Home>Articles>Electrical Wire Is Sized By What Type Of Measurement

Articles

Electrical Wire Is Sized By What Type Of Measurement

Modified: March 1, 2024

Electrical wire is sized using standard measurement units. Learn more about how wire is measured in this informative article.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

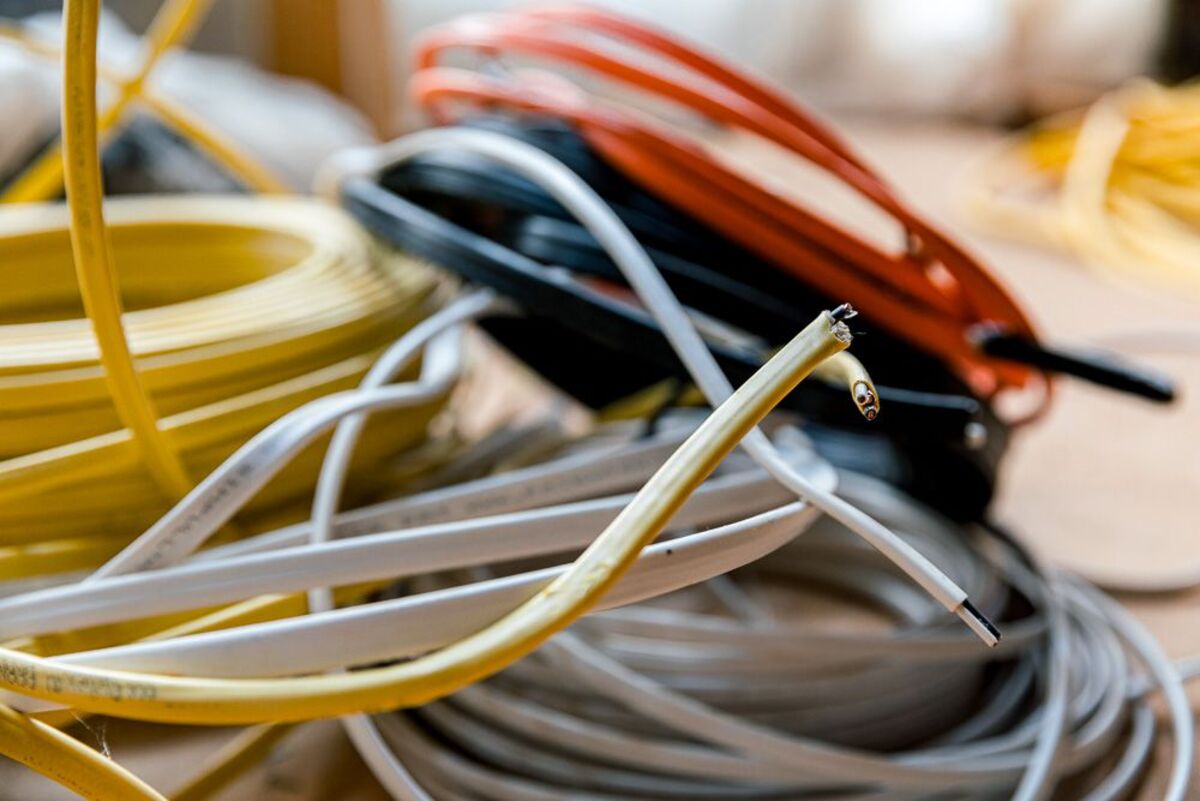

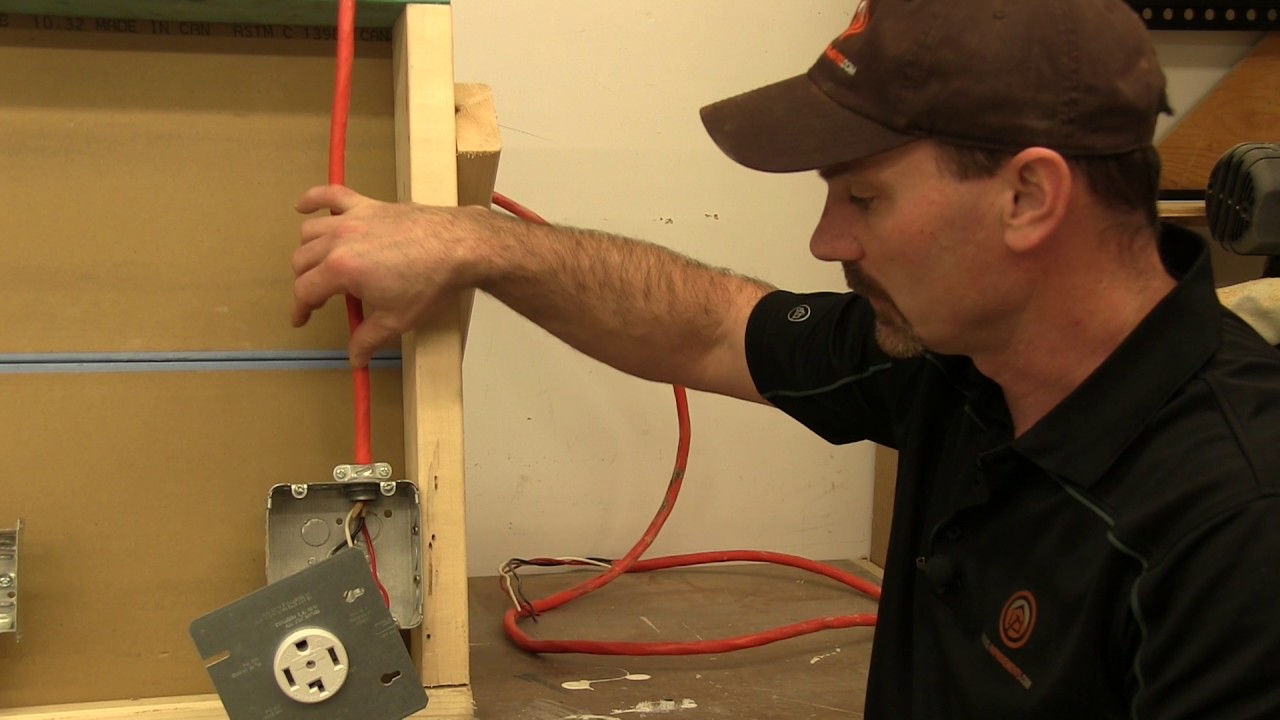

When it comes to electrical installations, selecting the right wire size is crucial for safety and optimal performance. Electrical wire sizing refers to determining the appropriate gauge or thickness of wire to carry the current load without overheating or causing potential hazards. The wire size directly affects the electrical conductivity, voltage drop, and overall efficiency of the electrical system.

In the United States, the most commonly used wire sizing system is the American Wire Gauge (AWG). AWG is a standard measurement system that assigns a specific numerical value to the size of a wire. Understanding how electrical wire is sized according to this system is essential for electricians, contractors, and even homeowners who may need to handle wiring projects.

In this article, we will delve into the different aspects of electrical wire sizing, including the American Wire Gauge (AWG) system, the measurement of electrical wire, and the various factors that affect wire size selection.

So, let’s dive into the world of electrical wire sizing!

Key Takeaways:

- Understanding the American Wire Gauge (AWG) system is crucial for selecting the right wire size, with smaller gauge numbers indicating thicker wires. Consider factors like current load and wire length to ensure safe and efficient electrical installations.

- Factors such as material, temperature rating, and environmental conditions play a critical role in wire size selection. By following NEC guidelines and consulting professionals, you can confidently choose the correct wire size for your electrical projects.

American Wire Gauge (AWG)

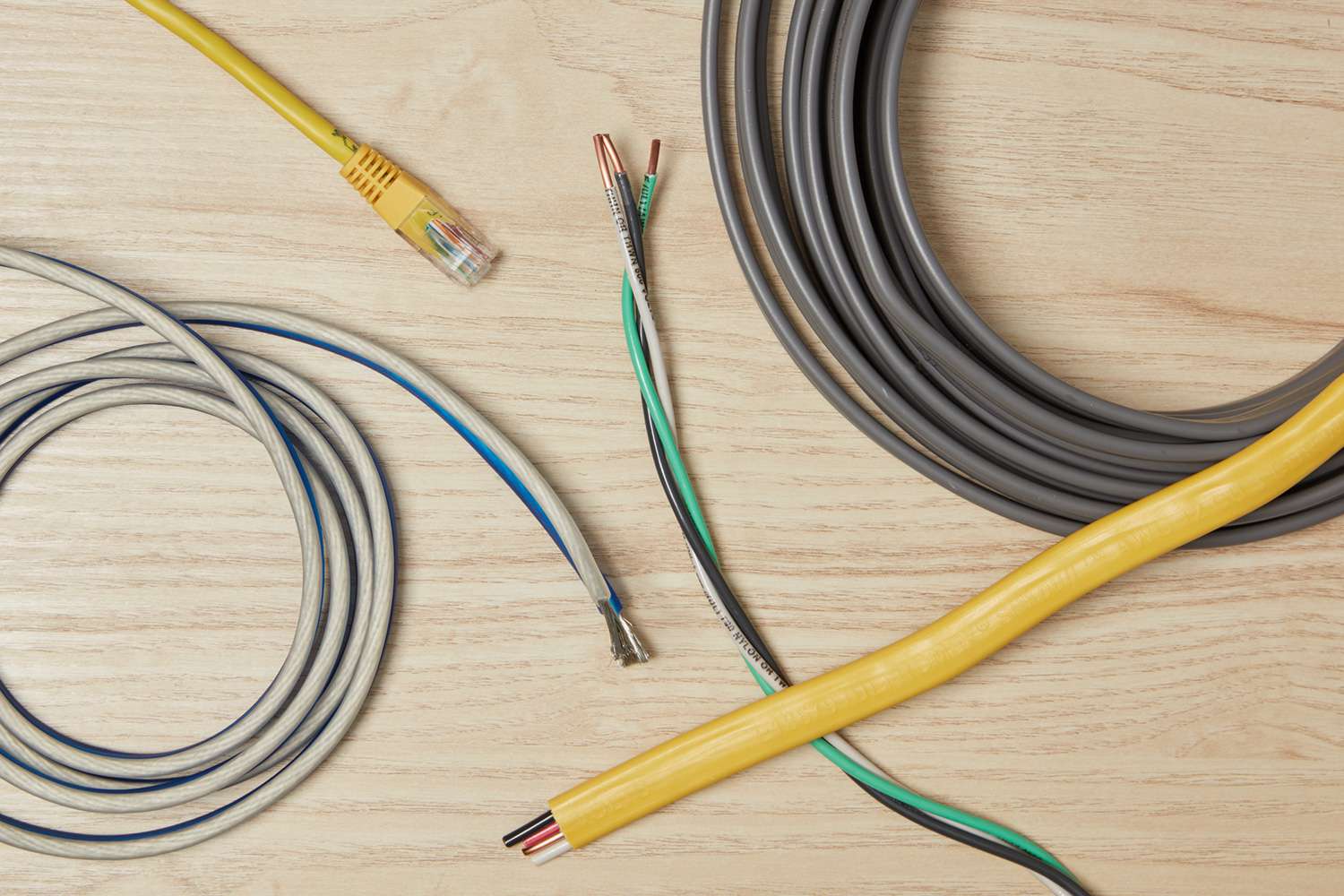

The American Wire Gauge (AWG) is a standardized measurement system used to categorize the size or diameter of electrical wire. It was developed in the late 19th century as a way to standardize wire sizes and ensure compatibility between different manufacturers and applications.

AWG assigns a specific numerical value to each wire size, with smaller numbers representing thicker wires and larger numbers representing thinner wires. The gauge numbers range from 0000 (4/0) to 40, with 0000 being the largest and 40 being the smallest.

One of the key features of the AWG system is that it uses a logarithmic scale, meaning that each step up or down in gauge number represents a doubling or halving of the wire’s cross-sectional area. For example, a wire with a gauge of 12 has twice the cross-sectional area of a wire with a gauge of 14.

AWG is widely used in North America for a variety of applications, including residential, commercial, and industrial electrical installations. It provides an easy way to determine the appropriate wire size for a given current load, minimizing the risk of overheating and ensuring the safe and efficient operation of electrical circuits.

It’s important to note that AWG is not the only wire sizing system used worldwide. In some countries, such as the United Kingdom, metric wire sizing systems like the cross-sectional area (mm²) or the Standard Wire Gauge (SWG) are used. However, AWG remains the most commonly used and recognized system in the United States.

Next, let’s explore how electrical wire is actually measured according to the AWG system.

Measurement of Electrical Wire

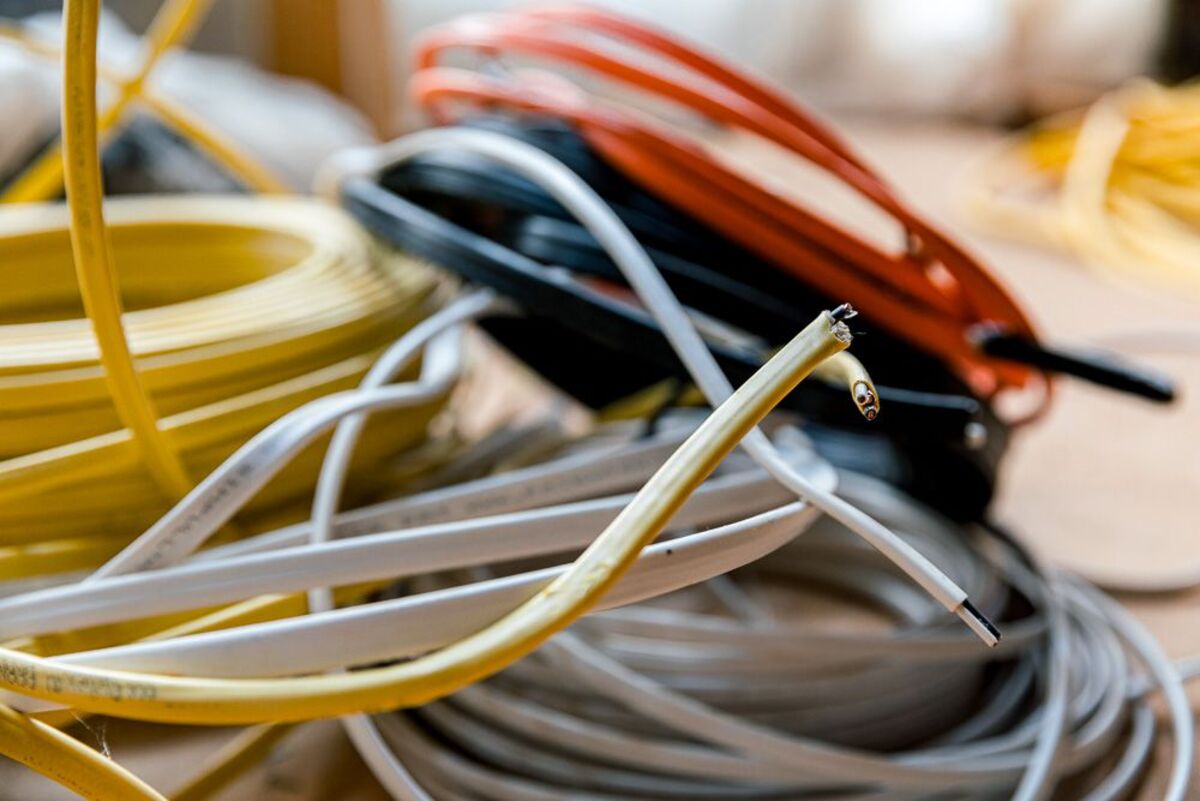

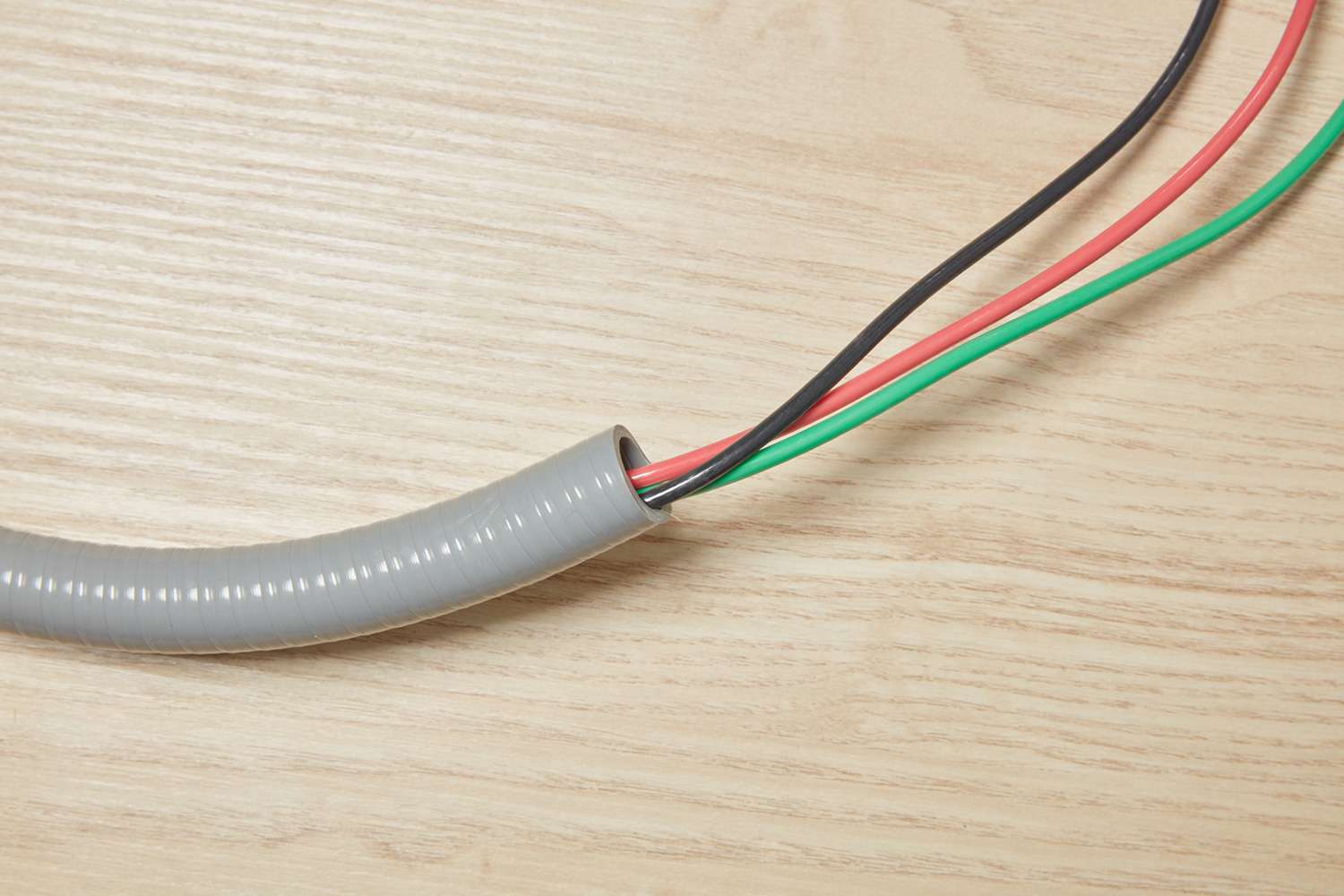

Electrical wire is measured using the American Wire Gauge (AWG) system, which assigns a numerical value to the size or diameter of the wire. The measurement of electrical wire is based on the wire’s cross-sectional area, or the amount of conducting material it contains.

The AWG system uses a mathematical formula to calculate the wire’s cross-sectional area, taking into account the gauge number. The formula is as follows:

Wire Cross-Sectional Area (in circular mils) = (92^(36-n))/39

Where ‘n’ is the gauge number of the wire.

The resulting value is given in circular mils, which is a unit of area measurement. One circular mil is equivalent to the area of a circle with a diameter of one mil (1/1000th of an inch).

For example, a wire with a gauge number of 10 has a cross-sectional area of approximately 10,380 circular mils, while a wire with a gauge number of 20 has a cross-sectional area of about 102 circular mils.

It’s important to note that as the gauge number decreases, the wire size increases. In other words, smaller gauge numbers indicate thicker wires, while larger gauge numbers indicate thinner wires.

Another commonly used measurement for electrical wire is the diameter, which is directly related to the gauge number. The diameter can be calculated using the following formula:

Wire Diameter (in inches) = 0.005 ×√(92^(36-n))

Where ‘n’ is the gauge number of the wire.

Using these formulas, electricians and contractors can accurately determine the size and diameter of electrical wire, ensuring that it is suitable for the intended application and current load.

Now that we understand how electrical wire is measured, let’s explore the factors that affect wire size selection.

Electrical wire is sized by its gauge, which is a measurement of the wire’s diameter. The lower the gauge number, the thicker the wire. Thicker wires can handle more current without overheating.

Factors Affecting Wire Size

When selecting the appropriate wire size for an electrical installation, several factors need to be considered. These factors ensure that the wire can safely carry the current load without exceeding its temperature rating and causing potential hazards. Let’s take a look at some of the key factors affecting wire size selection:

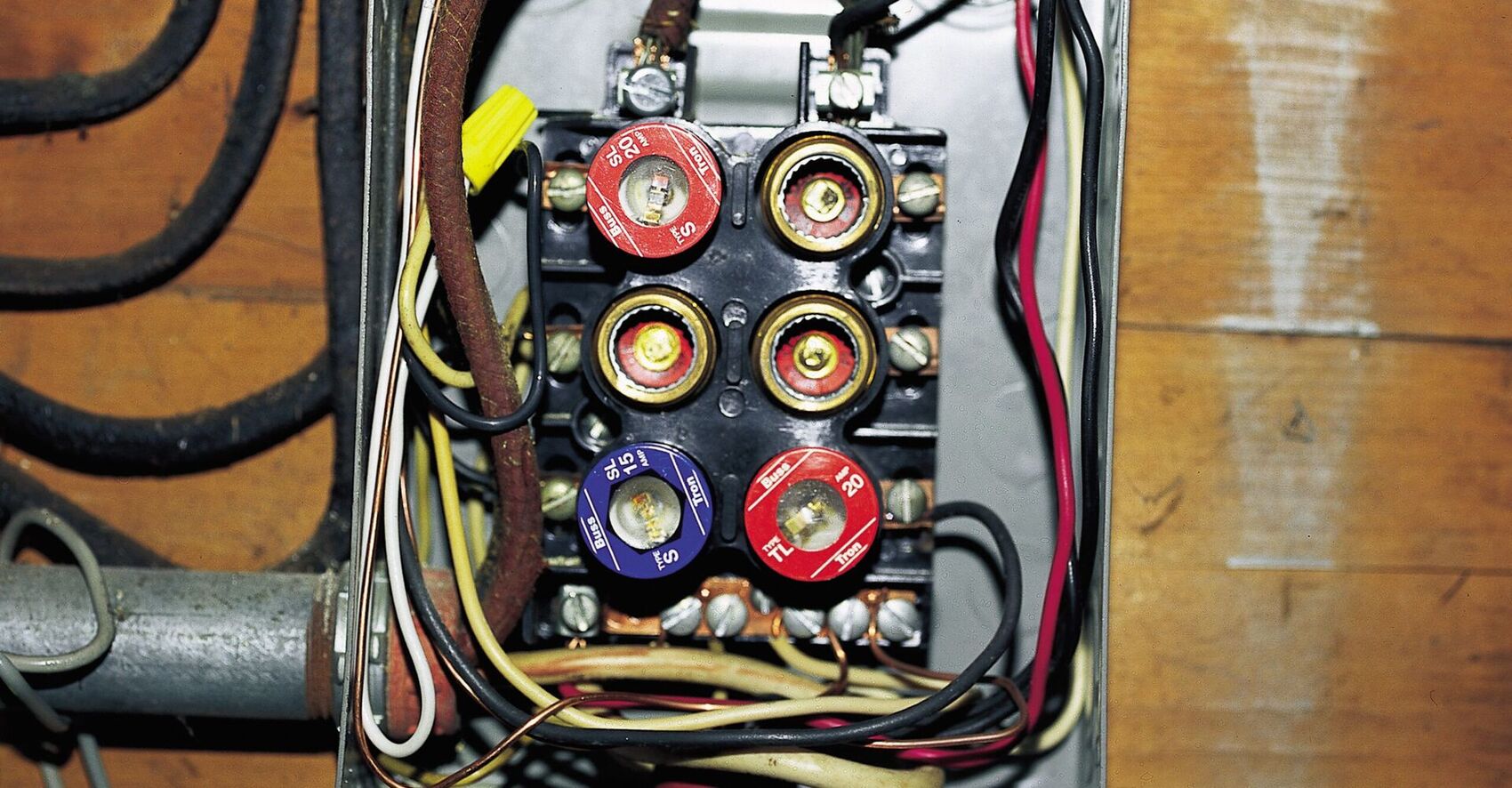

- Current Load: The amount of current that the wire needs to carry is a crucial factor in determining the wire size. Higher current loads require thicker wires to minimize voltage drop and prevent overheating. The National Electrical Code (NEC) provides guidelines for maximum current-carrying capacities for different wire sizes.

- Wire Length: The length of the wire plays a role in determining the wire size. Longer wire runs experience higher voltage drop due to the resistance of the wire. To compensate for this, thicker wires are required to minimize voltage drop and ensure the desired voltage is delivered to the load.

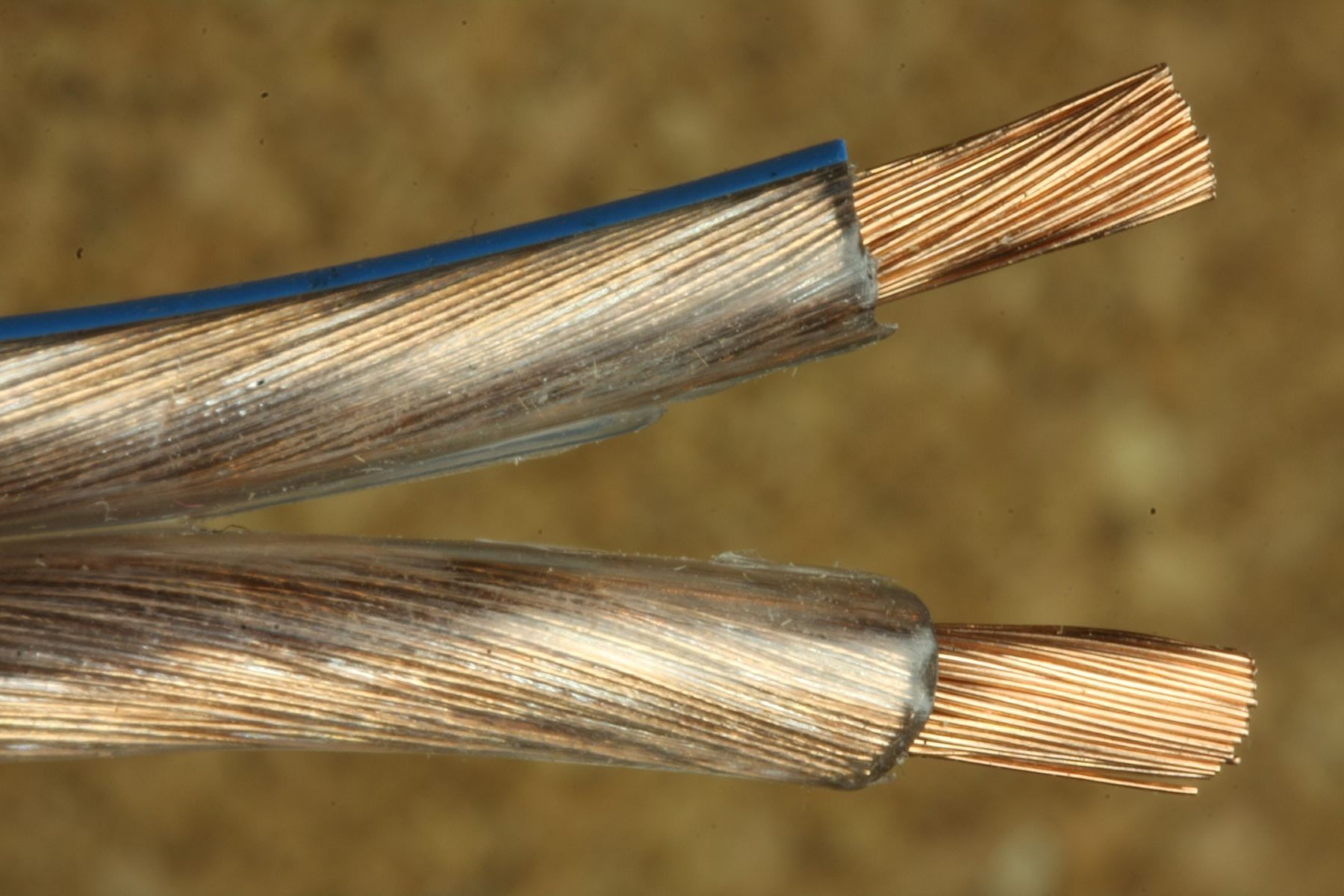

- Material: The material composition of the wire can affect its current-carrying capacity and resistance. Copper is the most commonly used material for electrical wiring due to its high conductivity. However, aluminum wires have a slightly higher resistance and may require a larger gauge size compared to copper for the same current load.

- Temperature Rating: Each wire size has a specific temperature rating, indicating the maximum temperature the wire can handle without degradation. The temperature rating should match or exceed the expected operating temperature of the electrical system. Higher ambient temperatures may require larger wire sizes to prevent overheating.

- Voltage Drop: Voltage drop refers to the decrease in voltage along the length of the wire due to its resistance. Excessive voltage drop can cause issues with equipment performance and efficiency. Thicker wires have lower resistance, resulting in reduced voltage drop, especially over longer wire runs.

- Environmental Conditions: The environmental conditions in which the wire will be installed can also impact wire size selection. Factors such as moisture, extreme temperatures, and exposure to chemicals or corrosive substances may necessitate the use of specialized wire with higher resistance to these conditions.

Considering these factors and consulting the NEC guidelines, electricians and contractors can determine the appropriate wire size to ensure a safe and efficient electrical installation.

Now that we have explored the factors affecting wire size selection, let’s conclude our discussion.

Conclusion

Choosing the correct wire size is essential for any electrical wiring project. The American Wire Gauge (AWG) system provides a standardized method for determining wire sizes, with smaller gauge numbers representing thicker wires. Understanding how wire is measured according to the AWG system, including its cross-sectional area and diameter, enables electricians, contractors, and homeowners to select the right wire for their specific application.

Factors such as current load, wire length, material, temperature rating, voltage drop, and environmental conditions all play a critical role in determining the appropriate wire size. Taking these factors into consideration ensures that the wire can safely carry the required current without exceeding its temperature rating or suffering from excessive voltage drop.

By following the guidelines set forth by the National Electrical Code (NEC) and consulting with knowledgeable professionals, individuals can confidently select the correct wire size for their electrical installations. This ensures the safe and efficient operation of the electrical system, minimizing potential hazards and ensuring optimal performance.

So, the next time you embark on an electrical wiring project, remember to consider the AWG wire sizing system and the various factors that influence wire size selection. By doing so, you’ll have peace of mind knowing that your electrical system is up to code and built to last.

Thank you for joining us on this journey through the world of electrical wire sizing!

Frequently Asked Questions about Electrical Wire Is Sized By What Type Of Measurement

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “Electrical Wire Is Sized By What Type Of Measurement”