Home>Technology>Smart Home Devices>How Toxic Is 3D Printer Resin

Smart Home Devices

How Toxic Is 3D Printer Resin

Published: January 21, 2024

Discover the toxicity level of 3D printer resin and its impact on smart home devices. Learn how to handle and use resin safely for your smart home projects.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

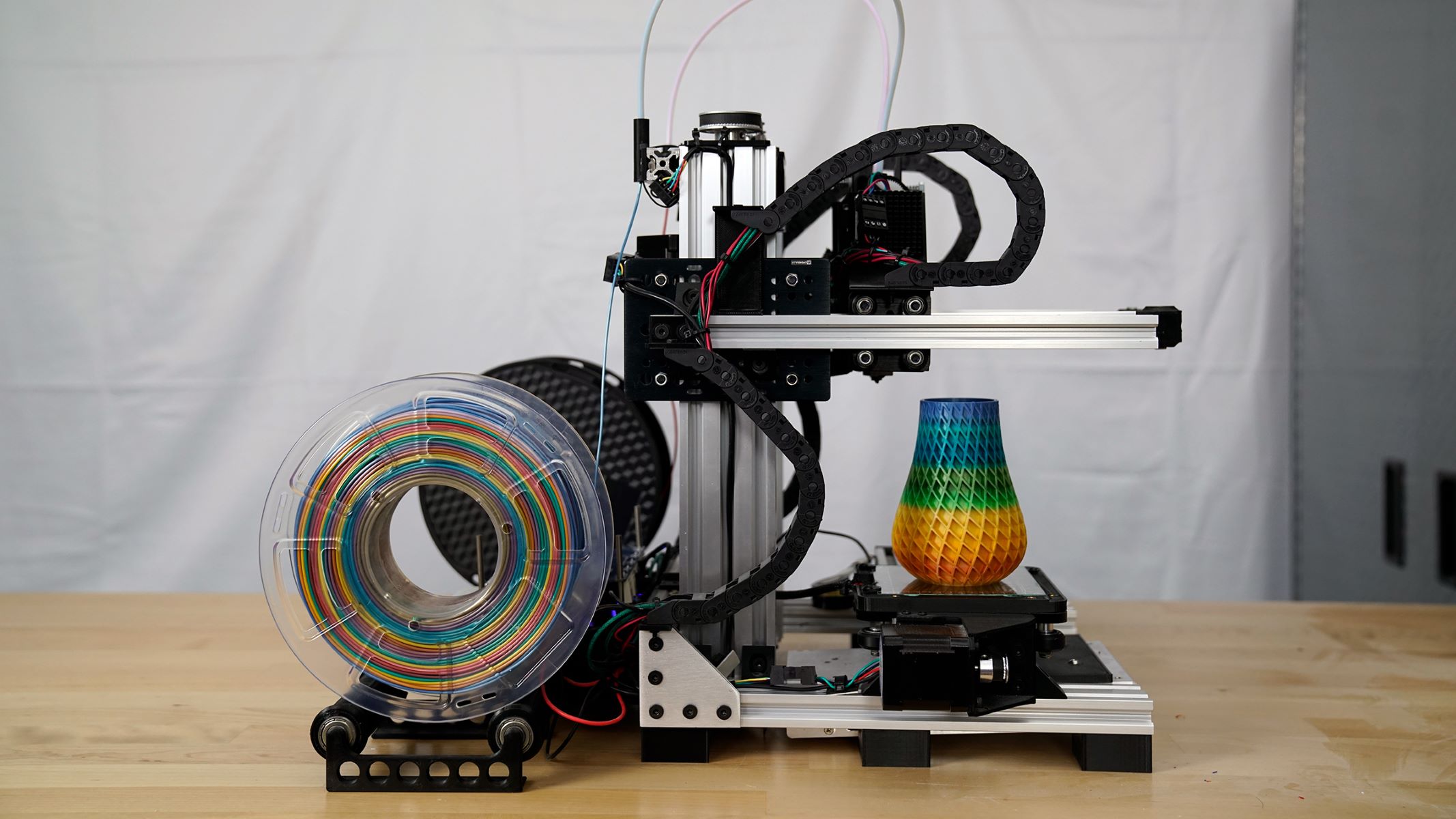

In recent years, 3D printing has revolutionized various industries, including manufacturing, healthcare, and design. This cutting-edge technology allows for the creation of intricate and customized objects through the layer-by-layer deposition of materials. One of the key components in 3D printing is resin, a liquid substance that solidifies when exposed to ultraviolet light. While 3D printer resin has enabled remarkable advancements in prototyping and product development, questions have arisen regarding its potential toxicity.

As the utilization of 3D printing continues to expand, it is essential to explore the safety implications associated with 3D printer resin. Understanding the nature of this substance and its potential health risks is crucial for individuals working with 3D printers, as well as for those who may come into contact with the resin or its byproducts. This article delves into the composition of 3D printer resin, its potential toxicity, the associated health risks, and safety measures that can be implemented to minimize exposure. By shedding light on these aspects, we aim to provide a comprehensive understanding of the safety considerations related to 3D printer resin.

Key Takeaways:

- 3D printer resin, used in cutting-edge technology, can emit harmful compounds and pose health risks. Proper safety measures, like ventilation and protective gear, are crucial for minimizing exposure and ensuring a safe working environment.

- Understanding the potential hazards of 3D printer resin is essential for implementing proactive safety measures. By prioritizing safety and responsible handling, the industry can continue to innovate while safeguarding the well-being of its workforce and the environment.

Read more: What Is A Resin 3D Printer

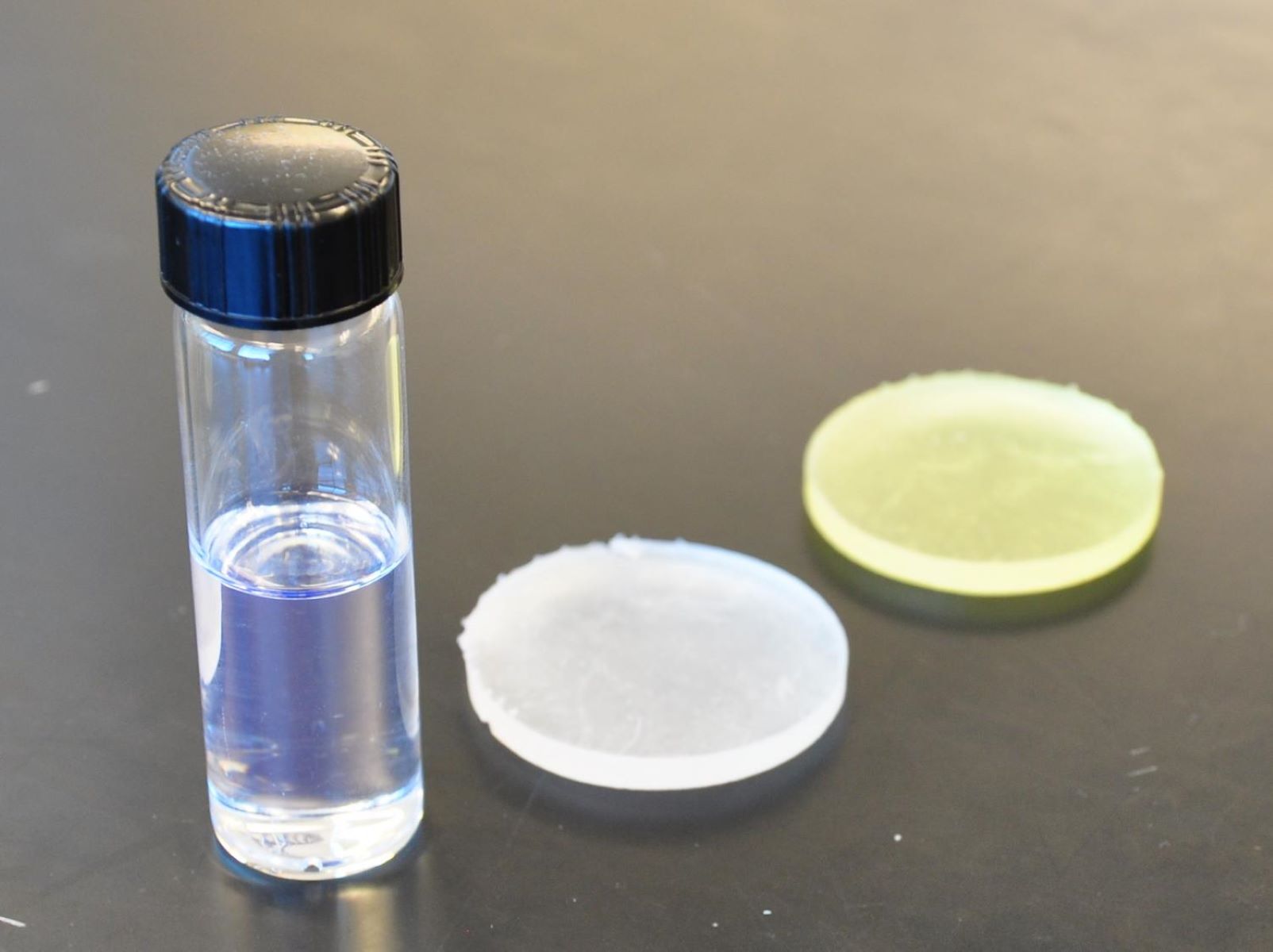

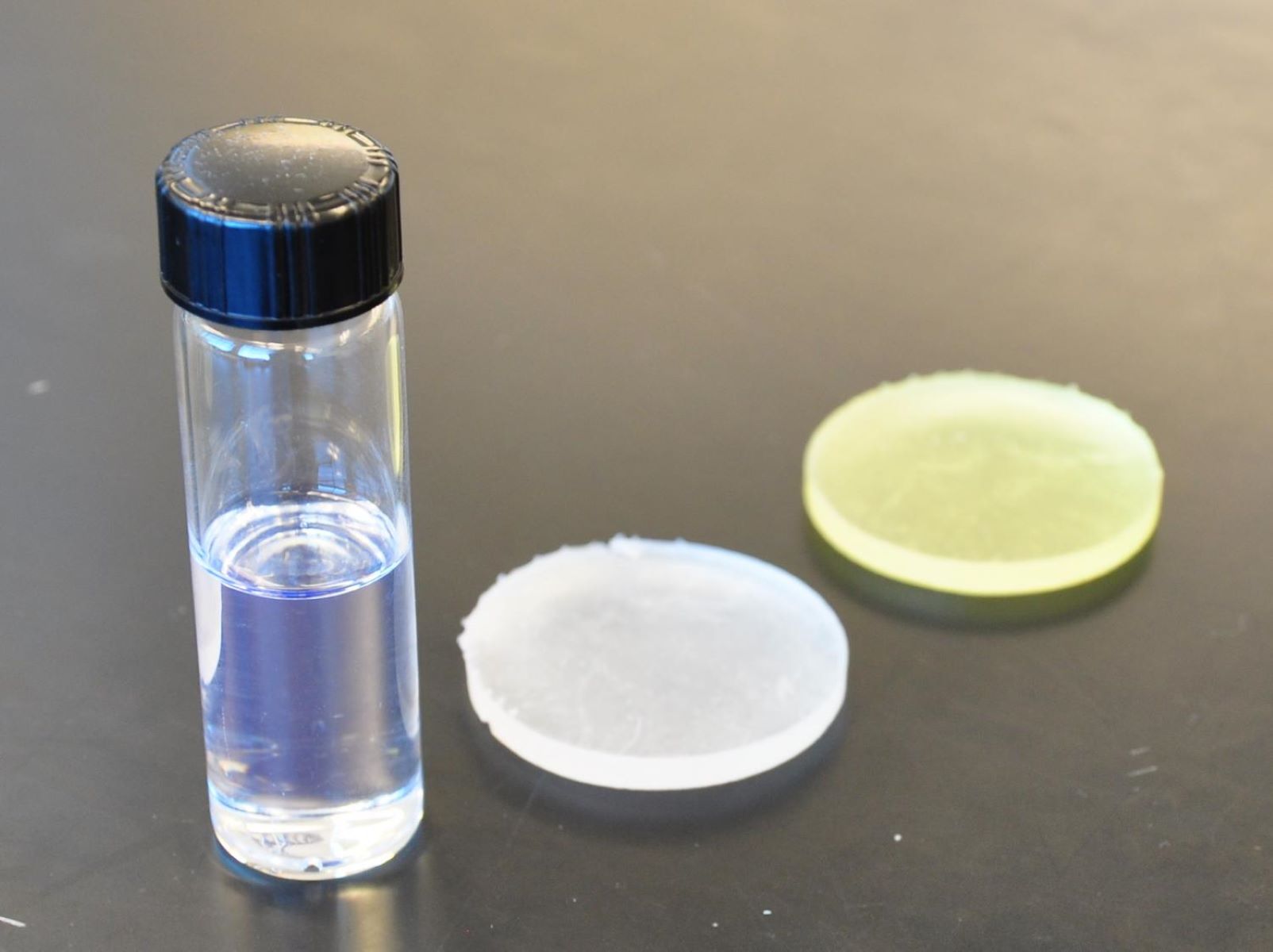

What is 3D Printer Resin?

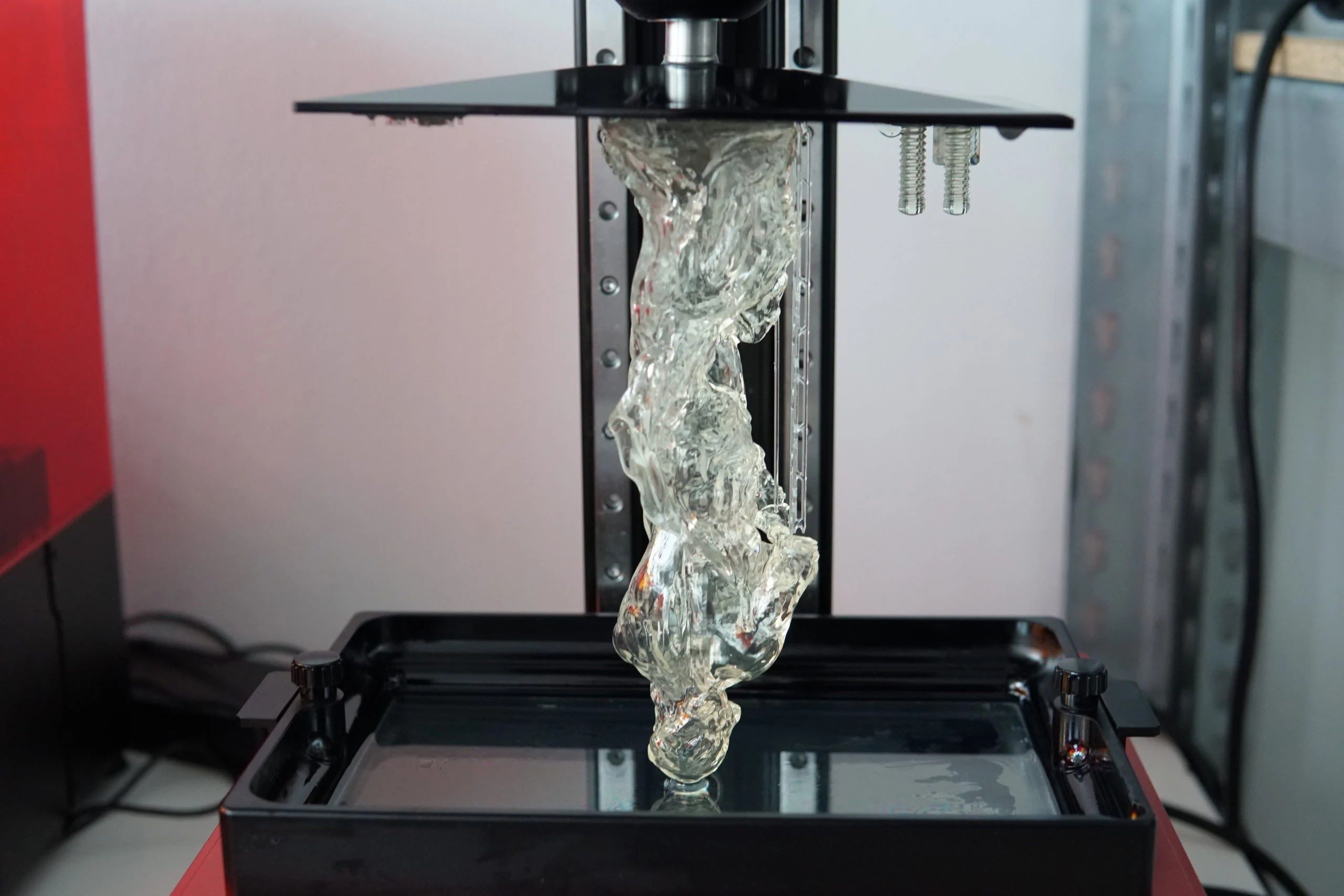

3D printer resin, also known as photopolymer resin, is a crucial component in stereolithography (SLA) and digital light processing (DLP) 3D printing technologies. It is a liquid material that exhibits the unique property of solidifying when exposed to specific wavelengths of light, typically ultraviolet (UV) light. This process, known as photopolymerization, enables the resin to transform from a liquid state to a solid, detailed object layer by layer, as directed by the 3D printer’s digital model.

3D printer resins are available in various formulations, each tailored to meet specific application requirements. These formulations may include standard, flexible, tough, castable, and biocompatible resins, among others. The diverse range of resin types allows for the creation of objects with varying characteristics, such as rigidity, elasticity, transparency, and biocompatibility.

Key components of 3D printer resin formulations include monomers, oligomers, photoinitiators, and additives. Monomers are the building blocks of the resin, while oligomers contribute to its mechanical properties and overall stability. Photoinitiators are compounds that facilitate the solidification process when activated by light, and additives may be incorporated to enhance specific attributes of the resin, such as color or impact resistance.

3D printer resin plays a pivotal role in achieving high-resolution, intricate 3D prints with smooth surface finishes. Its ability to solidify rapidly and retain fine details makes it an ideal choice for applications that demand precision and intricacy, such as jewelry making, dental prosthetics, and prototyping of intricate mechanical parts.

Understanding the composition and properties of 3D printer resin is essential for users and stakeholders in the 3D printing industry. This knowledge forms the basis for evaluating the potential risks associated with resin exposure and implementing appropriate safety measures to mitigate these risks.

Potential Toxicity of 3D Printer Resin

While 3D printer resin is instrumental in creating intricate and high-quality 3D prints, it is important to acknowledge the potential toxicity associated with this material. The resin’s composition, which includes various chemical components, raises concerns about its impact on human health and the environment.

One of the primary sources of concern is the presence of volatile organic compounds (VOCs) in 3D printer resin. VOCs are emitted as the resin undergoes the curing process, particularly during the exposure to UV light. These compounds can contribute to indoor air pollution and may pose respiratory risks to individuals working in close proximity to 3D printers. Prolonged exposure to VOCs has been linked to respiratory irritation, headaches, dizziness, and in some cases, more severe health effects.

Additionally, certain 3D printer resins contain monomers and oligomers that can be hazardous if not handled properly. These chemical components, when in liquid form, have the potential to cause skin and eye irritation upon contact. Furthermore, prolonged skin exposure to uncured resin may lead to sensitization or allergic reactions in some individuals. Inhalation of resin fumes or mists generated during printing processes can also present health risks, particularly in poorly ventilated environments.

Furthermore, the disposal of 3D printer resin and its byproducts raises environmental concerns. Improper disposal methods can result in the release of harmful substances into the ecosystem, impacting soil and water quality. As such, it is imperative to address the potential environmental impact of 3D printer resin and adopt responsible waste management practices within the 3D printing industry.

Recognizing the potential toxicity of 3D printer resin underscores the importance of implementing safety measures and adhering to best practices to minimize exposure and mitigate associated risks. By understanding the potential hazards posed by resin materials, users and stakeholders can take proactive steps to ensure a safe working environment and sustainable practices within the 3D printing ecosystem.

Always wear gloves and a mask when handling 3D printer resin to avoid skin contact and inhalation of toxic fumes. Dispose of resin and cleaning materials properly to prevent environmental contamination.

Health Risks Associated with 3D Printer Resin Exposure

Exposure to 3D printer resin and its byproducts can pose significant health risks, necessitating a thorough understanding of the potential hazards and the implementation of appropriate safety protocols. Individuals who work with 3D printers, particularly those involved in resin handling, printing, and post-processing, are at risk of exposure to the hazardous components present in the resin formulations.

One of the primary health risks associated with 3D printer resin exposure is skin irritation and sensitization. Direct contact with uncured resin can lead to skin irritation, redness, and in some cases, dermatitis. Prolonged or repeated skin exposure may result in sensitization, causing allergic reactions upon subsequent contact with the resin. As such, it is essential for individuals handling 3D printer resin to utilize appropriate personal protective equipment, such as gloves and protective clothing, to minimize skin contact and potential adverse effects.

Inhalation of resin fumes and mists during the printing process presents another significant health concern. When 3D printer resin is exposed to UV light for curing, volatile organic compounds (VOCs) and other potentially harmful substances may be released into the air. Inhalation of these airborne particles can lead to respiratory irritation, dizziness, headaches, and in some cases, more severe respiratory effects. Adequate ventilation and the use of respiratory protective equipment are crucial for mitigating the risks associated with inhaling resin emissions.

Furthermore, eye exposure to 3D printer resin can result in irritation and potential damage. Splashes or mists of uncured resin coming into contact with the eyes can cause irritation, redness, and discomfort. Proper eye protection, such as safety goggles or face shields, is imperative to safeguard against potential eye injuries when working with 3D printer resin.

It is important to note that certain 3D printer resins may contain hazardous chemicals, such as monomers and oligomers, which can pose specific health risks. These chemicals have the potential to cause adverse effects upon skin and eye contact, as well as inhalation. Understanding the specific composition of the resin being used is essential for implementing targeted safety measures and ensuring the well-being of individuals involved in 3D printing processes.

By recognizing the potential health risks associated with 3D printer resin exposure, individuals and organizations can prioritize safety and adopt preventive measures to minimize the likelihood of adverse health effects. Educating personnel on proper handling, storage, and disposal practices, as well as providing access to appropriate personal protective equipment, is essential for creating a safe working environment within the 3D printing industry.

Safety Measures for Handling 3D Printer Resin

Implementing comprehensive safety measures for handling 3D printer resin is essential for mitigating potential health risks and ensuring a secure working environment within the 3D printing industry. By adopting proactive safety protocols, individuals and organizations can minimize exposure to hazardous components present in the resin formulations and promote the well-being of personnel involved in 3D printing processes.

1. Personal Protective Equipment (PPE): Utilizing appropriate personal protective equipment, including nitrile gloves, safety goggles, and protective clothing, is crucial for minimizing skin and eye exposure to 3D printer resin. PPE serves as a critical barrier against direct contact with uncured resin, reducing the risk of skin irritation, sensitization, and eye injuries.

2. Ventilation: Ensuring adequate ventilation in 3D printing facilities is essential for mitigating the inhalation risks associated with resin emissions. Proper ventilation systems, such as local exhaust ventilation or the use of fume hoods, help to minimize the concentration of airborne particles, including volatile organic compounds (VOCs), generated during the resin curing process.

3. Safe Handling and Storage: Practicing safe handling procedures, such as avoiding skin contact with uncured resin, and adhering to proper storage guidelines for resin containers contribute to minimizing potential exposure risks. Storing resin in sealed containers in a well-ventilated area, away from direct sunlight and heat sources, helps maintain the integrity of the material and reduces the likelihood of accidental spills or leaks.

4. Waste Management: Establishing responsible waste management practices for 3D printer resin and its byproducts is essential for preventing environmental contamination. Proper disposal of used resin, empty containers, and waste materials in accordance with local regulations helps mitigate the environmental impact and promotes sustainable handling of resin waste.

5. Training and Education: Providing comprehensive training and education on the safe handling of 3D printer resin is imperative for fostering a culture of safety within 3D printing facilities. Educating personnel on the potential health risks associated with resin exposure, as well as the proper use of personal protective equipment and handling procedures, empowers individuals to make informed decisions and prioritize their well-being.

6. Risk Assessment and Control: Conducting regular risk assessments and implementing control measures tailored to the specific resin formulations used in 3D printing processes is essential for identifying and mitigating potential hazards. Understanding the chemical composition of the resin and its associated risks enables the implementation of targeted control measures to minimize exposure and ensure a safe working environment.

By integrating these safety measures into 3D printing operations, individuals and organizations can proactively address the potential hazards associated with 3D printer resin and create a secure working environment that prioritizes the well-being of personnel and the sustainability of the 3D printing ecosystem.

Read also: 8 Amazing Resin 3D Printer For 2024

Conclusion

3D printer resin, a fundamental component in stereolithography (SLA) and digital light processing (DLP) 3D printing technologies, has revolutionized the creation of intricate and customized objects. However, the potential toxicity of 3D printer resin and its associated health risks necessitate a comprehensive understanding of safety considerations and the implementation of proactive measures to minimize exposure.

Recognizing the potential hazards posed by 3D printer resin, including volatile organic compounds (VOCs) emissions, skin and eye irritation, and environmental impact, underscores the importance of prioritizing safety within the 3D printing industry. By acknowledging the potential health risks associated with resin exposure, individuals and organizations can take proactive steps to ensure a secure working environment and sustainable practices.

Implementing safety measures, such as utilizing personal protective equipment (PPE), ensuring adequate ventilation, practicing safe handling and storage, responsible waste management, providing comprehensive training, and conducting risk assessments, is essential for mitigating potential health risks and promoting a culture of safety within 3D printing facilities.

By fostering a proactive approach to safety and prioritizing the well-being of personnel, the 3D printing industry can continue to harness the innovative potential of 3D printer resin while minimizing the associated health and environmental risks. Through ongoing education, collaboration, and adherence to best practices, stakeholders in the 3D printing ecosystem can contribute to a safe and sustainable industry that continues to drive innovation and creativity.

Ultimately, by recognizing the potential toxicity of 3D printer resin and taking proactive steps to mitigate associated risks, the 3D printing industry can continue to thrive while prioritizing the safety and well-being of its workforce and the broader environment.

Frequently Asked Questions about How Toxic Is 3D Printer Resin

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Toxic Is 3D Printer Resin”