Home>Technology>Smart Home Devices>How Does A Resin Printer Work

Smart Home Devices

How Does A Resin Printer Work

Published: January 10, 2024

Discover how resin printers work and revolutionize your smart home devices with cutting-edge technology. Learn the ins and outs of resin printing for your home automation needs.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the fascinating world of resin printing! In recent years, 3D printing technology has advanced by leaps and bounds, and resin printing has emerged as a groundbreaking method for creating intricate and high-resolution 3D objects. Unlike traditional filament-based 3D printers, resin printers utilize a liquid resin material to produce objects with exceptional detail and precision.

Resin printing has revolutionized various industries, including manufacturing, healthcare, and design, by offering unparalleled capabilities in producing prototypes, intricate models, and custom components. Understanding the inner workings of resin printers can provide valuable insights into the potential applications and advantages of this cutting-edge technology.

In this comprehensive guide, we will delve into the intricate details of resin printing, exploring its underlying technology, the components of a resin printer, the process of creating 3D objects, as well as its advantages, limitations, and diverse applications. Whether you are a seasoned enthusiast or a newcomer to the world of 3D printing, this exploration of resin printing technology promises to expand your knowledge and inspire your imagination.

Join us on this enlightening journey as we unravel the inner workings of resin printing and discover the boundless possibilities it offers in the realm of 3D fabrication. Let's embark on an exploration of resin printing technology and unlock the secrets behind its mesmerizing ability to transform digital designs into tangible, awe-inspiring creations.

Key Takeaways:

- Resin printing uses liquid resin and UV light to create highly detailed 3D objects with smooth finishes, revolutionizing industries from healthcare to art and design.

- While resin printing offers exceptional precision and diverse material properties, it also has limitations such as material constraints and post-processing requirements, requiring careful consideration for effective utilization.

Read more: How To Clean A Resin Printer

Overview of Resin Printing Technology

Resin printing, also known as stereolithography (SLA) or digital light processing (DLP) printing, is a revolutionary 3D printing technology that utilizes photopolymer resin to create intricate three-dimensional objects with exceptional precision and detail. Unlike traditional filament-based 3D printing, which involves the layer-by-layer deposition of molten plastic, resin printing relies on the precise solidification of liquid resin using ultraviolet (UV) light.

The process begins with a digital 3D model, which is sliced into thin layers using specialized software. These layers are then sequentially exposed to UV light, causing the liquid resin to solidify and adhere to the build platform. As each layer solidifies, the build platform gradually moves downward, allowing the printer to add subsequent layers until the entire object is formed.

One of the key distinguishing features of resin printing is its ability to produce objects with incredibly fine details and smooth surface finishes. This is attributed to the minimal layer height achievable with resin printers, often reaching as low as 25 microns, resulting in objects that exhibit intricate features and precise geometries. Additionally, the photopolymer resin used in this process can be formulated to exhibit a wide range of material properties, including flexibility, transparency, and high-temperature resistance, making it suitable for diverse applications.

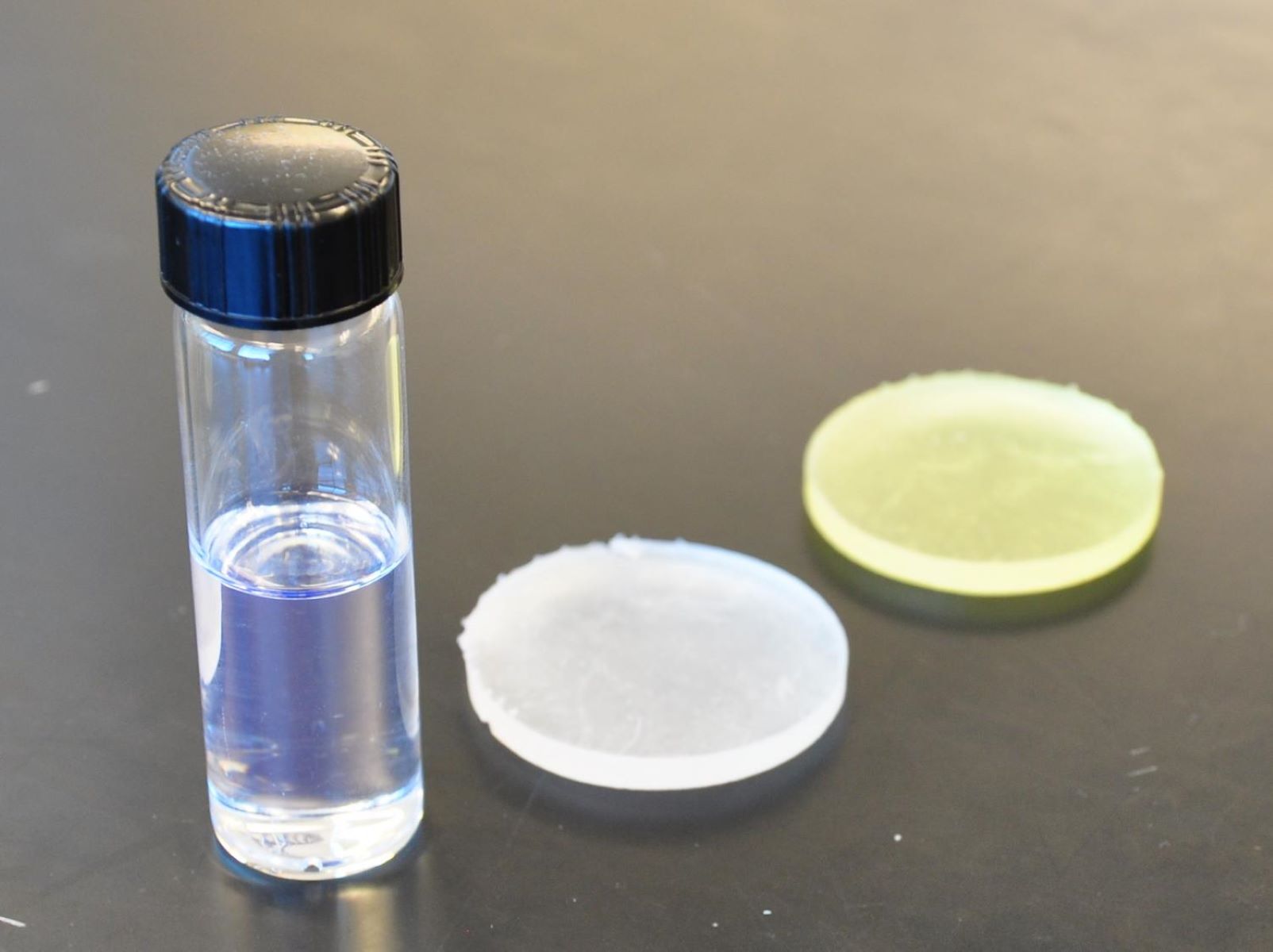

Resin printing technology encompasses two primary methods: SLA and DLP. SLA printers utilize a laser to selectively solidify the resin, while DLP printers employ a digital light projector to flash entire layers of the object simultaneously. Both methods offer exceptional resolution and are capable of producing objects with intricate internal and external features.

As the demand for high-precision 3D printed objects continues to grow across various industries, resin printing technology has garnered widespread attention for its ability to deliver unparalleled detail, accuracy, and surface quality. Its unique approach to additive manufacturing has positioned resin printing as a transformative force in the realm of rapid prototyping, custom manufacturing, and artistic expression.

Now that we have gained a foundational understanding of resin printing technology, let’s explore the essential components that constitute a resin printer and the crucial roles they play in the 3D printing process.

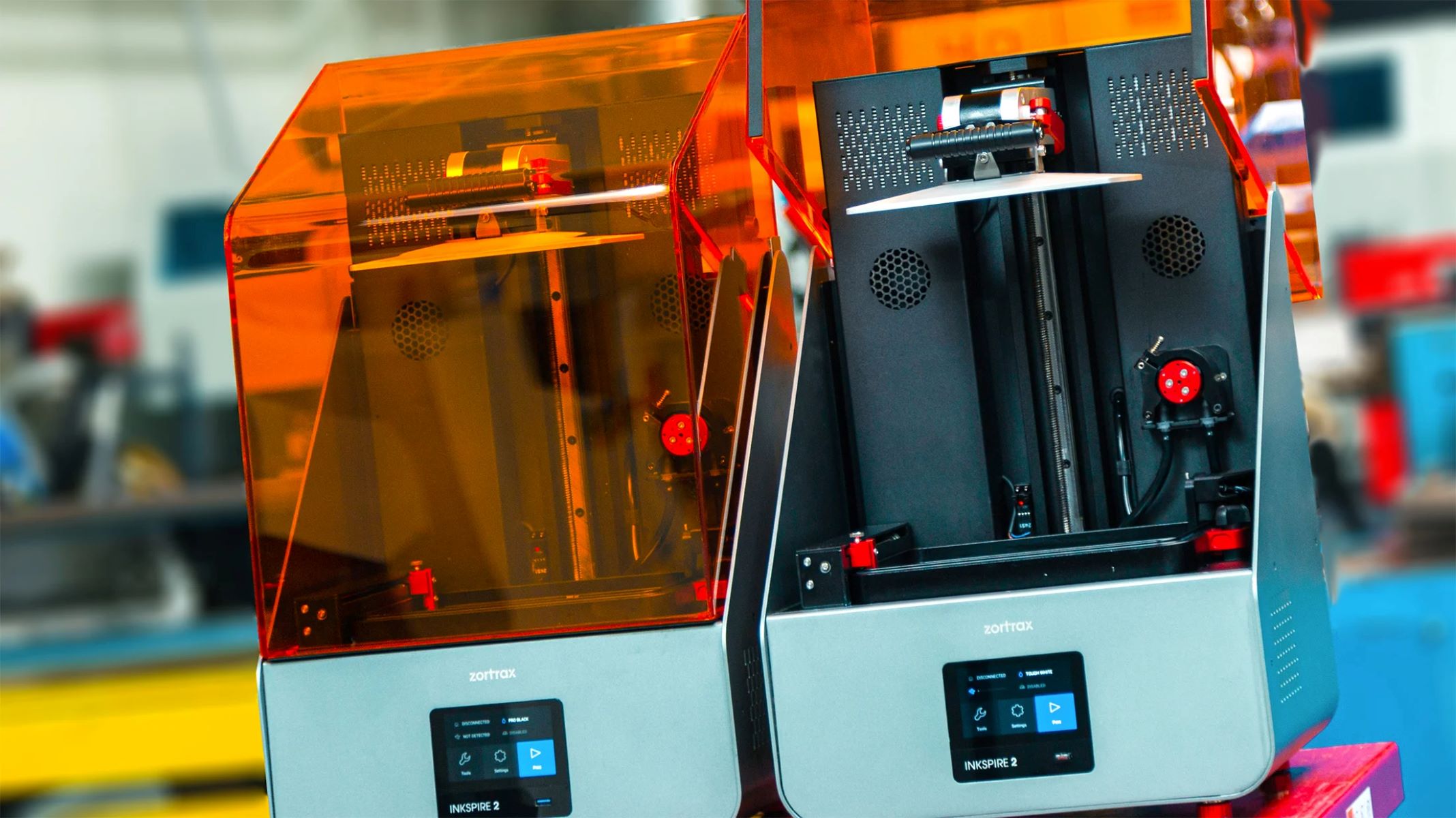

Components of a Resin Printer

A resin printer comprises several essential components that work in harmony to transform digital designs into tangible 3D objects with remarkable precision and detail. Understanding the function of each component provides valuable insight into the intricate process of resin printing and the critical roles they play in achieving exceptional print quality.

- Build Platform: The build platform serves as the foundation upon which the 3D object is gradually constructed. It moves vertically or tilts during the printing process, allowing each layer of resin to be added and solidified. The build platform’s stability and precise movement are crucial for maintaining the dimensional accuracy and surface quality of the printed object.

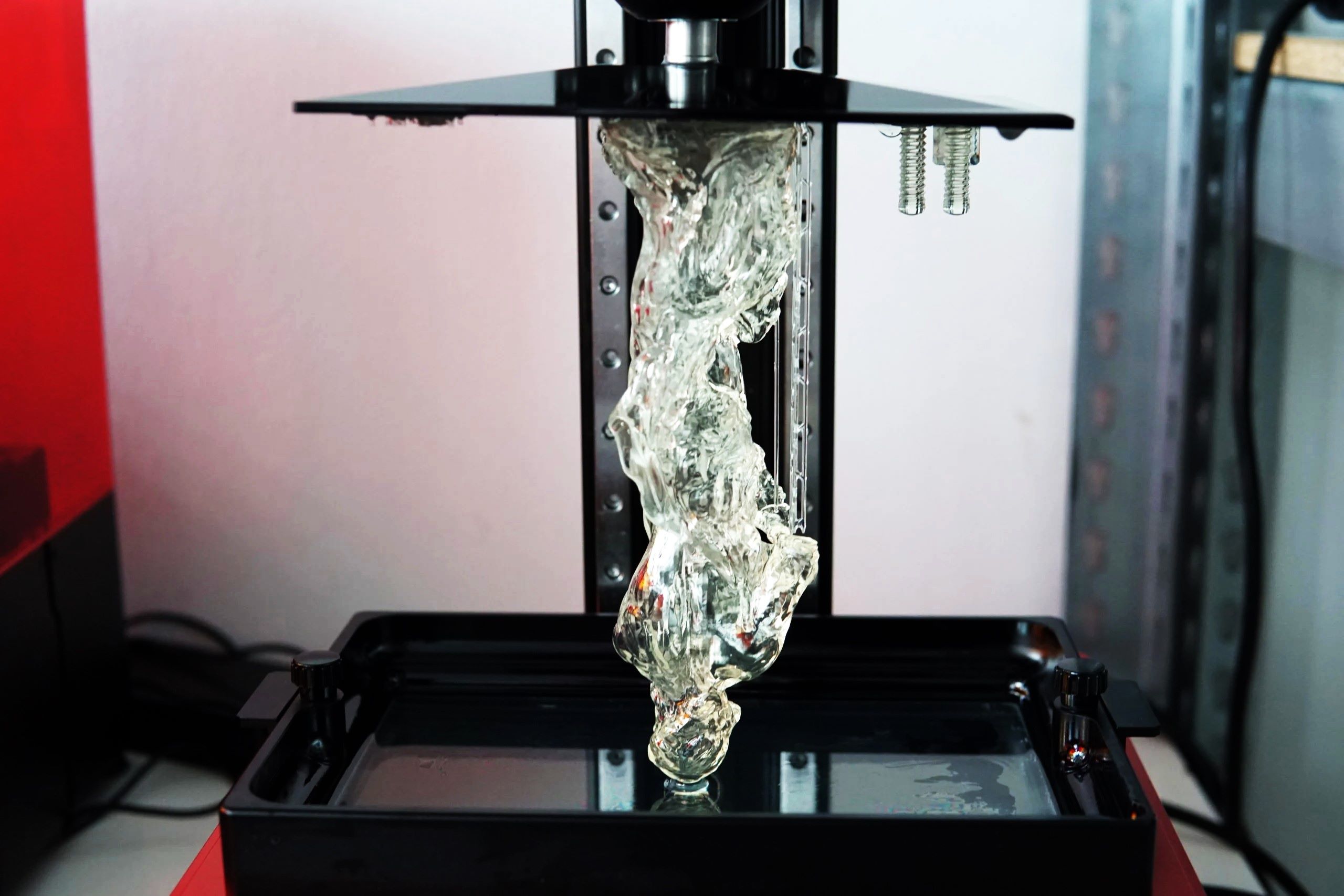

- Resin Tank: The resin tank holds the liquid photopolymer resin and is equipped with a transparent bottom that allows UV light to penetrate and solidify the resin. It is designed to maintain a consistent level of resin during printing and facilitate the controlled release of each layer as the object is formed.

- UV Light Source: An integral component of resin printing, the UV light source emits high-intensity ultraviolet light that solidifies the liquid resin when exposed to specific areas, following the pattern dictated by the sliced 3D model. The precision and intensity of the UV light source directly impact the print resolution and overall print quality.

- Control Electronics: The control electronics, including the microcontroller and associated circuitry, govern the precise movement of the build platform, the activation of the UV light source, and the coordination of all essential printing parameters. These electronics ensure synchronized operation and accurate layer-by-layer construction of the 3D object.

- Resin Cartridge or Vat: Some resin printers feature a resin cartridge or vat that houses the photopolymer resin, providing a convenient and enclosed reservoir for the liquid material. This design minimizes exposure to ambient light and helps preserve the integrity of the resin, contributing to consistent print quality.

- Printed Circuit Board (PCB): The PCB serves as the central hub for controlling and coordinating the various functions of the resin printer. It facilitates the communication between the software, control electronics, and mechanical components, ensuring seamless operation and precise execution of the printing process.

Each of these components plays a crucial role in the intricate process of resin printing, contributing to the exceptional precision, surface quality, and material characteristics of the final 3D printed objects. As we continue our exploration, we will uncover the mesmerizing process through which a resin printer transforms digital designs into physical manifestations of creativity and innovation.

How Does a Resin Printer Create 3D Objects?

The mesmerizing process through which a resin printer brings digital designs to life involves a sequence of meticulously orchestrated steps, culminating in the formation of intricate and precise 3D objects. Understanding this process unveils the intricacies of resin printing and highlights the remarkable precision and detail it achieves.

The journey begins with a meticulously crafted digital 3D model, which serves as the blueprint for the physical object to be produced. This digital model is sliced into numerous thin layers, each representing a cross-section of the final object. The sliced layers are then translated into a series of instructions that dictate the precise movement of the build platform and the selective exposure of the liquid resin to UV light.

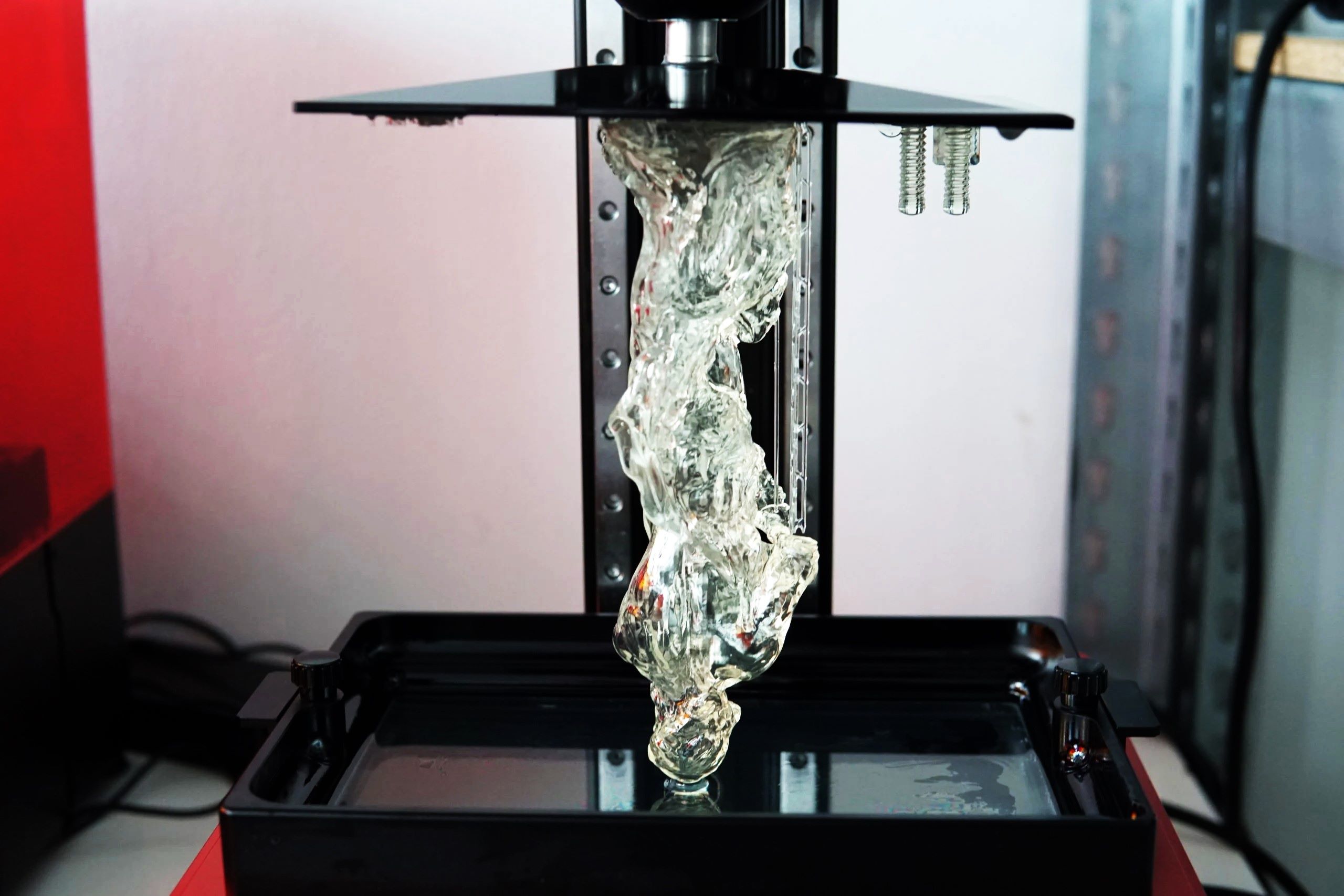

As the printing process commences, the build platform descends to the bottom of the resin tank, and a thin layer of liquid resin is spread across the transparent bottom of the tank. The UV light source then illuminates the resin, solidifying it in the pattern dictated by the corresponding layer of the 3D model. This process is repeated for each layer, with the build platform gradually ascending after the completion of each layer, allowing the printer to add subsequent layers until the entire object is formed.

The selective solidification of the resin, layer by layer, results in the gradual emergence of the 3D object within the liquid resin. The precision and accuracy of the UV light source, coupled with the controlled movement of the build platform, ensure that each layer adheres seamlessly to the preceding layers, ultimately yielding a cohesive and intricately detailed 3D object.

One of the defining characteristics of resin printing is its ability to produce objects with exceptionally fine details and smooth surface finishes. This is attributed to the minimal layer height achievable with resin printers, often reaching as low as 25 microns, allowing for the faithful reproduction of intricate geometries and complex features present in the original digital model.

Furthermore, the photopolymer resin used in resin printing can be tailored to exhibit a wide range of material properties, including flexibility, transparency, and durability, enabling the creation of objects with diverse characteristics and functionalities.

As the final layer is solidified and the printing process concludes, the build platform rises to reveal the completed 3D object, encapsulating the meticulous layer-by-layer construction that has transformed a digital design into a tangible manifestation of creativity and innovation.

With a newfound understanding of the captivating process through which resin printers create 3D objects, we can now explore the advantages and limitations of this transformative technology, shedding light on its potential applications and impact across various industries.

Advantages and Limitations of Resin Printing

Resin printing technology offers a myriad of advantages that have positioned it as a transformative force in the realm of 3D printing, while also presenting certain limitations that warrant consideration. Understanding the strengths and constraints of resin printing is essential for leveraging its capabilities effectively and making informed decisions regarding its application.

Read more: How Does An Inkjet Printer Work

Advantages:

- Exceptional Detail and Precision: Resin printing excels in producing objects with intricate details and precise geometries, thanks to its minimal layer height and high-resolution capabilities. This makes it ideal for creating prototypes, intricate models, and custom components with unparalleled accuracy.

- Smooth Surface Finish: Resin printers yield objects with remarkably smooth surface finishes, minimizing the need for post-processing and enhancing the visual appeal of the printed objects.

- Diverse Material Properties: Photopolymer resins can be formulated to exhibit a wide range of material properties, including flexibility, transparency, and high-temperature resistance, enabling the production of objects with diverse functionalities and applications.

- Rapid Prototyping: Resin printing facilitates rapid prototyping, allowing for the swift iteration and refinement of designs, thereby expediting the product development cycle.

- Intricate Internal and External Features: Resin printers are capable of producing objects with intricate internal and external features, making them well-suited for applications in jewelry, dental prosthetics, and artistic creations.

Limitations:

- Material Limitations: The material properties of photopolymer resins may not always align with the specific requirements of certain applications, limiting the versatility of resin printing in comparison to other 3D printing technologies.

- Post-Processing Requirements: While resin printing yields smooth surface finishes, post-processing steps such as UV curing and support structure removal may be necessary, adding additional time and effort to the printing workflow.

- Build Volume and Printing Speed: Resin printers often have smaller build volumes and slower printing speeds compared to filament-based 3D printers, which can impact the production of larger objects and overall printing efficiency.

- Material Handling and Safety: Photopolymer resins require careful handling and UV exposure precautions to ensure user safety, necessitating proper ventilation and protective measures in the printing environment.

Despite these limitations, the remarkable precision, surface quality, and material capabilities of resin printing technology have propelled it into the forefront of additive manufacturing, offering unique advantages for a wide array of applications. By recognizing its strengths and limitations, individuals and industries can harness the full potential of resin printing while mitigating its constraints, paving the way for innovative and impactful utilization of this transformative technology.

Applications of Resin Printing Technology

The versatility and precision of resin printing technology have unlocked a diverse range of applications across various industries, revolutionizing the way objects are designed, prototyped, and manufactured. From healthcare and engineering to art and jewelry, resin printing has made significant inroads, offering unparalleled capabilities that have spurred innovation and creativity.

Healthcare and Biomedical Engineering:

In the realm of healthcare, resin printing has facilitated the production of highly detailed anatomical models for surgical planning, medical education, and patient communication. Additionally, it has enabled the creation of custom prosthetics, dental implants, and orthodontic devices with exceptional precision and patient-specific adaptations, enhancing the quality of care and treatment outcomes.

Read more: How Does The Instax Printer Work

Engineering and Prototyping:

Resin printing technology has become indispensable in engineering and product development, allowing for the rapid prototyping of complex components, intricate mechanical parts, and architectural models. Its ability to produce objects with fine details and precise geometries has streamlined the design iteration process, accelerating product development cycles and fostering innovation across industries.

Art, Design, and Jewelry:

Artists, designers, and jewelers have embraced resin printing for its capacity to realize intricate and ornate creations with exquisite detail. From sculptural art pieces and custom jewelry to ornamental designs, resin printing has empowered artisans to bring their visions to life with a level of intricacy and finesse that was previously unattainable through traditional manufacturing methods.

Education and Research:

In educational and research settings, resin printing serves as a valuable tool for visualizing complex concepts, creating interactive teaching aids, and fabricating scientific models with precise anatomical and structural details. It has enriched learning experiences across disciplines, from biology and chemistry to architecture and archaeology, fostering a deeper understanding of abstract concepts through tangible, 3D representations.

Custom Manufacturing and Small-Scale Production:

Resin printing technology has found application in custom manufacturing, enabling the production of bespoke components, personalized accessories, and small-scale production runs with exceptional detail and customization. Its versatility in material properties and high-resolution capabilities has empowered businesses to cater to niche markets and offer unique, tailor-made solutions to their clientele.

These diverse applications underscore the far-reaching impact of resin printing technology, transcending traditional manufacturing boundaries and catalyzing innovation in fields that demand precision, customization, and creative expression. As resin printing continues to evolve, its potential to drive transformative change and unlock new possibilities across industries is poised to redefine the landscape of additive manufacturing and 3D fabrication.

Read more: How Does A Wireless Printer Work

Conclusion

Our exploration of resin printing technology has unveiled a world of precision, creativity, and transformative potential, offering a glimpse into the captivating process through which digital designs materialize into intricate and finely detailed 3D objects. The remarkable capabilities of resin printing, coupled with its diverse applications, have positioned it as a driving force in additive manufacturing, fostering innovation and redefining the possibilities of 3D fabrication.

From healthcare and engineering to art and custom manufacturing, resin printing has permeated diverse industries, empowering individuals and businesses to realize their creative visions with unprecedented precision and versatility. Its ability to produce objects with exceptional detail, smooth surface finishes, and diverse material properties has revolutionized prototyping, custom manufacturing, and artistic expression, while also enhancing educational and research endeavors.

As we reflect on the advantages and limitations of resin printing, it becomes evident that its transformative potential is accompanied by considerations that warrant attention. By understanding the nuances of resin printing technology and harnessing its strengths while mitigating its constraints, individuals and industries can leverage its capabilities effectively, driving innovation and achieving impactful outcomes.

Looking ahead, the evolution of resin printing technology holds the promise of further advancements, expanding its applications, enhancing material capabilities, and refining the efficiency of the printing process. As resin printing continues to push the boundaries of precision and customization, it is poised to redefine the landscape of manufacturing, unlocking new possibilities and inspiring a wave of creative exploration across diverse domains.

In closing, our journey through the realm of resin printing technology has illuminated the boundless potential it holds, inviting us to embrace its transformative power and envision a future where intricate designs seamlessly transition from the digital realm to tangible, awe-inspiring creations. As we stand at the threshold of a new era in additive manufacturing, resin printing stands as a testament to the convergence of precision, creativity, and innovation, offering a canvas for boundless imagination and a gateway to a world of limitless possibilities.

Frequently Asked Questions about How Does A Resin Printer Work

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Does A Resin Printer Work”