Articles

How To Oil An Electric Motor

Modified: December 7, 2023

Learn how to properly oil an electric motor with these informative articles. Discover the steps and tips for smooth motor operation and maintenance.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Electric motors are essential components of various machines and appliances, converting electrical energy into mechanical energy. To ensure their optimal performance and longevity, it is important to properly maintain and lubricate them. One of the most crucial maintenance tasks is oiling the electric motor.

In this article, we will delve into the process of oiling an electric motor, discussing the importance of this maintenance task, the types of oil to use, and providing a step-by-step guide for the oiling process. We will also highlight common mistakes to avoid and provide safety precautions to follow.

Whether you are a DIY enthusiast or a professional, understanding how to oil an electric motor can help you extend its lifespan, improve efficiency, and prevent potential breakdowns. So, let’s explore this important process and ensure your electric motors continue to run smoothly.

Key Takeaways:

- Regularly oiling an electric motor is crucial for optimal performance, longevity, and efficiency. It reduces friction, dissipates heat, and prevents corrosion, extending the motor’s lifespan and preventing breakdowns.

- Choosing the right oil, following safety precautions, and avoiding common mistakes are essential for effective motor oiling. Proper maintenance ensures smooth operation and prevents costly repairs or replacements.

Read also: 12 Amazing Electric Motor Oil for 2024

Understanding Electric Motors

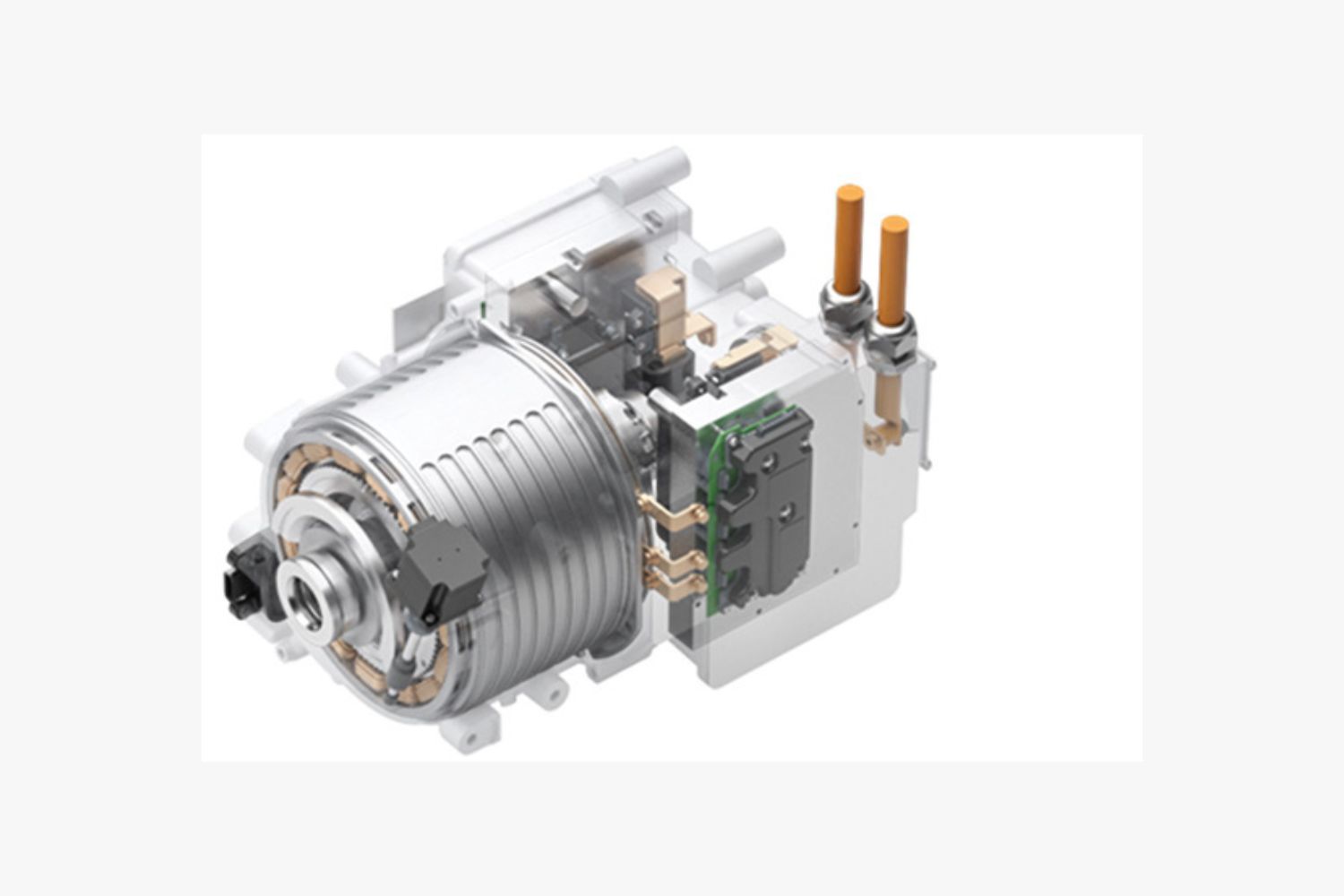

Before we dive into the process of oiling an electric motor, it’s important to have a basic understanding of how these motors function. Electric motors are devices that use an electrical energy source to generate mechanical energy, such as rotating a shaft or spinning a fan.

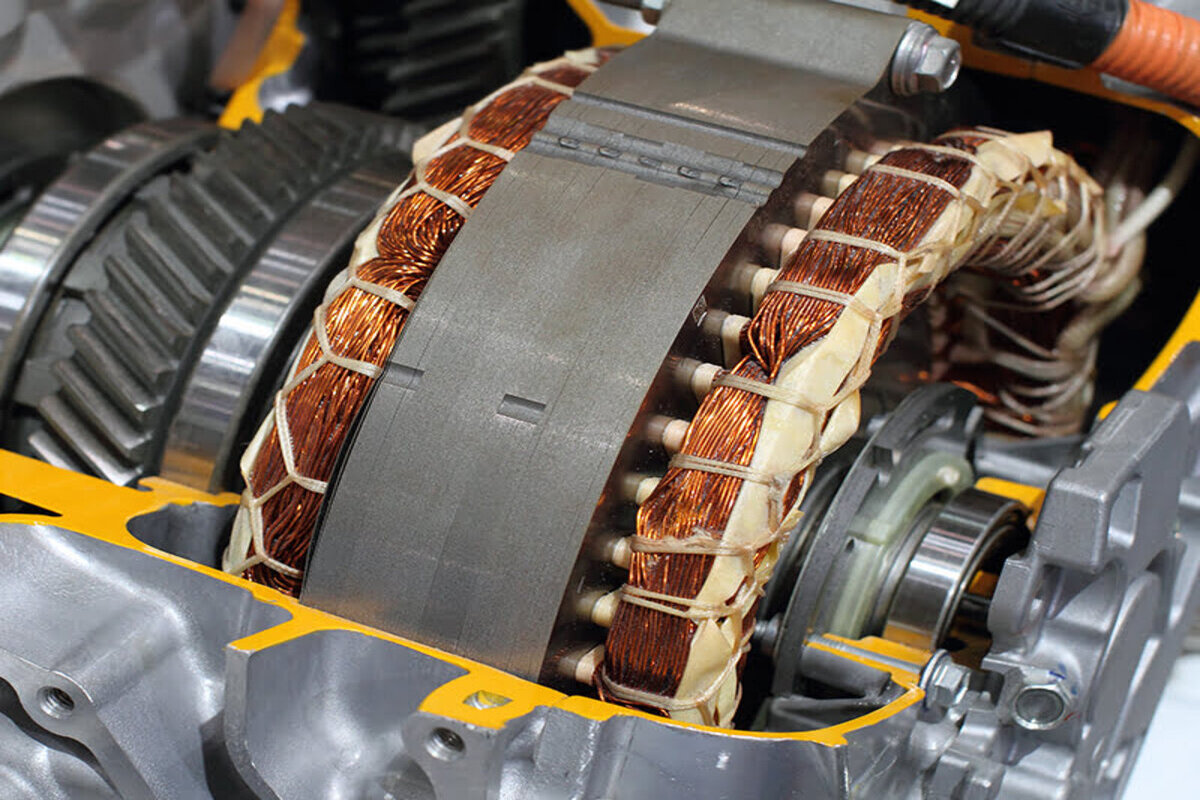

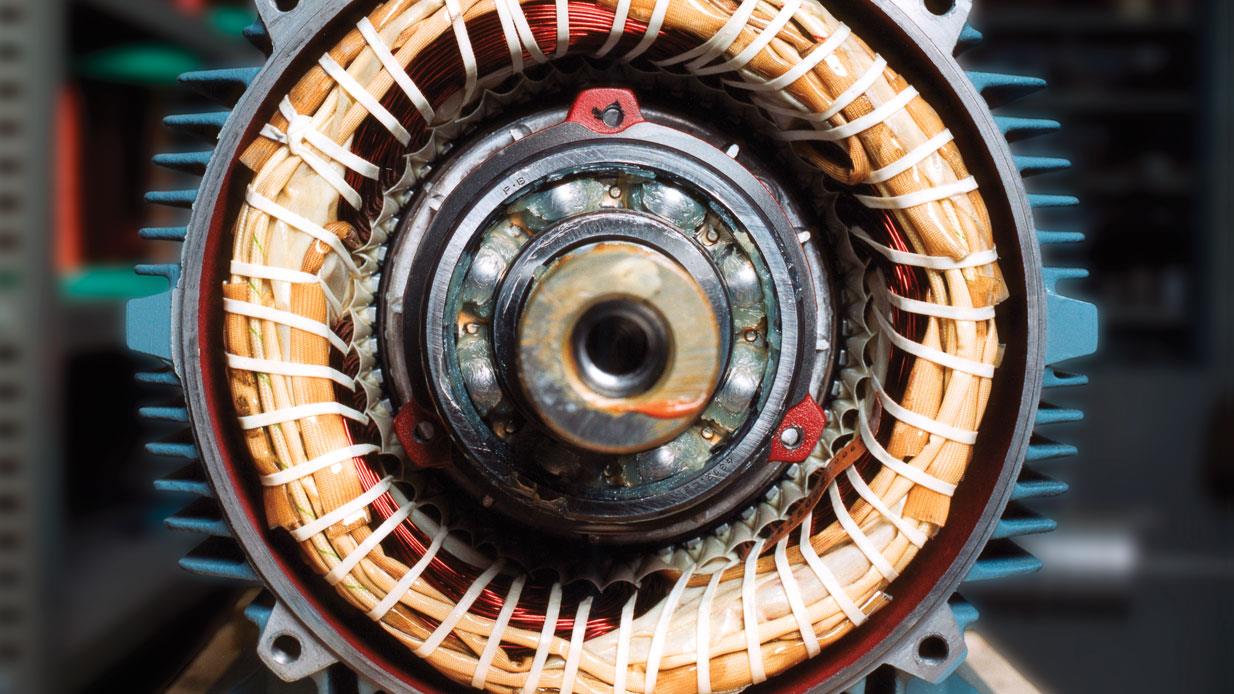

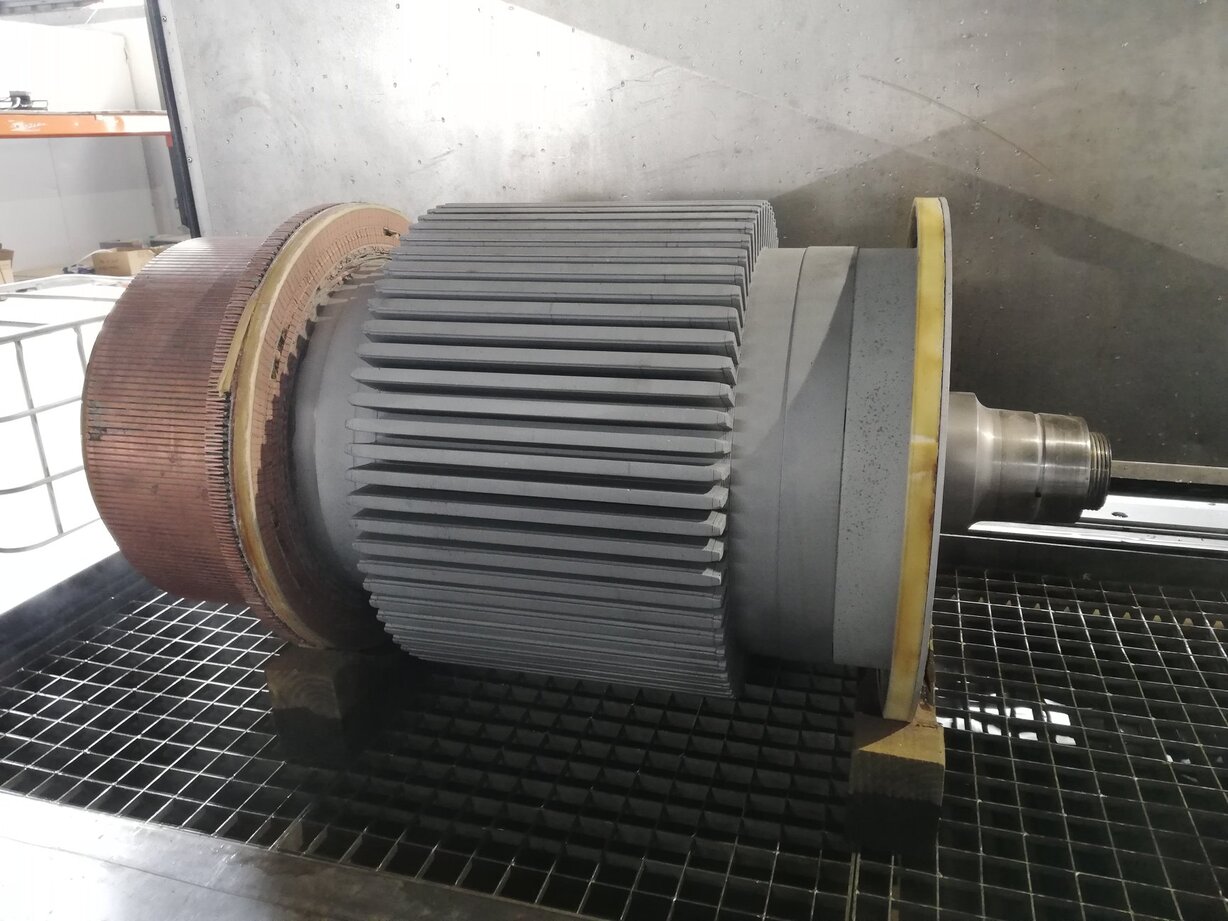

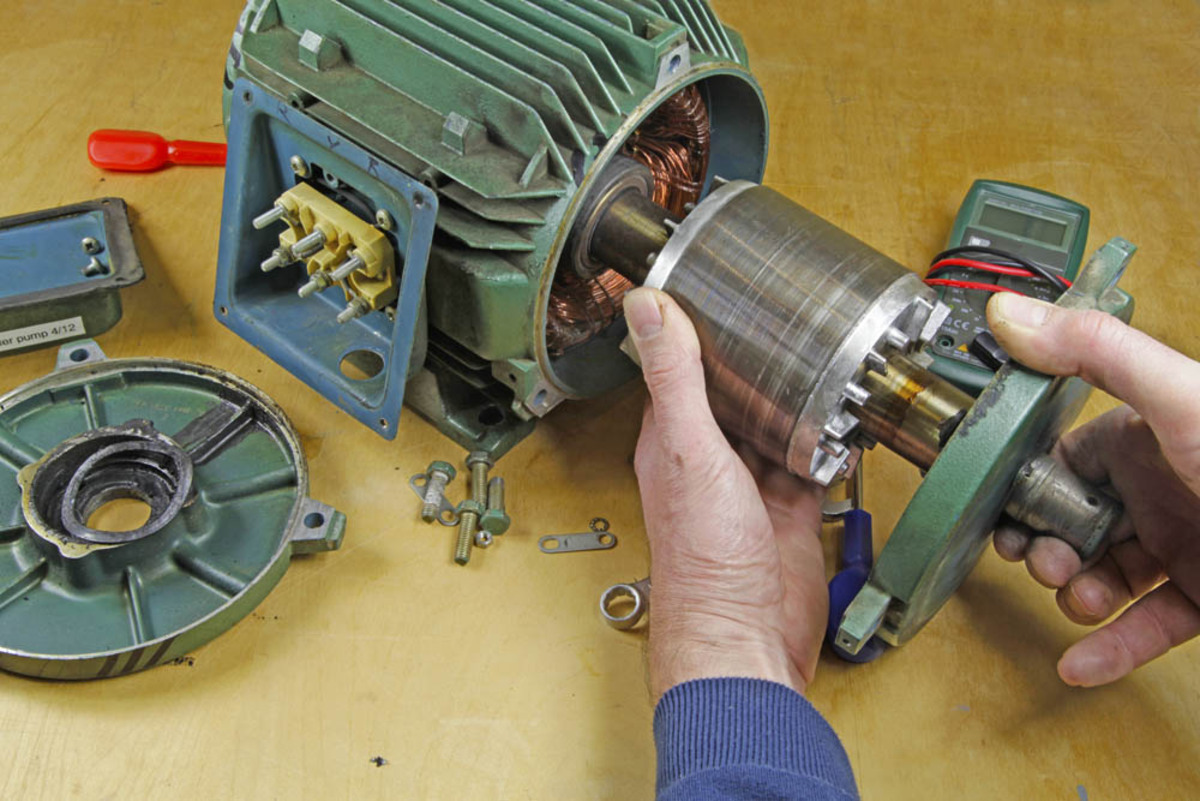

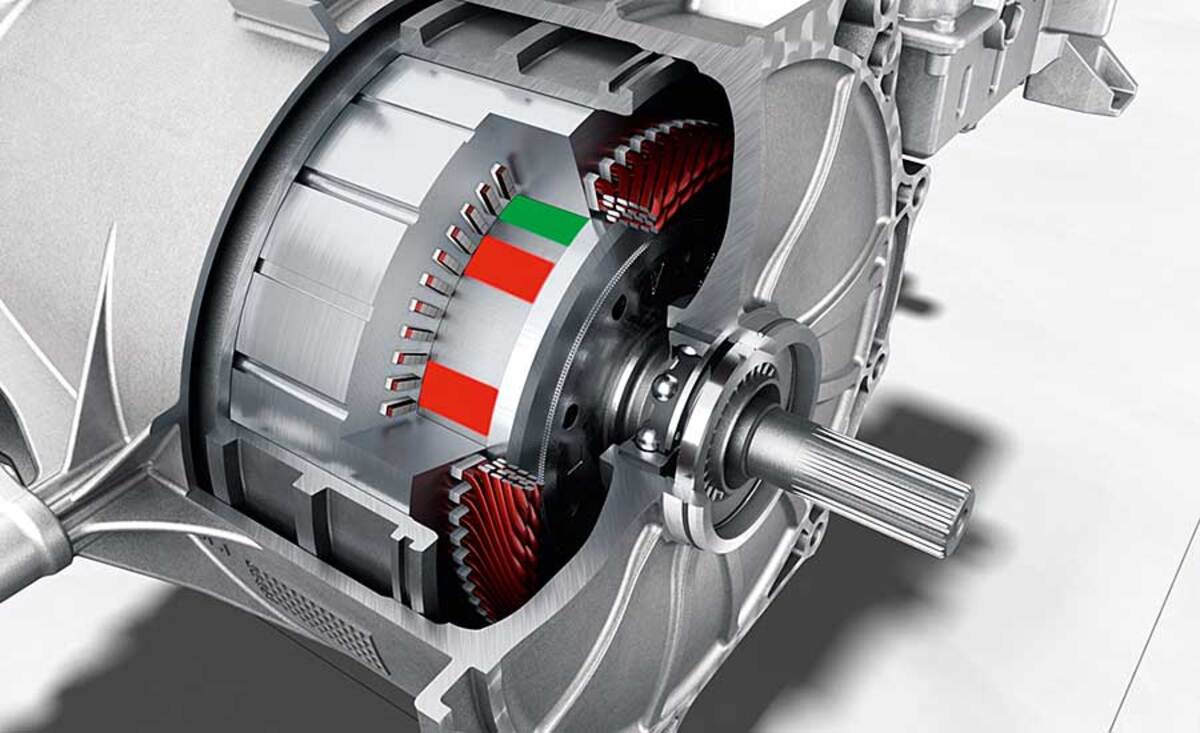

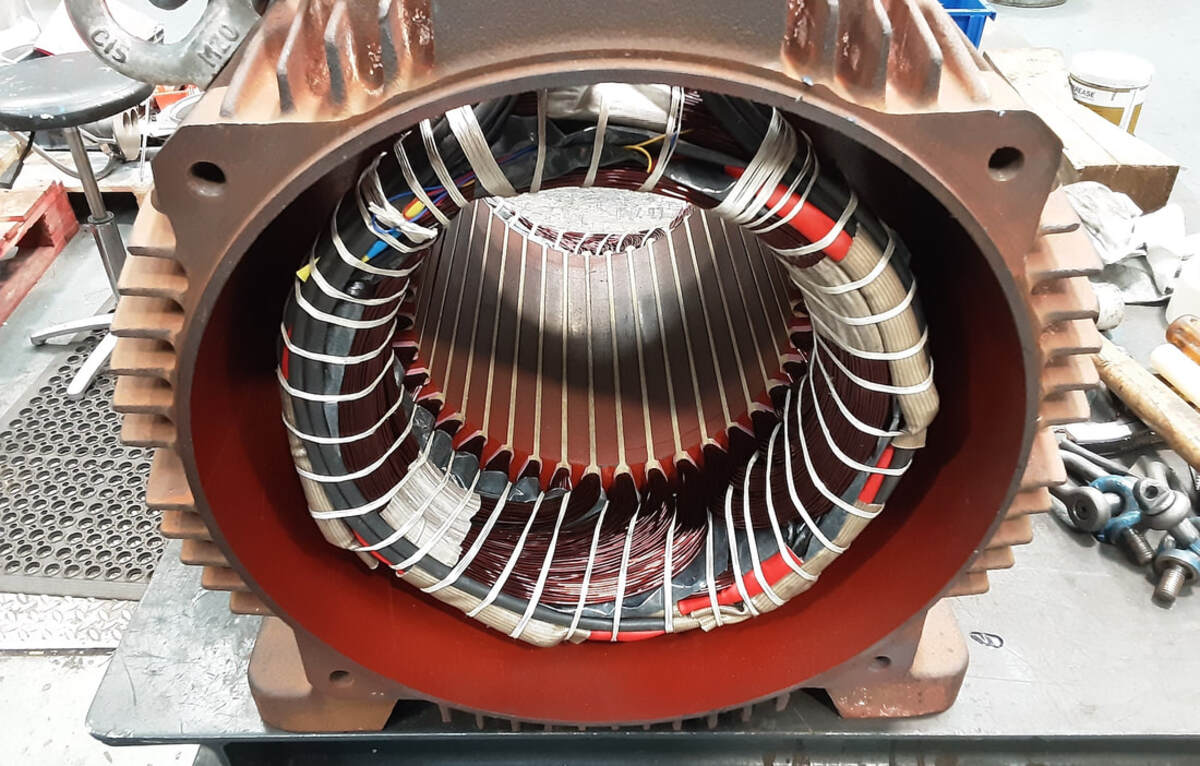

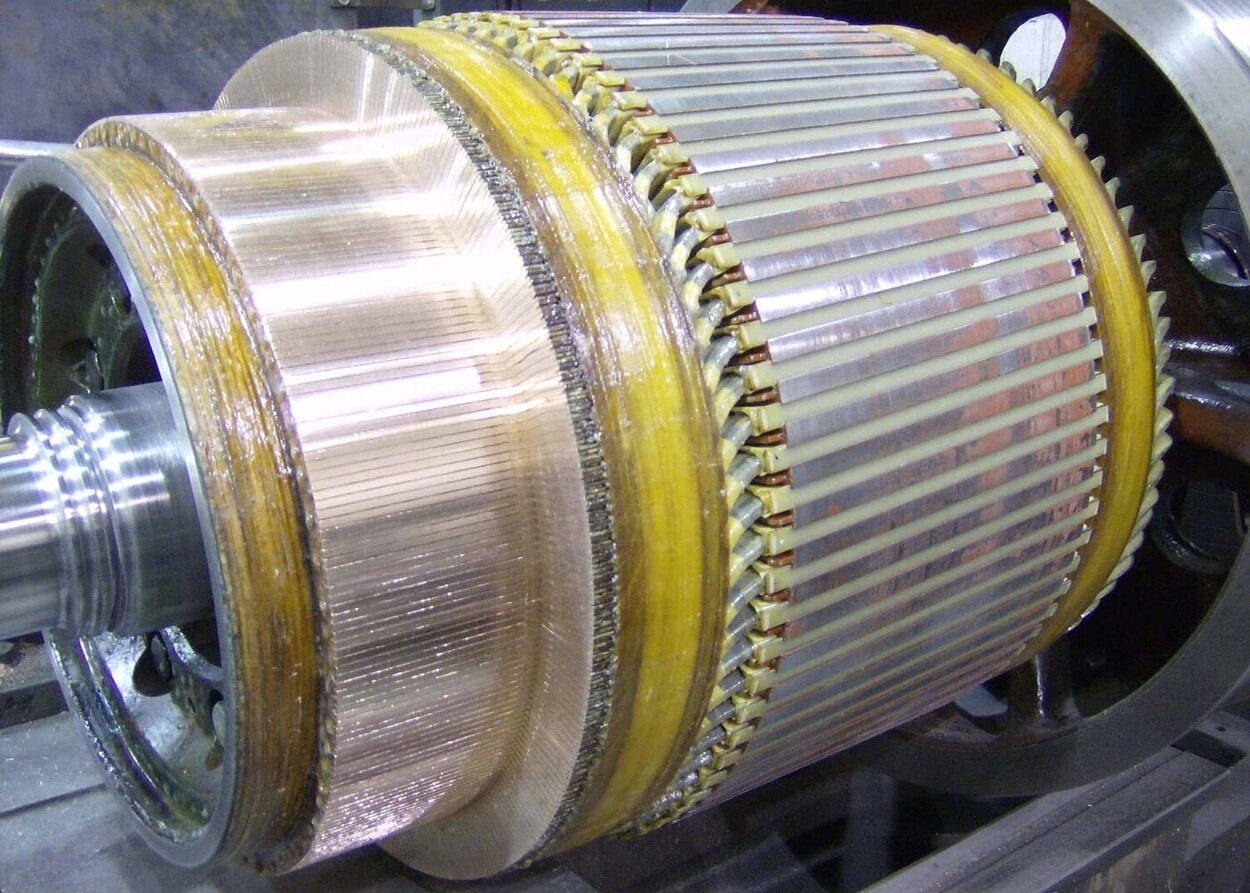

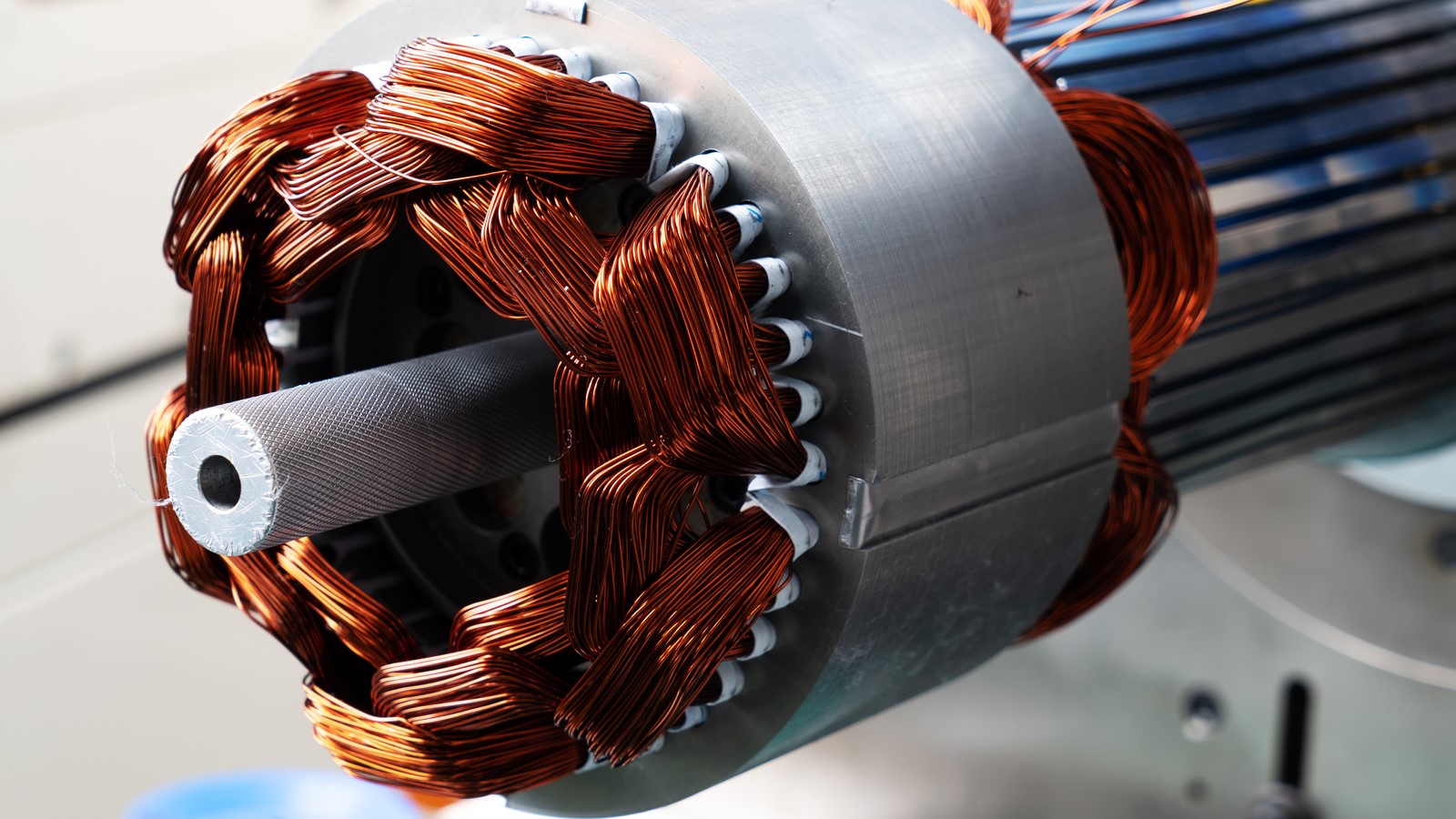

At their core, electric motors consist of two main components: a stator and a rotor. The stator is the stationary part of the motor and contains the primary winding, which is connected to an electrical power source. The rotor, on the other hand, is the rotating part of the motor and is connected to the load.

When electric current flows through the primary winding in the stator, it creates a magnetic field. This magnetic field interacts with the rotor, causing it to rotate, thus transferring electrical energy into mechanical energy.

Electric motors are used in a wide range of applications, from industrial machinery to household appliances. They can be found in HVAC systems, refrigerators, washing machines, power tools, and even the propulsion systems of electric vehicles.

As electric motors operate, various factors such as friction, heat, and wear and tear can affect their performance and efficiency. This is where regular maintenance, including oiling, comes into play.

Now that we have a basic understanding of electric motors, let’s explore why oiling is essential for their optimal functioning.

Why Oil an Electric Motor?

Oil is a critical component in maintaining the performance and longevity of electric motors. It serves several important purposes in the motor’s operation:

- Lubrication: The primary reason for oiling an electric motor is to provide lubrication. The moving parts of the motor, including the bearings and rotor, generate friction as they operate. Applying oil helps to reduce this friction, minimizing wear and tear on the components and ensuring smooth performance.

- Cooling: Electric motors generate heat during operation, which can potentially damage the motor if not properly managed. The oil acts as a coolant, absorbing and dissipating the heat produced by the motor, keeping it within safe temperature limits.

- Protection against Corrosion: Electric motors are often exposed to moisture and other environmental factors that can lead to corrosion. The oil forms a protective layer on the motor’s components, preventing rust and corrosion and extending their lifespan.

- Cleaning: Oiling an electric motor also helps to clean the internal components by removing dirt, dust, and other contaminants that might have entered the motor. This helps to maintain optimal performance and prevent damage caused by debris.

Regularly oiling an electric motor can bring several benefits, both in the short and long term. It can improve the efficiency of the motor, reduce friction and heat generation, prevent component damage and breakdowns, and prolong the motor’s life span.

Now that we understand why oiling is crucial for electric motors, let’s move on to the next step – choosing the right oil for your motor.

Choosing the Right Oil

When it comes to oiling an electric motor, selecting the right oil is paramount. The choice of oil depends on various factors, including the type of motor, operating conditions, and manufacturer’s recommendations. Here are some key considerations to keep in mind when choosing the right oil:

- Viscosity: The viscosity of the oil determines its thickness and resistance to flow. It is important to choose an oil with the appropriate viscosity for your motor. This information can typically be found in the motor’s manual or specifications provided by the manufacturer.

- Temperature Range: Consider the temperature conditions in which the motor operates. If the motor runs hot, you may need an oil with higher viscosity to withstand the heat. Conversely, in colder environments, a less viscous oil may be required to ensure proper lubrication at lower temperatures.

- Compatibility: Check the compatibility of the oil with the motor’s materials and seals. Some oils may contain additives that could potentially damage certain components of the motor. Refer to the manufacturer’s guidelines to ensure the oil is suitable for your specific motor.

- Additives: Depending on your motor’s requirements, you may need oil with specific additives. These additives can enhance the oil’s lubricating properties, protect against corrosion, or provide additional benefits such as reducing friction or improving heat dissipation. Again, refer to the manufacturer’s recommendations for guidance.

- Quality and Brand: Opt for high-quality oils from reputable brands to ensure the best performance and reliability. These oils are typically formulated to meet industry standards and undergo rigorous testing to ensure their effectiveness.

Remember, choosing the right oil is essential for the proper functioning and longevity of your electric motor. When in doubt, consult the motor’s manual or seek advice from the manufacturer or a professional in the field.

Now that we have covered the considerations for choosing the right oil, let’s move on to the next step – preparing for the oil application process.

Preparing for Oil Application

Before oiling an electric motor, it is important to properly prepare the motor and the surrounding environment. Here are some essential steps to follow:

- Clean the Motor: Start by cleaning the motor’s exterior and removing any dust, dirt, or debris that may have accumulated. Use a soft brush or a cloth to gently wipe away the dirt. Cleaning the motor helps ensure that no contaminants enter the motor during the oiling process.

- Inspect the Motor: Conduct a visual inspection of the motor’s components, paying close attention to the bearings, rotor, and other moving parts. Look for any signs of wear, damage, or loose connections. Address any issues before proceeding with the oil application.

- Ensure Proper Ventilation: Electric motors can generate heat and emit fumes during operation, especially when oil is applied. Make sure the area where the motor is located has adequate ventilation to prevent the buildup of heat and fumes. This helps maintain a safe work environment.

- Gather Required Tools and Materials: Collect all the tools and materials you will need for the oiling process. This typically includes the appropriate oil as discussed earlier, a clean cloth or brush for application, and any additional tools recommended by the manufacturer, such as a grease gun or a dropper.

- Follow Safety Precautions: Oiling an electric motor involves working with electrical components and potentially hazardous substances. Ensure that you follow proper safety precautions, such as wearing protective gloves and eyewear, turning off the power supply to the motor, and avoiding contact with hot surfaces.

By properly preparing the motor and the environment, you can help ensure a smooth and safe oil application process. Now that we have completed the preparation phase, let’s move on to the step-by-step guide for oiling an electric motor.

When oiling an electric motor, use a high-quality, non-detergent oil specifically designed for electric motors. Apply a few drops to each oiling point to ensure smooth and efficient operation.

Read more: How To Store Motor Oil

Step-by-Step Guide to Oil an Electric Motor

Now that you have prepared the motor and gathered the necessary tools and materials, let’s walk through the step-by-step process of oiling an electric motor:

- Refer to the manual: Consult the motor’s manual or the manufacturer’s instructions for specific guidelines and recommendations on oiling. This will provide you with tailored instructions for your particular motor.

- Locate the oil ports: Electric motors typically have oil ports or openings where the oil needs to be applied. These ports are usually located near the bearings or on the motor housing. Refer to the manual or markings on the motor to identify the oil ports.

- Clean the oil ports: Before applying the oil, use a clean cloth or brush to wipe away any dust or debris from the oil ports. This helps ensure that the oil can easily flow into the motor and prevents contamination.

- Add the oil: Depending on the motor, you may need to use a dropper, oil can, or grease gun to apply the oil. Carefully insert the applicator into the oil port and squeeze or apply the oil as recommended in the manual. Take care not to overfill the motor or allow any excess oil to spill onto other components.

- Distribute the oil: Once the oil has been added, gently rotate the motor or use a recommended procedure to distribute the oil evenly throughout the motor’s bearings and other moving parts. This ensures thorough lubrication and improved performance.

- Monitor the oil level: After applying the oil, keep an eye on the oil level using the oil sight glass or any other indication method specified by the manufacturer. Regularly check and replenish the oil if necessary to maintain the optimal level.

- Replace motor covers: Once you have completed the oiling process, securely place any removed motor covers or casings back in their original position. Ensure that they are properly sealed to prevent the entry of contaminants.

- Record the oiling: It is a good practice to keep a record of when you oil the motor, the type of oil used, and any other relevant details. This helps with future maintenance and ensures consistent care for the motor.

Following these steps will help you effectively oil your electric motor and keep it running smoothly. However, it is important to note that the specific process may vary depending on the motor type, model, and manufacturer’s recommendations. Always refer to the manual for the most accurate instructions.

Now that you know the step-by-step process, let’s discuss some essential safety precautions to keep in mind while oiling an electric motor.

Safety Precautions

When oiling an electric motor, it is vital to prioritize safety to protect yourself and prevent any potential accidents. Here are some crucial safety precautions to follow:

- Turn off the power: Before starting the oiling process, always ensure that the power supply to the motor is turned off. This prevents any risk of electric shock or injury.

- Wear protective gear: It is important to wear appropriate protective gear, such as gloves and safety glasses, to shield yourself from any potential hazards during the oiling process.

- Avoid hot components: Electric motors can become hot during operation. Before beginning the oiling process, allow the motor to cool down to a safe temperature to avoid burns or other injuries.

- Properly ventilate the area: Ensure that the area where the motor is located has proper ventilation to prevent the buildup of heat, fumes, or any potential risks associated with oil application. Open windows or use fans if necessary.

- Handle oil with care: If you are using oil that is incompatible with your skin, make sure to wear gloves for protection. Be cautious when handling oil to prevent spills and clean up any spills immediately.

- Follow manufacturer recommendations: Carefully follow the manufacturer’s instructions and recommendations for oiling the motor. Different motors may have specific requirements or precautions, so it is essential to adhere to them for optimal results.

- Properly dispose of used oil: After completing the oiling process, dispose of any used oil properly. Refer to local regulations or recycling centers to ensure the proper disposal methods are followed.

By observing these safety precautions, you can minimize the risk of accidents and injuries while oiling your electric motor. Safety should always be a top priority when working with electrical components and potentially hazardous substances.

Now that we have covered the safety precautions, let’s move on to discussing some common mistakes to avoid during the oiling process.

Common Mistakes to Avoid

When oiling an electric motor, there are several common mistakes that should be avoided to ensure the best results and prevent any potential issues. Here are some common mistakes to be aware of:

- Overfilling the motor: It is important not to overfill the motor with oil. Overfilling can lead to excessive heat generation, increased friction, and potential damage to the motor’s components. Follow the manufacturer’s recommendations for the appropriate oil level.

- Using the wrong type of oil: Using an incorrect or incompatible type of oil can have detrimental effects on the motor’s performance and longevity. Always refer to the motor’s manual or manufacturer’s recommendations to ensure you are using the appropriate oil for your specific motor.

- Neglecting regular maintenance: Oil applications should be a part of routine maintenance for electric motors. Neglecting regular oiling and maintenance can lead to decreased performance, increased wear and tear, and potential breakdowns. Stay on top of maintenance schedules to keep your motor running smoothly.

- Applying oil to the wrong location: Be sure to identify the correct oil ports or openings in the motor for oil application. Applying oil to the wrong location can result in inadequate lubrication or damage to other components of the motor.

- Ignoring signs of wear or damage: It is essential to regularly inspect the motor for any signs of wear, damage, or loose connections. Ignoring these warning signs and proceeding with oil application can exacerbate existing issues and lead to further damage.

- Not following safety precautions: Safety should always be a priority when working with electric motors. Neglecting safety precautions, such as failing to turn off the power supply or not wearing protective gear, can lead to accidents, injury, or damage to the motor.

- Allowing contaminants to enter the motor: Before applying oil, ensure that the motor and the surrounding area are clean and free from dirt, debris, and other contaminants. Allowing contaminants to enter the motor can hinder its performance and cause premature wear and tear.

By avoiding these common mistakes, you can effectively oil your electric motor and maintain its optimal performance. Always double-check the instructions, follow manufacturer recommendations, and stay vigilant during the process.

With our tips on avoiding common mistakes, we have covered the essential aspects of oiling an electric motor. Let’s now conclude our article.

Conclusion

Oiling an electric motor is a crucial maintenance task that ensures optimal performance, longevity, and efficiency. By understanding the workings of electric motors, the importance of oiling, and following the correct procedures, you can effectively maintain your motor and prevent potential issues.

Choosing the right oil, preparing the motor, and following the step-by-step guide are essential for successful oil application. Additionally, adhering to safety precautions and avoiding common mistakes will help you achieve the best results while keeping yourself and the motor protected.

Regularly oiling your electric motor can improve its efficiency, reduce friction and heat generation, prevent component damage, and extend its lifespan. It is a maintenance task that should be incorporated into your routine to keep the motor running smoothly and avoid costly repairs or replacements.

Remember to consult the motor’s manual or manufacturer’s recommendations for specific guidelines, as certain motors may have unique requirements. In case of any doubts, it is always beneficial to seek advice from professionals in the field.

Now that you have the knowledge and understanding of how to oil an electric motor, you can confidently maintain and care for your motors, ensuring their continued reliable operation for years to come.

Frequently Asked Questions about How To Oil An Electric Motor

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Oil An Electric Motor”