Home>Articles>What Are The Hazards Associated With Hand Tools

Articles

What Are The Hazards Associated With Hand Tools

Modified: October 20, 2024

Discover a wide range of articles on the topic of hand tools, learn about their power and potential hazards, and how to stay safe while using them.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

In any industry or profession that requires manual work, hand tools are a fundamental part of getting the job done. From hammers and screwdrivers to wrenches and pliers, these tools play a crucial role in various tasks. While they are essential for completing projects efficiently, it is important to recognize that hand tools can also pose significant hazards to users if not handled properly.

Hand tools are powered instruments that rely on manual force and mechanical energy to perform a specific function. Unlike power tools that use electricity or other power sources, hand tools are typically non-powered and require manual manipulation to operate. They are commonly used in construction, woodworking, automotive repair, and many other fields.

The hazards associated with hand tools can range from minor injuries to severe accidents. When safety precautions are not followed, users are at risk of lacerations, puncture wounds, fractures, eye injuries, and even amputations. It is crucial for individuals who work with hand tools to have a comprehensive understanding of the potential dangers and to take the necessary precautions to mitigate these risks.

This article aims to explore the hazards associated with hand tools and provide guidance on how to use them safely. By understanding and implementing proper safety measures, workers can significantly reduce the risk of accidents and promote a safer working environment.

Let’s delve deeper into the various hazards associated with hand tools and learn how to use them responsibly and safely.

Key Takeaways:

- Hand tools, while essential, pose various hazards such as cuts, impact injuries, and repetitive strain. Proper training, maintenance, and PPE use are crucial in minimizing risks and promoting a safe work environment.

- Understanding hand tool safety, selecting the right tool, and adhering to proper techniques are vital for accident prevention. Ongoing training and education foster a culture of awareness and responsibility in the workplace.

Read more: What Are The Hazards Of Hand Tools

Understanding Hand Tools

Before diving into the hazards associated with hand tools, it is important to have a clear understanding of what hand tools actually are. Hand tools are manual instruments designed to assist in completing tasks that require precision, control, and dexterity. They are typically handheld and do not require external power sources to operate.

Hand tools come in a variety of shapes, sizes, and purposes. Some of the most common hand tools include hammers, screwdrivers, wrenches, pliers, saws, chisels, and files. Each tool is designed for a specific task, and users must use the appropriate tool for the job at hand to ensure safety and efficiency.

Hand tools can be categorized into several types based on their function:

- Cutting tools: These tools, such as saws, knives, and shears, are used to cut through various materials.

- Fastening tools: Screwdrivers, wrenches, and pliers fall under this category, as they are used to tighten or loosen screws, bolts, and other fasteners.

- Striking tools: Hammers, mallets, and chisels are examples of striking tools, which are used to deliver force by striking or pounding.

- Measuring tools: Tools like rulers, tape measures, and calipers are used to take precise measurements.

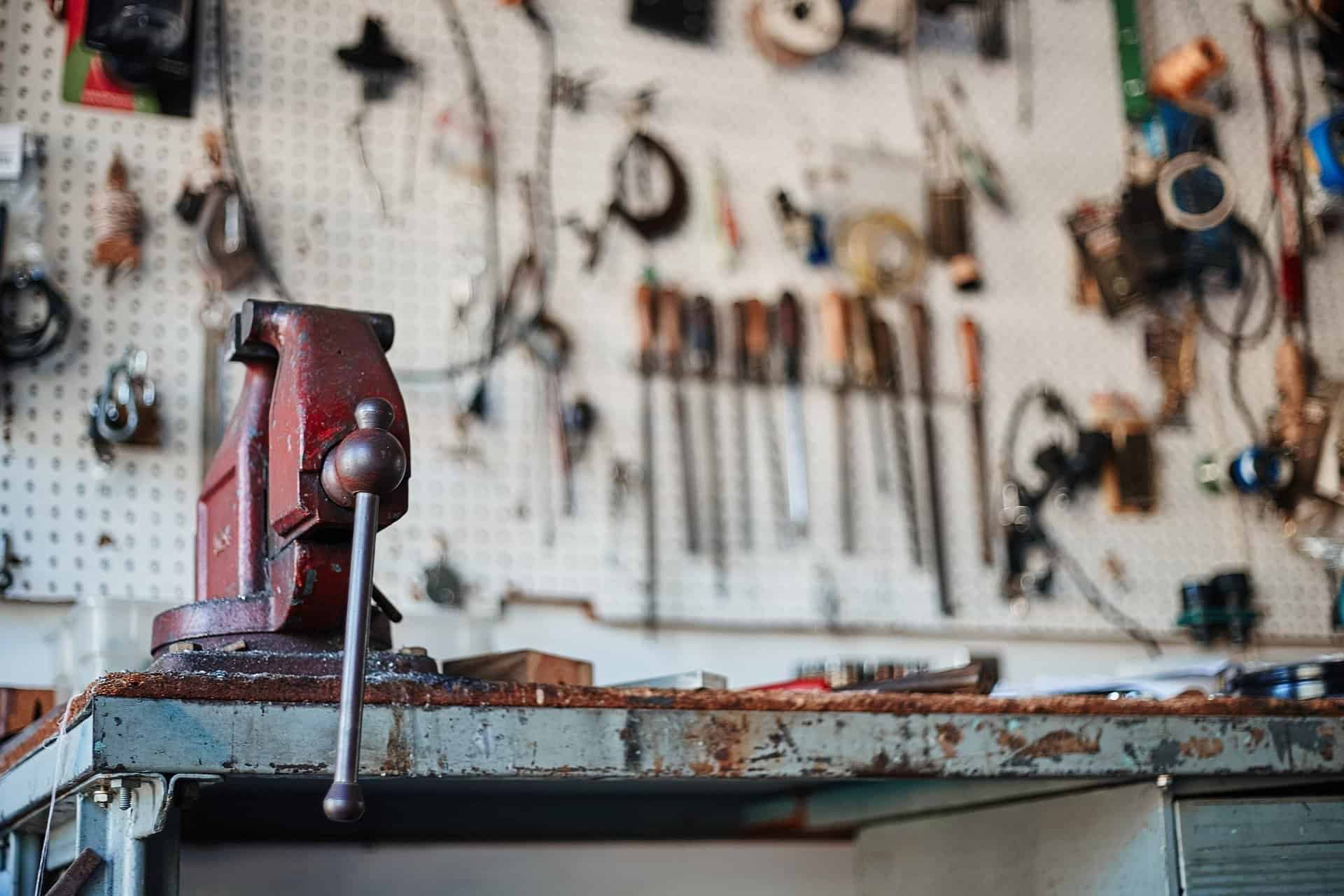

- Gripping tools: Pliers, wrenches, and vices fall under this category. They are designed to provide a strong grip and hold objects securely.

Each type of hand tool requires a specific technique for safe and effective use. It is essential for users to be familiar with the proper handling and operation of each tool to minimize the risk of accidents.

Furthermore, hand tools can be made using different materials, including steel, aluminum, and plastic. The choice of material often depends on the tool’s intended use and the level of durability required. Users should select hand tools that are crafted from high-quality materials to ensure longevity and reduce the risk of tool failure.

Understanding the different types of hand tools and their functions is vital for users to make informed decisions when selecting, handling, and using these instruments. By having a clear understanding of hand tools, individuals can increase their safety awareness and take appropriate precautions to prevent accidents in the workplace.

Hazards Associated with Hand Tools

While hand tools are essential for completing a wide range of tasks, it is crucial to be aware of the hazards they can pose if not used properly. Understanding these hazards is the first step in preventing accidents and injuries in the workplace. Here are some common hazards associated with hand tools:

- Cutting and piercing hazards: Many hand tools, such as saws, knives, and chisels, have sharp edges that can cause cuts or puncture wounds if mishandled or used improperly. It is important to exercise caution and use proper techniques when working with these tools to avoid accidental injuries.

- Impact hazards: Hand tools like hammers and mallets rely on forceful impacts to perform their tasks. If not used with care, these tools can cause impact injuries, such as fractures or bruising. Users should ensure a secure grip and focus on accurate striking techniques to minimize the risk of accidental impacts.

- Hand-arm vibration syndrome (HAVS): Some hand tools, particularly those that vibrate during operation, can lead to long-term health issues. Prolonged exposure to vibration from tools like grinders or jackhammers can cause HAVS, resulting in symptoms like numbness, tingling, and reduced dexterity in the hands. Regular breaks and the use of anti-vibration gloves can help mitigate this hazard.

- Chemical hazards: Certain hand tools may be used in conjunction with chemicals, such as solvents or adhesives. Mishandling or improper storage of these chemicals can lead to skin irritations, respiratory issues, or even chemical burns. It is essential to follow proper safety guidelines and use appropriate personal protective equipment (PPE) when working with hazardous chemicals.

- Eye and face hazards: Many hand tools generate debris, sparks, or dust during use, which can pose a risk to the eyes and face. For example, when using a power drill or grinding tool, particles can fly into the air and potentially cause eye injuries. It is crucial to wear safety goggles or face shields to protect against such hazards.

- Electric shock hazards: Although hand tools are generally non-powered, there are instances where they can come in contact with live electrical components or exposed wires. This can result in electric shocks, which can be extremely dangerous. Users should exercise caution and ensure that tools are properly insulated and used in areas free from electrical hazards.

These hazards highlight the importance of practicing safe and responsible tool use. By being aware of the potential risks associated with hand tools, individuals can take appropriate precautions to prevent accidents, protect themselves, and maintain a safe work environment.

Common Hand Tool Hazards

Hand tools are widely used in various industries, and while they make tasks easier, they also come with inherent hazards. Understanding the common hand tool hazards is crucial for anyone working with these instruments. Here are some of the most prevalent hazards associated with hand tools:

- Lacerations and puncture wounds: Sharp-edged hand tools, such as knives, chisels, or wire cutters, can cause lacerations or puncture wounds if not handled with care. Inadequate grip or incorrect use can lead to slips or slips, resulting in severe injuries. It is important to maintain a firm grip on the tool and use proper cutting techniques to prevent accidental cuts and punctures.

- Striking injuries: Tools like hammers or mallets, which require striking force, pose the risk of striking injuries. Mishitting the target or a glancing blow can lead to bruising, fractures, or even broken bones. Ensuring a controlled strike and using the appropriate tool for the task at hand is essential to minimize the risk of striking injuries.

- Repetitive strain injuries (RSIs): Continuous and repetitive use of hand tools can lead to RSIs, such as carpal tunnel syndrome or tendonitis. Tasks that involve repetitive motions, gripping, or exerting force over an extended period can strain the muscles and tendons, resulting in chronic pain and reduced mobility. Taking regular breaks, using ergonomic handles, and practicing proper hand positions can help prevent RSIs.

- Eye and face injuries: Working with hand tools that generate debris or sparks, such as grinders or drills, can pose a risk to the eyes and face. Without proper eye protection, particles can enter the eyes and cause injuries, including corneal abrasions or foreign bodies. Wearing safety goggles or face shields is crucial to safeguard the eyes and face from potential hazards.

- Falling and tripping hazards: Improper storage or leaving hand tools unattended can create falling and tripping hazards in the workplace. Tools left on elevated surfaces or crowded work areas can inadvertently fall and cause injuries. Organizing and securing tools when not in use can help mitigate the risk of accidents due to falling or tripping hazards.

- Electric shock: Hand tools that come into contact with live electrical components or faulty wiring can cause electric shocks. Users should be cautious when working on or near electrical systems and ensure that tools are properly insulated and suitable for the task. Safety precautions like wearing insulated gloves and testing the tool on a known power source can prevent electric shock accidents.

These common hand tool hazards emphasize the importance of proper training, adherence to safety guidelines, and the use of personal protective equipment (PPE). By being aware of these hazards, workers can take proactive measures to prevent accidents, injuries, and potential long-term health issues associated with hand tool use.

Proper Use and Safety Measures

Using hand tools safely requires a combination of knowledge, skill, and adherence to safety measures. By following proper use and safety guidelines, individuals can minimize the risk of accidents and injuries. Here are some important tips for using hand tools safely:

- Select the right tool for the task: Use the appropriate hand tool for the specific job at hand. Using the wrong tool can increase the risk of accidents and result in damage to the tool or the object being worked on.

- Inspect the tool before use: Before using any hand tool, inspect it for any damage or defects. Check for signs of wear, loose handles, or malfunctioning parts. Do not use a tool that is damaged or shows signs of wear as it may compromise safety.

- Ensure a proper grip: Maintain a firm and secure grip on the tool. Avoid using excessive force or gripping the tool too tightly, as it can lead to muscle strain or loss of control.

- Follow proper technique: Learn and follow the recommended technique for using each hand tool. Using incorrect techniques can increase the risk of accidents and lead to injuries.

- Be aware of your surroundings: Pay attention to your surroundings and ensure there is adequate space to safely use the hand tool. Keep bystanders at a safe distance and be cautious of other potential hazards in the area.

- Use appropriate force: Apply only the necessary force required for the task. Using excessive force can lead to loss of control and increase the risk of accidents.

- Store tools properly: After use, store hand tools in a designated place. Proper storage prevents tools from falling, getting damaged, or causing accidental injuries.

- Maintain sharpness and functionality: Keep cutting tools properly sharpened so that they work efficiently. Dull or blunt tools can require excessive force, increasing the risk of slips and accidents. Additionally, regularly inspect and maintain the functionality of hand tools to ensure they are in proper working condition.

- Keep your focus: Avoid distractions while using hand tools. Stay focused on the task at hand to maintain control and prevent unnecessary accidents.

- Never use tools inappropriately: Avoid using hand tools for tasks they are not intended for. Using a tool incorrectly can lead to accidents and damage the tool or the object being worked on.

Remember, safety is paramount when using hand tools. By following these proper use and safety measures, individuals can significantly reduce the risk of accidents and injuries. Always prioritize caution and take the necessary precautions to create a safe working environment.

Always wear appropriate personal protective equipment, such as gloves and eye protection, when using hand tools. Inspect tools for damage before use and always follow proper operating procedures.

Personal Protective Equipment (PPE) for Hand Tool Use

When working with hand tools, personal protective equipment (PPE) plays a critical role in ensuring the safety and well-being of individuals. PPE is designed to protect against specific hazards and mitigate the risk of injuries. Here are some essential PPE items to consider when using hand tools:

- Eye protection: Safety goggles or safety glasses are essential for protecting the eyes from debris, sparks, or dust generated during hand tool use. They should be impact-resistant, provide a secure fit, and cover the entire eye area to provide maximum protection.

- Hand protection: Using gloves is crucial to protect the hands from cuts, abrasions, and puncture wounds when handling hand tools. Choose gloves made of appropriate materials, such as leather or cut-resistant fabrics, based on the tasks being performed.

- Respiratory protection: In certain situations where hand tools generate harmful dust, fumes, or particles, respiratory protection may be necessary. Respirators, such as dust masks or respirator masks, should be worn to prevent the inhalation of hazardous substances.

- Foot protection: Safety shoes or steel-toed boots provide essential foot protection from falling tools, heavy objects, or potential crushing hazards. They should have slip-resistant soles and meet the required safety standards for the specific work environment.

- Hearing protection: Hand tools that produce loud noises, such as power drills or impact tools, can cause hearing damage over time. Earplugs or earmuffs should be worn to protect against excessive noise exposure and prevent hearing loss.

- Protective clothing: Depending on the nature of the work and the specific hazards involved, wearing protective clothing may be necessary. This can include items such as aprons, coveralls, or specialized clothing that provides additional protection against heat, chemicals, or other hazards.

It is essential to select PPE that is appropriate for the specific task and offers adequate protection. Here are some additional considerations when using PPE:

- Ensure PPE is in good condition, properly maintained, and fits correctly.

- Train and educate workers on the proper use, care, and limitations of the PPE.

- Regularly inspect PPE for any signs of damage or wear and replace as needed.

- Always wear PPE in the designated work areas and adhere to safety protocols.

- Encourage proper hygiene practices, such as cleaning or sanitizing PPE regularly, especially when shared among workers.

Remember, personal protective equipment is a crucial line of defense when working with hand tools. It is necessary to prioritize the use of appropriate PPE to minimize the risk of injuries and create a safe working environment.

Maintenance and Inspection of Hand Tools

Maintaining and regularly inspecting hand tools is essential for ensuring their safe and effective use. Proper maintenance not only extends the lifespan of the tools but also helps prevent accidents and injuries. Here are some key steps to follow for the maintenance and inspection of hand tools:

- Clean tools after use: Remove any dirt, debris, or moisture from hand tools after each use. Wipe them down with a clean cloth or use compressed air to blow away any residue. This helps prevent the buildup of rust or corrosion, which can compromise the function and safety of the tool.

- Sharpen cutting tools: Regularly check cutting tools, such as knives or chisels, for sharpness. Dull tools require more force to use and can lead to slips and accidents. Use appropriate sharpening techniques or seek professional sharpening services to maintain the cutting effectiveness of these tools.

- Lubricate moving parts: Apply lubricating oil or grease to the moving parts of hand tools, such as hinges or sliding mechanisms. This reduces friction and ensures smooth operation. However, be cautious not to apply excessive amounts of lubricant, as it can attract dirt and debris.

- Tighten loose handles or components: Regularly check for loose handles, screws, or nuts on hand tools. Use the appropriate tools, such as screwdrivers or wrenches, to tighten any loose components. Loose handles can compromise the stability and control of the tool, leading to accidents.

- Inspect for damage or wear: Perform regular visual inspections of hand tools to identify any signs of damage, wear, or deformation. Check for cracks, chips, or signs of excessive wear on the tool surfaces. Also, inspect handles or grips for any signs of splitting or fraying. If any damage is detected, the tool should be repaired or replaced to maintain safety.

- Store tools properly: Proper storage is essential for maintaining the condition of hand tools. Store them in dry, clean areas away from direct exposure to moisture or extreme temperatures. Use toolboxes, racks, or designated compartments to keep tools organized and prevent them from getting damaged or causing accidental injuries.

- Follow manufacturer’s instructions: Always refer to the manufacturer’s guidelines for specific maintenance instructions for your hand tools. Different tools may have specific care requirements, and following the manufacturer’s recommendations ensures proper maintenance and safe use.

Additionally, it is important to encourage all individuals working with hand tools to promptly report any issues or concerns regarding tool condition or function. This allows for timely repairs or replacements and prevents the use of damaged tools that could lead to accidents.

By regularly maintaining and inspecting hand tools, individuals can ensure their safe and optimal performance. This practice enhances workplace safety, prolongs the life of the tools, and reduces the risk of accidents and injuries.

Training and Education on Hand Tool Safety

Effective training and education on hand tool safety are crucial for ensuring the safe and responsible use of hand tools in the workplace. Properly trained individuals are equipped with the knowledge and skills necessary to mitigate risks and prevent accidents. Here are some important aspects to consider when it comes to training and education on hand tool safety:

- Mandatory safety training: Employers should make hand tool safety training a mandatory requirement for all individuals who work with hand tools. This training should be provided to new employees during their onboarding process and regularly refreshed for existing employees.

- Tool-specific training: Provide training on the proper handling, operation, and maintenance of specific hand tools. Each tool may have unique safety considerations and techniques, and employees should be familiar with these specific guidelines.

- Safe work practices: Educate workers on safe work practices when using hand tools. This includes topics such as using proper body mechanics, maintaining a clutter-free work area, and practicing good housekeeping to prevent trips, falls, and other accidents.

- Hazard identification and risk assessment: Train employees to identify potential hazards associated with hand tool use and conduct risk assessments before starting a task. This helps individuals recognize and address potential risks before proceeding with work.

- Proper tool selection: Teach employees how to select the right tool for the job and the importance of using the appropriate tool for specific tasks. Emphasize the dangers of using tools that are not designed or suited for a particular task.

- Safe handling and storage: Train workers on the proper handling, carrying, and storage of hand tools to minimize the risk of injuries due to mishandling or falling tools. Highlight the importance of storing tools in designated areas and securing them appropriately.

- Personal protective equipment (PPE) training: Provide thorough training on the correct selection, use, and care of personal protective equipment related to hand tool use. This includes instruction on wearing eye protection, gloves, hearing protection, and other necessary PPE items.

- Reporting and addressing hazards: Teach employees how to report and address hazards or concerns related to hand tool safety. Encourage an open and proactive reporting culture to ensure that potential hazards are promptly addressed and resolved.

- Regular refresher training: Conduct regular refresher training sessions to reinforce hand tool safety knowledge and ensure that employees stay updated on best practices and any new safety guidelines or regulations.

It is essential to make hand tool safety training interactive and engaging. Utilize hands-on demonstrations, visuals, and real-life scenarios to enhance the learning experience. Encourage active participation, ask for feedback, and address any questions or concerns employees may have during the training sessions.

Remember, training and education on hand tool safety are ongoing processes. It is important to create a culture of safety and continuous learning in the workplace to ensure that individuals remain knowledgeable, skilled, and proactive in maintaining a safe working environment when using hand tools.

Conclusion

Hand tools are indispensable instruments that help us accomplish a wide range of tasks efficiently. However, it is essential to recognize and address the potential hazards associated with hand tool use. By understanding these hazards and implementing proper safety measures, we can greatly reduce the risk of accidents and injuries in the workplace.

Throughout this article, we have explored the various hazards that hand tools can present. From cuts and puncture wounds to impact injuries and repetitive strain, it is clear that working with hand tools requires caution and knowledge. However, with proper training and education, individuals can develop the necessary skills to handle hand tools safely and responsibly.

Using the correct hand tool for each task, inspecting and maintaining tools regularly, and adhering to safe work practices are key components of hand tool safety. Additionally, the use of personal protective equipment (PPE) can provide an extra layer of protection against hazards. Safety goggles, gloves, respiratory protection, and other forms of PPE play a vital role in safeguarding individuals from potential injuries.

Training and education are paramount when it comes to hand tool safety. By providing comprehensive training, employers can empower workers with the knowledge and skills needed to use hand tools safely. This includes tool-specific training, hazard identification, proper maintenance procedures, and the importance of selecting and using the right tools for the job.

In conclusion, hand tool safety is a responsibility that should not be taken lightly. By implementing proper safety protocols, maintaining tools, and providing ongoing training and education, we can create a workplace environment where individuals feel confident and empowered to use hand tools effectively and safely.

Remember, safety is everyone’s responsibility. Let us prioritize hand tool safety and promote a culture of awareness, caution, and continuous learning to ensure that accidents and injuries are minimized, and our work environment remains safe and productive.

Frequently Asked Questions about What Are The Hazards Associated With Hand Tools

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Are The Hazards Associated With Hand Tools”