Articles

What Are The 6 Parts Of An Electric Motor

Modified: August 27, 2024

Discover the 6 essential parts of an electric motor in this informative article. Learn how each component works together to power various machines and devices.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

An electric motor is a crucial component in many different devices and industries, from household appliances to industrial machinery. It is an electromechanical device that converts electrical energy into mechanical energy, making it an indispensable part of our modern world.

Understanding the various components of an electric motor is essential for anyone interested in how it works and its applications. In this article, we will explore the six main parts that make up an electric motor and discuss their functions and importance in the overall operation of the motor.

Whether you are a student studying electrical engineering, a DIY enthusiast looking to understand your home appliances better, or simply curious about the inner workings of electric motors, this article will provide you with valuable insights into the key components that drive their functionality.

So, let’s dive in and discover the fascinating world of electric motors!

Key Takeaways:

- The stator, rotor, and armature are the essential components of an electric motor, each playing a crucial role in converting electrical energy into mechanical energy and driving the motor’s functionality.

- Bearings and the commutator are vital for minimizing friction, converting AC to DC, and ensuring smooth rotation, contributing to the overall efficiency and longevity of electric motors.

Read also: 10 Amazing 6Hp Electric Motor for 2025

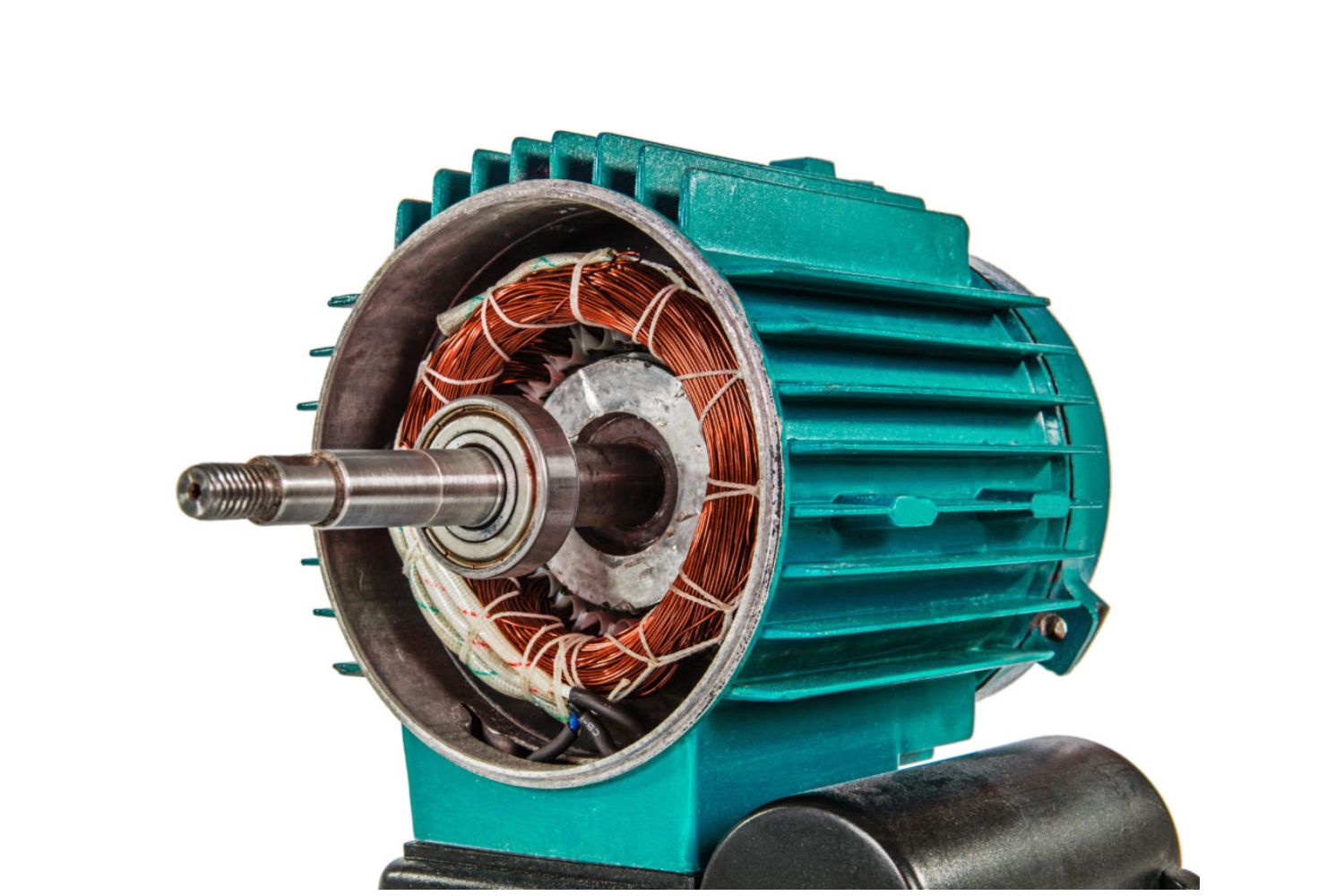

Stator

The stator is one of the primary components of an electric motor and plays a crucial role in its operation. It is a stationary part that surrounds the rotor and creates a magnetic field necessary for the motor’s function.

The stator is typically made up of a set of stacked laminated steel cores, which are insulated from each other. These cores are wound with insulated copper wires, forming multiple coils, or windings. The windings are connected in such a way that they produce a rotating magnetic field when electric current flows through them.

The number and arrangement of the windings on the stator determine the motor’s performance characteristics, such as speed, torque, and power output. Different configurations of windings can be used to achieve specific motor designs suited for various applications.

When an electrical current is applied to the stator windings, a magnetic field is generated. The polarity of this field alternates as the electric current changes direction, resulting in a rotating magnetic field. This rotating field interacts with the magnetic field produced by the rotor, causing the rotor to turn.

In some types of electric motors, such as three-phase induction motors, the stator windings are designed to create a magnetic field that rotates synchronously with the rotor. This synchronization allows efficient power transfer and smooth motor operation.

Overall, the stator acts as the primary source of the magnetic field in an electric motor and is responsible for initiating and maintaining the rotational motion.

Rotor

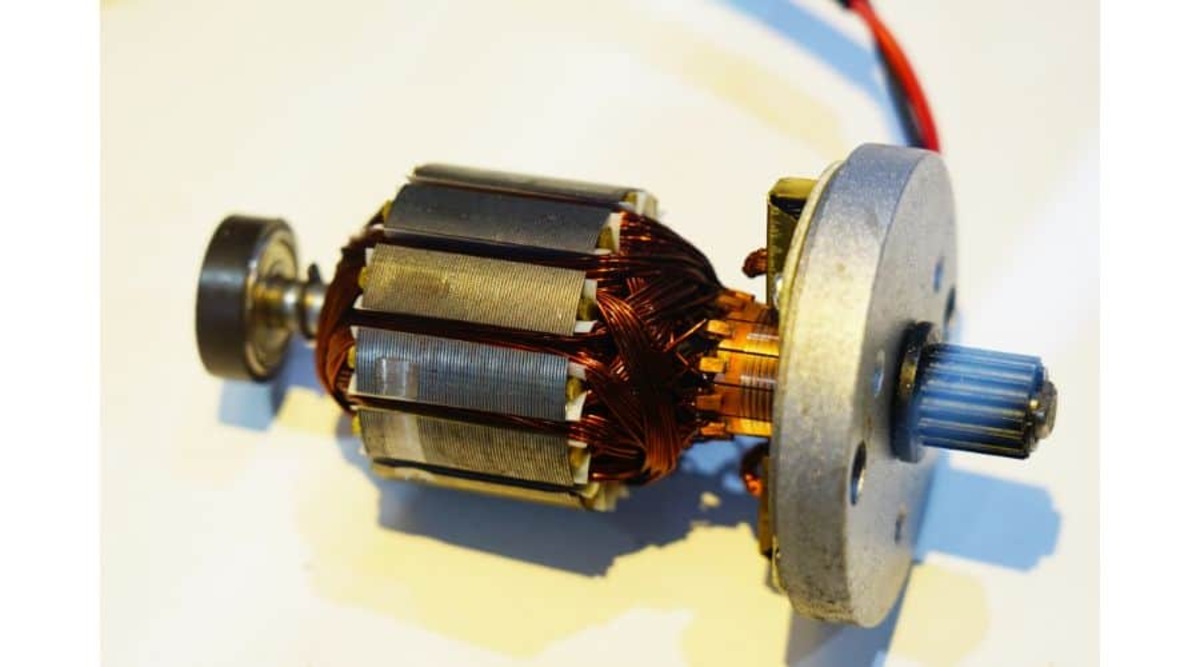

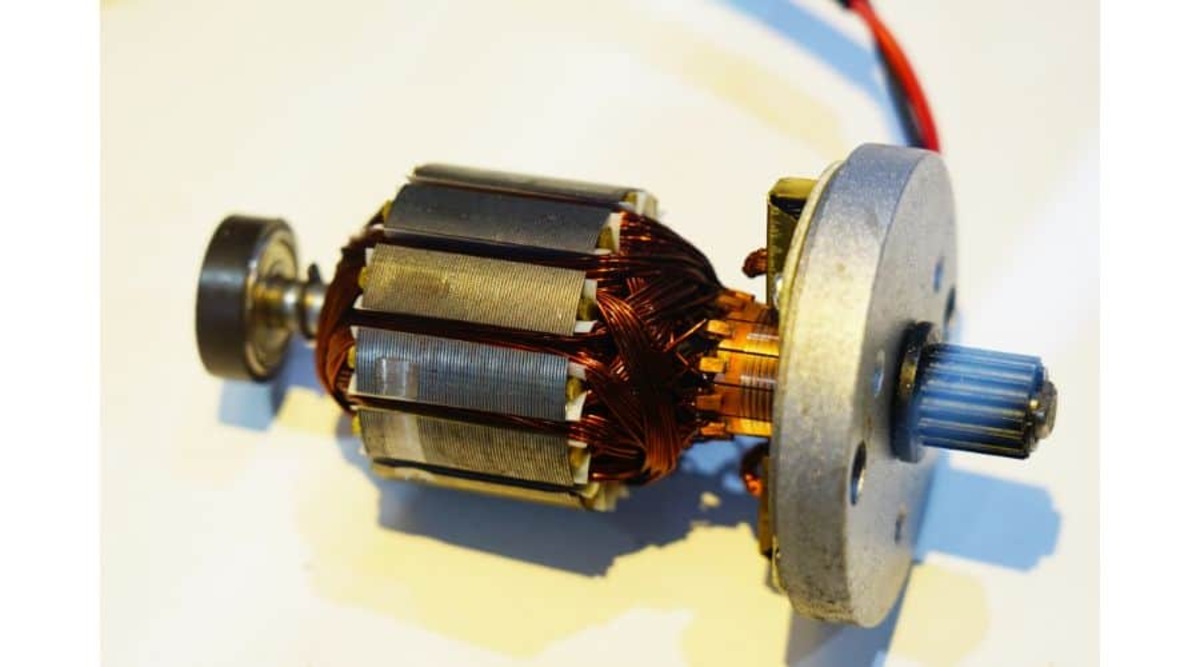

The rotor is another essential component of an electric motor, working in conjunction with the stator to convert electrical energy into mechanical energy. Unlike the stator, the rotor is a moving part that rotates within the magnetic field created by the stator.

The rotor is typically made up of a cylindrical core made of steel laminations, which are either solid or slotted depending on the motor design. The laminations help reduce energy losses due to eddy currents and improve the motor’s efficiency.

The core of the rotor is often fitted with conductive bars or coils, which are connected to form a closed loop. These conductive elements create a magnetic field when an electric current flows through them, which interacts with the magnetic field of the stator.

There are various types of rotors used in electric motors, with the most common being the squirrel cage rotor. This type of rotor consists of conducting bars that resemble a squirrel cage, hence the name. When electric current is applied to the rotor, the interaction with the stator’s rotating magnetic field induces a torque, causing the rotor to spin.

In other types of motors, such as synchronous motors, the rotor may have a different design, such as permanent magnets or field windings. These designs offer specific advantages in terms of efficiency, torque, or speed control.

It is important to note that the rotor’s design and construction heavily influence the motor’s performance, including characteristics such as starting torque, speed, and efficiency. Motor manufacturers carefully select or design rotors to meet specific application requirements and optimize overall motor performance.

Overall, the rotor is a critical component that enables the conversion of electrical energy into mechanical energy, allowing the motor to perform its intended function.

When assembling an electric motor, ensure that you have the six essential parts: stator, rotor, bearings, air gap, windings, and shaft. Each part plays a crucial role in the motor’s operation.

Bearings

Bearings are essential components in an electric motor that enable the rotation of the rotor and minimize friction. They support the moving parts of the motor, allowing them to rotate smoothly and efficiently.

There are typically two main types of bearings used in electric motors: ball bearings and sleeve bearings. Each type has its advantages and is chosen based on factors such as motor size, speed, load, and operating conditions.

Ball bearings consist of a number of small metal balls housed within a raceway. These balls reduce friction and allow for smooth rolling motion between the rotating and stationary parts of the motor. They are known for their durability, high efficiency, and low maintenance requirements.

Sleeve bearings, on the other hand, use a cylindrical sleeve or bushing to support the rotor shaft. The sleeve is usually made of a low-friction material, such as bronze or oil-impregnated brass, which reduces wear and friction. Sleeve bearings are commonly used in smaller motors or applications with lower speeds and light loads.

In addition to ball and sleeve bearings, some motors may employ specialized bearings, such as thrust bearings, to handle axial forces or radial thrust loads. These bearings are designed to withstand the specific forces exerted on the rotor shaft during operation.

Proper lubrication is crucial for the smooth operation and longevity of bearings. Lubricating oils or greases help to reduce friction, dissipate heat, and protect against wear and corrosion. Regular maintenance and lubrication of bearings are necessary to ensure optimal motor performance and prevent premature failure.

Overall, bearings play a vital role in minimizing friction and ensuring the smooth and reliable rotation of the motor’s moving parts. They contribute to the overall efficiency, longevity, and performance of electric motors.

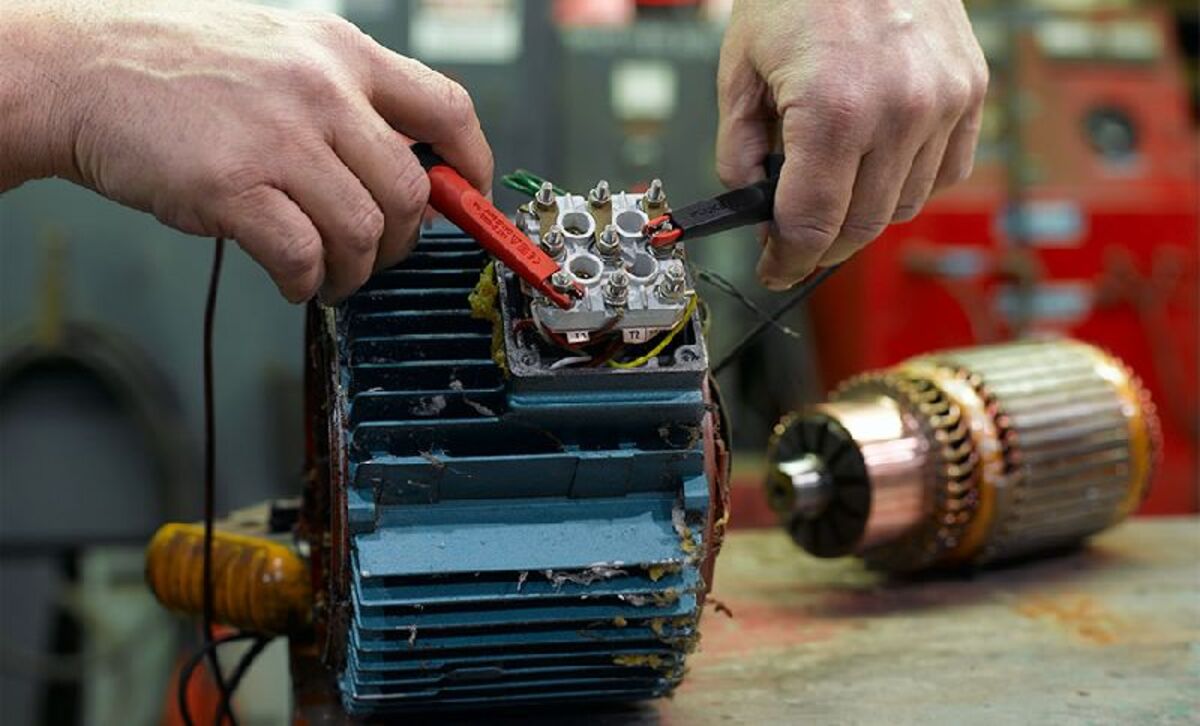

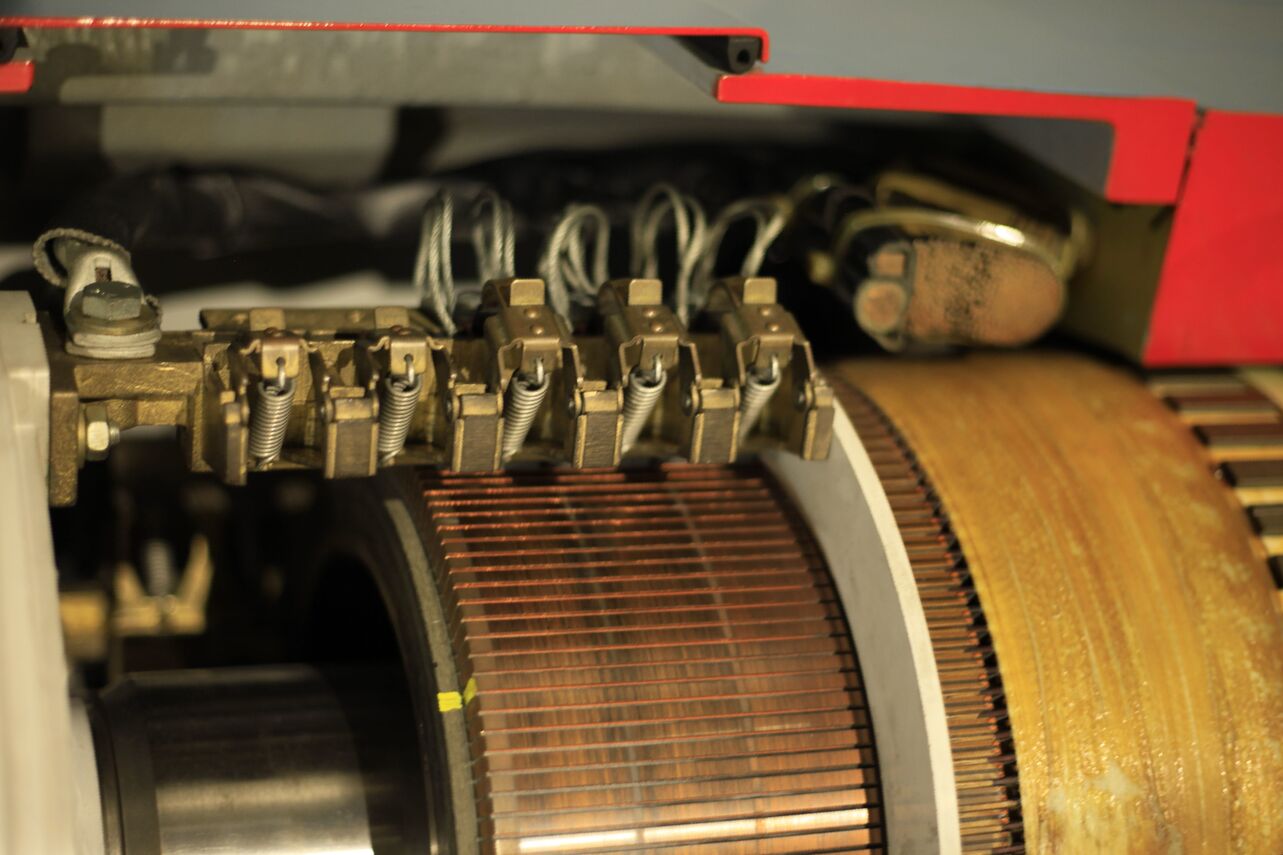

Commutator

The commutator is a critical component found in certain types of electric motors, such as DC (direct current) motors. It is responsible for the conversion of alternating current (AC) to direct current (DC) within the motor.

The commutator is typically a segmented cylindrical structure made up of stacked metal segments, usually copper, insulated from each other. These segments are attached to the rotor and make electrical contact with stationary brushes.

As the rotor spins, the commutator and brushes work together to change the direction of the electric current flowing through the motor’s coils. This changing current direction in the coils, combined with the magnetic field generated by the stator, creates the rotational motion of the rotor.

Each segment of the commutator is connected to a different winding of the rotor. As the rotor rotates, the brushes maintain contact with the commutator segments, ensuring a continuous flow of electric current to the appropriate coils.

The design and construction of the commutator are crucial for maintaining smooth operation and reducing wear. The segments and brushes should have sufficient conductivity to minimize resistance and ensure efficient power transfer. Additionally, the commutator must be properly balanced to avoid vibration and uneven brush wear.

In modern electric motor designs, especially for larger motors and AC induction motors, the commutator is not present. These motors use electronic control systems to regulate the current flow, eliminating the need for a physical commutator.

Overall, the commutator is a vital component for certain types of electric motors, facilitating the conversion of AC to DC and enabling the generation of rotational motion.

Read more: What Is An Electric Motor Capacitor?

Armature

The armature is a key component of electric motors, particularly in DC motors. It is a rotating part of the motor that interacts with the magnetic field produced by the stator to generate the mechanical output.

The armature is typically constructed with a core made of laminated steel sheets, which reduces energy losses due to eddy currents. The core is designed to provide a path for the magnetic flux and support the winding conductors.

Coils of insulated wire are wound around the armature core, forming multiple windings or poles. These windings are connected in a specific configuration to generate the desired magnetic field and produce the necessary torque to drive the motor.

When electric current flows through the armature windings, it creates a magnetic field that interacts with the magnetic field produced by the stator. This interaction causes the armature to rotate, converting electrical energy into mechanical energy.

The armature winding configuration can vary depending on the motor design and desired performance. For example, in a DC motor, the armature windings may be connected to a commutator, which allows for the reversal of current direction and ensures smooth rotation.

In addition to serving as the rotating element of the motor, the armature also plays a role in generating the motor’s torque and controlling its speed. The number of armature windings, their configuration, and the strength of the magnetic field all contribute to the motor’s performance characteristics.

For higher power motors, the armature may also incorporate cooling mechanisms, such as cooling ducts or fans, to dissipate heat generated during operation. Proper heat dissipation is crucial for maintaining optimal motor performance and preventing damage.

Overall, the armature is a crucial component that converts electrical energy into mechanical energy, driving the rotation and powering the motor’s intended application.

Frequently Asked Questions about What Are The 6 Parts Of An Electric Motor

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Are The 6 Parts Of An Electric Motor”