Articles

How Does A Diaphragm Water Pump Work

Modified: January 20, 2024

Learn how a diaphragm water pump works and discover all the essential information you need. Read our comprehensive articles on this topic and become an expert.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Water pumps play a crucial role in various industries, agricultural operations, and even in our homes. They are responsible for transferring water from one location to another, providing a steady supply for irrigation, firefighting, and household use. One type of water pump that has gained popularity in recent years is the diaphragm water pump.

A diaphragm water pump is a versatile and reliable pump that uses the motion of a flexible diaphragm to create suction and discharge pressure. It is commonly used for applications that require low to moderate flow rates and relatively low pressures. The design of the diaphragm pump allows it to handle a wide range of fluids, including water, chemicals, and even viscous liquids.

In this article, we will explore the inner workings of a diaphragm water pump, understand its components, and discover its advantages and disadvantages. We will also dive into its various applications and provide some tips on how to properly maintain and care for these pumps.

So, let’s dive in and unravel the mystery behind the functioning of a diaphragm water pump.

Key Takeaways:

- Diaphragm water pumps are versatile, reliable, and self-priming, making them ideal for various applications such as agriculture, chemical processing, and residential water systems.

- While diaphragm water pumps offer minimal maintenance and quiet operation, they have limitations in pressure, flow rates, and susceptibility to diaphragm wear. Regular maintenance and careful consideration of specific application requirements are essential for optimal performance.

Read more: How Does Water Pump Work

What is a Diaphragm Water Pump?

A diaphragm water pump is a type of positive displacement pump that uses a flexible diaphragm to create suction and discharge pressure. It is specifically designed to handle moderate flow rates and relatively low pressures. The diaphragm serves as a partition between the wet and dry sides of the pump, allowing it to handle a wide range of fluids, including water, chemicals, and even viscous liquids.

The diaphragm pump consists of several key components, including the diaphragm itself, inlet and outlet valves, and a power source. The diaphragm is usually made of a flexible material such as rubber or Teflon, which allows it to expand and contract as the pump operates. This movement of the diaphragm creates the necessary pressure differentials to move the fluid through the pump.

The inlet and outlet valves play a crucial role in the functioning of a diaphragm pump. The inlet valve opens to allow fluid to enter the pump, while the outlet valve opens to allow fluid to be discharged. These valves ensure that the fluid flows in the desired direction and prevent backflow.

A diaphragm water pump can be operated using various power sources, including electric motors, hydraulic systems, or even compressed air. The choice of power source depends on the specific application and the desired flow rate and pressure requirements.

Overall, diaphragm water pumps are known for their versatility, durability, and reliability. They can handle a wide range of fluids and are suitable for applications in various industries, including agriculture, chemical processing, wastewater treatment, and even for household use.

Now that we have a basic understanding of what a diaphragm water pump is, let’s delve into its components and how it works.

Components of a Diaphragm Water Pump

A diaphragm water pump consists of several key components that work together to achieve its pumping action. Understanding these components is essential to grasp how the pump operates and how it moves fluids effectively. Let’s take a closer look at each component:

- Diaphragm: The diaphragm is the heart of a diaphragm water pump. It is usually made of a flexible material such as rubber or Teflon. The diaphragm serves as a partition between the wet and dry sides of the pump. As the diaphragm flexes, it creates the necessary pressure differentials to draw in and discharge the fluid.

- Inlet and Outlet Valves: The diaphragm pump is equipped with both an inlet valve and an outlet valve. The inlet valve allows fluid to enter the pump chamber, while the outlet valve controls the flow of fluid out of the pump. These valves play a crucial role in ensuring that the fluid flows in the desired direction and prevents any backflow.

- Casing: The casing of a diaphragm water pump provides structural support and houses the different components. It is typically made of durable materials such as stainless steel or plastic. The casing also helps to seal the pump chamber and prevent any leakage.

- Power Source: The power source of a diaphragm water pump can vary depending on the specific application. It can be powered by an electric motor, hydraulic system, or even compressed air. The power source provides the energy needed to drive the diaphragm and create the necessary pressure differentials for fluid movement.

- Check Valves: Check valves are essential components that ensure the proper flow direction within the pump. They are typically located at the inlet and outlet ports of the pump. These valves allow fluid to flow in only one direction, preventing any backflow and maintaining the desired flow path.

- Connecting Rod: The connecting rod connects the diaphragm to the power source. It converts the rotary motion of the power source into the reciprocating motion of the diaphragm. This motion allows the diaphragm to flex and create the necessary pressure differentials.

- Seals and Gaskets: Seals and gaskets are used to ensure a tight and leak-free seal between different components of the diaphragm pump. They prevent fluid leakage and maintain the efficiency of the pump.

By understanding the various components of a diaphragm water pump, we can now move on to explore how these components work together to achieve the pumping action. In the next section, we will delve into the working principles of a diaphragm water pump.

Working Principles of a Diaphragm Water Pump

The working principles of a diaphragm water pump revolve around the reciprocating motion of its flexible diaphragm. This motion creates suction and discharge pressure, allowing the pump to draw in fluid from the inlet side and push it out through the outlet side. Let’s explore the working principles in more detail:

1. Suction Phase: The diaphragm water pump begins its cycle in the suction phase. As the power source activates, it moves the connecting rod, which in turn moves the diaphragm. As the diaphragm moves upward, the pressure inside the pump chamber decreases. This decrease in pressure creates a suction effect, drawing fluid into the chamber through the inlet valve.

2. Filling Phase: Once the fluid enters the pump chamber, the inlet valve closes to prevent backflow. The diaphragm continues its upward motion, creating more space inside the chamber. This increase in volume allows the chamber to fill with fluid from the inlet side.

3. Compression Phase: After the filling phase, the direction of motion of the diaphragm changes. It starts moving downward, compressing the fluid inside the pump chamber. The compression of the diaphragm creates an increase in pressure, forcing the fluid towards the outlet side of the pump.

4. Discharge Phase: As the diaphragm reaches its lowest point, the outlet valve opens to allow the fluid to be discharged. The diaphragm’s downward motion generates enough pressure to push the fluid through the outlet valve and into the desired destination.

5. Return Phase: After the discharge phase, the diaphragm returns to its original position, starting another cycle in the suction phase. This continuous reciprocating motion of the diaphragm allows the diaphragm water pump to consistently draw in and move fluids.

It is worth mentioning that the operation of a diaphragm water pump can be controlled by adjusting the speed and stroke length of the diaphragm. This versatility allows the pump to handle different flow rates and pressures, making it suitable for various applications.

Now that we understand the working principles of a diaphragm water pump, let’s walk through the step-by-step process of how these pumps work in practice.

Step-by-Step Process of How a Diaphragm Water Pump Works

The operation of a diaphragm water pump can be broken down into several steps that outline the process of how it works. Let’s go through each step to paint a clear picture of the pump’s functionality:

Step 1: Suction Phase

The diaphragm water pump cycle begins with the suction phase. The diaphragm moves upward, creating a decrease in pressure inside the pump chamber. This drop in pressure causes the fluid to be drawn in through the inlet valve into the chamber.

Step 2: Filling Phase

Once the fluid enters the pump chamber, the inlet valve closes to prevent backflow. The diaphragm continues its upward motion, creating more space inside the chamber. This increased volume allows the chamber to fill with fluid from the inlet side.

Step 3: Compression Phase

As the diaphragm reaches its peak position, the direction of motion changes, and it starts moving downward. This downward movement compresses the fluid inside the chamber, increasing the pressure. The compression of the diaphragm forces the fluid towards the outlet side of the pump.

Step 4: Discharge Phase

Once the diaphragm reaches its lowest point, the outlet valve opens, allowing the fluid to be discharged. The downward motion of the diaphragm generates enough pressure to push the fluid through the outlet valve and into the desired destination.

Step 5: Return Phase

After the discharge phase, the diaphragm returns to its original position, starting another cycle in the suction phase. This reciprocating motion of the diaphragm allows for a continuous pumping action.

The speed and stroke length of the diaphragm can be adjusted to control the flow rate and pressure of the pump. Increasing the stroke length or speed will result in higher flow rates and pressures, while decreasing them will achieve the opposite effect.

It’s important to note that diaphragm water pumps are self-priming, which means they have the ability to draw in fluids from a lower level. This makes them highly effective in applications where the pump needs to overcome gravity or suction lift challenges.

Overall, the step-by-step process of how a diaphragm water pump works is a continuous cycle of suction, filling, compression, discharge, and return. These pumps provide reliable fluid transfer, making them suitable for a wide range of applications.

Now that we have explored the working process of a diaphragm water pump, let’s examine the advantages and disadvantages of using this type of pump.

When using a diaphragm water pump, make sure to regularly check and clean the diaphragm to ensure proper functioning and prevent clogs or damage.

Read more: How Does An Electric Water Pump Work

Advantages of Using a Diaphragm Water Pump

Diaphragm water pumps offer several advantages that make them preferred choices in various industries and applications. Let’s explore some of the key advantages:

- Self-Priming: One of the primary advantages of diaphragm water pumps is their self-priming capability. They can draw in fluids from a lower level, eliminating the need for external priming and making them suitable for applications where the pump needs to overcome suction lift challenges.

- Versatility: Diaphragm water pumps are highly versatile and can handle a wide range of fluids, including water, chemicals, and even viscous liquids. This versatility makes them suitable for various industries, such as agriculture, chemical processing, wastewater treatment, and more.

- Solids Handling: Diaphragm pumps can effectively handle liquids with small solids or abrasive particles without clogging or damage to the pump. The flexible diaphragm seals off the solids, allowing smooth and efficient fluid transfer.

- Adjustable Flow Rates and Pressure: Diaphragm water pumps allow for adjustable flow rates and pressure by controlling the stroke length and speed of the diaphragm. This adaptability makes them suitable for a wide range of applications with different requirements.

- Minimal Maintenance: These pumps require minimal maintenance due to their simple design. They have fewer moving parts, which reduces the chances of mechanical failure. Routine maintenance typically involves inspecting and replacing the diaphragm and checking the valves for any signs of wear or damage.

- Quiet Operation: Diaphragm water pumps are known for their quiet operation compared to other types of water pumps. This makes them ideal for applications where noise levels need to be kept to a minimum, such as residential areas or indoor environments.

- Reliability and Durability: Diaphragm pumps are designed to be reliable and durable, able to withstand demanding conditions and deliver consistent performance over time. The diaphragm’s flexibility and rugged materials used in construction contribute to their longevity.

These advantages make diaphragm water pumps a popular choice for a wide range of applications. However, it’s important to also consider the potential disadvantages associated with using this type of pump, which we will explore next.

Now that we have looked at the advantages of using a diaphragm water pump, let’s discuss the potential disadvantages that should be taken into consideration.

Disadvantages of Using a Diaphragm Water Pump

While diaphragm water pumps offer many advantages, it’s important to consider their potential disadvantages before selecting them for specific applications. Let’s explore some of the disadvantages associated with using diaphragm water pumps:

- Limited Pressure: Diaphragm water pumps are not designed for high-pressure applications. Their operating pressure is typically limited and may not meet the requirements of certain industries or applications that demand high-pressure levels.

- Limited Flow Rates: Similarly, diaphragm water pumps are most effective for low to moderate flow rate applications. They may not be suitable for applications requiring extremely high flow rates as other pump types are better suited for those requirements.

- Prone to Diaphragm Wear: The diaphragm is a critical component of a diaphragm water pump, and over time, it can wear out or suffer from fatigue. This wear and tear can lead to reduced efficiency and eventually require the replacement of the diaphragm.

- Sensitivity to Viscous Fluids: While diaphragm pumps can handle viscous liquids to some extent, extremely viscous fluids can pose challenges. High viscosity fluids can affect the performance of the pump, requiring additional measures or alternative pump options for efficient operation.

- Risk of Contamination: Diaphragm pumps have multiple moving parts and crevices, which can potentially create areas where particles or contaminants can accumulate. Regular maintenance and proper cleaning are necessary to mitigate the risk of contamination in sensitive applications.

- Power Consumption: Depending on the specific application and size of the diaphragm water pump, it may consume a decent amount of power to achieve the desired flow rates and pressures. This higher power consumption may result in increased operational costs.

- Size Limitations: Diaphragm water pumps are available in various sizes, but they may not be ideal for applications with space constraints. Larger diaphragm pumps may require more space compared to other types of pumps, limiting their suitability in certain environments.

It is crucial to carefully evaluate the requirements and limitations of your specific application to determine if a diaphragm water pump is the most appropriate choice.

Despite these disadvantages, diaphragm water pumps continue to be widely used due to their versatility, reliability, and ease of maintenance. The key is to weigh the pros and cons in relation to your specific pumping needs.

Now that we have examined both the advantages and disadvantages of diaphragm water pumps, let’s explore some common applications where these pumps excel.

Applications of Diaphragm Water Pumps

Diaphragm water pumps find applications in various industries and environments due to their versatility and ability to handle different fluids. Let’s explore some common applications where diaphragm water pumps excel:

- Agriculture and Irrigation: Diaphragm water pumps are often used in agricultural operations for irrigation purposes. They can handle water with sediment and small solids, making them ideal for pumping water from wells, ponds, or streams to irrigate crops.

- Chemical Processing: Diaphragm pumps are commonly used in the chemical processing industry. They can handle a wide range of corrosive and abrasive fluids, making them suitable for transferring chemicals, acids, and solvents in various manufacturing processes.

- Wastewater Treatment: Diaphragm pumps play a crucial role in wastewater treatment facilities. They are used for transferring sludge, handling sewage, and dosing chemicals in treatment processes. The ability of diaphragm pumps to handle viscous fluids and small solids makes them valuable in wastewater applications.

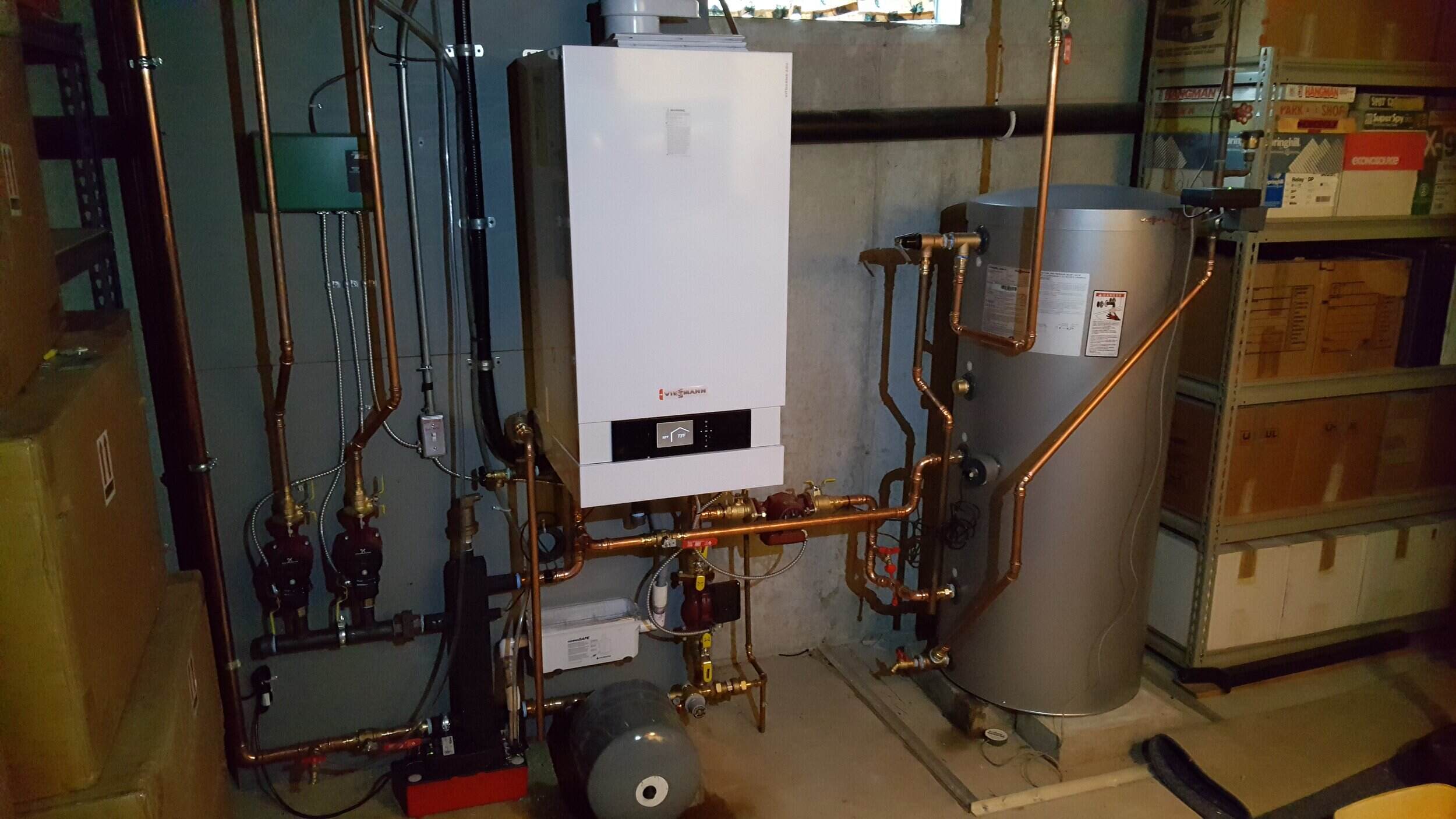

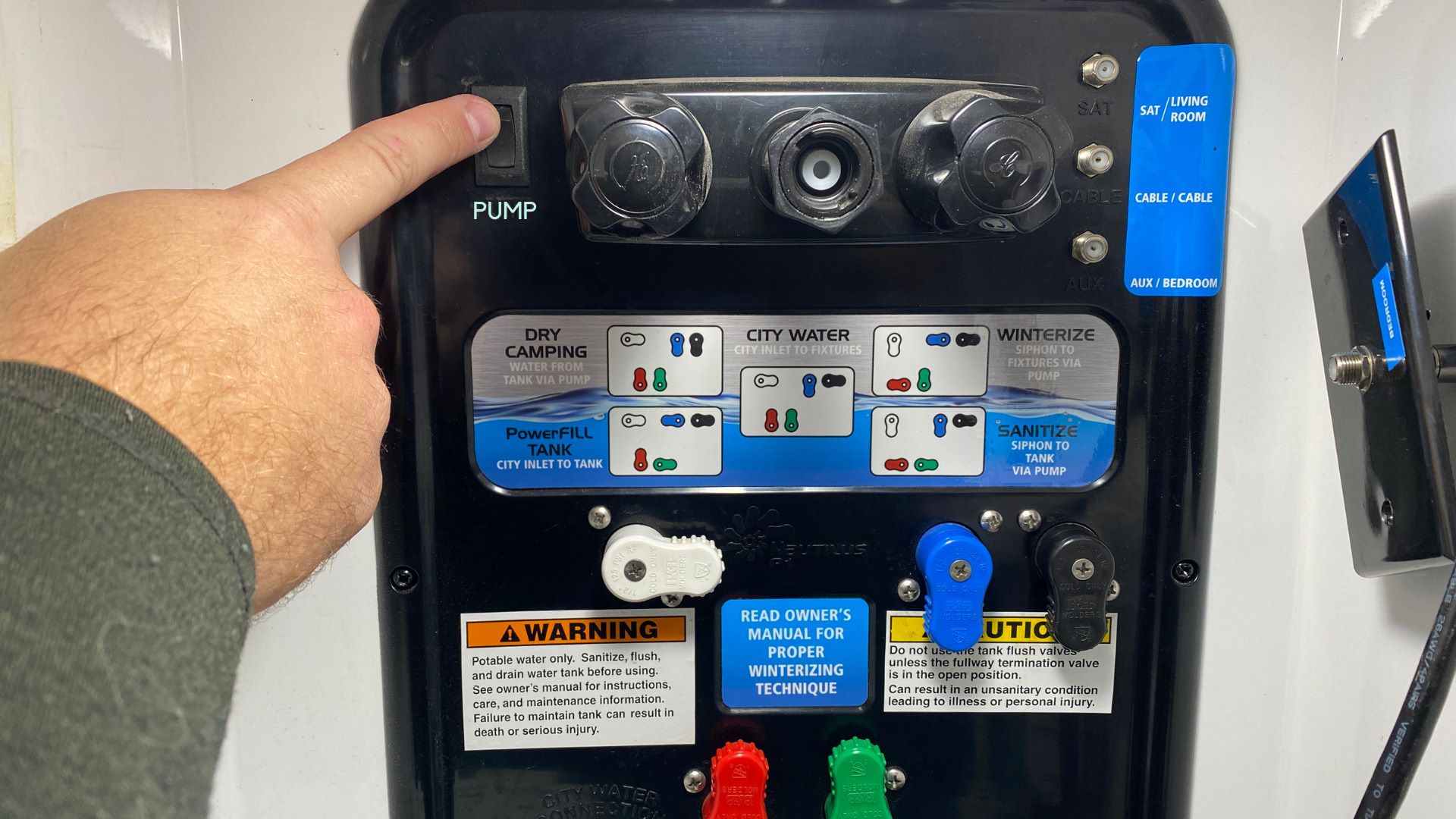

- Residential and Commercial Water Systems: Diaphragm water pumps are often used in residential and commercial water systems. They provide a reliable and efficient solution for boosting water pressure, ensuring adequate flow rates, and maintaining water supply in buildings.

- Fuel and Oil Transfer: Diaphragm pumps are suitable for transferring fuels, oils, and lubricants in various industries, including automotive, marine, and oil and gas. Their ability to handle a wide range of fluids and resistance to corrosion makes them an excellent choice for fluid transfer applications.

- Food and Beverage Industry: Diaphragm pumps are commonly used in the food and beverage industry. They are employed for transferring fluids such as juices, syrups, sauces, and dairy products. Diaphragm pumps with sanitary designs and materials are used to maintain the integrity and hygiene of the food products.

- Medical and Laboratory Applications: Diaphragm pumps find application in medical and laboratory settings. They are used for transferring fluids, suctioning, and other critical processes that require precise control, low noise levels, and the ability to handle sensitive fluids.

These are just a few examples of the diverse applications where diaphragm water pumps excel. Their versatility, self-priming capability, and ability to handle various fluids make them a reliable choice in countless industries and environments.

Now that we have explored the applications of diaphragm water pumps, let’s discuss some essential maintenance and care tips to ensure their optimal performance.

Maintenance and Care Tips for Diaphragm Water Pumps

To ensure the longevity and optimal performance of your diaphragm water pump, regular maintenance and proper care are essential. Here are some key maintenance tips to keep in mind:

- Inspect the Diaphragm: Regularly inspect the diaphragm for any signs of wear, damage, or fatigue. If you notice any tears, cracks, or loss of flexibility, replace the diaphragm promptly to prevent any further damage or inefficiencies.

- Check the Valves: Periodically check the inlet and outlet valves for proper functioning. Make sure they open and close smoothly and are free from any obstructions or debris. Clean or replace the valves if necessary to maintain proper flow and prevent backflow.

- Clean the Pump: Keep the pump clean and free from dirt, debris, and contaminants. Regularly wipe down the exterior surfaces and ensure that the air vents are clear. Avoid allowing any foreign substances to enter the pump, as they can cause clogs or damage.

- Monitor the Seals and Gaskets: Inspect the seals and gaskets regularly to ensure they are intact and providing a tight seal. Replace any worn or damaged seals to prevent leakage and maintain the efficiency of the pump.

- Follow Manufacturer’s Guidelines: Refer to the manufacturer’s guidelines and recommendations for maintenance intervals, lubrication requirements, and any specific instructions for your diaphragm water pump model. Following these guidelines will help ensure proper maintenance and extend the life of the pump.

- Maintain the Power Source: If your diaphragm water pump is powered by an electric motor or any other power source, ensure that it is well-maintained as per the manufacturer’s instructions. Regularly check the connections, lubricate if required, and keep the motor or power source clean and free from debris.

- Keep Spare Parts on Hand: It’s advisable to keep spare diaphragms, valves, and other critical parts on hand. This allows for quick replacement in case of any unexpected failures or routine maintenance requirements. Having spare parts readily available can minimize downtime and ensure uninterrupted operation.

Remember to always prioritize safety when performing any maintenance tasks on your diaphragm water pump. Follow proper safety procedures, such as disconnecting the power source, relieving pressure, and wearing appropriate personal protective equipment (PPE).

By following these maintenance and care tips, you can help prolong the life of your diaphragm water pump, ensure its optimal performance, and minimize the risk of unexpected breakdowns or inefficiencies.

Now that we have explored maintenance and care tips, let’s summarize the key points discussed in this article.

Read more: How Does Hand Water Pump Work

Conclusion

In conclusion, diaphragm water pumps are versatile and reliable machines that play a vital role in various industries and applications. They utilize the reciprocating motion of a flexible diaphragm to create suction and discharge pressure, allowing for the efficient transfer of fluids.

We have explored the components of a diaphragm water pump, including the diaphragm, inlet and outlet valves, casing, power source, check valves, connecting rod, and seals. Together, these components work harmoniously to achieve the pumping action.

Understanding the working principles of a diaphragm water pump has provided insight into the step-by-step process of how it operates. The suction phase, filling phase, compression phase, discharge phase, and return phase work in unison to continually draw in and move fluids.

Diaphragm water pumps offer several advantages, such as their self-priming capability, versatility in handling different fluids, and minimal maintenance requirements. They excel in applications such as agriculture and irrigation, chemical processing, wastewater treatment, residential and commercial water systems, fuel and oil transfer, and the food and beverage industry.

While diaphragm water pumps have many advantages, it’s important to consider potential disadvantages, including their limited pressure and flow rates, susceptibility to diaphragm wear, and sensitivity to viscous fluids.

To ensure optimal performance and longevity of diaphragm water pumps, following proper maintenance and care tips is crucial. Inspecting the diaphragm, checking valves, cleaning the pump, monitoring seals and gaskets, and adhering to manufacturer’s guidelines are essential practices.

In summary, diaphragm water pumps are reliable and efficient tools for fluid transfer in various industries. Understanding their components, working principles, applications, and maintenance considerations will help you make informed decisions when selecting and maintaining these pumps.

By harnessing the power of diaphragm water pumps, you can ensure a steady flow of fluids, efficient operations, and the success of your applications and processes.

Frequently Asked Questions about How Does A Diaphragm Water Pump Work

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Does A Diaphragm Water Pump Work”