Articles

How To Use Flex Pipe For Plumbing

Modified: March 1, 2024

Learn how to use flex pipe for your plumbing projects with our informative articles. Discover tips, tricks, and step-by-step guides to ensure a successful installation.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to our comprehensive guide on how to use flex pipe for plumbing. If you’re planning a plumbing project or need to repair existing pipes, flex pipe can be a game-changer. In this article, we will explore what flex pipe is, its advantages, how to choose the right type, the tools and materials needed, step-by-step installation guide, tips for a proper installation, common mistakes to avoid, and some frequently asked questions.

Flex pipe, also known as flexible plumbing pipe, is a versatile alternative to traditional rigid pipe materials like copper or PVC. It is a flexible tubing made from materials such as cross-linked polyethylene (PEX), chlorinated polyvinyl chloride (CPVC), or flexible polyethylene. Flex pipe offers numerous benefits over rigid pipes, making it a popular choice for both professional plumbers and DIY enthusiasts.

One of the significant advantages of flex pipe is its flexibility, which allows for easy installation in tight spaces, around corners, and even in complicated plumbing systems. It can bend and flex to accommodate different angles and configurations, reducing the need for elbows and connectors. This feature not only makes the installation process more convenient but also minimizes the risk of leaks caused by joint fittings.

Another key advantage of using flex pipe for plumbing is its resistance to corrosion and scaling. Unlike traditional metal pipes, flex pipe is highly resistant to rust, pinhole leaks, and chemical damage. This durability ensures a long-lasting and reliable plumbing system, reducing the frequency of repairs and replacements.

Additionally, flex pipe has excellent thermal properties. It can withstand both high and low temperatures, making it suitable for both hot and cold water supply lines. This versatility allows for greater flexibility in plumbing applications, accommodating a wide range of temperature-controlled systems.

In the next sections of this article, we will cover in detail how to choose the right type of flex pipe for your plumbing needs, the essential tools and materials required for installation, and provide a step-by-step guide to help you navigate the installation process smoothly. We will also share valuable tips to ensure a proper installation and highlight common mistakes to avoid.

By the end of this article, you’ll have a comprehensive understanding of how to use flex pipe for plumbing and be well-equipped to tackle your own plumbing projects. Let’s dive in!

Key Takeaways:

- Flex pipe offers a versatile, durable, and cost-effective solution for plumbing, providing flexibility, resistance to corrosion, and suitability for various applications.

- Proper planning, careful execution, and adherence to manufacturer guidelines are essential for a successful flex pipe installation, ensuring a leak-free and reliable plumbing system.

What is Flex Pipe?

Flex pipe, also known as flexible plumbing pipe or flexible tubing, is a type of pipe that offers a flexible and versatile alternative to traditional rigid pipe materials. It is made from materials such as cross-linked polyethylene (PEX), chlorinated polyvinyl chloride (CPVC), or flexible polyethylene, which give it its unique properties.

The flexibility of flex pipe allows it to bend and curve easily, making it ideal for plumbing applications in tight spaces and around obstacles. This flexibility eliminates the need for multiple connectors and fittings, simplifying the installation process and reducing the risk of leaks caused by joint fittings.

Flex pipe is commonly used in both residential and commercial plumbing systems for a variety of applications, including water supply lines, drainage systems, hot water recirculation, and even radiant heating. It can be used for both hot and cold water, offering excellent thermal properties that make it suitable for a wide range of temperature-controlled systems.

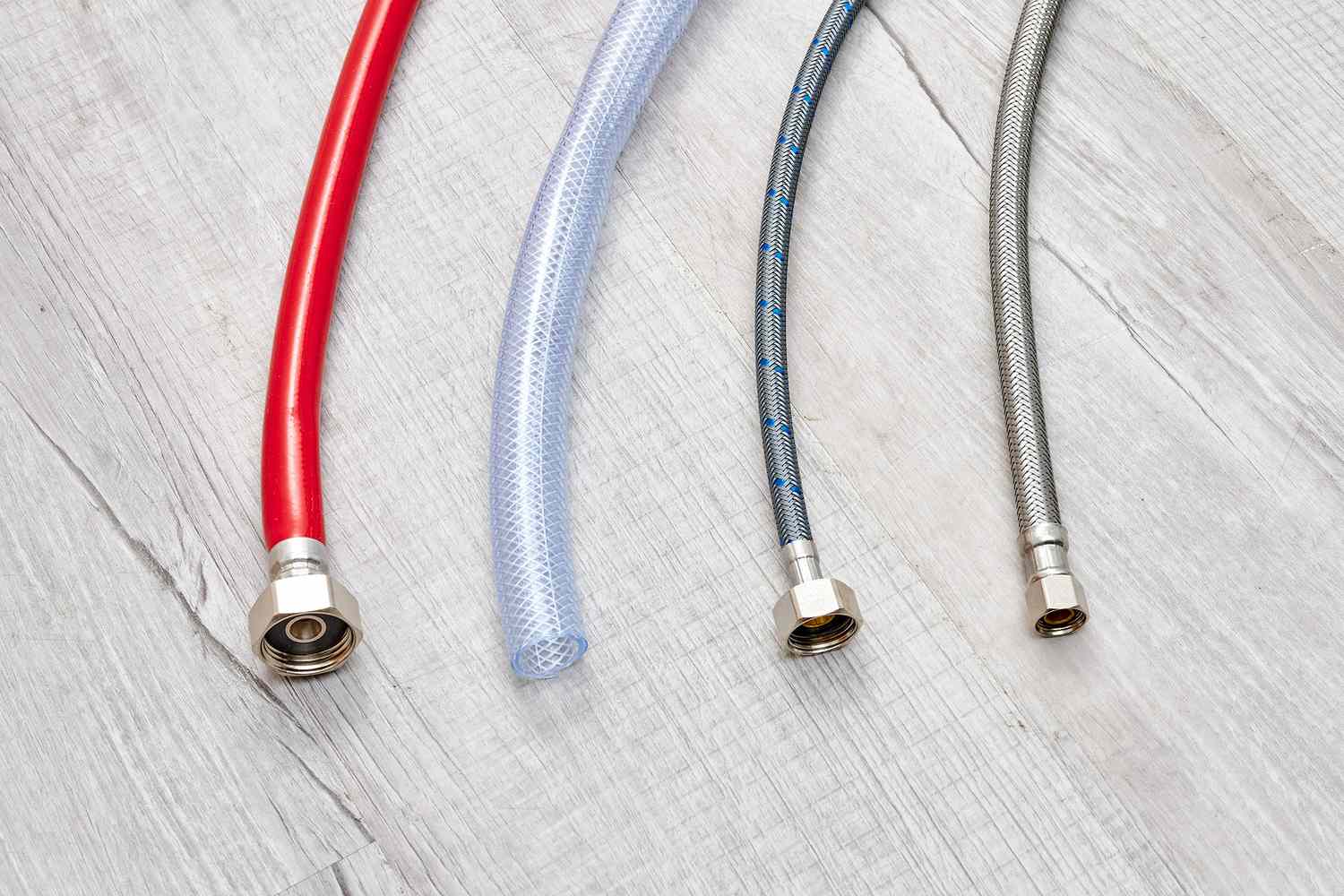

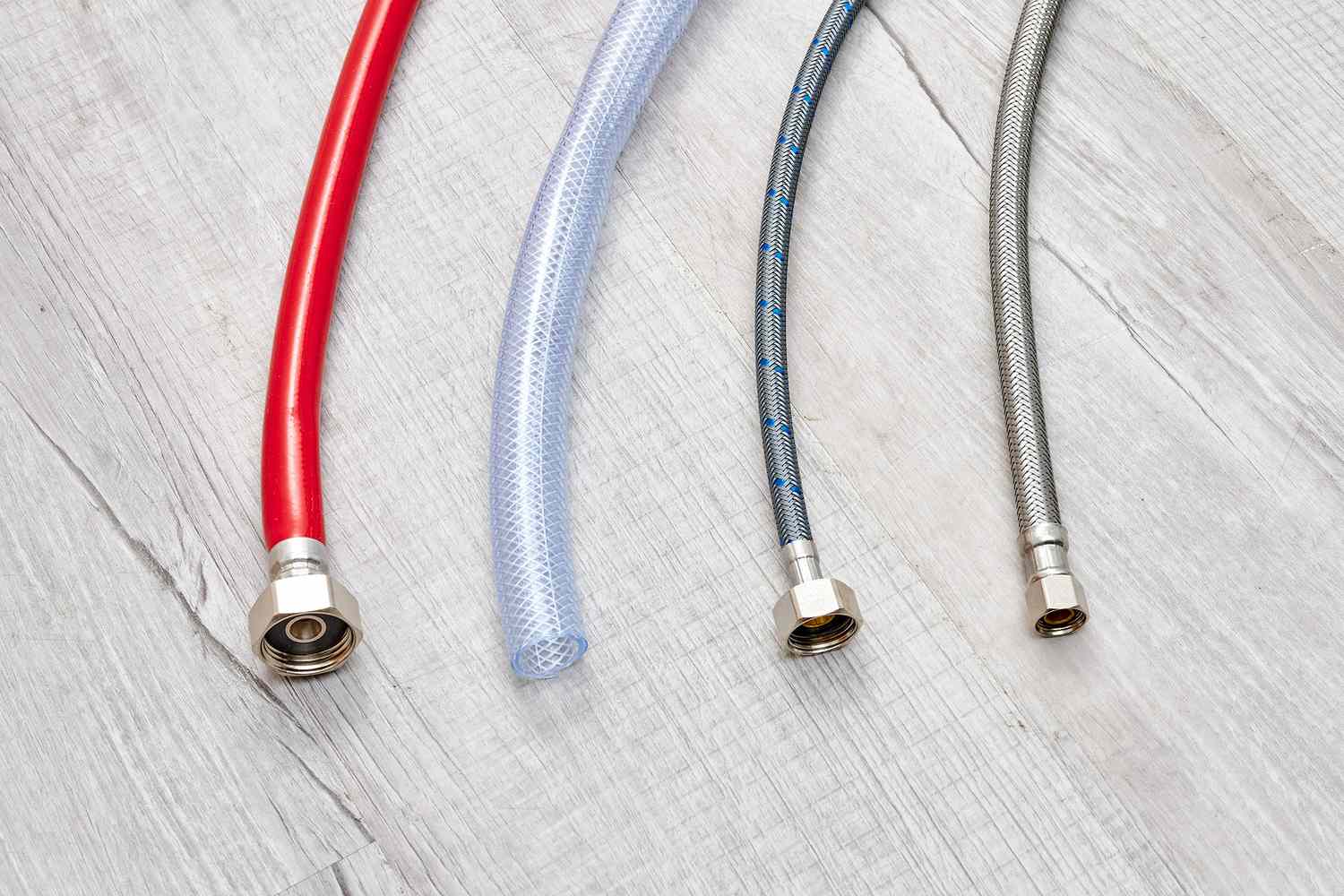

There are different types of flex pipe available, each with its own unique characteristics and intended uses. Some common types include:

- PEX (Cross-linked Polyethylene) Pipe: PEX pipe is one of the most popular types of flex pipe. It is highly flexible, resistant to freeze damage, and durable. PEX pipe is commonly used for water supply lines and radiant heating systems.

- CPVC (Chlorinated Polyvinyl Chloride) Pipe: CPVC pipe is a rigid-flexible hybrid pipe that offers excellent corrosion resistance. It is commonly used for hot water lines and carries higher temperature water compared to PEX pipe.

- Flexible Polyethylene Pipe: Flexible polyethylene pipe, also known as flex tubing, is a cost-effective option for basic plumbing applications. It is lightweight, easy to install, and often used for irrigation systems and outdoor plumbing projects.

Flex pipe is often color-coded to indicate its intended use. For example, red PEX pipe is typically used for hot water lines, while blue PEX pipe is used for cold water lines. This color coding helps streamline the installation process and ensure proper connections and labeling.

Overall, flex pipe offers significant advantages over traditional rigid pipe materials. Its flexibility, durability, resistance to corrosion, and thermal properties make it a reliable and efficient choice for plumbing projects. In the next sections, we will explore the benefits of using flex pipe in more detail, guide you on choosing the right type of flex pipe for your plumbing needs, and provide a step-by-step installation guide.

Advantages of Using Flex Pipe for Plumbing

Flex pipe offers numerous advantages over traditional rigid pipe materials, making it a preferred choice for plumbing projects. Whether you’re a professional plumber or a DIY enthusiast, here are some key benefits of using flex pipe for your plumbing needs:

- Flexibility: The primary advantage of flex pipe is its flexibility. It can easily bend and curve, allowing for easy installation in tight spaces, around corners, and even in complex plumbing systems. This flexibility eliminates the need for multiple connectors and fittings, simplifying the installation process and reducing the risk of leaks caused by joint fittings.

- Durability: Flex pipe is highly durable and resistant to corrosion, rust, pinhole leaks, and chemical damage. Unlike traditional metal pipes, flex pipe can withstand the test of time and withstand the harsh conditions of plumbing systems.

- Easy Installation: The flexibility of flex pipe makes it easy to install, even for novice DIYers. Its ability to navigate tight spaces and bend around obstructions simplifies the installation process and reduces the need for complex and time-consuming maneuvers.

- Thermal Properties: Flex pipe has excellent thermal properties, allowing it to withstand both high and low temperatures. This makes it suitable for a wide range of plumbing applications, including hot water supply lines, radiant heating systems, and temperature-controlled systems.

- Reduced Noise and Vibration: The flexibility of flex pipe helps to reduce noise and vibration in plumbing systems. This can significantly improve the overall comfort and enjoyment of your living or working space.

- Cost-Effective: Flex pipe is often more cost-effective than traditional rigid pipe materials like copper or PVC. It is generally less expensive to purchase and requires fewer additional fittings and connectors, further reducing installation costs.

- Adaptability: Flex pipe can be used in a variety of plumbing applications, including water supply lines, drainage systems, hot water recirculation, and radiant heating. Its versatility makes it a flexible solution for different types of plumbing projects.

Overall, using flex pipe for plumbing offers a range of advantages that contribute to a streamlined installation process, increased durability, and improved performance. Its flexibility, durability, ease of installation, thermal properties, and cost-effectiveness make it an excellent choice for both professionals and DIY enthusiasts.

In the next sections, we will go into further detail on how to choose the right type of flex pipe for your plumbing needs and provide a step-by-step installation guide to ensure a successful and efficient plumbing project.

Choosing the Right Type of Flex Pipe

When it comes to choosing the right type of flex pipe for your plumbing needs, there are a few factors to consider. Different types of flex pipe have varying characteristics and are designed for specific applications. Here are some key points to keep in mind when selecting the appropriate flex pipe for your project:

- Material: Flex pipe is typically made from materials such as cross-linked polyethylene (PEX), chlorinated polyvinyl chloride (CPVC), or flexible polyethylene. The material you choose will depend on the specific requirements of your plumbing system.

- Intended Use: Consider the specific application for which you need to use the flex pipe. For example, if you’re installing a hot water line, you will need a flex pipe that is suitable for high temperatures, such as CPVC pipe. If it’s a cold water line, PEX pipe may be a better choice.

- Sizing: Flex pipe comes in various sizes, typically measured in diameter. Ensure that you choose the correct size that matches the requirements of your plumbing system. Taking accurate measurements and understanding the flow rate and pressure requirements will help in selecting the right size.

- Color Coding: Some types of flex pipe, such as PEX, are color-coded to indicate their intended use. For example, red PEX pipe is typically used for hot water lines, while blue PEX pipe is used for cold water lines. Make sure to choose the right color-coded pipe for your specific application.

- Certifications: Look for flex pipe that has appropriate certifications and approvals from relevant authorities. This ensures that the pipe meets safety and quality standards set by industry organizations.

- Compatibility: If you’re connecting the flex pipe to existing plumbing systems, ensure that the chosen flex pipe is compatible with the connectors and fittings you plan to use. Check if any adapters or transition fittings are required for a seamless connection.

- Budget: Consider your budget when choosing flex pipe for your plumbing project. While cost shouldn’t be the sole determining factor, it’s essential to select a pipe that meets your requirements without unnecessary expenditure.

It’s recommended to consult with a plumbing professional or a knowledgeable salesperson at a reputable plumbing supply store to help you select the right type of flex pipe for your specific project. They can provide guidance based on your requirements, local building codes, and industry standards.

By carefully considering the material, intended use, sizing, color coding, certifications, compatibility, and budget, you can choose the right type of flex pipe that ensures a successful and efficient plumbing installation.

Next, we’ll discuss the tools and materials you’ll need to complete your flex pipe plumbing project.

Tools and Materials Needed

Before you begin your flex pipe plumbing project, it’s important to gather all the necessary tools and materials. Having the right equipment on hand will make the installation process smoother and more efficient. Here’s a list of the tools and materials you’ll need:

Read more: How To Clean Plumbing Pipes

Tools:

- Pipe Cutter: A pipe cutter is essential for cutting the flex pipe to the desired length. It ensures clean and precise cuts.

- Adjustable Wrench: An adjustable wrench is used to tighten nuts and fittings securely. It allows for easy adjustment and tightening in tight spaces.

- Deburring Tool: A deburring tool helps remove any rough edges or burrs from the cut ends of the pipe. This ensures a clean and smooth connection.

- Crimping Tool: If you’re using PEX pipe, a crimping tool is necessary to create watertight connections. It compresses copper rings (crimp rings) around the pipe and fittings to form a secure connection.

- Pipe Bender: If you need to make bends in the flex pipe, a pipe bender is necessary. It helps shape the pipe without causing any kinks or damage.

- Tape Measure: A tape measure is used to accurately measure the lengths of pipe needed for your plumbing project.

- Marker or Pencil: Use a marker or pencil to mark the cutting points on the flex pipe.

- Safety Equipment: Remember to wear appropriate safety equipment, such as gloves and safety glasses, to protect yourself during the installation process.

Materials:

- Flex Pipe: Choose the appropriate type of flex pipe for your specific plumbing project. This may include PEX, CPVC, or flexible polyethylene pipe, depending on your needs.

- Fittings: Select the necessary fittings based on your plumbing system requirements. This may include connectors, elbows, tees, valves, and other fittings specific to your installation.

- Adapters: If you’re connecting the flex pipe to existing plumbing systems, you may need adapters or transition fittings to ensure a proper connection.

- Crimp Rings or Clamps: If you’re using PEX pipe, you will need crimp rings or clamps to secure the fittings to the pipe.

- Threaded Fittings: If your plumbing system requires threaded connections, make sure to have the appropriate threaded fittings and pipe tape for sealing.

- Pipe Supports: Depending on the length and configuration of your flex pipe, you may need pipe supports or hangers to ensure proper support and stability.

- Teflon Tape or Pipe Sealant: If you’re using threaded connections, Teflon tape or pipe sealant is necessary to create a watertight seal.

- Plumber’s Putty or Silicone Caulk: Plumber’s putty or silicone caulk may be needed for sealing around fixtures or drains.

Make sure you have all the necessary tools and materials before you start your flex pipe plumbing project. This will save you time and prevent interruptions during the installation process. If you’re unsure about any tool or material, consult with a plumbing professional or a trusted supplier for guidance.

In the next section, we will provide a step-by-step guide on how to use flex pipe for your plumbing project.

Step-by-Step Guide to Using Flex Pipe for Plumbing

Using flex pipe for plumbing projects is a straightforward process that can be accomplished with the right tools and materials. Follow this step-by-step guide to ensure a successful installation:

Step 1: Prepare the Work Area:

Clear the work area and ensure that you have enough space to maneuver comfortably. Turn off the water supply to the area where you’ll be working to prevent any accidents or water damage.

Read more: How To Insulate Plumbing Pipes

Step 2: Measure and Cut the Flex Pipe:

Measure and mark the length of the flex pipe needed for your plumbing installation. Use a pipe cutter to make clean and precise cuts. Ensure that the ends are straight and free from any burrs or rough edges by using a deburring tool.

Step 3: Install Fittings and Connectors:

Depending on the specific plumbing system and the type of flex pipe you’re using, install the necessary fittings and connectors. If you’re using PEX pipe, ensure that the crimp rings or clamps are properly positioned on the pipe and secure them using a crimping tool.

Step 4: Bend and Position the Flex Pipe:

If your plumbing system requires bends or curves, use a pipe bender to shape the flex pipe accordingly. Carefully position the pipe in the desired configuration, ensuring that it aligns with your plumbing plan.

Step 5: Connect the Flex Pipe to Existing Plumbing:

If you’re connecting the flex pipe to existing plumbing lines, use the appropriate adapters or transition fittings to ensure a proper connection. Tighten the fittings securely using an adjustable wrench.

Read more: How To Replace Plumbing Pipes

Step 6: Support the Flex Pipe:

If your flex pipe is long or requires additional support, use pipe supports or hangers to ensure proper support and stability. This will help prevent sagging or excessive stress on the pipe.

Step 7: Test the Installation:

Before completing the project, turn on the water supply and test the installation. Check for any leaks or abnormalities in the flow of water. If you notice any issues, tighten the fittings or connections as necessary.

Step 8: Finish and Clean Up:

Once you’re satisfied with the installation, clean up the work area and ensure everything is properly secured. Turn the water supply off and proceed to the final steps of your plumbing project, such as sealing around fixtures or drains using plumber’s putty or silicone caulk.

Remember to follow any additional steps or guidelines specific to your flex pipe type and the requirements of your plumbing system. If you’re unsure about any step, consult with a plumbing professional or refer to the manufacturer’s instructions.

By following this step-by-step guide, you’ll be able to successfully use flex pipe for your plumbing project. In the next section, we’ll provide some valuable tips to ensure a proper installation.

Tips for Ensuring a Proper Installation

To ensure a proper and successful installation when using flex pipe for plumbing, consider the following tips:

- Plan and Prepare: Before starting the installation, plan out the project and gather all the necessary tools and materials. Familiarize yourself with local building codes and manufacturer guidelines to ensure compliance.

- Proper Measurements: Take accurate measurements of the flex pipe needed for your plumbing system. Double-check your measurements to ensure you have the correct length and size of pipe before making any cuts.

- Clean Cuts: Use a pipe cutter to make clean and straight cuts on the flex pipe. Smooth out any rough edges using a deburring tool to ensure a proper fit and prevent leaks.

- Secure Fittings: Properly secure fittings and connectors to the flex pipe, ensuring a watertight seal. Follow manufacturer instructions for using crimp rings or clamps if using PEX pipe.

- Avoid Over-Tightening: While it’s important to tighten fittings securely, avoid over-tightening, as it can damage the pipe or fittings. Use an adjustable wrench and apply firm but controlled force when tightening.

- Support the Pipe: Properly support the flex pipe using pipe supports or hangers as needed. This helps prevent sagging and ensures the pipe remains in position during use.

- Test for Leaks: After completing the installation, test the plumbing system for any leaks. Turn on the water supply and closely inspect the connections. If you detect any leaks, address them immediately by tightening the fittings or making any necessary adjustments.

- Follow Manufacturer Guidelines: Always refer to the manufacturer’s instructions for the specific type of flex pipe you’re using. These guidelines provide detailed information on installation methods, tools, and materials specific to the flex pipe in question.

- Consult a Professional: If you’re uncertain about any aspect of the installation process or need professional advice, don’t hesitate to consult with a licensed plumber or plumbing professional. They can provide guidance and ensure a proper and safe installation.

Following these tips will help ensure a proper installation and promote the longevity and functionality of your plumbing system. Remember, proper planning, careful execution, and attention to detail are key to a successful flex pipe installation.

In the next section, we’ll highlight some common mistakes to avoid during the flex pipe plumbing process.

Read more: How To Hide Plumbing Pipes

Common Mistakes to Avoid

When using flex pipe for plumbing projects, it’s important to be aware of common mistakes that can occur during the installation process. By avoiding these errors, you can ensure a smooth and successful plumbing project. Here are some common mistakes to watch out for:

- Improper Cutting: One of the most common mistakes is making improper cuts on the flex pipe. Ensure that you use a pipe cutter and make clean, straight cuts. Rough edges or uneven cuts can lead to leaks or difficulties when connecting fittings.

- Failure to Secure Fittings: Inadequately securing fittings and connectors can lead to leaks and compromised connections. Make sure to properly tighten fittings with an adjustable wrench or using a crimping tool for PEX pipe. Avoid under-tightening or over-tightening, as both can damage the pipe or fittings.

- Incorrect Pipe Sizing: Using the wrong pipe size for your plumbing system can result in poor water flow, increased pressure drop, and potential leaks. Ensure that you accurately measure and select the appropriate pipe size that matches your system requirements.

- Inadequate Support: Failing to properly support the flex pipe can lead to sagging or excessive stress, which may cause leaks or damage over time. Use appropriate pipe supports or hangers, especially for longer runs of pipe or areas with heavy loads.

- Failure to Test for Leaks: Neglecting to test the plumbing system for leaks after installation can result in undetected issues and potential water damage. Always thoroughly check for leaks by turning on the water supply and closely inspecting connections before completing the project.

- Ignoring Manufacturer Guidelines: Each type of flex pipe has its specific installation requirements outlined by the manufacturer. Not following these guidelines can result in improper installations, void warranty, and potential plumbing issues down the line. Always refer to the manufacturer’s instructions for the specific type of flex pipe you’re using.

- Skipping Professional Consultation: If you’re unsure about any aspect of the flex pipe installation, it’s best to consult with a licensed plumber or plumbing professional. They have the expertise to properly assess your project, offer guidance, and ensure a safe and efficient installation.

By being aware of these common mistakes and taking the necessary precautions, you can avoid potential pitfalls and ensure a successful flex pipe plumbing project.

In the next section, we’ll address some frequently asked questions (FAQs) about using flex pipe for plumbing.

Frequently Asked Questions (FAQs)

Here are some frequently asked questions about using flex pipe for plumbing:

1. Is flex pipe suitable for both hot and cold water lines?

Yes, flex pipe is designed to be used for both hot and cold water lines. Different types of flex pipe, such as PEX and CPVC, are specifically designed to handle a wide range of temperatures and are suitable for various plumbing applications.

2. Can I use flex pipe for outdoor plumbing projects?

Yes, flex pipe can be used for outdoor plumbing projects. Flexible polyethylene pipe, in particular, is a popular choice for irrigation systems and outdoor plumbing applications due to its durability and resistance to weather conditions.

Read more: Which Plumbing Pipe Is The Best

3. Can I connect flex pipe to existing plumbing systems?

Yes, you can connect flex pipe to existing plumbing systems. Adapters or transition fittings may be necessary to ensure a proper connection between the flex pipe and the existing pipes. Consult a professional or refer to the manufacturer’s guidelines for specific instructions on connecting flex pipe to different plumbing systems.

4. How do I know which size of flex pipe to use?

The size of flex pipe you need to use will depend on the flow rate and pressure requirements of your plumbing system. It’s important to accurately measure the size needed for your specific application. Consult a professional or refer to plumbing code requirements to ensure the correct sizing for your project.

5. Can flex pipe be used for underground plumbing?

Some types of flex pipe, such as PEX pipe, are suitable for underground plumbing installations. However, it’s important to consult local building codes and regulations to ensure compliance and proper installation methods when using flex pipe for underground plumbing.

6. Is it necessary to use special tools for installing flex pipe?

While there are specific tools designed for working with flex pipe, such as pipe cutters, crimping tools (for PEX pipe), and deburring tools, they are not always required. However, using the appropriate tools will make the installation process easier and help achieve proper fittings and connections.

Read more: What Is A Drain Pipe In Plumbing

7. Can I use flex pipe for gas lines?

No, flex pipe is not suitable for gas lines. Gas lines require specially designed piping systems that are approved for use with natural gas or propane. Always consult a professional and follow specific codes and regulations when it comes to gas line installations.

8. Is flex pipe more prone to leaks compared to rigid pipes?

When installed correctly, flex pipe can be just as reliable and leak-resistant as rigid pipes. Proper fittings, secure connections, and regular inspections for leaks are essential regardless of the type of pipe used. Following manufacturer guidelines and industry best practices will help ensure a leak-free plumbing system.

If you have any other specific questions or concerns about using flex pipe for your plumbing project, it’s recommended to consult a licensed plumber or plumbing professional for expert advice.

Now, let’s conclude our guide on using flex pipe for plumbing.

Conclusion

Flex pipe offers a flexible, durable, and efficient solution for plumbing projects. Its flexibility, resistance to corrosion, and thermal properties make it an excellent choice for various applications, including water supply lines, drainage systems, and hot water recirculation. By following the steps and tips outlined in this guide, you can ensure a proper and successful flex pipe installation.

When using flex pipe for plumbing, it’s essential to choose the right type of flex pipe that meets your specific needs. Consider factors such as material, intended use, sizing, and compatibility with existing plumbing systems. By doing so, you can optimize the performance and longevity of your plumbing system.

Remember to gather all the necessary tools and materials before starting your project. Having the right equipment will make the installation process smoother and more efficient. Properly measuring, cutting, securing fittings, supporting the pipe, and testing for leaks are crucial steps in ensuring a successful installation. By avoiding common mistakes and following manufacturer guidelines, you can prevent issues and maintain a leak-free and reliable plumbing system.

If you have any specific concerns or questions about using flex pipe for your plumbing project, it’s always a good idea to consult a licensed plumber or plumbing professional. They have the expertise to provide valuable guidance and ensure a safe and effective installation.

We hope this comprehensive guide has provided you with the information you need to confidently use flex pipe for your plumbing projects. By taking advantage of its flexibility and advantages, you can create a reliable and efficient plumbing system that meets your needs for years to come.

Frequently Asked Questions about How To Use Flex Pipe For Plumbing

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Use Flex Pipe For Plumbing”