Home>Articles>How Long Can An Extension Cord Be Used In A Facility

Articles

How Long Can An Extension Cord Be Used In A Facility

Modified: March 1, 2024

Learn about the appropriate length of extension cords used in facilities and stay informed with our insightful articles.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Extension cords play a crucial role in providing convenient access to power in various facilities. Whether it is in an office setting, a manufacturing plant, or a construction site, extension cords are a common sight. They allow us to connect electrical devices and equipment to outlets that are located far away or are not easily accessible. However, it is important to understand that using extension cords in a facility comes with certain considerations and safety precautions.

In this article, we will explore the factors to consider when using extension cords in a facility, the code and safety regulations that govern their usage, how to determine the maximum length of extension cords, safety precautions to follow, signs of wear and damage to watch out for, the importance of maintenance and inspection, and alternatives to using extension cords.

By understanding the various aspects involved in using extension cords in a facility, you will be better equipped to ensure the safety of your facility and the people working in it.

Key Takeaways:

- Prioritize Safety and Compliance

Consider power rating, cord length, and environment when using extension cords. Adhere to safety regulations, conduct regular inspections, and prioritize maintenance to ensure a safe and compliant electrical setup in your facility. - Explore Safer Alternatives

Explore alternatives such as adding more outlets, using power strips with surge protection, and implementing wireless charging technology to create a more permanent and efficient power solution in your facility.

Read more: How Long Can I Use An Extension Cord

Factors to Consider When Using Extension Cords

Before utilizing extension cords in a facility, it is important to take certain factors into consideration. These factors ensure that the extension cords are used safely and efficiently. Here are some key factors to keep in mind:

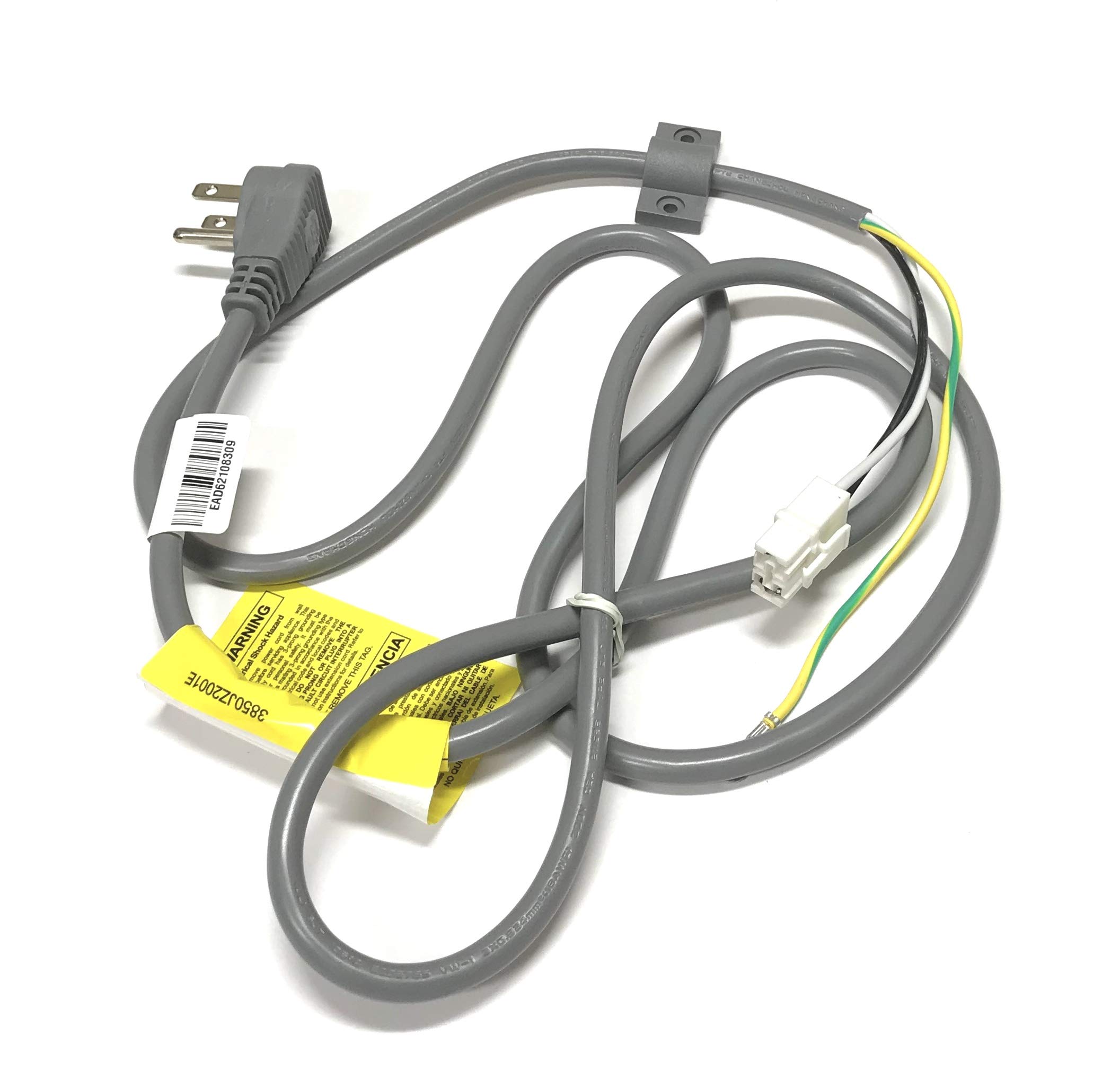

- Power Rating: Extension cords come with different power ratings, indicated by the gauge of the wire. The gauge determines the maximum current the cord can handle. It is essential to choose an extension cord that can safely carry the power load of the equipment or devices you plan to connect to it. Using an extension cord with a lower power rating than required can lead to overheating and potential fire hazards.

- Length: The length of the extension cord plays a crucial role in its safety and effectiveness. Using excessively long extension cords can result in voltage drop, causing equipment to malfunction or operate at suboptimal levels. It is important to choose the appropriate length of extension cord that minimizes voltage drop and ensures smooth operation.

- Type of Cord: Extension cords are available in various types, including indoor, outdoor, and specialty cords. It is important to select the right type of extension cord based on your specific needs. Outdoor extension cords are designed to withstand outdoor conditions and are equipped with features such as weather-resistant jackets and grounding pins. Using the wrong type of extension cord can pose safety risks.

- Environment: Consider the environment in which the extension cord will be used. If the facility has harsh conditions, such as exposure to chemicals, extreme temperatures, or excessive moisture, it is essential to choose extension cords that are specifically designed to withstand these conditions. Failure to do so can result in damage to the cord and potential safety hazards.

- Usage Duration: Take into account how long the extension cord will be in use. Continuous usage for extended periods can lead to heat buildup and potential wear and tear. If you anticipate long periods of usage, consider using a heavier-duty extension cord that can handle the sustained power load.

By considering these factors, you can ensure that the extension cords being used in your facility are suitable for the intended purpose and are capable of providing a safe and reliable power source.

Code and Safety Regulations for Extension Cords in Facilities

Using extension cords in facilities comes with specific code requirements and safety regulations. These guidelines are crucial to maintaining a safe working environment and reducing the risk of electrical hazards. Here are some key code and safety regulations to keep in mind:

- National Electrical Code (NEC): The NEC sets the standards for electrical installations and is widely adopted across the United States. It provides guidelines for the safe use of extension cords in facilities, including requirements for cord length, power rating, and acceptable uses. Familiarize yourself with the NEC requirements to ensure compliance.

- Maximum Load Capacity: Each extension cord has a maximum load capacity, which is determined by its wire gauge. It is crucial to adhere to the recommended load capacity to prevent overload and subsequent overheating. Exceeding the maximum load capacity can lead to fire hazards and damage to the cord and connected equipment.

- Proper Use: Extension cords should be used for temporary power connections only. They are not intended to replace permanent wiring or serve as a permanent power solution. Avoid using extension cords as a permanent installation as this can pose safety risks. Instead, consider hiring a licensed electrician to install additional outlets if necessary.

- Avoid Overloading: It is essential to avoid overloading extension cords by connecting too many devices or equipment to a single cord. Overloading can cause the cord to overheat and may lead to electrical fires. Distribute the load among multiple extension cords or consider using power strips with built-in overload protection.

- No Dangling Cords: Extension cords should not be left hanging or lying on the floor where they can become tripping hazards or be subjected to damage. Secure the cords properly using appropriate cord management solutions, such as cord clips or hooks, to prevent accidents and prolong the lifespan of the cords.

- Regular Inspection: Regularly inspect the extension cords for wear and damage. Look for any frayed or exposed wires, cracked insulation, or loose plugs. If any damage is detected, repair or replace the cord immediately to avoid electrical hazards.

- Training and Education: Ensure facility personnel receive proper training and education on the safe use of extension cords. This includes understanding the code requirements, recognizing potential hazards, and knowing how to safely handle and maintain extension cords.

By following these code and safety regulations, you can minimize the risk of electrical accidents and create a safe working environment for everyone in your facility.

How to Determine the Maximum Length for Extension Cords in a Facility

Determining the maximum length for extension cords in a facility is crucial to ensure proper voltage supply, prevent voltage drop, and maintain electrical safety. Here are some steps to help you determine the maximum length for extension cords:

- Check the Power Rating: Start by checking the power rating of the electrical devices or equipment you plan to connect to the extension cord. This information is typically found on the device’s label or in the user manual. It will indicate the power requirements in terms of watts or amps.

- Identify the Voltage: Determine the voltage supply of your facility. In most cases, this is 120 volts for standard household outlets or 240 volts for higher-powered equipment. The voltage supply is essential for calculating the current flow and determining the appropriate wire gauge for the extension cord.

- Calculate the Current: Use Ohm’s law (I = P / V) to calculate the current required by the connected devices. Divide the power requirement (in watts) by the voltage supply (in volts) to obtain the current flow (in amps). For example, if the device requires 1200 watts on a 120-volt supply, the current would be 10 amps.

- Consider Voltage Drop: Determine the acceptable voltage drop based on the type of equipment or device. Some devices can tolerate a slight voltage drop, while others require a consistent voltage supply. Typically, a voltage drop of 3% or less is considered acceptable. This means that the maximum voltage drop from the power source to the device should not exceed 3% of the supply voltage.

- Refer to Wire Gauge Charts: Consult wire gauge charts provided by the National Electrical Code (NEC) or reputable sources to determine the appropriate wire gauge for the required current and acceptable voltage drop. These charts provide information on the maximum length of the extension cord based on wire gauge and current rating.

- Consider Safety Margin: It is advisable to add a safety margin to the calculated maximum length to ensure optimal performance and prevent potential issues. Increasing the wire gauge or reducing the length slightly can help compensate for voltage drop and ensure a reliable power supply.

- Select the Appropriate Extension Cord: Based on the calculations and considering the safety margin, select an extension cord with the appropriate wire gauge and length to meet the requirements. It is recommended to choose a cord with a higher amp rating than required to prevent overloading and reduce the risk of overheating.

By following these steps and using the appropriate wire gauge and length, you can determine the maximum length for extension cords in your facility, ensuring a safe and efficient power supply for your electrical devices and equipment.

Safety Precautions for Using Extension Cords in a Facility

To ensure the safe use of extension cords in a facility, it is important to follow certain safety precautions. By taking these precautions, you can prevent electrical hazards and maintain a secure working environment. Here are some key safety precautions to keep in mind:

- Inspect the Cords: Before using an extension cord, carefully inspect it for any signs of wear, damage, or loose connections. Check for frayed wires, exposed conductors, cracked insulation, or bent prongs. If any damage is detected, replace the cord immediately. Do not attempt to repair damaged cords as it can compromise their safety.

- Choose the Right Cord: Select extension cords that are appropriate for the specific application. Ensure that the cord has the correct power rating, wire gauge, and length for the intended use. Using the wrong type of extension cord can lead to overloading, overheating, and potential safety hazards.

- Avoid Overloading: Do not overload extension cords by connecting too many devices or equipment to a single cord or power strip. Each extension cord has a maximum load capacity, indicated by its wire gauge. Exceeding this capacity can lead to overheating and fire hazards. Distribute the load among multiple cords or power sources, if necessary.

- Use Grounded Cords: Grounded extension cords provide an added layer of safety by grounding any potential electrical faults. Whenever possible, use extension cords with grounded plugs and outlets. Avoid using adapters or removing the grounding prong, as this increases the risk of electrical shock.

- Avoid Pinching or Crushing: Do not place extension cords in areas where they can be pinched, crushed, or run over by heavy equipment or furniture. Pinching or crushing can damage the cord and compromise its electrical integrity. Ensure that cords are routed properly, away from doorways, walkways, or areas with high foot traffic.

- Do Not Use Outdoors: Unless specifically designed for outdoor use, avoid using extension cords outdoors. Outdoor extension cords are built to withstand exposure to weather conditions and have weather-resistant jackets and grounding features. Indoor cords used outdoors can lead to electrical shock, short circuits, and other hazards.

- Avoid Moisture: Keep extension cords away from wet or damp areas to prevent the risk of electrical shock. Moisture can damage the cord and increase the conductivity of electricity, making it more hazardous. If using extension cords in areas prone to moisture, ensure that they are specifically rated for wet locations.

- Unplug Correctly: When unplugging an extension cord, always pull from the plug itself rather than yanking on the cord. Yanking the cord can cause stress on the internal connections and lead to damage. Additionally, never unplug a cord by pulling on the cord of another device that is connected to it.

- Store Properly: When not in use, store extension cords in a safe and organized manner. Avoid loosely coil the cords, as this can cause them to tangle or become damaged. Use cord reels or storage hooks to keep them neatly organized and prevent tripping hazards.

By following these safety precautions, you can ensure the safe and effective use of extension cords in your facility, minimizing the risk of electrical accidents and promoting a secure work environment.

Extension cords should only be used temporarily and should not be a permanent solution for powering devices. The maximum recommended length for an extension cord is 100 feet, but shorter is always better to reduce the risk of overheating and fire hazards.

Read more: How Long Can A 220V Extension Cord Be

Signs of Wear and Damage on Extension Cords

Regular inspection of extension cords is essential to identify any signs of wear or damage. Recognizing these signs early on can help prevent electrical hazards and ensure the safe use of extension cords in a facility. Here are some common signs of wear and damage to look out for:

- Frayed or Exposed Wires: Check the entire length of the extension cord for frayed or exposed wires. Fraying can occur when the cord is bent or twisted excessively. Exposed wires pose a significant safety risk as they increase the likelihood of electrical shock or short circuits.

- Cracked or Damaged Insulation: Inspect the insulation covering of the cord for any cracks, cuts, or tears. Damaged insulation can lead to electrical contact with conductors or wires, potentially causing electrical shocks or fires.

- Bent or Loose Prongs: Examine the prongs of the plug for any signs of bending or looseness. Bent prongs may not make proper contact with the electrical outlet, resulting in intermittent power supply or electrical arcing. Loose prongs can also cause sparks and electrical shorts.

- Heat or Burn Marks: Feel along the length of the extension cord while it is in use. If you notice any areas that feel unusually hot or find burn marks on the cord or plug, this indicates overheating. Overheating is often a sign of overloading or an internal wiring issue and needs to be addressed immediately to prevent fire hazards.

- Discoloration or Melted Sections: Discoloration or melted sections on the insulation or plug of the cord can indicate excessive heat exposure. This may result from being placed near heat sources or being in contact with hot surfaces. Discoloration and melting can weaken the cord’s integrity and lead to electrical failures.

- Loose Connections: During inspection, check for any loose connections between the plug and the cord, or at any junctions or connectors. Loose connections can lead to power interruptions, sparks, and potential electrical hazards.

- Odor of Burning: If you notice a strong smell of burning plastic or other unusual odors coming from the cord, unplug it immediately. These odors can indicate internal damage or overheating, which can lead to electrical fires. Cease using the cord and replace it as soon as possible.

- Tripping Hazards: Look for any cuts, nicks, or other physical damage to the cord’s outer jacket. A damaged outer jacket can expose the inner wires, increasing the risk of electrical shock and compromising the cord’s overall safety. Additionally, check for any knots or tangles that could create tripping hazards.

If any of these signs of wear or damage are present, it is crucial to immediately remove the extension cord from service. Replace the cord with a new one that meets the necessary specifications to ensure the safe and reliable supply of electricity in your facility.

Maintenance and Inspection of Extension Cords in a Facility

Maintaining and regularly inspecting extension cords in a facility is essential to ensure their safe and efficient operation. By implementing proper maintenance practices and conducting thorough inspections, you can identify potential issues early on and prevent electrical hazards. Here are some key steps for maintaining and inspecting extension cords:

- Establish a Maintenance Schedule: Develop a maintenance schedule for extension cords in your facility. Determine how frequently the cords should be inspected based on their usage and environmental conditions. Regular inspections help identify any signs of wear, damage, or other issues that may compromise the cords’ safety.

- Train Personnel: Provide training to facility personnel on proper maintenance and inspection procedures for extension cords. Educate them on how to identify potential hazards and what steps to take when issues are found. Encourage them to report any concerns or problems with the cords to ensure timely action.

- Visual Inspection: Conduct a visual inspection of the entire length of each extension cord. Look for signs of wear, such as frayed wires, cracked insulation, or loose connections. Pay attention to the plugs, prongs, and connectors for any signs of damage or overheating. Ensure that the outer jacket is intact and free from cuts or tears.

- Check for Proper Grounding: Verify that grounded extension cords have their grounding prongs intact and that they make proper contact with the outlet. Grounding of extension cords is crucial for reducing the risk of electrical shocks and ensuring the safe operation of equipment.

- Tension and Cord Management: Check the tension of extension cords to ensure they are properly stretched and not overly taut or loose. Improper tension can strain the cord, leading to damage or hazardous conditions. Additionally, inspect the cord management system to ensure that cords are securely fastened and organized to prevent trip hazards and entanglement.

- Test Continuity: Use a continuity tester to check the electrical continuity of the extension cord. This test ensures that the conductive pathways within the cord are intact and can carry electrical current without interruptions. Any interruptions or open circuit readings indicate a problem and the need for repair or replacement.

- Inspect Ground Fault Circuit Interrupters (GFCIs): If the extension cords are equipped with built-in GFCIs, regularly test and inspect them for proper functioning. GFCIs are crucial for quickly detecting ground faults and preventing electrical shocks. Follow the manufacturer’s instructions to test the GFCIs at recommended intervals.

- Repair or Replace Damaged Cords: If any signs of wear, damage, or other issues are identified during the inspection, take immediate action. Determine whether the cord can be repaired by a qualified professional or if it needs to be replaced. Do not attempt to repair a damaged cord yourself, as this can lead to further safety hazards.

- Maintain Documentation: Keep a record of all maintenance and inspection activities for each extension cord. Document the dates of inspections, any issues identified, repairs made, and replacement dates. This documentation helps track the history of each cord, monitor their condition over time, and ensure compliance with maintenance protocols.

By implementing a regular maintenance and inspection program for extension cords in your facility, you can identify and address potential safety concerns promptly. This proactive approach ensures the overall safety of your electrical system and minimizes the risk of electrical accidents.

Alternatives to Using Extension Cords in a Facility

While extension cords serve as a temporary solution for providing power in facilities, it is important to explore alternatives that offer a more permanent and safer electrical setup. Here are some viable alternatives to using extension cords:

- Add More Outlets: One of the simplest solutions is to hire a licensed electrician to install additional outlets in areas where power is needed frequently. This eliminates the need for extension cords altogether, providing a safer and more convenient power source.

- Power Strips with Surge Protection: Power strips with surge protection can accommodate multiple devices and provide additional outlets. They are a great alternative to extension cords when multiple devices need to be connected in close proximity. However, it is important to use power strips with built-in surge protectors to safeguard equipment from power fluctuations.

- Dedicated Circuits: For high-power equipment or machinery that requires a significant amount of electricity, installing dedicated circuits is a recommended solution. Dedicated circuits ensure a dedicated power supply to specific equipment, reducing the risk of overloading and improving efficiency.

- Wireless Power Transfer: Wireless charging technology is becoming increasingly popular, especially for charging mobile devices and other electronic gadgets. Implementing wireless charging stations in common areas and workstations can eliminate the need for multiple cords and provide a streamlined and efficient charging experience.

- Retractable Cord Reels: Retractable cord reels can be installed in strategic locations throughout the facility, making it easy to access power whenever and wherever needed. These reels enable the use of shorter, fixed-length cords, reducing the risk of tangling or tripping hazards.

- Permanent Power Distribution Units (PDUs): PDUs are electrical power distribution devices that provide multiple outlets in a compact and organized manner. They can be installed in equipment racks, server rooms, or workstations, providing a centralized and efficient power solution without the need for extension cords.

- Redesign Workspace Layout: Assess the layout of your facility and consider rearranging workstations or equipment to minimize the need for long extension cords. By optimizing the placement of devices and arranging outlets strategically, you can reduce the reliance on extension cords.

- Use Cord Covers and Cable Management Solutions: Implement cord covers and cable management solutions to organize and protect cords that are unavoidable in certain areas. These solutions help prevent cords from becoming tripping hazards and minimize the risk of damage caused by pulling or bending.

Each facility is unique, so it is important to assess the specific power requirements and layout to determine the best alternative to extension cords. By implementing these alternatives, you can improve safety, enhance efficiency, and create a well-organized and professional work environment.

Conclusion

Extension cords play a crucial role in providing convenient access to power in various facilities. However, it is important to use them safely and understand the potential risks they pose. By considering factors such as power rating, cord length, and environment, you can ensure the proper use of extension cords in your facility.

Adhering to code and safety regulations, determining the maximum length for extension cords, and following safety precautions are vital for protecting the facility and its occupants. Regular inspections and maintenance of extension cords help identify signs of wear and damage, allowing for timely repairs or replacements.

Moreover, exploring alternatives to using extension cords, such as adding more outlets, utilizing power strips with surge protection, or implementing wireless charging technology, can provide a more permanent and efficient power solution in the facility.

Ultimately, by prioritizing safety precautions, proper maintenance, and exploring alternatives, you can create a safer and more efficient electrical setup in your facility. Ensuring a secure working environment and reducing the risk of electrical hazards is essential for the well-being of both employees and the facility itself.

Remember, the effective and safe use of extension cords requires vigilance, adherence to regulations, and regular inspection. By implementing these practices, you can maintain a safe and reliable power supply, promoting productivity and peace of mind in your facility.

Frequently Asked Questions about How Long Can An Extension Cord Be Used In A Facility

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Long Can An Extension Cord Be Used In A Facility”