removal and Smoothing: Grit sandpaper is highly effective for material removal and surface smoothing, especially when precision and controlled abrasion are required. It excels in leveling uneven wooden surfaces, removing old finishes, and preparing surfaces for painting or staining. On the other hand, steel wool, particularly the finer grades like #0000, is renowned for its polishing and finishing capabilities, leaving surfaces with a smooth, lustrous sheen. It is ideal for achieving a satin-smooth finish on woodwork and metalwork, as well as for cleaning and polishing metal surfaces.

- Versatility and Conformity: Grit sandpaper comes in various grit sizes and forms, including sheets, rolls, discs, and belts, catering to a wide range of tools and applications. It offers versatility in addressing different sanding needs, from heavy material removal to fine surface preparation. Steel wool, with its flexible and conformable nature, is well-suited for intricate and detailed work, allowing craftsmen to access and polish hard-to-reach areas with ease.

- Residue and Embedded Particles: While both grit sandpaper and steel wool produce fine particles during the sanding or polishing process, steel wool has a higher likelihood of leaving steel particles embedded in the workpiece. This can potentially lead to rust spots, especially on wood surfaces, if the particles are not thoroughly removed. Grit sandpaper, on the other hand, provides controlled material removal with minimal residue, making it a preferred option for projects where cleanliness and minimal debris are crucial.

Ultimately, the choice between grit sandpaper and steel wool depends on the specific requirements of the project, the desired finish, and the surface being worked on. For tasks that necessitate precision material removal, surface refinement, and controlled abrasion, grit sandpaper is the go-to option. Conversely, when seeking a smooth, polished finish with a lustrous sheen, especially on woodwork and metalwork, steel wool, particularly the fine #0000 grade, is the ideal choice.

By understanding the unique characteristics and applications of both grit sandpaper and steel wool, craftsmen and DIY enthusiasts can make informed decisions, ensuring the successful completion of their projects with impeccable finishes.

Conclusion

As we conclude our exploration of grit sandpaper and steel wool, we have gained valuable insights into the distinctive characteristics and applications of these essential abrasive materials. Grit sandpaper, with its versatile grit sizes and forms, offers precise material removal, surface smoothing, and preparation for finishing touches, making it indispensable in woodworking, metalworking, and refinishing projects. On the other hand, steel wool, renowned for its abrasive and polishing capabilities, excels in achieving a smooth, lustrous finish on woodwork and metalwork, as well as in cleaning and preparing surfaces for refinishing.

Understanding the differences between grit sandpaper and steel wool is crucial for selecting the most suitable abrasive material based on the specific requirements of a project. While grit sandpaper provides controlled abrasion, minimal residue, and versatility in addressing various sanding needs, steel wool, especially the finer grades like #0000, is ideal for achieving a polished finish with a satin-smooth sheen and for accessing hard-to-reach areas with ease.

By recognizing the unique advantages and applications of both grit sandpaper and steel wool, craftsmen, artisans, and DIY enthusiasts can enhance the quality and precision of their projects, ensuring flawless finishes that meet their exacting standards. Whether it’s refining wooden surfaces, polishing metalwork, or preparing surfaces for painting or staining, the choice between grit sandpaper and steel wool hinges on the desired finish, the nature of the material being worked on, and the level of precision required.

In the world of craftsmanship and DIY endeavors, the selection of the right abrasive material, be it grit sandpaper or steel wool, can elevate a project from satisfactory to exceptional. These tools, with their distinct properties and applications, play a pivotal role in achieving professional results and transforming raw materials into refined, polished works of art.

Armed with a deeper understanding of grit sandpaper and steel wool, let’s embark on our future projects with confidence, knowing that we have the knowledge and tools to achieve impeccable finishes and bring our creative visions to fruition.

Frequently Asked Questions about What Grit Sandpaper Is Equal To 0000 Steel Wool

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Grit Sandpaper Is Equal To 0000 Steel Wool”